-

Posts

3,542 -

Joined

-

Last visited

-

Days Won

13

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by DXB

-

You should see 2700 at rotation speed. Full power with brakes on should give around 2650.

-

Top of the yellow arc is pretty common for me on the ground at low idle. Having it drop out of the green at any other time would indeed be alarming, so I’d want the alarm to stay. This is where the flashing red warning of the digital instrument could be a lifesaver.

-

Beautiful work...can you show us some pix?

-

Odd approach clearance...am I an idiot or did ATC screw up?

DXB replied to DXB's topic in Mooney Safety & Accident Discussion

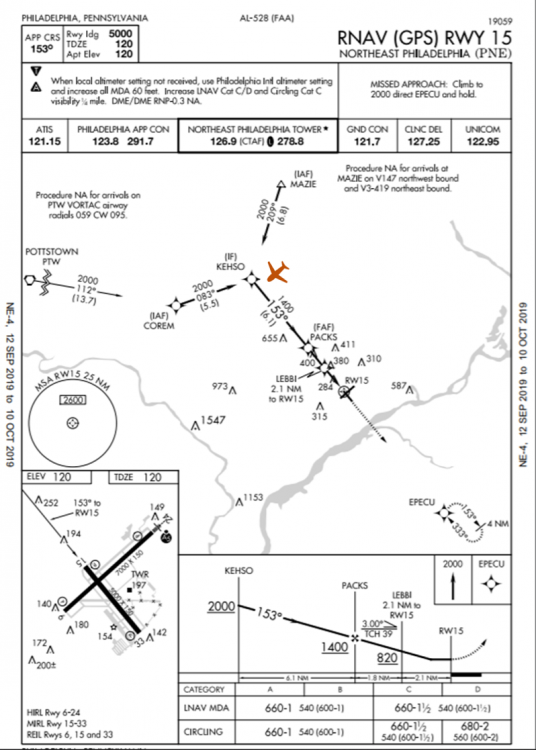

My needle was at full deflection for the FAC. And even if I were already very close to the FAC, telling me go direct to the FAF is simply the wrong way to issue the approach clearance - it goes against the most basic rules for controllers giving vectors to final and shouldn't ever happen in Philly or anywhere else. Last night I had a discussion with my favorite instructor, who reviewed the tape as well. I wound up agreeing with him - controllers know the rules for how to vector someone onto final very well, and it's unlikely this controller would violate those ingrained rules deliberately. Instead, she simply brain farted by thinking PACKS was an IAF or IF and not the FAF. If that was really what she was thinking, then my saying "how about 180 to join the FAC?" as @midlifeflyer suggests might have led her to see her mistake but also might have generated more confusion if she didn't. My instructor suggested something like "you want me to cross the FAF at 3000 and then start the procedure?" to make it clear she was sending me direct to the FAF. Regardless, my brain was poised at that point to hand fly an intercept (basic autopilot) and proved not plastic enough to shift into analyzing what was going on when I got that bizarre instruction. -

Odd approach clearance...am I an idiot or did ATC screw up?

DXB replied to DXB's topic in Mooney Safety & Accident Discussion

That is indeed a GREAT article! A caveat is that being a savvy negotiator has a learning curve and takes some experience. I now gone from a brand new baby IFR pilot to one in the awkward adolescent phase, just trying out these negotiating skills, seeing what works. But one certainly has to try to negotiate in order to develop the skills over time. -

I went through the same frustration 4 years ago when I got my EDM900. The early obsession is a good thing and part of the learning process. Switching alarm settings in the device can help. The brain also automatically develops a filter for the TMI stuff it does, and it becomes less of a distraction over time - you simply readjust what you see as normal vs. concerning. It is worth poring over your downloaded data early on and understanding what it shows. Paying for analysis is one good way to learn the types of information that are inherent in the data and learning how to look at the data on your own. Also, if you look at paid analysis carefully and ask some questions, you will find that the data is easy to overinterpret - the service sometimes ascribes potential problems to features of the data that can have other, more benign interpretations. Thinking through these limitations is another part of the learning process. Despite this learning curve, the monitor really shines is in helping narrow down the problem when something is going wrong. At these moments, it is worth its weight in gold for safety and peace of mind. And the diagnostic efficiency it offers will ultimately offset the cost.

-

Odd approach clearance...am I an idiot or did ATC screw up?

DXB replied to DXB's topic in Mooney Safety & Accident Discussion

Thank you - I agree this may have been the single best way to handle the situation if I could have come up with it in the moment. I've gotten more assertive with ATC in the modest 1.5 years of IFR experience under my belt (particularly when it comes to dodging weather), but my lack of confidence when I get an instruction that doesn't make sense is still hard to overcome sometimes - discussing with folks like you here helps a lot. -

Odd approach clearance...am I an idiot or did ATC screw up?

DXB replied to DXB's topic in Mooney Safety & Accident Discussion

I pulled the tape. Relevant portion starts at 27:45ish. My callsign is 71L. I didn't get the quoted wording perfect in the post above, but I think the meaning of the controller instruction is the same I think. She told me to go left direct PACKS rather than intercept the final approach course, told me to maintain 3000 until established. She didn't sound that busy, and it would have been no more work to give me an intercept heading rather than tell me go direct PACKS. I don't get it. I spoke with Philly TRACON - they were polite and receptive. KPNE-App-Sep-02-2019-1530Z download.mp3 -

Odd approach clearance...am I an idiot or did ATC screw up?

DXB replied to DXB's topic in Mooney Safety & Accident Discussion

Yeah that's exactly what I ended up doing, cheating onto the approach course a bit a couple miles from the FAF and then starting down. I was still about 2600ish at the FAF. It would have made most sense to question the controller immediately, but these snap decisions are tough for a relatively inexperienced pilot who gets confused at a high workload time. -

Odd approach clearance...am I an idiot or did ATC screw up?

DXB replied to DXB's topic in Mooney Safety & Accident Discussion

Thanks gonna pull the tape now and call Philly TRACON and also file NASA. I'm confident it went down this way. I seem to be getting this kind of sloppiness in Philly more often lately for some reason - they used to be great. I mention the pegged advisory glideslope merely to indicate that I was being asked to come down unreasonably steep in IMC on final approach, not that the glideslope has any official role in the approach. I broke out at 1500 about 2 miles from the rwy, which is still within my ability to produce a reasonable landing - had ceilings been lower and the IMC been more solid, I would have balked. -

This just happened. I was at 3000ft and getting vectors to final for the RNAV (LNAV + V) Rwy 15 at KPNE. I have flown this approach at my home drome many times. See my aircraft position on approach plate below - I was in and out of IMC, assigned altitude 3000, assigned heading 240. Ceiling was about 1500. From my shown position, I was expecting an intercept heading for the final approach course along with the approach clearance. Instead I just got this clearance: "Fly direct PACKS [the FAF]. Maintain 3000 until established on a published portion of the procedure [she actually went to the trouble to say that full phrase]. Cleared RNAV Rwy 15." Sources of my confusion: 1. If vectoring someone to final, I thought ATC was obligated to give an intercept a certain distance outside the FAF. I have never been told to start the procedure at the FAF. Isn't this against the rules?! 2. Telling me to start the procedure at the FAF and maintain 3000 until that point leaves me diving for the MDA with the advisory glideslope at full deflection. Asking me to do this inside the FAF in IMC seems unreasonable. So should I be irritated at Philly TRACON, or are my admittedly amateurish IFR skills simply still not up to snuff in this case?

-

I may have learned something here - I thought glazing was mainly a concern if running low power settings during breakin, not a cause for increased blowby on an aging cylinder. Is this accurate? How does one diagnose "glazing" in your situation? I also wonder why there isn't a solvent fix for glazing - it's just combusted oil residue and carbon after all. One reads about Seafoam and such in the automotive world. When deciding to IRAN cylinders vs. major overhaul, the number of years since last overhaul might also be an additional consideration - i.e. 10 years might favor IRAN, 30+ might favor overhaul. Also it's not uncommon to pull a cylinder and pay labor to sandblast it clean before rehoning, only to find a minute crack that makes it unservicable and requires replacement - so the costs keep going up and those resources might be better put toward an overhaul.

- 42 replies

-

- top overhaul

- cylinders

-

(and 1 more)

Tagged with:

-

HELP another STEC 30 altitude hold oscillation thread

DXB replied to DXB's topic in Avionics/Panel Discussion

Follow up on thread - fixed !! To recap the problem - my pitch servo would either work perfectly or oscillate wildly - no rhyme or reason as to when and where. It would often do both on the same flight. Smooth air or turbulence made zero difference. The oscillations recently got so bad that the altitude hold would slam the nose 10 degrees down suddenly for no apparent reason. I wondered if Boeing had secretly upgraded the firmware without telling me Per the STEC folks at Oshkosh this year, there are about a dozen causes for this problem. Simple stuff I looked at that failed to identify or fix the issue: - “exercising” the servo per the manual - looking for moisture in the static lines - trying it on alternate static - leaving it slightly out of trim - checking cable tensions on the pitch servo - checking electrical contacts to the pitch servo So I figured that I was looking at an issue with the pressure switch, the control module, or the servo itself that was going to cost me serious $$$ to get sorted. But the intermittent nature of the problem made me think it was just a loose contact somewhere. First thing I tried was crawling under the panel and finding the connector between the pressure switch and the control module. I painted the contacts with Stabilant 22. Hurray!!! Blind avionics squirrel finally got a nut on his own -

Sometimes metal fatigued and cracks... and breaks.

DXB replied to aviatoreb's topic in Miscellaneous Aviation Talk

My ignorance of metallurgy and engineering leads to some nightmares here. This thread illustrates an example of a very beefy piece of aluminum fatiguing over time under repeated loads until failure. The Mooney wing spar is also a beefy piece of aluminum that is loaded repeatedly. We generally say these planes have no limit to their service life if maintained, and so I imagine the same concern does not apply. But I have no idea why it wouldn't? -

I went with a B&C a couple pf years ago based on claims of better durability than Skytec. Wt increase is only a couple pounds over the lightest skytec.

-

Very interesting discussion. The red box/fin concept is what keeps me from using the power settings and altitudes that get the best performance. My lowly C model will cruise >150kt easily at 5000-6000 AGL, 2500rpm, WOT (~24.5-24.8). This is 75% power, where the POH and Lycoming manual say its ok to lean. Doing so allows me to run ~10gph with 3 CHTs <360 and my problem cylinder #2 in the 380s. It is very appealing to operate this way. But the red fin/red box graphs say this is the worst possible thing to do, so I avoid except to show off once in a while how fast a C can go. I’d love for this concern to be debunked....my engine seems happier here than at 24squared from a CHT perspective despite 24 squared being only 70% power - which may support the OPs observation regarding higher rpm.

-

The short body Mooneys went to the full length rudder in ‘69. I have the short rudder and have never found it lacking in authority - I have never come close to running out of rudder on a takeoff roll even in a strong direct crosswind. If you are doing as @Yetti describes above, there is something else wrong here, perhaps with the steering mechanism. BTW even my primitive ‘68 POH has a few words on crosswind takeoff technique. It might be worth reviewing.

-

Surefly electronic ignition question

DXB replied to charlesual's topic in Vintage Mooneys (pre-J models)

Surefly and electroair have boldly brought ignition timing technology into the 1980s for certified aircraft engines. Let’s not get greedy -

Obtuse question: What are the advantages of moving to the tail? I guess accessing r without getting killed by the prop for a jump start is easier.

-

Price of doing business. The Greatest Landing Gear System demands these sacrifices as tribute from its fortunate users every now and then

-

Once you’ve mastered your new ride, consider becoming a MAPA safety foundation instructor. We amateurs need more pros like you to keep us amateurs in line.

-

I'd certainly rather hit the treetops under CAPS than gliding without CAPS. Though CAPS is no substitute for airmanship and judgement, I'm in no position to Monday morning quarterback the decisions this pilot made before he pulled the chute. For someone first considering getting into flying, videos like this make a very strong impression of the CAPS system offering an enormous safety dividend that nothing else can. The marketing wins handily. For many of us, that enthusiasm is tempered by awareness of situations where CAPS won't save you as well as disdain for the exaggerated safety claims and the invulnerable attitudes that these claims tend to breed. Nevertheless, anyone who has flown over unforgiving terrain with an uneasy feeling in a piston single cannot deny the appeal of having the option that the chute provides. If I ever replace the Mooney with another piston single for serious traveling, it will have a ballistic parachute.

-

Surefly electronic ignition question

DXB replied to charlesual's topic in Vintage Mooneys (pre-J models)

Another possibly dumb question- If the surefly is using variable timing and the conventional mag has fixed timing , a fouled plug driven by the surefly would seem problematic because the ignition timing on the affected cylinder could become way off from the others. Am I wrong here? Is the Surefly system smart enough to deal with this issue? -

Mike, I am based out of KPNE and would be happy to help however I can Dev pm sent

-

The plane rolled out of factory in December 1967. The most famous movie that came out that month was The Graduate. I named the plane Mrs. Robinson - she is indeed the older woman in my life.