-

Posts

3,513 -

Joined

-

Last visited

-

Days Won

13

Everything posted by DXB

-

nope and I don't think one is planned

-

Not that I know of - it's just the fine wires. I've been running Tempest UREM37BY massives without issue for over 7 years - I'll put in my 3rd set in 50 hours. As you note, they last about 500 hrs.

-

This video from Champion gives me confidence that I'd be able to maintain their fine wire plugs safely - I think they are in my future. Ironically, I swore I'd never buy Champion anything again after their plug resistance issue, which they ultimately resolved quietly without ever admitting it. Now Tempest seems to be in a similar pickle - there were at least some batches of fine wires that were prone to lose their center electrode. Admitting the issue, recalling the relevant plugs, and detailing the fix in public leaves them on the hook for a lot, perhaps including in relation to this lawsuit, although like you I seriously doubt the plug was a critical factor in this crash. They've likely already identified and quietly resolved this manufacturing issue, but since they have incentives not to detail the problem and their fix, it's hard to be sure.

-

Interesting points on fine wires made here. When I got my plane in 2014 (C model with an carb'd O-360), it had Champion massive plugs up top and Champion fine wires on the bottom (likely installed by previous owner because of fouling problems on the bottom). The bottom fine wire plugs would still foul like crazy unless I leaned very aggressively on the ground. After they fouled once in flight and gave me a little scare, I was done with them. It turns out back then Champion plugs had a high resistance issue and that was probably the critical factor, not the fine wire design - all my plugs had the resistance issue when tested upon removal. As a new inexperienced owner, I was afraid of cleaning the delicate appearing fine wires, so I replaced with Tempest UREM37BY plugs, which have a longer center electrode for foul resistance, and they have served me very well. However, they require regular cleaning and gapping and replacement every 400-500 hours. Based on @A64Pilot's guidance, I'll probably put all fine wires on my engine after overhauling it in the next couple years.

-

There are some cases where that is true. But in the end I suspect there will be zero contribution to safety or justice in this particular case - just a bunch of legal hyenas feeding on the opportunity created by a deceased pilot at the expense of everyone else.

-

Remember this lawsuit? Fatal J model crash due to water contamination in fuel per NTSB, with no evidence of mag failure. The lawsuit against Lycoming claimed the flawed dual mag design caused the crash and ultimately led to a 6.3 million** jury verdict for the plaintiff. The ability to file that suit somehow in City of Philadelphia was a factor I'm certain (perhaps the most plaintiff-friendly jury pool in the country within a relatively plaintiff-friendly legal landscape in Pennsylvania). Hopefully Tempest has zero connection to Philadelphia, otherwise they'd be toast given the evidence of a missing center electrode for a single plug (despite all the other likely factors in this crash). I see their corporate offices are in NC and this law firm is in FL. **I just looked up result of Lycoming's appeal, which failed, leading to additional "delay" damages being awarded - now 9.1 million total as of last month.

-

I'd suggest not lifting a finger to help these plaintiffs lawyers at least until there is an NTSB report firmly implicating a spark plug failure. Those vultures latch on to anything that might have happened that could be traced to a manufacturer of in order to leverage a windfall settlement, and they succeed far too often based on the most tenuous evidence. They do little to serve justice but are a major contributor to our operating costs.

- 112 replies

-

- 18

-

-

Honestly I have zero desire to stall my Mooney except a few feet off the runway when I'm landing. I'm not too uncomfortable demonstrating a power off stall from level-ish attitude, watching the ball and recovering not too long after hearing the horn. Power on stall? No thanks. I foolishly did my first BFR after getting my Mooney with a random early 20s CFI with no Mooney experience - when he asked for a power on stall, I flat refused - he then made me land and go back up in a 172 to demonstrate it - big waste of time in my view. My current Mooney instructor has deep experience in the type and won't do power on stalls during the BFRs. According to him during my last BFR, "the last two students I had do it got into an incipient spin, and I had to get them out, so now I just demonstrate it." His "demonstration" was still pretty hair raising for me. I did once get some spin recovery training in a Decathalon - it was utterly shocking and paralyzing when experiencing a spin for the first time, even though it was super easy to get out of it once I regained some executive function via coaching. The main thing I learned though was that I don't ever want to experience that in my plane.

-

Yeah I've wondered about this too. They also ask if I ever operate on grass - I am honest and say yes, maybe one to two times a year. It's usually at Katama or some similar putting green-like runway in dry conditions. I wonder if that answer affects my rate? I suspect I take on more risk dinging the prop from taxiing in the grass at Oshkosh every year.

-

@twall001 This statement misses the mark completely. You are not uninsurable in a Mooney without an IR, and the IR is neither needed nor recommended before you transition to one. You might not want to start off in a K model or Acclaim, but much of the Mooney fleet is perfectly appropriate for your experience level, given some transition training and respect for their distinctive flight characteristics (as with ANY unfamiliar plane). There are also no perils in not having an IR in a Mooney that do not apply to any other plane. At the same time, there is hardly a more favorable piston single platform for both your IFR training and subsequent real world IFR flying than a Mooney.

-

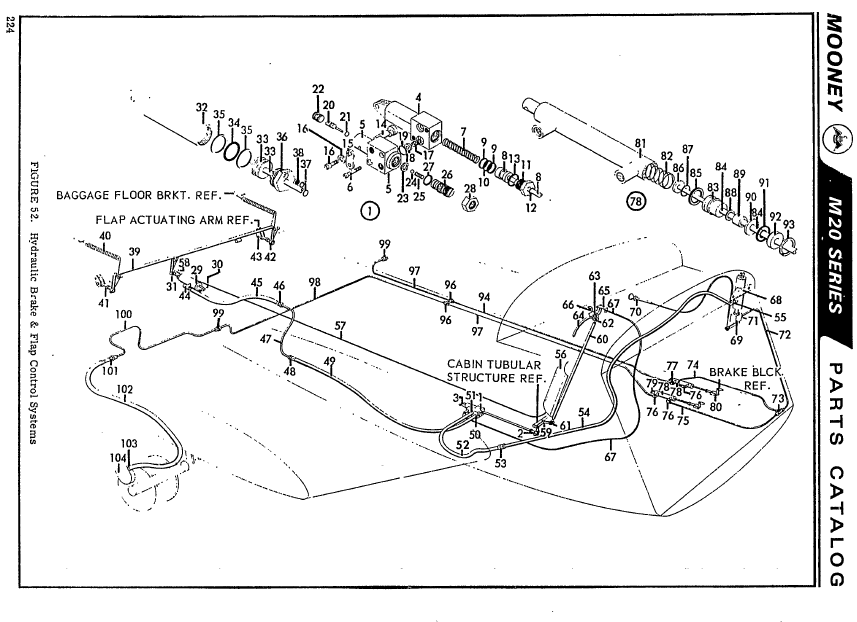

'68C with hydraulic flaps. I've posted on this before a few years ago - still haven't found a clear solution: My flaps mostly work well - two full pumps for half flaps, four full pumps for full flaps. The issue is that after putting in two pumps on the ground for takeoff flaps, the pump handle will sometimes SLOWLY come back up part way on its own, and the flaps will accordingly come up slightly. It's now part of my final before takeoff flow to make sure the flap handle is all the way down along with pushing mixture to full and boost pump to on. This problem never happens when the flaps are loaded by air pressure on the take off roll or in flight, so it's a pretty minor issue because they work perfectly in the air. I assume there is a check valve in the system that is not getting enough pressure to close a the ball valve fully until there is enough pressure in the system - provided by air pressure on the flaps themselves. At last annual, some fresh hydraulic fluid was flushed through the system with the thought that there was some gunk on the seat of the valve that needed to be cleared, but doing so made no difference. Supposedly the flap pump in the belly was rebuilt by Airmods in NJ in 2015 a year after I got the plane due to a small leak at the pump, but of course I can't confirm what they actually did because I wasn't there. However the problem appeared a few months after that annual. I don't want to reflexively pull that pump again without a perfect idea of what's going on. I suspect it could only be one discrete issue in the eyes of someone who really knows that hydraulic system? The parts manual schematic of the hydraulic system is below.

-

A surly, divisive diatribe? Yes. Some elements of truth in it? Absolutely . But it's not a Mooney-specific issue. To me, the new and/or under-resourced private pilot buying an old Bravo doesn't seem much more precarious than the same pilot picking up a late model SR22T before making a smoking crater, an all too common story. In my own defense, 8 years ago, I bought a carefully vetted C as a newly minted amateur pilot not because I couldn't afford a higher sticker price but rather because I didn't ever want to feel in over my head both in terms of maintenance needs and airplane performance. In retrospect, that was a good decision, though I now realize I could have also handled an E or J just fine. I've had enough time and resources to learn about maintenance and keep up with it pretty well, along with thoroughly updating the panel. If one is fully game to take the best possible care of a plane, much of the learning and judgement is actually knowing when not to throw money at a perceived problem, only to dig a deeper hole (I've definitely done this a few times, even recently ). After the instrument ticket and 1200 hours, could I safely move up to an Acclaim now if I wanted to devote the transition effort and resources needed? Probably, but the return on investment doesn't seem to be there, given the largely recreational nature of my missions.

-

Tense moments with ATC due to an intermittent PTT

DXB replied to TuomoMooneyFlying's topic in Videos

To be honest I'm not sure exactly what "the gate" is, but I'm open to throwing in the term if I can figure it out - I do enjoy trying to sound like the pros flying jets -

Mmmm....Sabremech cowl. Hoping this is progressing well @Sabremech

-

What are your CHT's After LASAR Cowl Installation

DXB replied to C.J.'s topic in Vintage Mooneys (pre-J models)

Your experience with the C model is typical. Idle mixture only matters when idling - it has zero effect on climb/cruise temps, so your mechanic missed the mark there. Your temps as described in climb are actually a bit better than average considering the Powerflow. Mine came with the cowl closure so I have nothing to compare to, but I've heard multiple folks say it made zero perceptible difference for them in terms of cooling or cruise speed. -

Tense moments with ATC due to an intermittent PTT

DXB replied to TuomoMooneyFlying's topic in Videos

Good tips from a presumptive pro. Looks like he touched down right on the aiming point and made the requested turnoff so it wasn't a "long" landing. I suppose a long landing doesn't matter much from an ATC perspective, and a long rollout would be needed primarily due to slippery runway conditions. I've always wondered how best to handle it when told to keep my speed up. I generally acknowledge, and then say I need to slow to 105 kt for my gear speed just before the FAF if on an approach or on 2 mi final if visual. -

Interesting info - East Coast Propeller is the reputable choice around here locally and probably where I would have sent it - I'm past 10 years so probably looking at an overhaul unless I can find another reputable place to IRAN. I'm probably going to wait a year or two and do it at the same time as my engine. It's nice to work this stuff out in advance and avoid surprises when the time comes.

-

What are your CHT's After LASAR Cowl Installation

DXB replied to C.J.'s topic in Vintage Mooneys (pre-J models)

I'm pretty sure they all have a doghouse, which is a piece of dogsh*t in my view. Crap mixture distribution via the carb is another offender, and perhaps the dominant one - It's really just #2 and #4 that have the issue for me (both in climb and cruise) - the other two cool nicely, even after putting in a Powerflow exhaust and advancing timing at lower power settings via the Surefly mag. You really need to have the richer carb option on these engines also. From '68 onward they fixed the cowl flap position on the C, which I suspect didn't help either. I've "illegally" retarded baseline timing to -23ish on mine but it didn't noticeably help. At high CHTs, I think there is a cylinder longevity issue, maybe not in the low 400s though. My hottest cylinder in climb (#4) actually lasted longer (~1350 hrs) than the other 3 before needing to be reworked - it rarely went any higher than the 430s in climb though, even on the hottest day. When my blowby-related oil consumption rose to 1qt/3hrs and #4 had a consistently oily bottom plug, I figured it was time and I replaced #4 with factory new, hoping to make it another several hundred hours before overhauling. After 1.5 years and 200 hours, oil consumption is back down to 1qt/3hrs, the crosshatch looks polished out of #4, and it now also has an oily TOP plug . A little while before swapping #4, the Powerflow went in, which made it commonplace to break CHTs of 450 on that cylinder in climb, and I gotta think that's what led to the premature wear. Now I leave the throttle out 1 inch when going to full power on the runway - this has barely perceptible effect on MP and fuel flow but keeps #2/4 CHTs in early climb below 420 generally. It must be improved mixture distribution that occurs here, though I think they also cool worse from an airflow perspective. I wish I'd figured this out when #4 was brand new instead of abusing it so badly -

Thanks- important info - when my inevitable IRAN/reseal job happens in the next few years, I gotta make sure it gets NYCO GN3058 and serviced with that going forward. Ah - and I forgot I'd posted the pic you found of my prop when it first started leaking liquifying #6. It's been serviced with #5 for 3 years now with reduction (but not cessation) of the leakage since then, and I'm convinced there's plenty of goop inside the hub, so I don't feel urgency to pull the prop off for this reason.

-

I think there is some time needed for the the #6 to start breaking down and thin liquid to escape past the seals. Mine was fine for about 7 years until a bit of thin grease started to appear near the hub on one blade, particularly in summer months. Hartzell is clear on time and hour interval requirements for greasing the hub, so I would be hesitant to ignore that - I think the idea is to dilute and/or flush old congealed grease. I think they also commonly recommend gently probing around in the opposite fitting to break up any congealed grease might prevent the grease from getting flushed out. A common practice among many A&Ps has been to keep pumping until you have grease coming out the opposite fitting, which Hartzell advises against for the reason you cite - the central hub getting filled and pressurized, causing the seals to herniate. For my scimitar prop, they recommend 6 pumps OR to stop the moment grease comes out the opposite fitting. They might also recommend a reseal job on my prop, which I am resistant to for the time being - the minor appearance of the leak and the fact that grease comes out the opposite fitting after just one or two pumps gives me confidence that the hub isn't about to run dry and self destruct.

-

It doesn't sound like you're overfilling the hub if you're putting in just a couple pumps/year and nothing is coming out the opposite fitting. It is worth knowing what grease was put in the hub at last reseal - generally its Aeroshell 5 (thicker) vs. Aeroshell 6 (thinner). I bet you have 6, which has a reputation for breaking down and liquifying, generating a thin sheen that gets past the seals (not heavier nodular chunks, which would be more worrying). With just a small amount of this leaking and the low hours you're flying, I doubt the hub is at risk of running dry of grease , so I would be in no rush to do another reseal job. I've been living with a similar issue for a few years now flying 100-150 hrs/year, adding a few squirts #5 at annual on top of the original #6 in the hub from factory new 11 years ago - it does immediately come out the opposite fitting for me. There is no problem with mixing the two greases.

-

This is a great point. From what I glean synthetic oil is better for literally everything related to engine longevity except carrying the byproducts of tetraethyl lead combustion.

-

Reasonable, but the main appeal of running the filter longer for amateurs like me who do their own oil changes may be putting off the contortionism act at the back of the accessory case, not filter cost (though draining and reusing may make sense for victims of the current Soviet Russia-like filter rationing economy). Regardless, changing and cutting the filter silences my recurring nightmares of my lifters and cam lobes turning to dust, so I keep doing it every time I change the oil for my mental health

-

TruTrak Autopilot Pre Order's / Status Update

DXB replied to Jeev's topic in Avionics/Panel Discussion

I thought it was a phenomenon specific to swept wing aircraft, but I would swear I've experienced it before my C model. At the very least, the short bodies don't have the best yaw stability. If I ever upgrade my 2 axis STEC-30 to something modern, I'm going with the yaw damper option for sure. -

Oil control rings and lessons learned - with pics!

DXB replied to canamex's topic in Vintage Mooneys (pre-J models)

As an armchair A&P wannabe with no real skills, this has been a pretty educational post for me. The question comes up - is that top ring really broken or merely sitting out of its groove after decompressing? I had thought a broken ring would produce massive blowby - worse than the 1wt/3 hrs described here. Asking for a friend who is also getting the same amount of oil consumption, which is pretty stable, and wondering what to do.