-

Posts

1,364 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Vance Harral

-

What is this stuff in my gascolator?

Vance Harral replied to Vance Harral's topic in General Mooney Talk

15-20 *inch* pounds is the torque spec on the gascolator. It's very light. Use caution, I broke my fuel selector last year after mis-understanding the torque spec, and finding a replacement was a saga. You can undo the rod on the nose gear door. Or, if your airplane is more workhorse than beauty queen, a long-shaft phillips screwdriver with a bit of flex in the shaft, and a willingness to bend and rub on the gear door during the deed, can also get the job done. We don't necessarily replace the gasket every year, I will re-use it a second year if it appears to be in good shape. LASAR does indeed sell the gasket and fancy washer, but be aware they sold me a faulty gasket last year. I'm not saying it's their fault, necessarily - they just stock parts from Mooney. But it was definitely bad. You can read about it here: https://mooneyspace.com/topic/34307-fuel-selector-woes/?do=findComment&comment=584949 -

Yoke set screw: to Loctite or not

Vance Harral replied to Vance Harral's topic in General Mooney Talk

Concur with Robert. After our original loctite debacle, I'm skeptical of any "works great" story that doesn't include a positive PIREP on the ability to remove it at the next inspection. -

The especially eagle-eyed will note that at some point in the history of our airplane, the bolt and nut in the "before" video were installed backward. The bolt head is supposed to be aft, and the nut forward. There is a slight downward tilt of the mechanism from aft to forward, so with the bolt head aft, the bolt would theoretically stay in place if the nut were to fall off. In the backward installation, if the nut were to come off, the bolt would be more likely to work completely loose. That's the aviation "standard", though I don't put much faith in it - I'd rather be sure nuts don't come off!

-

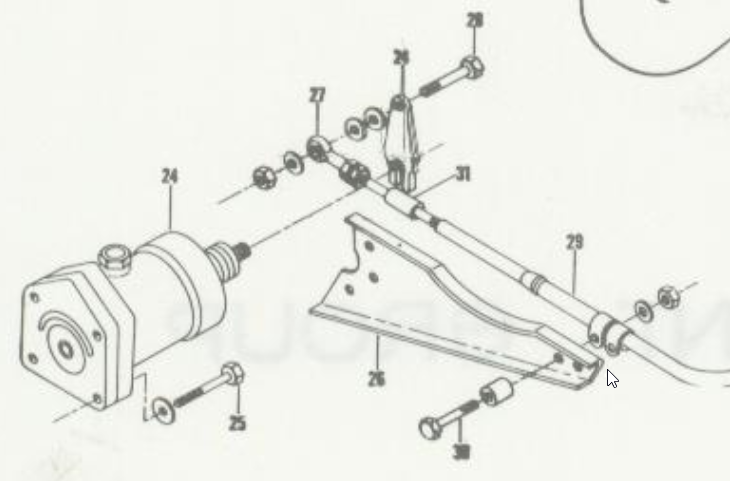

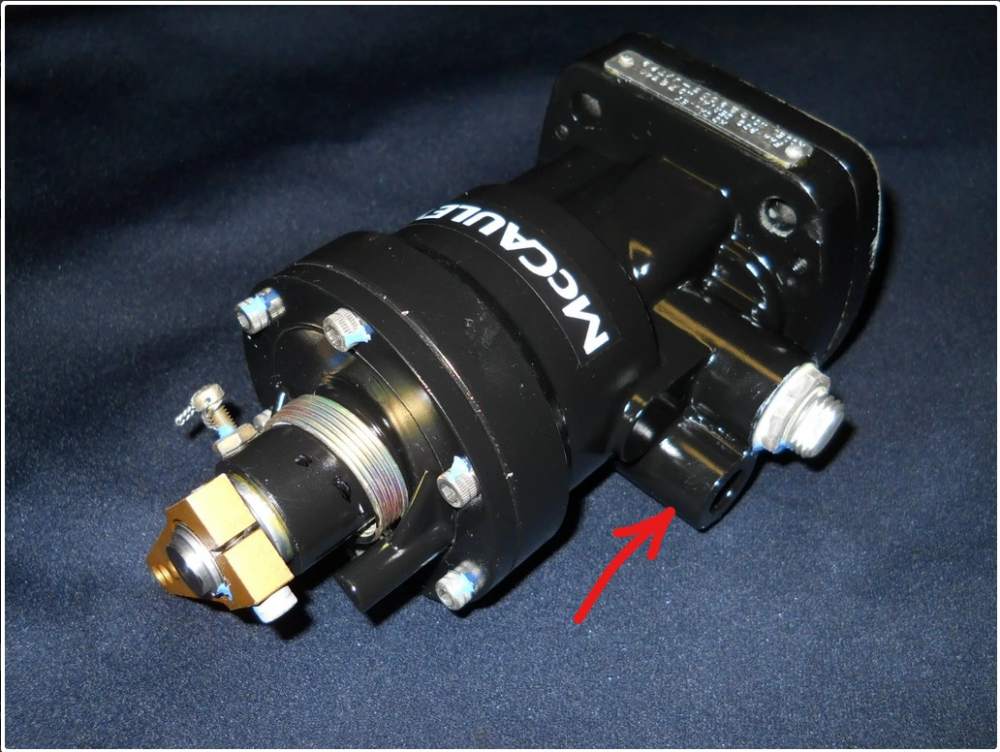

Guessing you've already decided on your course of action, but I finally got a fresh look at our McCauley governor and I remembered why grinding the case was necessary. In many governor installations, the part of the accessory case that receives the governor has threaded studs installed. The governor slides over the studs, then you install nuts to fasten the governor tight to the accessory case. That is not the way it's installed in Mooneys, however. Instead, the governor is installed with MS20074-05-14 bolts, which are a little over 1.5" long - see item #25 in the parts manual pic below. The design of the McCauley governor is such that it is not possible to slide a 1.5" bolt through one of the four mounting holes, because of a protrusion on the case which I've marked with a red arrow below (I believe this is a pickup port for a prop synchronizer system). So to install the McCauley governor, you must either swap the mounting bolts for threaded studs (unclear to me if this is "legal"), or grind the case protrusion just enough to slide the bolt in.

-

For those of you not familiar with SB M20-289A, or those who just haven't gotten around to performing it, here are before/after videos on our 1976 M20F. We've been aware of the issue for a while now, but it was only within the last year that our original installation actually began to have the clearance problem described in the S.B. Ordered the kit from Mooney, and installing the new spacers does make a significant difference. Before: After: Video link https://youtu.be/MqET4p8saMI

-

Yoke set screw: to Loctite or not

Vance Harral replied to Vance Harral's topic in General Mooney Talk

Follow-up: we decided to try this "second set screw acting as jam nut" idea. Installed a second screw in each yoke about 3 weeks ago, seems to be holding nicely so far. -

What is this stuff in my gascolator?

Vance Harral replied to Vance Harral's topic in General Mooney Talk

We checked this today. It sinks like a stone, which makes it all the more mysterious that it was on top of the screen rather than the bottom. The shop IA got tied up today and hasn't really had a chance to look closely and consult. It'll probably be Monday before he can really dig into it. -

What is this stuff in my gascolator?

Vance Harral replied to Vance Harral's topic in General Mooney Talk

Ideas that it may have something to do with the boost pump are interesting. We have the "new" Weldon pump, but it was installed over 15 years ago, and has about 1000 hours of service (a lot less time actually in operation, of course). -

What is this stuff in my gascolator?

Vance Harral replied to Vance Harral's topic in General Mooney Talk

We did have a patch job done in March of 2020. This stuff wasn't in the gascolator in April of 2020 at last year's annual. If the shop that did the patch job left shop rag material in the tank, it took more than two months to migrate to the gascolator. But perhaps that's not implausible. -

What is this stuff in my gascolator?

Vance Harral replied to Vance Harral's topic in General Mooney Talk

Don't know. But we saved it, I will check tomorrow. The plan is to look. Hoping not to have to drain the tanks to do, so, but can do that if necessary. -

What is this stuff in my gascolator?

Vance Harral replied to Vance Harral's topic in General Mooney Talk

I was the last person to lay hands on the screen a year ago, and no I did not not clean it with a shop rag. I'll work with the shop tomorrow to check the fuel servo finger screen, thanks for the tip. Checking it again after a few hours' operation is definitely on the agenda. -

What is this stuff in my gascolator?

Vance Harral replied to Vance Harral's topic in General Mooney Talk

I'm about 95% sure our airplane does not have that post-boost-pump screen, because we have a replacement Weldon boost pump. But I'll double-check tomorrow. Thanks for the tip, any and all ideas are welcome. -

What is this stuff in my gascolator?

Vance Harral replied to Vance Harral's topic in General Mooney Talk

It's certainly possible I misunderstand how the fuel selector works, but I don't think so. Below are a couple of photos of the Dukes fuel selector/gascolator in our airplane. These are taken from underneath the airplane, looking up. The feed lines from the tanks are at the top (i.e. at the "back" of these photos), while the line to the boost pump is at the bottom (the "front" of these photos). The screen is beneath the level of all the supply and feed lines. With the bowl removed, when the fuel selector is moved from OFF to LEFT/RIGHT, fuel drains through the center of the unit, not through the screen. It comes out the four small holes in the center post that you see in the photo, and fills the bowl. It must then flow up through the screen, to exit out the boost pump line, and on to the engine driven pump. The arrangement appears to work like a P-trap on a sink. The gunk was entirely located above the screen (or "behind" the screen relative to these photos). That's the engine side, not the tank side. -

What is this stuff in my gascolator?

Vance Harral replied to Vance Harral's topic in General Mooney Talk

The idea that it came from a fuel provider is an interesting one. That would be a one-off event, consistent with finding junk in the screen, but none when draining the tanks or pumping through the electric pump. Still, I'm mystified by the fact the material is on the downstream side of the screen, opposite side from the fuel tanks. If the contaminant came from or passed through the fuel tanks, I would have expected to find it on the upstream side of the screen. Might be a good idea to get a look at the pickup screens in the fuel tanks in any case. Any way to do that safely without completely gdraining the tanks? I have a cheap endoscope I can feed down there. I don't mind if doing so winds up killing the endoscope, but I wouldn't want material sloughing off the endoscope to contaminate the fuel or cause other problems. I might try draining some fuel into a bucket and putting the scope in there first as an experiment. -

Opened up the gascolator at the annual inspection today and found a significant amount of what I'll call "dryer lint" on the screen. Photos below. Note that the first photo with the material resting on the screen was taken after I'd already run my finger across it, which caused it to roll up into the snake shape shown in the photo. Originally it was evenly caked across the whole screen. The stuff was caked on thick enough to be disconcerting - seemingly enough of it to impede fuel flow, though we haven't seen any fuel pressure or fuel flow issues since the last annual. It's red in color, and looks and feels like cotton fibers. Couple of guys in the shop speculated it's from a fiber washer or gasket, but as far as I know there's nothing like that in the Mooney fuel system. My initial guess was fuzz from a red shop rag, but I don't really think there's a shop rag in the tanks or elsewhere in the fuel system. I'm pretty sure this isn't decaying tank sealant, for two reasons. First, the texture doesn't match what I'd expect of tank sealant. It's not plasticized, rubbery, or gelatinous - again, it's fuzzy like cotton. But more importantly... and here's where it gets weird... all the material was on the engine side of the screen, not the fuel tank side. In other words, it seems like the material is settling into the gascolator from "downstream", opposite the normal direction of fuel flow. I'm not sure how that's possible, but 100% of the material was on the top side of the screen (fuel from the tanks flows through the center of the gascolator to the bottom cup, then up through the screen, thence to the electric fuel pump). Upon discovering the problem, we drained about a half gallon from each tank through the gascolator, and that fuel came out as clear and blue as the pool at a 5-star hotel. Then we cleaned out the gascolator and screen, reassembled, and used the boost pump to run another half gallon through the gascolator and boost pump out of each tank, through the hose that feeds the fuel servo. That too came out nice and clean. So it's a mystery where the stuff came from, and we can't reproduce it. What says the Mooneyspace hive mind? Any and all speculation is welcome.

-

The radios that do the transmitting only have a single mic input (two wires, one for the actual audio and one for the PTT). The behavior of a multi-input system is governed by the audio panel and/or intercom to which the headsets connect. It's possible to set up a system where both mics transmit when any PTT switch is activated. But that would be unusual, because as you said, it's almost always undesirable. I've flown in airplanes with portable intercoms and PTTs which transmit both mics when any PTT switch is pressed, but this is usually an accident of bad hookup/design/PTT understanding. Any panel-mounted setup installed by an avionics shop is going to have independent PTT behavior.

-

Just don't adjust them too far and/or fail to protect them with teflon tape. We tightened up our door linkages many years ago because it seemed like they were mis-rigged (no slop in linkage, they just didn't come together as close as we wanted). Looked good after adjustment. A few months later we realized they were rubbing together in flight and the doors had developed some surface damage at the "lip" where they come together. Just cosmetic, not really an airworthiness issue. But your airplane looks like it has nice paint.

-

Electric Landing Gear Circuit Breaker ('67 M20F)

Vance Harral replied to BWatts's topic in Vintage Mooneys (pre-J models)

Thanks for the clarification. That crank unit is an integrated assembly in the parts manual. It never occurred to me it had internal gearing. -

Electric Landing Gear Circuit Breaker ('67 M20F)

Vance Harral replied to BWatts's topic in Vintage Mooneys (pre-J models)

I'm wondering if there is some difference between the Dukes and ITT actuators here. My understanding is they are of similar design, but 40 cranks in our 1976F would not be anywhere near full transition. We have an ITT actuator. Earlier airplanes had the Dukes actuators. Both actuator types are subject to the AD that requires periodic inspection of the gear train, and I always assumed they were basically the same; but maybe not. -

Electric Landing Gear Circuit Breaker ('67 M20F)

Vance Harral replied to BWatts's topic in Vintage Mooneys (pre-J models)

I'm guessing 4200 RPM is the unloaded speed of the motor, but I don't think it turns anywhere near that fast under load. Your math is about right except there is no gearing between the emergency crank cable and the motor shaft in the M20F vintage of airplanes. The emergency engage just slides the crank cable spline directly into the motor shaft, it's a 1:1 hookup. The motor shaft is geared to the drive mechanism by a worm gear arrangement, which originally had a 20:1 ratio. J model actuators and "upgraded" early-model actuators have 40:1 gears. We've had both in our airplane, so I'm pretty familiar. Prior to the 40:1 upgrade, gear transit time was about 3 seconds, and emergency extension required about 70 cranks from full up to full down. After installing the 40:1 gears, gear transit time is about 6 seconds and emergency extension requires about 140 cranks from full up to full down. Doing the math for 40:1 gears, 6 seconds is 0.1 minutes to make those 140 turns. That's about 1400 RPM at the motor shaft. -

We've had prop governors off the airplane twice in 17 years, both times due to oil leaks from seals in the governor case itself (not the seal between the governor and the engine accessory case). It stands to reason that the seals go after a while, they are not particularly sophisticated. In both cases we asked about IRAN only, but the shops we used (two different ones) stated that there was enough internal wear to warrant a full overhaul. Back in the mid-2000s we just had the Garwin governor overhauled and reinstalled. Got another 10-ish years out of it before it started leaking, and that's what led to the McCauley replacement. You can judge for yourself whether 10 years and about 1000 hours is a typical run, and how to pro-rate the overhaul cost. The thing that shied us away from the PCU5000 was not just that the overhaul was expensive, but that shops were already seeing these units come in for overhaul, enough to comment on the cost of parts. My perception was that the PCU5000 was new enough that it seemed unusual that the shops were already seeing units needing overhauls. That may not be a rational concern, though. There are certainly operators that fly airplanes hundreds of hours per year, and that can rack up thousands of hours on equipment in relatively short times.

-

Faced with exactly the same advice from TrueSpeed a couple of years ago, we went with the McCauley. I don't regret it, necessarily, but I also wouldn't call it a smooth experience. First, the McCauley governor would not fit on our 1976 M20F with Lycoming IO-360-A1A, without grinding away a small portion of the housing of the governor itself. Truespeed had no idea this would happen and they were surprised when I called them about the problem. Since they didn't mention it to you, It appears they either don't remember that we had this problem on the same airplane/engine, or are choosing not to tell you about it. I looked for photos I took at the time, but I am unable to locate them at the moment. If you want to know more, I can get out to the hangar this weekend and take some pictures. The portion of the governor housing that had to be ground away was small, non-structural, and we haven't had any problems with the governor in the two years since. But it just seemed kinda ridiculous to have to take a grinder to a freshly overhauled and painted governor. Truespeed was kind and straightforward in helping us resolve the problem, but they didn't offer us a discount or extended warranty on the overhauled McCauley due to our problem. Second, if you go with the McCauley, make sure you get documentation from Truespeed regarding AD 2020-19-06. The issue is not that Truespeed is going to give your a governor with a bad idler gear, it's just that it's another piece of AD paperwork you'll need to present to anyone verifying AD compliance in the future. Giving up on the Garwin governor seemed like a no-brainer at the time, but if I had it to do all over again, I'd give more consideration to overhauling the Garwin instead of opting for the McCauley. We actually still have the old Garwin core, and we're keeping it around "just in case".

-

I own both Lightspeed Zulus, and a QT halo. I wear the QT for flight instruction in Cessnas, but I use the Zulus in the Mooney, and the occasional other, louder aircraft. For whatever reason, I just can't get enough noise suppression with the QTs for them to be pleasant in louder aircraft. I've tried all the different tips: rubber, silicone, yellow foam. I can hear the radio and intercom fine, and I'm sure they're doing a reasonable job of filtering out the most damaging amplitudes/frequencies. But they are undeniably, unquestionably, poorer at reducing overall ambient noise than any over-the-ear, active ANR headset I've ever worn. I read stories all the time from people who say QTs and/or Clarity Aloft in-the-ears are just as good, or even better, than an over-the-ear ANR. But I simply don't have that experience. It's entirely possible this is just a function of my ear anatomy. One thing I haven't tried yet - but will do so when I get around to it - is custom ear molds for the QTs. I know the developer pooh-poohs them, but several folks I know use them, and it might bridge the gap in performance. The QTs are certainly comfortable, and I want to like them a little more than I actually do.

-

Yoke set screw: to Loctite or not

Vance Harral replied to Vance Harral's topic in General Mooney Talk

The retrofit kit is pretty spendy. We got a quote from Mooney on just the shafts (we can re-use the existing yokes), and it was $1250 a side, or $2500 total. We've been casually on the lookout for a quality used part from salvage ever since, but there are many different types of yoke shaft, and the exact P/N we need is hard to come by. Again, for most of our ownership it seemed simple just to perform the inspection, but I'm feeling less and less like that with every inspection cycle.