Deb

Supporter-

Posts

360 -

Joined

-

Days Won

3

Deb last won the day on November 13 2019

Deb had the most liked content!

Profile Information

-

Gender

Female

Recent Profile Visitors

7,752 profile views

Deb's Achievements

-

Yup, thanks Paul. Pompano (KPMP) or (North Perry) KHWO is likely more affordable than KFXE. We sent Hank a more comprehensive PM.

-

Scott Ashton started following Deb

-

@DonMuncy has made an electronic version of the switch. There’s a thread here: @Aerodon posted a replacement part number 940138-501 in that thread.

-

EarthboundMisfit started following Deb

-

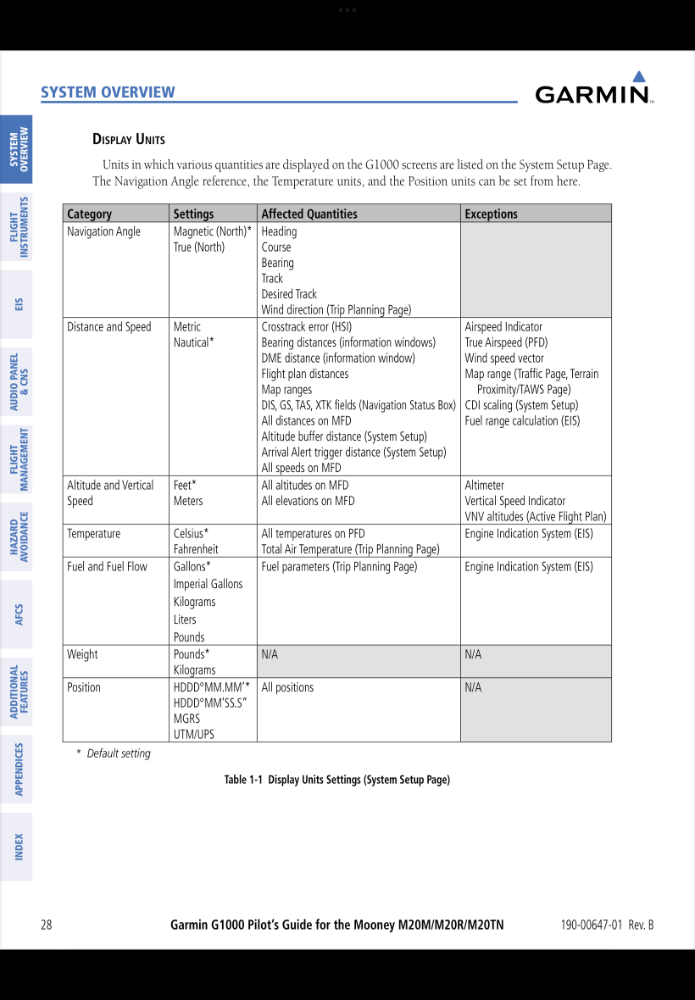

According to the G1000 Pilot’s Guide for the Mooney M20M/M20R/M20TN, that function is “N/A”: On the PC simulator, the cursor skips the “Position” field in the Display Units box. We don’t know if this is alterable in configuration mode. @PaulM or @Pmaxwell might know. Garmin provides this helpful warning: Warning: Only qualified maintenance personnel should perform this procedure. Improper configuration can lead to system errors.

-

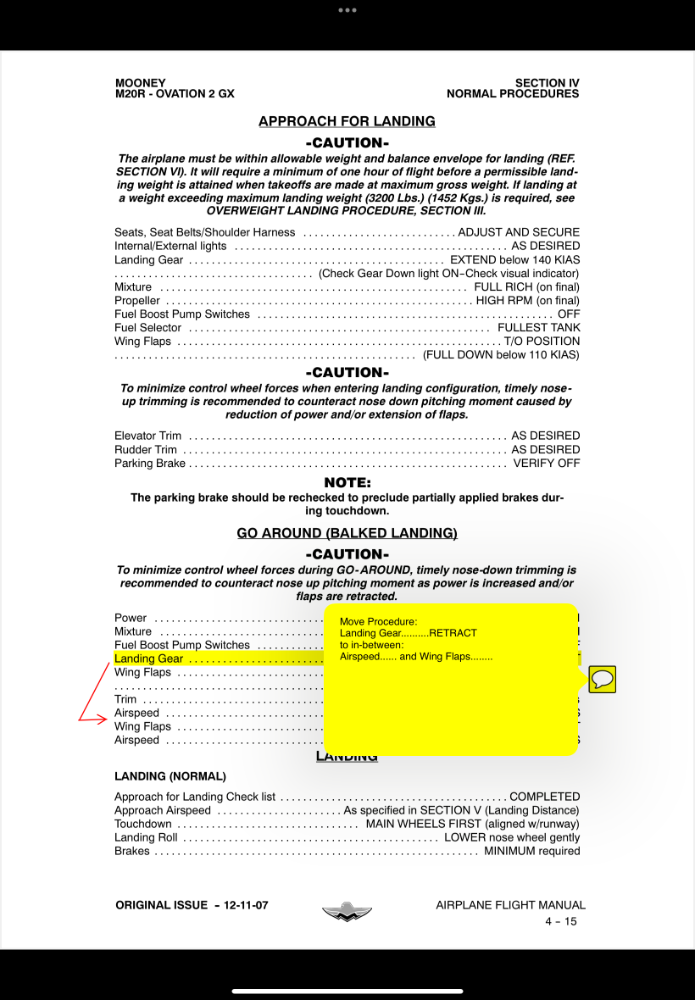

Retract Gear or Flaps First in a Go Around ?

Deb replied to donkaye, MCFI's topic in Modern Mooney Discussion

-

Retract Gear or Flaps First in a Go Around ?

Deb replied to donkaye, MCFI's topic in Modern Mooney Discussion

-

This is a continuation of this thread:

-

Based on the G100UL fuel leak thread what's your position?

Deb replied to gabez's topic in General Mooney Talk

Del Lehmann posted this on BeechTalk (https://www.beechtalk.com/forums/viewtopic.php?f=7&t=234904&start=645): I do not generally take in fuel leaks as a stand-alone job, but I have repaired many Mooney wings due to bird/animal strikes, hail damage, ramp rash.....maybe 15-20 wings over 30 years. Every integral fuel tank skin that we have drilled off lacked faying surface sealant between the internal structure (ribs, stringers) and the skin. It's obvious they were assembled dry, then buttered up the seams and rivet butts by working through the access holes. This is unique among the big four (I've seen some early Piper tanks like this, but rare). Cessna and Beech all have faying surface sealant. I've heard that Mooney did try assembling the tanks wet for a period of time and then went back to dry. If they were actually shooting the rivets with wet faying sealant, that wouldn't have helped. The riveting (hammering) action will displace the sealant. The wet sealant also acts as a lubricant between the bucking bar and rivet, causing an improper upset we call "elephant foot". The rivet bucktail sets before the shank swells tight. This is worse than shooting together dry. The best way is to apply the faying sealant, then put a Cleco in every hole (Cleco is a temporary fastener. Need lots of Clecos). Then once the sealant is cured you can shoot the solid rivets. The faying sealant also acts as an adhesive between the skin and structure and inhibits movement. Now, the only potential leaks are the rivet butts, so all one has to do is butter the butts, leak test and good to go for decades. That's not what Mooney did. -

Phil Corman discusses 4 routes across the Rockies on page 13 of the November, 2013 issue of The Mooney Flyer. Here’s a link to that issue: https://themooneyflyer.com/issues/2013-NovTMF.pdf#page13. Back Country Pilot has a longer article here: https://backcountrypilot.org/knowledge-base/destinations/193-colorado-crossing-continental-divide.

-

The 4 charges were dismissed by a judge (one charge of entering an area without a special use permit was dismissed with prejudice). The tribe has the option of refiling the other 3 charges. Video here:

-

If i was landing i would say it is not that important. If i was 10 gallons away from landing i would say yes! Our Ovation 2 POH states: FUEL LIMITATIONS –WARNING– Takeoff maneuvers when the selected tank contains less than 12 gallons of fuel have not been demonstrated. So we’d want more than 12 gallons in the selected tank for landing in case we needed to go around.

-

joepilotmooney started following Deb

-

-

It’s actually a bit more nuanced; here’s the definitive answer from John Collins: The LPV CDI FSD (Full Scale Deflection) is 1 NM until reaching a point 2 NM prior to the FAF. The FSD then transitions to the value for the FAF to threshold. At the FAF, this is equivalent to +/- 2 degrees measured from a calculated point beyond the threshold such that when at the threshold, the FSD is +/- 350 feet. It continues at a fixed value of +/- 350 feet until reaching a reference point (about 1000 feet from the threshold) and after that, is changes to a fixed value of +/- 0.3 NM. So as a practical matter, it is similar to an ILS with a runway length of about 10000 feet. It is angular for the final approach course (+/- 2 degrees) and not a fixed value. It is +/- 350 feet at the threshold and continues at this value for another 1000 feet before increasing back to 0.3 NM. My reference for this is from RTCA DO229D, which is the technical specification for a TSO C145/146 WAAS GPS Navigator. You have to be a member of RTCA to get this document for free or must pay $370 for a copy. Here is some description from the 10/12/2017 AIM 1-1-18, d 4 (page 1-1-34): 4. Both lateral and vertical scaling for the LNAV/VNAV and LPV approach procedures are different than the linear scaling of basic GPS. When the complete published procedure is flown, ±1 NM linear scaling is provided until two (2) NM prior to the FAF, where the sensitivity increases to be similar to the angular scaling of an ILS. There are two differences in the WAAS scaling and ILS: 1) on long final approach segments, the initial scaling will be ±0.3 NM to achieve equivalent performance to GPS (and better than ILS, which is less sensitive far from the runway); 2) close to the runway threshold, the scaling changes to linear instead of continuing to become more sensitive. The width of the final approach course is tailored so that the total width is usually 700 feet at the runway threshold. Since the origin point of the lateral splay for the angular portion of the final is not fixed due to antenna placement like localizer, the splay angle can remain fixed, making a consistent width of final for aircraft being vectored onto the final approach course on different length runways. When the complete published procedure is not flown, and instead the aircraft needs to capture the extended final approach course similar to ILS, the vector to final (VTF) mode is used. Under VTF, the scaling is linear at ±1 NM until the point where the ILS angular splay reaches a width of ±1 NM regardless of the distance from the FAWP.

-

There is Sun-n-Fun pricing at $195 each. @OSUAV8TER may have even better pricing…