-

Posts

2,834 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by MB65E

-

Some say that tie down ring was never designed to hold the weight of the tail. There has been some heated debate here in the past. I personally don't do it and find it easier to use the hoist thank to lug a tail stand filled with cement around. -Matt

-

I wouldn't load the tail with anything. Get a small step ladder, put it under the tail, then jack the wings up. Finally to take the nose off the ground, jack the nose up with an engine hoist bringing the tail in contact with said small ladder. Don't load the fuselage , but just enough so it does not teeter on the main jacks fwd/aft. -matt

-

Four corners would be awesome! However, I'm having thoughts of more comfy seats in ours. -Matt

-

Nice filter location. That will really clean up the lower cowl. See you at Osh...with or with out our airplanes. -Matt

-

Other Mooneys heard on the radio while flying

MB65E replied to lsearcy's topic in General Mooney Talk

I heard several during my travels from LA to the Bay Area and PHX last weekend. Over 13hrs running back and forth. Airplane did great, no squawks. I did unfortunately miss the PRB functions. ABQ center had a hard time hearing an east bound Mooney out of PHX Monday evening, I tried to realy. 7164v was the only one I wrote down. -Matt -

Mine is .05ips after engine and prop overhaul. No adjustment done during my prop balance. I did take my time with the overhaul and race balance the crank. My buddies Eagle was .77 at idle and over 1.0 during cruise. Yikes. I did learn a bit on what all the other values mean during the balance process. My highest values were the combustion values. My guy said they could be lower if I matched all the Fuel flows and put fine wires in. Not willing to do the fine wires, but I'll take a look at the fuel flows. Great SoCal Guy!! Pm if you'd like his contact info. Cheers!

-

Wow! Well the factory is making them again. Some one here said they talked to a worker and he said it takes 30 man hours to make. Hopefully, some one here has a spare. Please list the year of door your after. Also , if you have the internal unlock function. At least you didn't gear up the thing!!! Pulling that beaker is fun until it's not. I quit playing with landing gear functions in the air. The best place to practice gear items is in the hangar on jacks. Good luck getting it back together! -Matt

- 26 replies

-

- 1

-

-

- Baggage Door

- Cargo Door

-

(and 1 more)

Tagged with:

-

Both, I like it! That's an awesome idea! I have always liked avblend for the valves and cylinders in general. Lycoming cam corrosion scares me. After a personal connection with an engine rebuild, I started using Camguard to "help" prevent the cam corrosion. However, I really believe the avblend works well in the valves. Side note: Just last week-I've been having rough cold starts in my old Bmw 318 (close to 200k mi). A pint of Avblend in the oil and it all went away. Cheers! -Matt

-

HI John! Just wondering whats left of your stock-pile? I can't believe no one has responded to this in 3 years! Great Stuff!! -Matt

-

Tell me about -- GTN Squelch Issues...

MB65E replied to Marauder's topic in Avionics/Panel Discussion

I think it's 5.3 now. Check and see If there is a new source of power near the headsets cables/harness. Ugg, Matt -

Tell me about -- GTN Squelch Issues...

MB65E replied to Marauder's topic in Avionics/Panel Discussion

I've had issues with 128.2, and a few others in that range. It's a pulsating tone that progresses until you transmit, then it starts over again. If I touch the tip of the antenna while this pulsating tone is going on in the hangar, it goes away. Also, it was really bad when I had the power wires for the ANR next to the comm cords. Since then I have disconnected the 12v ANR source. This was a documented problem that Garmin was going to fix with Software updates. I think there is a build up of something in the Comm coax. Very frustrating to have a $10k+ box that sound worse than my kids headphones. -Matt -

I have seen several of those on eBay. At least the cut out is the same shape... -Matt

-

You could do the entire routing with out talking to LA, but I'd at least pick up SoCal/La center for traffic advisories. I'd file IFR for 11k go over the top of LAX then head on down to SD. SoCal is great to work with. I'd let Center worry about it all Due to the TFRs, Restritced airspace near Pendleton, and then Miramar, and then the marine layer...and then... -Matt

-

I can't say enough good things about PCE. Chris and John are awesome to work with! They are a great source for excellent Cylinder cores and overhauls. Sorry to here Ned ! However, I can tell your in good hands. -Matt

-

Changing the AFT most rudder idler bushing?

MB65E replied to MB65E's topic in Vintage Mooneys (pre-J models)

You are Awesome! Thanks for the Info! -Matt -

Changing the AFT most rudder idler bushing?

MB65E replied to MB65E's topic in Vintage Mooneys (pre-J models)

So a lightning hole in the but rib of the elevator!!! Haha! Got it! I have 4 nice B-47 bearings and 2 bushings that came out of the M20K idlers I have. They are in good shape! Hopefully, My idler is not too far gone. Thanks Clarence!! Also, Canadian question for you... Do you know any Techs that worked at Cold Lake in the 419TS in the NDT back shop? I need some Canidian NDT manuals for another project. Cheers!! -Matt -

Changing the AFT most rudder idler bushing?

MB65E replied to MB65E's topic in Vintage Mooneys (pre-J models)

Thanks Mike, that's why I stopped last year. I'll see what I can find. The idlers are really buried back there. I wouldn't be suprisrd if they were installed at the factory before the aft skin went on. Cheers, -Matt -

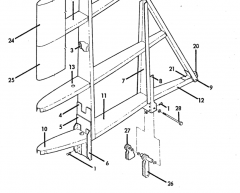

So I'm debating changing the bushing in the aft most rudder idler in the tail cone. The play in the system is otherwise tight at all the rod ends. This aft idler is where the slop is. The idler rocks laterally a good 3/16", however all the play is not transmitted to the rudder itself. Last annual I wanted to take it apart to see what I could shim up. I had my hands twisted up there, bent wrenches with a torch to make something grab the flats on the hardware, and then I got smart. I realized I had no way to rethread the nut, let alone pull the -40 bolt out the other-side thru the skin. How does one change the bushing? I was thinking of cutting a 1/2" hole in the skin to pull the bolt and allow access to the nut. Then placing a rubber plug, or a stainless wilkie button in the hole. Anyone ever remove this idler before? Item # 27 in the picture. It also appears that Mooney switched to needle bearings on the later models… I have a K idler I grabbed off of ebay thinking it would fit, the throw was not the same. It had the bearings. If anyone has had one apart recently I'd like to know if the 65's had the needle bearings. Thanks Again, -Matt http://mooneyspace.com/gallery/image/36707-rudder-idler-27/

-

From the album: Super 21

Changing the Rudder Idler Bushing on our '65 E… Any thoughts on removing the AN3-40 bolt that attaches the elevator and rudder idlers?? -

3 Meyer a-422 jacks (like new) Huntsville Al

MB65E replied to lwikle's topic in Avionics / Parts Classifieds

Haha! I remember that now. Thanks again for the Antenna! Its working well. -Matt -

3 Meyer a-422 jacks (like new) Huntsville Al

MB65E replied to lwikle's topic in Avionics / Parts Classifieds

To jack the nose on some AC... Not Moonies. -Matt -

3 Meyer a-422 jacks (like new) Huntsville Al

MB65E replied to lwikle's topic in Avionics / Parts Classifieds

That's a great price!! These jacks work awesome on Mooneys. However, I already have a set. I've also used them on some light Citations. Good luck with the sale. -Matt -

I don't think the pads have broken in yet. Give it some time and they will improve. However, I'd have your tech looks at it again with a fresh set of eyes. Make sure the fluid is topped, and double check the pads and rotors. I just taxied a 36'' wheeled Huskey that had new pads on it. It was a miserable Taxi. -Matt

-

If it's a VEP switch with the gold alumnium casting, it's marked with torque seal to indicate tampering if the stripe it broken. Get with your A&p, put the A/C on Jacks, hook up a pitot static test box and try to retract the landing gear. This way you can dial up the A/s as needed. If you are good you don't need the box, sergical tubing will work. Then discuss with your IA if he is comfortable adjusting the switch. A flat blade screwdriver, common sense, and a watchful eye on the ASI you will be able to dial in the switch pressure. The switch is adjustable, but the manufacture of the aircraft and switch need to limit their liability. Finally, There could also just be some debris in the metered orifice. It might just need to be cleaned. -Matt