All Activity

- Past hour

-

Thank you! I will contort myself under the panel the next time I'm at my hangar, and I'll see what I can see!

-

Retract Gear or Flaps First in a Go Around ?

1980Mooney replied to donkaye, MCFI's topic in Modern Mooney Discussion

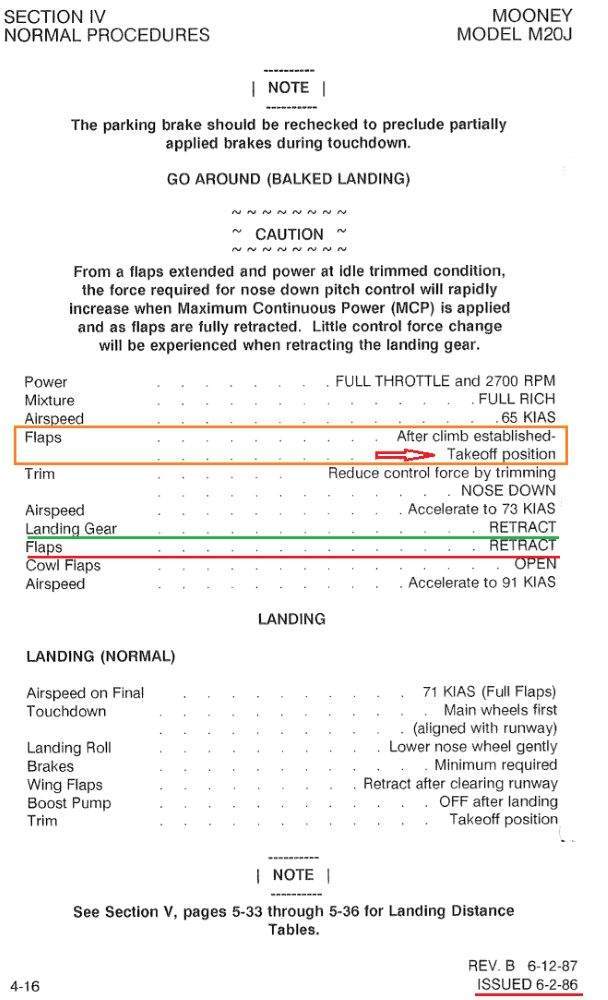

The problem is that Mooney has not been consistent on what they published in the M20J POH's as the "method recommended by the manufacturer". If you look at the M20J POH's in the Download section, you will find 1977 - 1984 POH says first "After establishing climb, Retract Flaps to 0 degrees" and then last "Retract Landing Gear" 1985 and later POH says after establishing climb, first Retract Flaps to "take-off position", then "Retract Landing Gear" and then last Retract flaps fully to 0 degrees. The change does not correspond to the standard installation of wing tips in 1981. The change does not correspond to the standard installation of "Take-off Flaps Preselect" switch in 1987. The change does not correspond to the standard GW increase to 2,900 lbs in 1991. I would argue that the M20J did not change materially yet the Factory guidance for Balked Landing did. So what should an owner do? -

Hello all: Installed an Engine Saver engine dehumidifier on my Ovation. It works by pumping dry air at low PSI through the breather tube, through the crankcase and cylinders and out the exhaust valve(s) through the exhaust. The tube from the machine goes into the breather tube and has rubber gaskets attached to it to prevent air from coming back out the breather tube. This only works if the gaskets are above the ice hole in the breather tube. Otherwise i am pumping dry air out the Ice Hole. The tube seems navigable with the hose/ gaskets for about 8” or so and then runs into a bend or obstruction that prevents further insertion. I am asking so I don’t have to de-cowl the airplane…..which i will do if I have to but I am looking for the short answer if anyone has it. The Engine saver is supposed to lower internal engine humidity to 5% or lower and it’s super simple to use so i would like to keep it. But, I can only do that if I am above the ice hole with the dry air tube/ gaskets.

-

Most race cars, even in amateur series, can corner well over 1g with race tires. Add aero downforce and cornering g-forces can go significantly higher. So even without aero a properly set-up car on sticky tires will often outcorner even a race bike. Bikes don't make enough downforce due to either aero or weight or have a tire contact patch big enough to provide the lateral forces needed to match a car. Straight line acceleration is a no-brainer, though, that's where the bikes get all their speed and lap time.

- Today

-

I hate to say that I don't have record of what it has been running at over the years consistently, but off the top of my head I would be around 380-400 on climb and then around 340-380 in cruise. On a couple of hot days recently I got a couple of cylinders over 400 and the JPI gave me warnings, but cooled off in cruise. How would you physically check fuel flow amounts besides the gauge? Is there a way to adjust (add) fuel flow after the mixture knob at full rich (on engine) to see if that helps?

-

I want one. You had me at "what would Ricardo Montalban drive". I do kind of think, though tech has improved in this industry, you got more satisfaction out of some of those model concepts.

-

Very interested in this topic. I also have a cylinder that runs much hotter than the others (by about 50 degrees), but mine is at a much lower temperature altogether (295-315 for cylinders #1, #3, and #4, 360-365 cylinder #2). Which of your cylinders peaks last when leaning? For me it is also the "problem" cylinder, #2. Since I generally run my engine at peak or slightly below peak (depending on altitude), this means my #2 cylinder is the richest, which kind of explains why it is the hottest. Also, it seems you have high temps overall while climbing (I take it all your temps are close to 400 during climb). Have you checked your fuel flow at full rich? It should be around 18 gph at sea level or close. Anything less than that and you'll get hot CHTs during climb. I understand it is not hard to adjust the full throttle, full rich fuel flow. You did not say what your temps are in cruise, and what leaning procedure you use (do you run ROP or LOP). Also, what speed do you use during the climb? In my E I try to climb around 115-120 mph IAS for best cooling. I personally would not jump to replacing/overhauling the cylinder just yet. But others on this list may have other views.

-

I can just imagine debriefing this story down the road. "Well, it started as a maintenance conversation, but eventually there was no way to turn back. A few forum members got together and set up a bandit street race...."

-

Hope everyone is well! I haven't posted in a long time, been enjoying flying the M20F with really no problems, until now. Recently I got cylinder 3 warnings on the JPI over 400 and cylinder 3 seems to be running warmer than the others by about 50 degrees, and recently crept toward 450 degrees when climbing and so I brought it back in. Here are the things we have done to diagnose/troubleshoot: REMOVED #3 SPARK PLUGS, CLEANED & GAPPED. REMOVED AND SERVICED #3 INJECTOR. RE-INSTALLED SERVICED SPARK PLUGS AND INJECTOR. REMOVED AND REPLACED CHT PROBE #3 WITH NEW, P/N: 1260. SWAPPED CYLINDER #3 AND #2 INJECTORS. LEAK TESTED, NO LEAK. REPOSITIONED GROUND WIRE FOR THE JPI. FUNCTION CHECK SATISFACTORY. REMOVED AND REPLACED BOTH #3 SPARK PLUGS WITH NEW, P/N URHM38E. REMOVED & REPLACED #3 INTAKE GASKET WITH NEW, P/N: 654227. COWLING WAS CHECKED FOR PROPER COOLING CAPABILITIES – AND NO ISSUE WAS FOUND WITH THAT. COMPRESSION CHECK: FIRING ORDER: 1-3-2-4 // COMPRESSIONS: 72-76-76-78. NORMAL PERAMITERS BORESCOPE: CHECK OK // NO SIGN OF GLAZING IN CYLINDER #3. CROSS HATCHING VISIBLE IN THE #3 CYLINDER. AT THIS POINT, IT IS SUGGESTED TO REMOVE AND REPLACE #3 CYLINDER. Also I was told they flushed the spider (fuel injector system) and also swapped the fuel injector nozzle between 3 and another cylinder but the swapped locations were not affected leading me to think the nozzle is fine. Any other things I should check or try? Also do you recommend replacing with new cylinder or re-honing? If any of you have done please let me know what to expect in cost/time and anything else I should expect to plan for. THANKS ALL!

-

Post up a photo or see if you can get to the backside and look at the model number of your indicator. I’ve got all the old Bendix King interconnect wiring diagrams.

-

Retract Gear or Flaps First in a Go Around ?

Slick Nick replied to donkaye, MCFI's topic in Modern Mooney Discussion

My ‘91 has preselect, it’s easy to just move it one click and then up to the gear handle. Like I said above, I’ve tried both ways, and can’t detect any appreciable difference in climb performance. Flaps-gear-flaps, if that’s the method recommended by the manufacturer, should be what’s used. They’ve done the flight testing and assessed the performance under a number of conditions, and that’s good enough for me. -

65 M20C AOG Carb Heat cable broken at the level arm

jamesm replied to NicholasM20's topic in Vintage Mooneys (pre-J models)

interesting on my 67'C the smaller duct shown in your picture is just capped off. wonder what made them decide is or isn't needed and what is it's purpose? -

Cams, headers and pistons. As I said above, the engine was put on a drag bike and driven by a pro. It had a huge tire and a wheelie bar. Oh, I did polish the pistons, chambers and ports. I didn't put it on a flow bench because I was poor and didn't have one. I just made them look shiny. I did have time and elbow grease. This was 45 years ago after all.

-

It is hard to beat the laws of physics. Power to weight ratio and low aerodynamic drag favors the bike. Same with braking, Less mass to slow down. Most bikes have crazy huge brakes too. My bike has 3 12" brake disks for two wheels. It stops crazy fast.

-

My 1987 FZR1000 which was a monster and it was 11.2 with a pro driving, I was a good second slower. The Ducati Panigale is low 9’s. What were you running to get 9.2 for a 77?

-

65 M20C AOG Carb Heat cable broken at the level arm

47U replied to NicholasM20's topic in Vintage Mooneys (pre-J models)

Consider asking your A&P to add the hose to the carb heat dump valve. The hose is routed to the left exhaust cavity and gets the hot muffler air out of the lower cowl. And the linkage wire to actuate the dump valve looks a little banged up… -

I think this is true only at the F1 level with a skilled driver where serious downforce aerodynamics permit going well past 1g in cornering. As a rank amateur motorcyclist doing track days, I would get 1g turns (45° lean) with an old entry level 600 sport bike without mods and few cars can do that. The skilled riders are leaning much more in racing. I found a video for straight line drags, where the motorcycle beat 2000 HP EV, F1 car, and rally car.

-

Sure you can Calling for help that isn’t there isn’t very useful, nor is asking someone to chase something you lost sight of. Think post 1990s we have falsely elevated the goverment to this hero/god like status, it’s kinda funny

-

kortopates started following Recommendations for hail repair and paint work in the Denver area.

-

For sheet metal work : https://www.beeglesaircraft.com/ Sent from my iPhone using Tapatalk

- 1 reply

-

- 1

-

-

He's right for racing. Bikes generally don't have enough tire contact patch or downforce to corner or brake as well as a decent race car.

-

Were you able to find the part number to see if it is a 720 or 760 channel version? I will buy it if it is a 760 rather than trying to do any repairs on my 720-channel unit.

-

Pay attention to the fine print.

-

JMD joined the community