All Activity

- Today

-

jamesyql started following NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

-

IO-360 ‘warm engine’ start on M20J

Justin Schmidt replied to Tiny18Driver's topic in Modern Mooney Discussion

Mine backfires doing that -

But then there is no aviation markup

-

You can still get it at the NAPA.

-

IO-360 ‘warm engine’ start on M20J

McMooney replied to Tiny18Driver's topic in Modern Mooney Discussion

probably true, but, it works within 5 or 6 blades every time. Guess you could just crank with the pump on till it starts. -

Not needed Can be removed Probably can't get the shock itself anyway.

-

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

cliffy replied to cliffy's topic in General Mooney Talk

I have a question- WHAT'S THE ALTERNATIVE? Here we have a company that can produce any part we need for an orphaned line of airplanes-Mooney There are only about 7,000 of them left (and we kill dozens every year shrinking that field) We have another company stepping in to help US get the parts WE need from the sole supplier And all we do is bitch about it! SO, JUST WHAT IS THE ALTERNATIVE? Provide a viable LEGAL solution Don't just bitch about it! What if we CAN'T ever get any more parts? What do we do then????? Its a very small consumer base needing parts whose construction is tightly controlled by an outside agency- the FAA That equals $$$$$$$$$$ To make every part for every Mooney ever made TAKES THE ENTIRE ACTORY less the assembly line That takes money to support- more $$$$$$$ Have any of you actually seen the production facility in production? Minus the assembly line? Either you make parts there or you move it somewhere else - at what cost? More $$$$$$$ ALL airplane parts are priced at today's cost to produce a new airplane - NOT 50 years ago. Priced any new Beech parts lately? How many Bonanzas are sitting because of bad ruddervator skins? They can't get them. Our Mooneys will be paper weights or boat anchors if we can't get the parts we need The days of being Cheap Bastards is over. You want to fly a Mooney (or any other airplane) pony up to the bar and pay the bill. As I have said several times- we are flying antiques! They will eventually die a lingering death But without parts it becomes genocide!!! Suck it up folks - there is no alternative except to buy a different make airplane that is in production Sorry for the attitude but this bitching does nothing constructive for the situation we are in. -

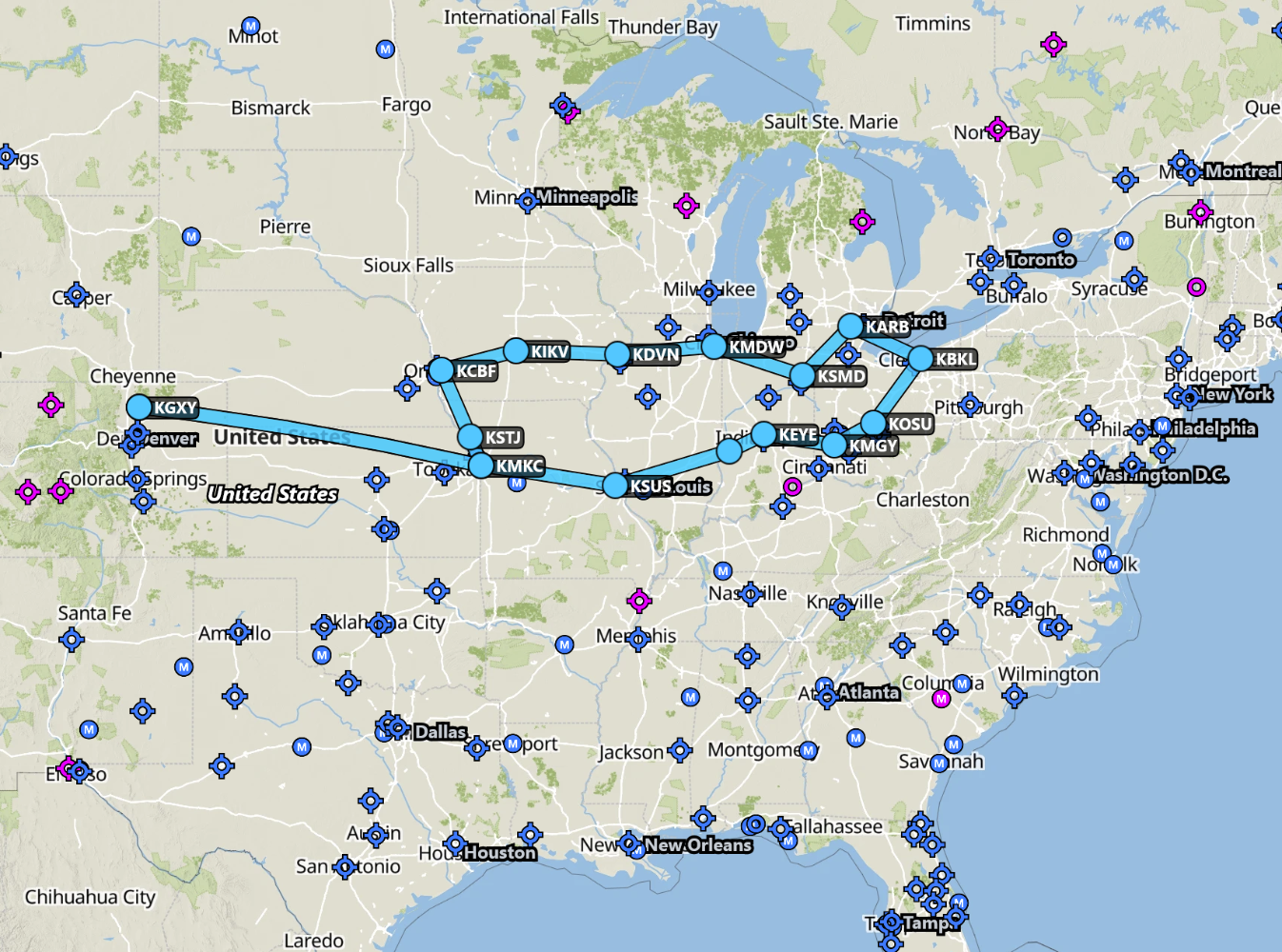

Wrapped up the 2025 Commemorative Air Reliability Tour and was joined by 2 other Mooneys. Met in Kansas City on Wednesday, Sept 24, made the loop and got back to KC Sunday, Sept 25. Flew formation in route for most of the tour, which turned out to be an excellent way to get up, get down and stay together. Had overnight stays in Kansas City, Indianapolis, Detroit, and Chicago. Highlights included a stop at Garmin in Olathe, KS for a tour of the aviation factory hosted by Jarrett Haffner; a tour of the Wright Brothers National Museum in Carillon Park in Dayton, OH; a quick trip out to Portage Lake in Pinckney, MI for evening air tours in a '46 Piper J3 Cub, and a trip to Wrigley Field to see the Chicago Cubs best St. Louis 7-3. Airports Visited: KMKC Charles B. Wheeler Downtown – Kansas City, MO; KSUS Spirit of St. Louis – St. Louis, MO; KHUF – Terre Haute Regional Airport – Terre Haute, IN; KEYE Eagle Creek – Indianapolis, IN; KMGY – Dayton/Wright Brothers Airport – Dayton, OH (not on original tour but a worthy stop for us); KOSU Ohio State University – Columbus, OH; KBKL Burke Lakefront Airport – Cleveland, OH; KARB Ann Arbor Municipal – Ann Arbor, MI; KSMD Smith Field Airport – Fort Wayne, IN; KMDW Chicago Midway International – Chicago, IL; KDVN Davenport Municipal – Davenport, IA; KIKV Ankeny Regional Airport – Ankeny, IA; KCBF Council Bluffs Municipal – Council Bluffs, IA; KSTJ Rosecrans Memorial Airport – St. Joseph, MO. Airports in bold were overnight stops. Around 2000 miles total from home and about 24 hours of flight time x 3 Mooneys = 6000 miles of reliability without any issues, mechanicals or wx difficulties. So much fun in the Mooney!! https://fordairtour.org/

-

You can just draw lines on ForeFlight map. They stay with the map till you erase them and zoom with the map. After you draw the picture you like, you just follow the lines. I bet if you put in a feature request to turn the lines into waypoints for drawing pictures in the sky, they may do it. Sometimes you just want to waste some avgas boring holes in the sky, might as well make a picture.

-

Yeah, that method is why I just can't get to enthusiastic about these 'sky images'. Sorry to be the 'wet blanket' but I just don't see how there is much skill involved; hell, just let the AP fly it if you go to the work to load the waypoints into your panel GPS.

-

It may not be the prettiest result, but I’m pretty sure it will be much stronger than what I had. Thank you to Byron for chronicling your 2013 rebuild, and for the updated information and photos you added. After removing all of the vacuum bagging materials I’ll post a picture of the final result.

- 62 replies

-

- carbon fiber

- fiberglass

-

(and 2 more)

Tagged with:

-

Progress report. I did much of the preparation at home and today I brought the cowl and all of my supplies back to the airport and began the finishing work. I prepared and cut all of the supplies before mixing the MGS 285L epoxy. The first thing was to add the sealing tape and cover with painters tape which provided a barrier and keep resin out of that area. I also chose to leave the existing honeycomb in place, and that turned out to be a good decision. Since part of the honeycomb was exposed, I covered these areas with 2 layers of fiberglass cloth to provide a barrier to the carbon fiber and to prevent galvanic corrosion. Since one area was lateral, I had to extend my strips of carbon fiber to cover that. I used the same mix on the epoxy as Byron. 50:50 of slow and fast hardener added to the epoxy and the 5% Antimony trioxide powder turned it a milky color. After covering the aluminum with fiberglass I laid 4 strips of unidirectional carbon fiber to cover each of the existing honeycomb ribs and the fiberglass base. I intended to use the blue foam to make a stiffening ridge, but it was not stable as I added the layers and it kept falling over so I abandoned that part. If I had done individual ribs it probably would have worked, but I needed to compete this in one bagging. Then I added 3 layers of the 19oz weaved carbon fiber cloth to cover the fiberglass and carbon fiber strips, and this layer was much heavier than the unidirectional strips. Since I already had the peel ply, the fiber, and the vacuum bag ready, all I had to do was add the layers on top of the epoxy and strips. Instead of using a fitting, I just made a wrinkle in the bagging film and used the sealing tape to seal the hose itself. I bought a cheap 3cfm vacuum pump a Harbor Freight and it worked well. The existing cracks cause excessive leaking so I added some painters tape on the outside to cover the cracks. That worked well and I achieved a good seal.

- 62 replies

-

- carbon fiber

- fiberglass

-

(and 2 more)

Tagged with:

-

Need help identifying the part # for an Air Speed Indicator on a 1961 M20B

-

kuiperst joined the community

-

Ruff Air started following Dog House Rebuild

- Yesterday

-

Flaps fail to retract on Ground (1990 J)

DC_Brasil replied to DC_Brasil's topic in Modern Mooney Discussion

Thanks for sharing the pictures! My plane is fresh out of the annual. I am guessing the flap screws must have been lubricated during the annual so the A&P should have accessed that part. That may have introduced some instability to the switch. I will check those. Thanks! -

rbmaze started following Final Report on Aerocruz 100 (TT) Autopilot Install

-

Flaps fail to retract on Ground (1990 J)

Ragsf15e replied to DC_Brasil's topic in Modern Mooney Discussion

For sure. When I replaced my up limit switch, it still worked ok when i bench tested it but there was a slight dead spot in its actuation that was causing it to stop retraction but not allow them back down. I could easily see how a vibrating airplane or shaking the flaps could alleviate this. Note though, when mine stuck up the first time I tried this and it didn’t do anything, so maybe not always going to help. Or maybe I needed to shake harder. -

After ordering various edge seals, the one that works best is from Amazon. The color will match the seats so it all looks intentional. https://www.amazon.com/dp/B0B8RRPVZT?ref=ppx_yo2ov_dt_b_fed_asin_title&th=1

-

Flaps fail to retract on Ground (1990 J)

N201MKTurbo replied to DC_Brasil's topic in Modern Mooney Discussion

With the flaps down, leave the master on with the flap switch in the up position. Get out of the plane and grab the trailing edge of the flaps and shake them up and down. They will probably come up. This will get you by until you GT new switches or clean the ones you have. -

Ragsf15e started following Flaps fail to retract on Ground (1990 J)

-

Flaps fail to retract on Ground (1990 J)

Ragsf15e replied to DC_Brasil's topic in Modern Mooney Discussion

I had to work on mine a little while ago. I doubt it has anything to do with the cb if it wasn’t popped. There are two limit switches and two relays (in some models). Both the relays and the limit switches eventually fail. If they are sticking down, id first check the down limit switch. Once you look at the schematic and open up the airplane to look, its not hard to figure out. Mine wouldn’t come down all the time and the up limit switch was at fault. A new one wasn’t expensive from online electronics sources (exact part number). -

I'll look through logs now, but its coming out anyways. Fortunately whoever put it in, did not modify any of the factory wiring and left the connectors there. Since the other end of the switch wiring is disconnected/capped off, its easy to remove and not worry about. Seems a lot safer than having that switch in the loop!

-

Well Ross I’ve got your answer, I’m not attempting to be a smart ass but providing my facts. Around about 1985 I had a very nice Cherokee 160, my instructor had a Mooney model E nice I became enamored with his speed when he passed me one Sunday on our way to lunch at Lancaster which is the home of Weber Mooney Service and Sales. I didn’t want him to pass me again so Mr Henry Weber a very nice honest man made me a great deal on a 1977 201 J which worked well until Mooney went into financial difficulties 1988 they offered planes at a huge discount over prior years but using direct marketing good ol Dirk Vandersee found my contact info and talked us into a looksee he flew a new 1988 up to Wilmington my wife said as long as it’s not red we can be nice and say no and take him to dinner. Coming down the ILS was a nice red and white J being new was faster and new equipment one problem nice Mr Weber wanted to know why I’d buy from Mooney passing him by not giving him a chance I politely informed him of the huge discount he mentioned son, yep I was young at one time but stupid, he said he will beat Mooney’s deal easy any time why the heck would they cut my throat he said after all I’ve done to help the company. So Mr Dirk the deals off I’m dealing with Mr Weber, still go there by the way, oh back to the E model need for speed I was talking to Ross, we some 17 years later wanted to do a lot more trips so along came a new red Bravo GX long range tanks Mooney company again in financial difficulty so I got my last great deal on a Mooney in my quest for speed like Andrei, unfortunately the company being somewhat the sleez they can be and I didn’t know Mooneyscape or any other social site to provide info that a Mooney Acclaim was being introduced I purchased from Premiere who didn’t let the cat out of the bag. Ultimately due to unscrupulous insurance agents I sold the Bravo believing I would’nt be able to get insurance after age 75, after selling the Bravo my lying agent found insurance and I ended up with the speed queen a Mooney Acclaim TypeS. Sorry Ross I really thought it wouldn’t be so voluminous to write up my question for speed like Andrei.

-

M20Apprentice started following Sidewinder for Mooney, Like New Condition

-

Hello, I am M20Doc's apprentice. I am selling a Redline aviation sidewinder mooney electric tug. It is in a like new condition and has been tested for any faults. These sell for $2390USD at: Sidewinder for Mooney - www.redlineaviation.com I am asking 1800USD for this tug. Please reach out to me if interested. 226-668-2283, brycedennis219@gmail.com located in Ontario, Canada. Thank you, Bryce

-

- 1

-

-

Hello, Wanted to know if anyone has experienced this issue. In two out of my last 4 flights, during my departure checklists (i.e. engine ready running) I checked the full movement of the flaps. After extending to full, they will not retract. I had to pull the flap actuator CB, give it a minute or so, reset it, and then it works again. They work well in flight and after landing (no issues whatsoever). Any thoughts?

-

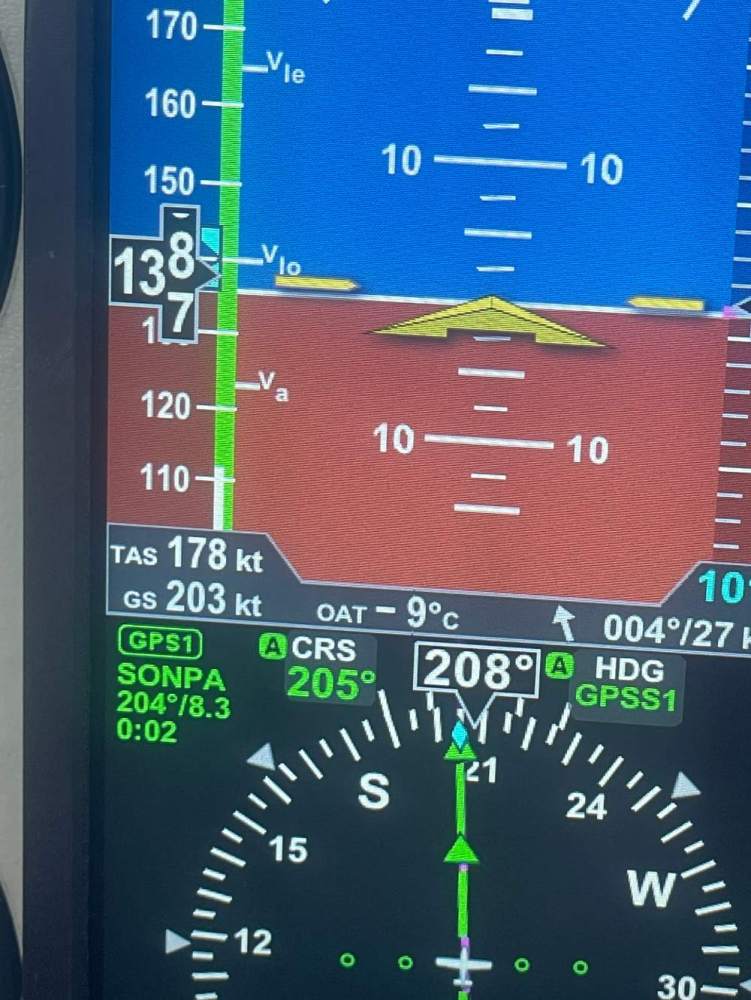

Update: New Maggie Harness, Gami Injectors and new Tempest Fine wire Spark plugs... Engine runs runs smoother, more even RPM drop at Engine run up. Also idle is stable after a flight when taxi, before I had some issues were I needed to add some rpm to have it running and not quit. Guess the harness fixed that. Did some Gami spread test and most likely in average I have 0.7 with Gami. Cyl 1 & 3 is to lean. Hopefully Gami will send replacement, they are not the fastest to respond. LOP, is not perfect but now I can at least fly LOP 29.5" 2300 10.1 (LOP 5-15 degree). After some fiddling I can get engine to run OK, but I expect improvement when I get replacement injectors. On my from ESSB to ESML I got a new speed record at FL160. 29" 2300rpm 10.1g/h, Cowl flap closed, All CHT under 369f, TIT ~1590-1600f Tail winds are nice :-)

-

M20Apprentice joined the community

-

IO-360 ‘warm engine’ start on M20J

DC_Brasil replied to Tiny18Driver's topic in Modern Mooney Discussion

Lycoming IO-360-A3B6D here. That's exactly how I do it.