-

Posts

12,484 -

Joined

-

Days Won

110

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by jetdriven

-

Prop RMPs ~2650 on Takeoff, but can't go above ~2500 in flight

jetdriven replied to AdamJD's topic in General Mooney Talk

Anything is possible for sure. -

Prop RMPs ~2650 on Takeoff, but can't go above ~2500 in flight

jetdriven replied to AdamJD's topic in General Mooney Talk

It’s governing it to 2500 rpm. The arm hits the stop and the cable has cushion. It just doesn’t seem to work properly after takeoff -

Alton Bay Bonanza crash

jetdriven replied to Shadrach's topic in Mooney Safety & Accident Discussion

ill go look again. The Nall report has a lot of info. -

Alton Bay Bonanza crash

jetdriven replied to Shadrach's topic in Mooney Safety & Accident Discussion

actually i think the SE piston accident rate between part 91 and 135 is something like 30 times less -

Standard thickness side windows are fine and the standard vent is fine too. If you want a vent on the copilots side in the door window, you could do that but most people just open the door so I think it's a limited use. The quarter inch windshield is worth doing, but you have to bevel or sand the edge enough and create a step so that it will fit in the channel. It's another 3-4 hours of labor. But I think the quarter inch windshield is a good idea for hitting birds at 200 miles an hour. Do yourself a favor and get the solar control UV gray.

-

YES. its annoying

-

VA doesn’t have much to do with turbulence, that’s the maximum speed you can input any single control input without damaging the airframe. The top of the green arc relates to turbulence. And the Mooney is very strongly built, so keep it out of the yellow in rough turbulent air. Don’t make any full control inputs above VA.

-

Alton Bay Bonanza crash

jetdriven replied to Shadrach's topic in Mooney Safety & Accident Discussion

We called our insurance company and were covered because it is an FAA listed airport so we went there. It's fine.- 45 replies

-

- 12

-

-

O&N icing mast installation, low fuel indication

jetdriven replied to Mobius708's topic in Vintage Mooneys (pre-J models)

the vent is supposed to bend forward behind that mast -

turn on the avionics master and master swtch for 20 mins every 3 months.

-

SCAT Tube Sizes for the Engine Bay - 1984 M20J

jetdriven replied to MisfitSELF's topic in Modern Mooney Discussion

the rear piece is 2.5" x 36, the front is 2", not as sure the length, 24" IIRC is a couple inches short.- 1 reply

-

- 1

-

-

I used citrustrip on one set and I used a benzyl alcohol-peroxide stripper. Both worked fine. then prekote and tons of distilled water. Bake them and then apply epoxy DTM or Strontium chromate primer on them. then urethane 2k of your choice. We used white. its been like new for eleven years now.

- 34 replies

-

- paint

- wheel paint

-

(and 1 more)

Tagged with:

-

We put a Tempest filter on a Piper Arrow and it seems equivalent to a Donaldson, its synthetic paper media. They flow more air than a Brackett.

-

We are an authorized installation specialist of Surefly. No buyers remorse yet. Lots of fans.

-

we get 124J hoses from Aero hose shop in granite city IL. They are OC, no stated life limit. Some are 15 years old here, still in service.

-

Yankees start on the other side of that river, here in Alexandria, Robert E. Lee’s boyhood home is just down the street, and it’s no secret why all the war dead are buried in Lee’s (wife’s) front yard in Arlington. pretty good booze availability, but yeah special stuff you gotta get it somewhere else.

-

The Bluetooth comes from the 275 EIS display so you’re betting that the unit works, just the display goes bad, also the GEA24B must work as well. That’s a pretty narrow set of failures. Personally the only thing I need to keep going is an oil pressure gauge , the rest of it’s nice to have but not critical.

-

its 1900$. https://www.aircraftspruce.com/catalog/pnpages/05-04532.php?gad_source=1&gclid=CjwKCAiA74G9BhAEEiwA8kNfpQOesqcyZNCgoXpGRkCqSreaEqVcP5P51f-fgDf_d3Lr8qfRYu75pxoCrPMQAvD_BwE

-

Replaced Starter - Invoice was WAY more than expected

jetdriven replied to gwav8or's topic in Vintage Mooneys (pre-J models)

The upper cowling probably, but the lower cowl is a whole bunch of extra stuff such as the landing light wiring, the carburetor air boot, or the ram air door, which takes 15 or 20 minutes of it just to disconnect without it falling apart. the the oil cooler and the hoses that go to that. They’re fastened into the inside of the lower cowl also. -

What's this thing above my battery in my M20J

jetdriven replied to Thedude's topic in Modern Mooney Discussion

It will double beyond that. Look at the price of a 10–24D master cylinder. I think it’s about three times what it was a year ago. And it wasn’t cheap a year ago. -

What's this thing above my battery in my M20J

jetdriven replied to Thedude's topic in Modern Mooney Discussion

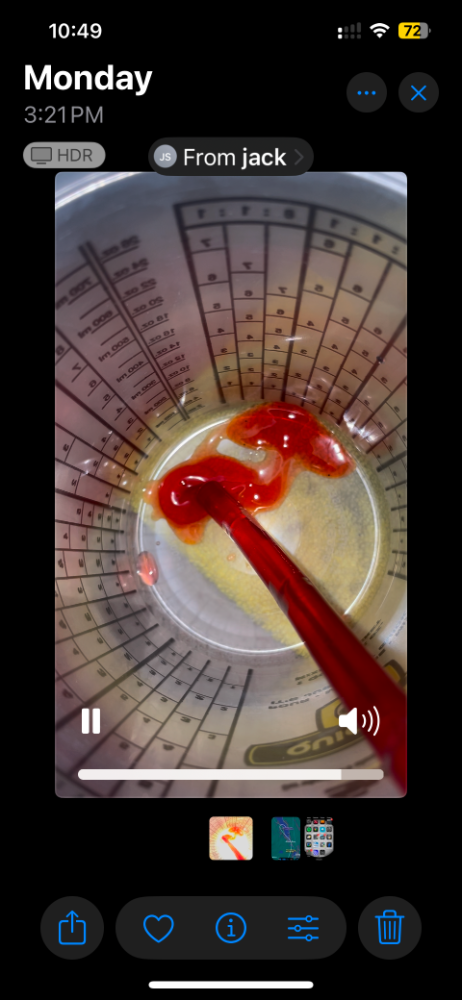

This is the brake fluid from a Cherokee 180 that we own. I noticed that the brakes appeared to drag and release very slowly, and I thought it was a combination of old brake fluid and brake caliper slide pins that were not lubricated, but this is absolutely astounding. The stuff has the consistency of mayonnaise. Now, if you change this 5606 out for Aeroshell 31 it won’t do that anymore because the synthetic fluid lasts longer and is better at colder temperatures. -

Because the lifters get little spots of rust on them and they form little pits and then pits turn into spalling and then spalling turns into cratering and then cratering wears down the camshaft. The cam is a symptom. It’s not the cause. Continental engines we frequently pull the lifters out of them whenever we change the cylinder and sometimes just preemptively look for a pre-buy. They always have little micro pits and some are pretty torn up actually, and the cams are always good, and then you swap out new lifters and you pretty much save the engine. Where lycoming is more of a hopes and prayers kind of Strategy.

-

I had a client took his plane to a shop at another airport in the DC area, and they handed him a discrepancy list of like $25,000 worth of stuff, but looking at the list it looked to be about 4000 bucks of stuff. When he showed him, the documentation that a few of the write ups were trivial and actually allowed by the manufacturer, or how you could treat the corrosion on the rear wing attached fitting without pulling the wing off, the shop rolled his plane outside told him to go F himself and then faxed the discrepancy list to the Washington FSDO and told him the plane had to leave on a trailer. I fixed the three discrepancies that were legitimate on the ramp and then we ferried it over to my shop and fixed the rest. The FSDO guy said he’s not giving a ferry permit, even though I had inspected the aircraft, so we got the DER that he hired to engineer the wing skin crack repairs to state that it was safe for not more than 100 hours of flight time. Then he called the FSDO and got into a fight with the inspector because he still refused to give a ferry permit saying it was unairworthy, even though the DER says you don’t get to tell me that it’s not airworthy because I’m actually a designated engineering representative of the FAA and I’m telling you that it is. But it was really crazy how that went.