-

Posts

4,646 -

Joined

-

Last visited

-

Days Won

33

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by cliffy

-

There are actually 2 different Mooney drawings (as the parts manual says for different models) and I have both Mooney drawings somewhere Just don't know where I put them 15 years ago when Mooney Engineering gave them to me.

-

Aerocruz 100 for Mooney Ranger

cliffy replied to Fysiojohn's topic in Vintage Mooneys (pre-J models)

Just got back so I'll be looking at this THANKS! @Florian Guthardt -

The nuts do snug down to a shoulder on the rod capturing the two springs

-

The nuts at the back of the bungee units have nothing to do with any adjustment of the elevator angles They only snug up and impart a slight preload on the opposing springs inside the barrel. Any adjustment of the elevator angles to set the correct UP elevator angle at the correct STABILIZER setting ( see the TCDS) is done by the forward Heim joint connection by screwing in or out on that part of the bungee Now you MIGHT have a bungee spring stuck or even broken and you will have to disassemble the rear end of the bungees to inspect that and clean and relube. If you remove the bungees you will need to rerig the elevators and the proper UP angle at the proper STABILIZER setting per the TCDS. You might also check behind your instrument panel to see if any wires have fallen and are hooking onto the elevator controls Another area still is to check the 4 hole link at the back of the jack screw to see if it is worn. One side moves and can bet worn enough to be sloppy and loose when you pull up and down on the tail end (extending and retracting the jack screw in its threads).

-

Many times a push/pull cable will impart wear areas on the inner piano wire that match the outer wound sheath These wear areas are smaller in diameter making the piano wire look like a wavy surface. These wavy areas restrict the movement of the piano wire and the only fix is a new center wire. This happen especially in areas of turns and bends where the inner wire lays on the inside of the housing all the time. Vibration does the wear.

-

Aerocruz 100 for Mooney Ranger

cliffy replied to Fysiojohn's topic in Vintage Mooneys (pre-J models)

OK interesting In my Duncan paperwork it aid it would never follow the heading bug on the HDX - it would only follow track the HSI which mine does very well except for a slight bracketing of the course in smooth air. Very slight but still a little left/right action all the time. As far as the DE-select- what exactly are you referring to? If a source is deselected then will it loose the ability to track a flight plan input? Mine does that well. Mine right now will follow a GPS course input on the 100 control head (not in Skyview mode) or the HDX flight plan route (via the HSI as I under stand it) in Skyview mode. It would be "nice" to have both via Skyview but I'm hazy on how you do it @Florian Guthardt -

How to test/replace/repair ammeter gauge in 1970 E-model?

cliffy replied to AndreiC's topic in Vintage Mooneys (pre-J models)

Most of them are regular BUSS glass fuses about 1/4 inch in diameter Available everywhere Many times it has been so many years (40+?) that they have never been removed they will be all crudded up and have bad connections Be prepared to clean the holder contacts and the fuse ends when you take them out. The wires may be very brittle. Bonus question- Regs state that any airplane that has fuses installed should carry spare ones for replacement Does this apply to these fuses? :-) -

Aerocruz 100 for Mooney Ranger

cliffy replied to Fysiojohn's topic in Vintage Mooneys (pre-J models)

Final test flight today- All went perfect! Dynon controls the A/P IF you want Aerocruze 100 control head can do the same. Holds altitude solid in smooth air and within 20-30 feet in all turns large and small in light turbulence A/P will follow any flight plan in the Dynon (direct to or with waypoints) Dynon will control lateral direction via the magenta line ONLY! (CDI / HSI or "direct to")) It will not control it by the heading bug! Heading (in reality GPS track and not a true heading) you will need to revert to the A/P control head (a couple button pushes) Dynon does a fine job of driving the A/P in the vertical mode. Climbs, descents, alt captures all work fine Manual trim is necessary as you change airspeed, level off etc as it would without an A/P The Trim indicator is very sensitive and you will learn to trim to extinguish the trim called for and then tap the wheel the way it wants you to trim to get the indicator to extinguish BUT it will come back on if you sustain an up or down draft that stays a while. This has been reported on many websites. You will just get used to trimming till the light goes out double check with tap on the wheel and then forget about until descent. You will try a few times to see how far out the pitch trim is by holding the wheel and disconnecting with the wheel disconnect but you will see that the trim indicator is on when very little pressure is on the wheel. ALWAYS HOLD THE WHEEL IF YOU USE THE CONTROL WHEEL DISCONNECT SWITCH just in case it is way out of trim. This goes for any airplane with an autopilot. A couple of items to bear in mind- When setting up the serial out ports from the Dynon to feed the Aerocruze will need 2 unused serial port OUTS (the Ins can be OFF) One goes to the A/C TT Serial RS 232 in pin and the other goes to pin #18 "Skview" feed. Each has a different serial "sentence" that it needs to feed the A/P Its in the install manual and the 'Interface " manual In particular the feed to pin #18 on the A/P HAS to be "Dynon ADAHRS +System" When programming the ports on the Dynon you will NOT see the sentence on the first screen list- you MUST use the right big knob to track down to the next page to find it Below is just for pin 18 setup (The other pin has a different serial sentence to input) Interface Setup Interface with the Dynon SkyView is relatively simple. It requires an additional RS-232 serial connection to the autopilot from the Dynon D1000 or D700. Each SkyView screen contains five (5) serial ports. This interface will require an unused serial port to be available on the SkyView display. Which serial port is used doesn’t matter. The settings required for the serial port are shown below. 1) Set output device to DYNON ADAHRS + SYSTEM 2) Set In /Out Baud Rate to 9600 3) Input device can be set to OFF as this is unused for this interface 4) Autopilot baud rate MUST be set to 9600 as well. NOTE: This will also affect the primary serial input of the autopilot, which is connected to the GPS. If using a portable GPS, be sure to reset the GPS output baud rate to be 9600 as well. Pay attention to the wiring diagram as far as reversing the elevator servo wires. It shows how to do it in the install manual DO IT or else you will be in reverse sensing for pitch. If you are a computer nerd this installation will be easy if you are like me it will take some effort decipher the computer geek directions. Once installed and working it seems to work as good as any small airplane A/P with its own limitations. -

Things to look out for with an older C / Ranger model?

cliffy replied to Losbright1's topic in Vintage Mooneys (pre-J models)

Here ya go- Check that all the model numbers and serial numbers match on everything with the log book, engine, prop, airframe, I do radios also. Actually read the data plates and compare to the logs. Check that the parts actually installed match what is contained in the TCDS and/or the logs show an STC change for the big stuff and changes for radios and electronics. Anything added like engine monitors, fuel flow gauges, etc should show an STC listing in the log books. Pull the rear seat bottom and open up the inspection holes to check for corrosion on the spar caps. Look at the spars real well in the main wheel wells for same. As noted fill up fuel tanks the night before and look for leaks the next day. If you can jack the airplane do a gear over center torque check. Make sure the A&P has the correct tools to do it. While on jacks, move the main gears in and out toward the wing tips for excessive movement. Lift the main wheels to check for play in the donuts. The donuts should expand enough after 5 mins unloaded to not have much movement. Check the mouse boots for condition in the main wheel wells. While down by the main gear look at the spar bottom between the fuselage and wheel wells. Look for smoking rivets there. The rivets that hold the spar sandwich together. That can be a big $$$$$$. I found one in AU with almost every rivet loose on the bottom of the spar. It was grounded by the owner when Kerrville said it had to be repaired. Nose gear area - if on jacks this is easy- twist the nose wheel left and right to check for excessive play in the steering linkage. More than about 10-15 degrees either side of center before tightening up on the linkage is too much. You will see the slop way at the top of the nose gear on the rod end linkage up there. Most important on the nose gear! Look and feel for dents where the steering system touches on the tubing for dents where it touches. Turn the wheel by hand and you will see where it touches and stops. MAKE SURE THERE ARE NO DENTS THERE! The limit is 1/32" depression. Any dents and the nose gear comes out for repair $$$$ On the tail surfaces grab the tip of the stabilizer and try to move it up and down and fore and aft. If it moves or clicks you might have work to do. Limits are about 1/10th of an inch either way. Usually fixed by changing out the "close tolerance bolts' in the hinge. As noted lift up on the rudder to check for play in the jackscrew. Same limit about 1/10 of an inch. Lots of times it is wear on the 2 bolt hinge bracket at the aft end of the jackscrew and not the jackscrew it self. I found one stabilizer that moved 1/2 inch either side of center! Look over the outside surface of the entire airplane for dents, filliform corrosion, hangar rash (the elevator tips seem to be especially susceptible to this damage and NO repairs are allowed to control surfaces (no patches, partial skin replacement, etc). The FAA in one case here on MS made a big thing out of this stuff on a routine ramp check on one of our posters. Basically they said it didn't come that way from the factory so fix it. I check all the exterior control surface rod ends to see if they are loose enough to move or if dry and frozen. If dry and frozen I start looking at the logs real close to see if the lube and gear swing AD had been being done. One item missed almost always due to the effort but it can cause big headaches, is pulling the sidewalls inside and actually looking at the steel tubing frame for rust. If the windows are not sealed well, water gets in there and runs down inside on the tubes and rusts them. The insulation SB aside. There is actually a SB describing how to check for leaks by pulling the sidewalls and directing a water hose at the windows looking for leaks. Make sure everything, and I mean every switch, knob and button works as designed! Put power to it and try all radios in all modes, all lights, all warnings (landing gear warning horn, stall warning horn, etc), all exterior lights, everything that can be turned on or off or moved in and out. There was one write up on here a while back where someone bought a Mooney and the stall warning didn't work nor did the gear warning (IIRC). That makes the airplane unairworthy. If on jacks (and it should be) do a gear swing and make sure the gear works properly. I've seen them signed off 3 months ago and they hang 3" from the wells when sucked up. If its electric gear do a manual drop also to make sure it works. Had a couple on this board recently that went in for annual and the manual gear drop didn't work. So check it out. Look to see if the gear actuator has ever been removed, cleaned, checked for proper gear lash and relubed. If it hasn't you may be doing that on the next annual yourself It's that important. Disregard if its a manual gear. It goes without saying that a full log book check is required for all applicable ADs and required inspections even though the annual has just been done. The logs tell a story and knowing how to read them is a skill. Make sure you know what to look for or have someone that does. The engine stuff is the normal stuff. Compression check, oil filter inspection, looking for leaks, cracks, anything not normal. Pull the plugs and read them, they too have a story to tell. My caution to any whom I help buy an airplane? Trust no one selling an airplane period. Take nothing for granted. Don't trust anything even though it just had an annual. If you do, it will bite you in the arse. Check and verify everything before money changes hands. Once you pay for it , its yours! Good luck and show us pictures even of the prebuy! :-) :-) -

Aerocruz 100 for Mooney Ranger

cliffy replied to Fysiojohn's topic in Vintage Mooneys (pre-J models)

Use the Dynon HDX (7" or 10") Use the Aerocruze for the autopilot and if you need IFR capability (I don;t) add in a WAAS GPS navigator to feed the system (you might already have a compatible one installed). I have almost 2 complete Brittian systems in my hangar (none in the airplane, not needed). I'll probably have a complete flight report next week but the first 2 check flights show good right now. -

Backlash against Vector Airport Systems

cliffy replied to DXB's topic in Miscellaneous Aviation Talk

Taking pictures of license plates on a public road is Constitutionally legal as approved by the US Supreme Court. Just like our flights with ADSB are public information No right of privacy out in public. -

Aerocruz 100 for Mooney Ranger

cliffy replied to Fysiojohn's topic in Vintage Mooneys (pre-J models)

Aerocruze is built in and doesn't need an external gyro its built in but not mechanical It does require a GPS navigator either WAAS or even a hand held GPS with serial data feed out. The Dynon HDX will drive the Aerocruze with the Dynon head controls OR you can just use the Aerocruze knobs if you want. -

Aerocruz 100 for Mooney Ranger

cliffy replied to Fysiojohn's topic in Vintage Mooneys (pre-J models)

No but its just an internal threaded rod between the load sensor and the other Heim joint end, Nothing special except each end thread depth is different so you can't just chop off equal amounts off of each end. You have to measure it carefully to preserve the 12 threads engagement on each end. The supplied rod is just long enough to be able to do this between the bottom ends of the drilled holes. That's why I said to make a dummy rod and try it it too get the correct length before cutting the real supplied rod. This is probably the most difficult part of the install as I noted above as it determines the throw of the servo arm between the stops. Too short it hits one side and too long it hits the other. Just right and it clears the servo stops yet hits the airplane hard stops as it should. Even on the J/K install this rod has to be adjusted (just not shortened) to allow the correct length to be found. The shortened rod on the short bodies is just a different starting point for the same adjustment. -

Probably not as many full failures as there are "too worn out to use any more" due to not being disassembled and relubed as required over the years. With as little as they get used time and age have more to do with the grease drying out than anything else. Its a simple formula. Cheap annuals = no grease. No grease- No gears No Mooney specific knowledge = no gears No gears = No fly Call it price gouging, call it airplane tax, call it all you want, but the end game is the same. We fly antiques that no one wants to supply critical parts for due to legalities Why are we surprised when a manufacturer doesn't want to support something more than a half century old anymore? Does Ford still supply parts for a 63 Fairlane? Does Chevy still make exact replacement parts for a 64 Corvette? Most of our Mooneys are older than those flying them. We either cough up the money to do it ourselves OR the airplanes become beer cans (which they will eventually anyway) BTW we kill more airplanes by doing stupid stuff in them than get killed by no gears available.

-

Good points given here

-

The height of the speaker will also be a limiting factor. Too large of a magnet and it won't fit up in the hole

-

Aerocruz 100 for Mooney Ranger

cliffy replied to Fysiojohn's topic in Vintage Mooneys (pre-J models)

Forgot to add- I shortened the threaded portion of the link rod to accommodate the closer mounting of the servo to the connection point. This HAS to be done carefully and by shortening BOTH ends so as to keep the required 12 threads engagement required by the STC as the hole does not go all the way through the threaded link rod. Also be aware that on the early short bodies (up through 68) have an unbalanced throw of the elevators (10 down and 24 up) instead of the balanced 22 each way for 69 and on so for the early ones the at rest setting for the arm on the servo will be off set from equal throw between the hard stops on the servo to accommodate this anomaly This is done with the length of the treaded link rod. I strongly suggest that a practice threaded rod be made (utilizing the actual rod ends) to play with this adjustment before the actual part is cut to size. Its a trial and error effort. You will need to check and recheck that the MAIN elevator stops hit first BEFORE the hard stops on the servo touch It is a close fit but can be done THIS IS THE MOST IMPORTANT PART OF THIS INSTALLATION I would highly recommend that a check of the proper elevator throws on the airplane be done according to the maintenance manual BEFORE the pitch servo is installed. This can only be done by jacking the airplane to level and using travel boards. This step is a glaring omission on the STC paper work This will entail having the proper tools and understanding of how to do this job to check this item off the list. I would definitely NOT install the pitch servo without making sure the elevators are actually moving the correct distances up and down per serial number I have seen too many airplane out of rig to not do this important step. Only the full elevator rigging procedure should be done No short cuts. -

Used to use the PMA isle at Radio Shack

-

Aerocruz 100 for Mooney Ranger

cliffy replied to Fysiojohn's topic in Vintage Mooneys (pre-J models)

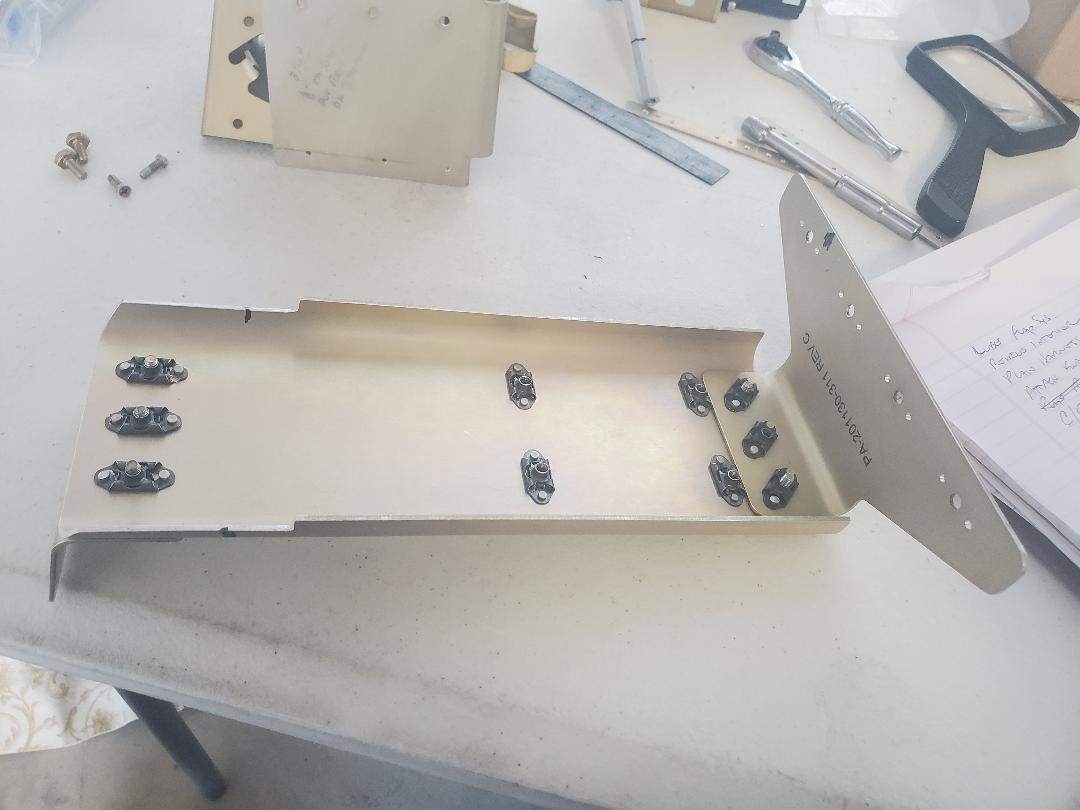

In the Duncan drawings there are two different ways to mount the tray. I used the long body one with the upper bracket hung from the floor of the baggage compartment. I just shortened the tray , remounted the supplied brackets (angle reset to 105 degrees to match the bulkhead angle) and used all the supplied hardware. I did make the gray angle bracket on the floor of the baggage compartment to mimic the stiffener that is on the long bodies but not on the short bodies. So the mounting is exactly as it is on the long bodies just with a shorter tray. I did it this way to avoid problems with using the bulkhead with the step issues. I notched the tray flanges to clear the flap rod as allowed on the drawings. The gray angle piece is .032 2024 with a radiused bend -

Aerocruz 100 for Mooney Ranger

cliffy replied to Fysiojohn's topic in Vintage Mooneys (pre-J models)

-

Aerocruz 100 for Mooney Ranger

cliffy replied to Fysiojohn's topic in Vintage Mooneys (pre-J models)

If you want an autopilot and not just a wing leveler then yes -

Nothing difficult about it except the headliner has to come down from the front to allow access. 2 wires and 4 screws on mine when I had it out. The speaker should be able to be sourced easily. If you use the speaker a lot get a good heavy duty one so it won't blow out on you. Take the old one out first, measure it and then order.

-

Backlash against Vector Airport Systems

cliffy replied to DXB's topic in Miscellaneous Aviation Talk

Just a curious thought- Did the landing fees go up AFTER the contract was signed with Vector? Is there an "administrative fee" attached to the bill? who pays Vectors "cut"? The airport sponsor or us through a additional fee? As one who ran a Pt 139 airport for a short while you have no clue how "clueless" most city councils (cities are the airport sponsor in most cases) are on anything let alone running an airport. All they see is the ability to collect revenue and nothing more. Beyond that they have blinders on. In some cases the FBO leases the ground for the tiedowns and ramp from the city. In some cases not. If they do I can see them wanting to recover those costs If not, its a financial gain using publicly paid for property (the ramp, FAA grant). If the city is part of the later then they are complicit. Every city wants an airport, not many want to pay for same. We pay fuel taxes for airport improvements (ramp resurface), do we then have to pay again to use that improvement (FBO access fees)? Airports CAN charge a landing fee IF they want. Many cities don't so as to attract business to the city. Every city that accepts Fed funds has some sort of study compiling the value to the city that the airport represents. It is still my opinion that IF the airport sponsor accepts Fed funds to keep the airport alive then they should have to provide a set number of tie down spots, rest room access and gate access on and off the airport as a condition of Fed fund acceptance. If they want to limit access to their city through a private company (FBO) with an exclusive contract for the entire airport then then the "gate fee" should be controlled by the city council and not the FBO. If the city wants to charge a fee so be it. At least an elected body is the determining factor. If the city (another name for Airport Sponsor) wants to charge BOTH a landing fee AND a 'Gate Fee" so be it, It should be transparent that is the city doing it. having the FBO do it only transfer the angst away from the city (which is what they want as elected officials). I started a conversation with Baker many years ago about FBO fees and the locking up of airports to no avail. I've been an AOPA member since the 1960s and I support them just because we need all the voices we can get BUT I think they have gone too far into a merchandizing company than an advocate for GA. JMO As to the analogy of fees for state parks think of it as the park is a "destination" in it self and not just an access point to a city. Park fees are fine IF I WANT TO GO TO THAT PARK. If I want to go to a city I don't pay a fee to get off of a Federally funded highway to enter the city- DO I? -

There's way more too this than the airport surface Birds? Hydraulic issues, need to get on the ground very fast in time, not a stabilized approach. landing long and very fast We won't know much until the CVR and the Flight Recorder are read Way too m any anomalies on this landing to even guess at this time.

-

Make sure you look at the tube structure in the fuselage BEHIND the sidewalls for evidence of water leaking through the side windows and running down on the tubing and rusting the tubes. There is a SB on this and a newer sidewall insulation that should have been put in. If you can remove the interior side walls for a prebuy then you might run it near a wash rack and run water down the sides over the side windows watching inside for any leaks. There is also SB to check the bottom rear ends of the tubing frame by removing a bolt each side and checking for rust inside that tube. Corrosion on the main spar between the main wheels (and under the rear seat on metal wing Mooneys) is another big issue as are fuel tank leaks showing up in the wheel wells on the main spar (blue stains soaking through the rivet)s Be prepared for a high $$$$ first annual next year. This is a fact most of the time on this website with newly purchased Mooneys. New airplane owner gets hit with high $$$ annual first time in the shop because of "differed" maintenance by the previous owner not disclosed at the purchase. I'm not trying to scare you off but you have to be aware of the pitfalls of ANY airplane purchase. You don't know what you don't know. As my second caveat on any airplane purchase- NEVER TRUST ANYTHING SAID BY THE OWNER OR THE SALESMAN, PERIOD! Check everything out yourself with the help of a Mooney knowledgeable mechanic. EVEN down to the data plate on the engine and the serial numbers on the prop to make sure they all match the log book entries. Just things to bear in mind as you look at candidates to purchase. Cool your jets and take your time Below is a prebuy check list I made up years ago for Mooneys Check that all the model numbers and serial numbers match on everything with the log book, engine, prop, airframe, I do radios also. Actually read the data plates and compare to the logs. Check that the parts actually installed match what is contained in the TCDS and/or the logs show an STC change for the big stuff and changes for radios and electronics. Anything added like engine monitors, fuel flow gauges, etc should show an STC listing in the log books. Pull the rear seat bottom and open up the inspection holes to check for corrosion on the spar caps. Look at the spars real well in the main wheel wells for same. As noted fill up fuel tanks the night before and look for leaks the next day. If you can jack the airplane do a gear over center torque check. Make sure the A&P has the correct tools to do it. While on jacks, move the main gears in and out toward the wing tips for excessive movement. Lift the main wheels to check for play in the donuts. The donuts should expand enough after 5 mins unloaded to not have much movement. Check the mouse boots for condition in the main wheel wells. While down by the main gear look at the spar bottom between the fuselage and wheel wells. Look for smoking rivets there. The rivets that hold the spar sandwich together. That can be a big $$$$$$. I found one in AUS with almost every rivet loose on the bottom of the spar. It was grounded by the owner when Kerrville said it had to be repaired. Nose gear area - if on jacks this is easy- twist the nose wheel left and right to check for excessive play in the steering linkage. More than about 10-15 degrees either side of center before tightening up on the linkage is too much. You will see the slop way at the top of the nose gear on the rod end linkage up there. Most important on the nose gear! Look and feel for dents where the steering system touches on the tubing for dents where it touches. Turn the wheel by hand and you will see where it touches and stops. MAKE SURE THERE ARE NO DENTS THERE! The limit is 1/32" depression. Any dents and the nose gear comes out for repair $$$$ On the tail surfaces grab the tip of the stabilizer and try to move it up and down and fore and aft. If it moves or clicks you might have work to do. Limits are about 1/10th of an inch either way. Usually fixed by changing out the "close tolerance bolts' in the hinge. As noted lift up on the rudder to check for play in the jackscrew. Same limit about 1/10 of an inch. Lots of times it is wear on the 2 bolt hinge bracket at the aft end of the jackscrew and not the jackscrew it self. I found one stabilizer that moved 1/2 inch either side of center! Look over the outside surface of the entire airplane for dents, filliform corrosion, hangar rash (the elevator tips seem to be especially susceptible to this damage and NO repairs are allowed to control surfaces (no patches, partial skin replacement, etc). The FAA in one case here on MS made a big thing out of this stuff on a routine ramp check on one of our posters. Basically they said it didn't come that way from the factory so fix it. I check all the exterior control surface rod ends to see if they are loose enough to move or if dry and frozen. If dry and frozen I start looking at the logs real close to see if the lube and gear swing AD had been being done. One item missed almost always due to the effort but it can cause big headaches, is pulling the sidewalls inside and actually looking at the steel tubing frame for rust. If the windows are not sealed well, water gets in there and runs down inside on the tubes and rusts them. The insulation SB aside. There is actually a SB describing how to check for leaks by pulling the sidewalls and directing a water hose at the windows looking for leaks. Make sure everything, and I mean every switch, knob and button works as designed! Put power to it and try all radios in all modes, all lights, all warnings (landing gear warning horn, stall warning horn, etc), all exterior lights, everything that can be turned on or off or moved in and out. There was one write up on here a while back where someone bought a Mooney and the stall warning didn't work nor did the gear warning (IIRC). That makes the airplane unairworthy. If on jacks (and it should be) do a gear swing and make sure the gear works properly. I've seen them signed off 3 months ago and they hang 3" from the wells when sucked up. If its electric gear do a manual drop also to make sure it works. Had a couple on this board recently that went in for annual and the manual gear drop didn't work. So check it out. Look to see if the gear actuator has ever been removed, cleaned, checked for proper gear lash and relubed. If it hasn't you may be doing that on the next annual yourself It's that important. Disregard if its a manual gear. It goes without saying that a full log book check is required for all applicable ADs and required inspections even though the annual has just been done. The logs tell a story and knowing how to read them is a skill. Make sure you know what to look for or have someone that does. The engine stuff is the normal stuff. Compression check, oil filter inspection, looking for leaks, cracks, anything not normal. Pull the plugs and read them, they too have a story to tell. My caution to any whom I help buy an airplane? Trust no one selling an airplane period. Take nothing for granted. Don't trust anything even though it just had an annual. If you do, it will bite you in the arse. Check and verify everything before money changes hands. Once you pay for it , its yours! Good luck and show us pictures even of the prebuy! :-) :-)