A64Pilot

Verified Member-

Posts

8,000 -

Joined

-

Last visited

-

Days Won

21

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by A64Pilot

-

Investigation Alaska lake crash dropped?!

A64Pilot replied to DXB's topic in Mooney Safety & Accident Discussion

In all honesty unless it’s changed recently, Alaska is well, different. Unless they are flying Commercial etc. a very great many pilots if they ever got their license are probably way over due a flight review and Medical? Neatest Dr is hundreds of miles away. I’m not talking about the people that live in Anchorage etc. Many live out largely by themselves with a Supercub or if they live high off the hog a 180, forget an A&P, where are you going to find one? The rules down here in the lower 48 often just aren’t possible to follow, I think everyone understands that. Now since that accident made the news tge FAA will respond, they have to, but if it didn’t It’s likely nothing would happen as there weren’t any fatalities. Commercial, part 135 of course is different as it should be. I’ve landed my Maule on the AK highway and taxied to the gas station and we ate lunch, they had real long hoses on a couple of the pumps to fuel airplanes, landing on roads is common, try that down here. -

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

Assuming as you say that they have deep pockets, then it’s likely that they have legal teams on retainer. Not saying that makes them invulnerable, but does make it real tough. Remember the Ford Pinto? The lawsuit? As I understand it the Jury awarded over 100 million, but Ford Lawyers had it reduced to 3 Mil and a new trial etc. Now I wasn’t there of course but I was told by someone who knew this kind of stuff that years later the Plaintiffs still hadn’t gotten much, Lawyers fees etc pretty much ate up what they had received and Ford had tied it up in courts etc for years. If you read about how complicit Ford was in the Pinto design, it was criminal, then later along came the Explorer, read about that too and you may not be pleased. -

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

Many years ago there were auto fuel STC’s granted and I think that set a precedent, that and the Political pressure to get rid of the lead pressured the FAA. What is different in my opinion is the Auto fuel STC’s approved an existing fuel, but the Gami stuff is a mixture of chemicals, that was never a fuel. Who is going to pay I think that @MikeOH has it pretty correct, if I understand George Braly was first a Laywer, so one would expect that he is pretty well protected from Lawsuits. I suspect that the individual aircraft owner is who will pay, as it may be that there are no deep pockets on the other side no Lawyer will take this on commission and even if someone were to take it upon themselves to fund it, it would likely take years to get a judgement, and about all I suspect you could do with that is frame it and hang it on the wall, because I think George may be “judgement proof” -

The purpose of pushing in is to increase the friction of the ball so that the flapper will move otherwise of course the ball just spins and you accomplish nothing. Newer ones the ball seems to be a tighter fit

-

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

I hear you and understand what your saying. But inadequate materials and or design if it exists is a fact of the GA fleet, one that has been operating for decades with minimal issue. So it is pretty apparent that these materials and design are in fact adequate with existing fuels. This new fuel was supposed to be completely transparent in its use, no significant changes. Nothing about except for certain makes etc. The fact that people have investigated wing fuel tanks with the Gami fuel in it and found that the sealant had been softened to the point that a borescope camera would leave indentations in the sealant and the fact that when they went back to 100 LL the sealant hardened up seems at least to me that it’s the fuel, not inadequate material or design that’s the issue, unless you accept that fuel tank sealant is inadequate? We had a joke in the Army, if you were caught doing something you shouldn't the course of action was to Lie, Deny, and make Counter Accusations., until the hammer falls. Seems that is what Gami is doing, all I can think of is that they believe there is a conspiracy against them and or maybe these issues will just go away, both of which just don’t make sense, bad news doesn’t get better with time, the more aircraft that use this fuel and accumulate damage, the more likely there will be lawsuits. The hammer falling. I just don’t see the logic in continuing? I mean Cirrus, a major manufacturer of new aircraft has come out and said don’t use it, but the real damning thing is their concern of one that has that has been brought to their attention isn’t airworthy now. What ever happened about that anyway? -

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

Why would anybody in Tx want the stuff? -

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

Krfg is Texas? -

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

Link doesn’t work for me, too many redirects. What was it saying? -

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

It was fairly obvious to me that this fuel was a safety concern from just what it did to O-rings, that was enough for me, the paint issues came along and that again screamed it was an aggressive solvent, I’m not talking about staining I’m talking about dissolving Jet-Glo. I wasn’t surprised at all when it ate fuel tank sealer, I expected that after the paint problems. Paint I see as the canary in the coal mine. I think in time we will see fuel pump leaks, maybe fuel servo problems and or fuel spider problems, anything in the fuel system that has “rubber” components. Maybe even fuel hoses. Then as it became apparent that “fresh” fuel wasn’t as big a problem as was what was left behind when the more volatile fluids flashed off made sense as assumption that only the fresh fuel was tested during the STC process. I can accept that as an honest mistake. But you need to own up to your mistakes, mistakes don’t get better with time. 1 in 1000 problems is unacceptable, 7 out of 100 is crazy, especially how quick the problems popped up, I’m used to mistakes only showing up months or years later, not within days. Over time that 7 out of 100 will increase I’m sure. I’m amazed it hasn’t been voluntarily withdrawn, will it take a fatality for that to happen? Do they think these issues are made up, that they don’t exist, or do they think they will just go away on their own? I guess I expect that in time the FAA will pull the STC -

Crosswind capability depends on gross weight, speed, power applied and even on which side the wind is coming from, obviously if your carrying power as surely most all of us are in a cross wind landing then you need a little right rudder and that cuts into what’s available, wind from the left does just the opposite. Additionally most every aircraft I’ve been around has a range of allowable rudder travel, if yours is at the min then you have less rudder authority than one that’s at the max So we end up in most of GA aircraft rather conservative cross wind numbers, there are some exceptions to this of course, Gulfstream killed a couple of test pilots and crew with a rather ridiculously difficult short field takeoff procedure because they wanted to advertise that the G650 could get into and out of very short fields, so they had no “fudge” at all. https://www.ntsb.gov/investigations/AccidentReports/Reports/AAR1202.pdf Long and short of this is that crosswind capability is very variable, oh and I forgot grass runways too, grass is much more forgiving if you don’t touch down perfectly straight so cross wind landings are easier on grass, so add that to the list.

-

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

I believe a primer has two check valves, one opens when you pull it back and allows it to fill with fuel, then as you push the primer it closers and the other opens allowing fuel to go to the engine, the way they are they both will open and allow fuel to be sucked through the primer by gravity or engine vacuum. I think when the primer is closed it blocks these valve openings so fuel can’t flow. I think maybe on the 140 in question a swelled O-ring was keeping the primer from fully closing, maybe. Just a guess actually but I can see it happening, and we know the Gami fuel swells Buna-N O rings. -

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

They do as of course Viton didn’t exist back then. Almost certainly due to its resistence to wear Cessna I believe recommended the switch to Viton in primers some time ago, not sure how long ago Viton is tougher, has I believe a higher durometer. Years ago when I was cave diving I switched to Viton on all my tanks because it’s an unlikely but possible point of failure. I don’t believe Viton is a direct replacement for Buna-N in all uses as it’s tougher to compress, at least the Viton I’ve used is. Anyway it’s one thing for Gami to recommend it, but a completely different thing for average guy to know this, and a third thing for them to understand the importance. Average person is sure it’s safe or the FAA wouldn’t have approved it, right? -

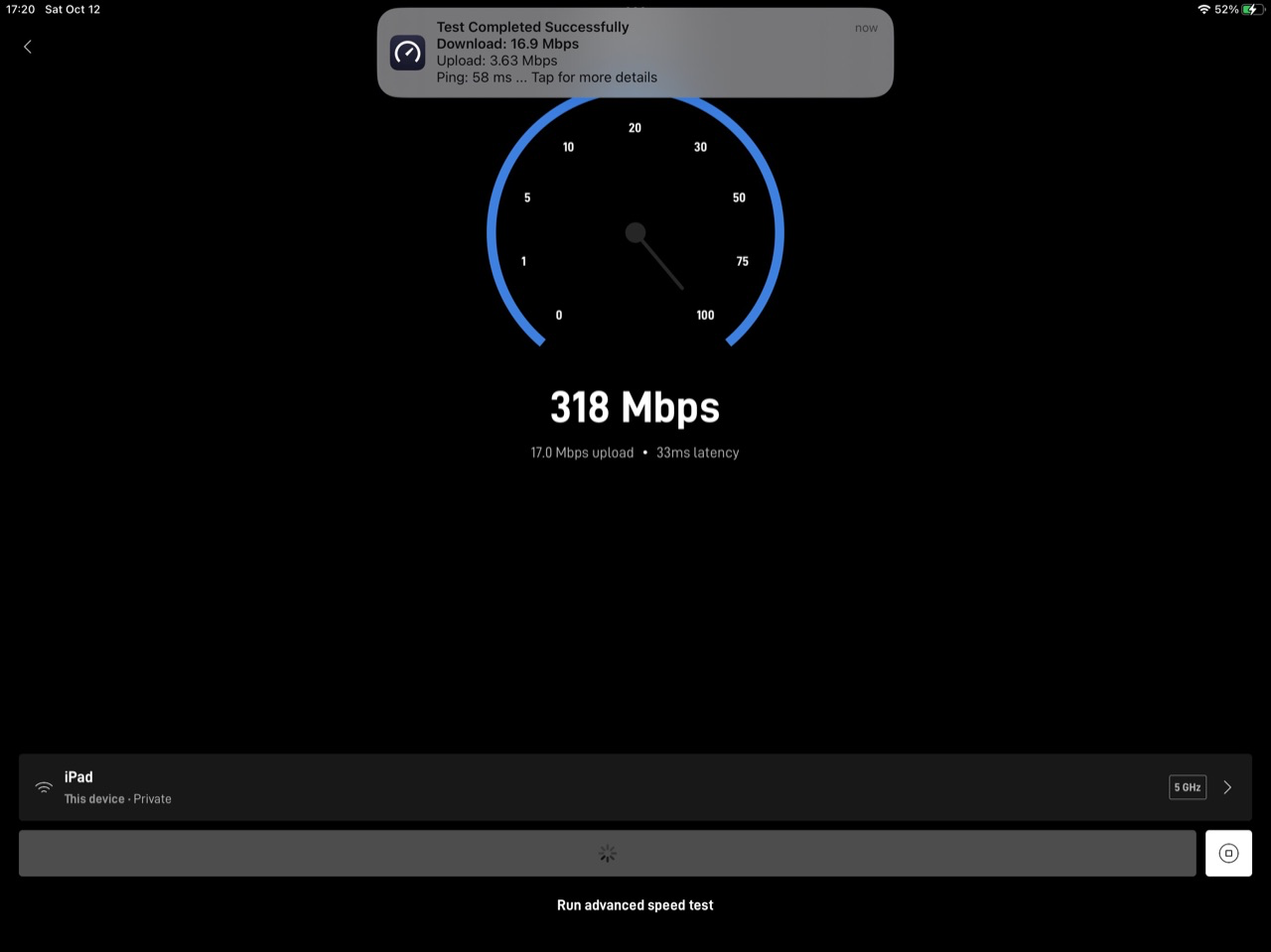

I pay $120 a month (residential), my neighborhood is full of them as it’s Starlink or phone line internet nothing else. So much for the Billions spent on Rural high speed internet. Musk applied to participate years ago and yiu wont believe why the Government turned SpaceX down. Speed is all over the place, I’ve seen as high as 300 and as low as 30. I think it switches Satellites ever 2.5 min I’ve read. Although speed is up and down it has plenty of bandwidth for me to stream 4K and us both to be online.

-

Interest in auto inflator for door seal?

A64Pilot replied to ragedracer1977's topic in Miscellaneous Aviation Talk

-

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

They are metal tanks held into the wing by metal straps, very much like an old car. The fuel lines to the strainer are steel, I don’t think there is any rubber in the fuel selector, but there may be one under the cap where the lever is attached. The original carb float was brass and the original needle and seat are steel, but I think modern floats are plastic of some kind and some needles have neoprene tips as the original steel on steel could leak slowly. Primers can be a source of engine failure / low power as if not closed they can make an engine run stupid rich. Normally the O-ring wears and I think the primer leaks slightly when used. Real easy to change but can be a significant airworthiness issue. -

Toronto CRJ inverted on landing

A64Pilot replied to toto's topic in Mooney Safety & Accident Discussion

Report I saw said 1172 FPM, that 72 isn’t insignificant, that combined with the fact that the right gear took almost all of the load instead of half if it touched down normally is probably well in excess of ultimate load. Touch down was at 7 deg right roll, so the right took most. The pitch attitude at touchdown was from what I read 1 deg nose up, meaning to me no flare. We can all demean the little CRJ, and maybe one of the old gen Boeings would have shrugged it off, but I think the Pilot takes the blame on this, but the non flying Pilot shares some too in my opinion unless they were raising hell for a go-around and were ignored. They have a vote or are supposed to surely, Military they do anyway. Pilot reduced Ng to 40 ish percent (idle) higher up than called for too so I assume he perceived he was high and or fast. I think he was over 100 ft and the Airline called for 50 I think, the approach was otherwise on speed etc. normal until right at the end from what I read. Turbo- props normally have two idles, ground and flight, flight is higher to help reduce spool lag, but the bigger PT-6’s anyway you can slam from flight idle to full and it’s about three seconds before it comes back, but when it does you had better reduce throttle quickly or you will overtorque and over temp in a hurry, Garrets being single spool engines respond nearly instantly just like a piston does. I have no jet time, but assume they are similar to the PT-6. Smaller PT-6’s respond more quickly than the bigger ones. -

Sorry I can’t help you. I’d guess due to the vintage of the aircraft that it’s likely you may be looking at an Owner Produced part, if your unfamiliar a quick search will lay out everything that’s need to produce your own FAA legal part, it’s very straight forward

-

You keep saying that, but don’t understand what I am saying. I’m saying that there is a range of say 1 to 5 oz weight measured at the trailing edge. If your at one ounce then your biased towards nose heavy, 5 oz and your biased trailing edge heavy. That weight is just numbers, I have no idea what a Mooney’s weight is but strongly suspect it’s different by model based on VNE, but haven’t looked. Not that I’ve seen that many flight controls balance specs, but I’ve never seen one that you weigh the nose, always the trailing edge, so they are all trailing edge heavy The only point is that if you’re towards max trailing edge heavy, it reduces your flutter margin, meaning flutter is more likely than if you’re at the light end of the range “nose heavy”. A catch 22 that I’d expect to see if weight is added aft of the hinge line is that it takes more weight to return the flight control to acceptable limits, the problem is that your only allowed a limited amount of weight that you can add, you may be at max weight and barely in the range. But if your having to change weight, I recommend balancing to bias nose heavy, within limits of course, the reason is as an aircraft ages the flight controls weight changes to bias towards tail heavy from any repairs, paint touch ups or just dirt accumulating over the years. It does that because almost all of the area of the control is aft of the hinge line. I have never seen one’s CG move toward the nose.

-

Validate the gauge, easiest way I know of is to remove the sender and put it into boiling water, the outside of the sender might have to be grounded to the engine.

-

KOXR Mooney blade failure

A64Pilot replied to ragedracer1977's topic in Mooney Safety & Accident Discussion

It will be immediately apparent upon visual inspection, usually. Never say always. I think rarely a scanning electron microscope is needed to see the beach marks, but that’s above my pay grade. Classic fatigue leaves witness marks called beach marks and they radiate from where the crack started. Not sure why they are called beach marks, maybe because they look like wave marks on a beach, maybe? https://www.quadco.engineering/en/know-how/material-fatigue-how-can-it-be-recognized.htm You find an inclusion prior to failure by NDT, often either eddy current or x-ray if we are talking aluminum, other methods for composites and magnetic steel although eddy current works fine for steels like 4130 etc. -

How deep do you want to run a Lyc IO-360? Mine will continue to run smoothly well below the point where it loses a LOT of power, (D single drive mag) at least 75C LOP, although a hotter spark will allow larger electrode gap and that will ignite lean mixtures better. Oh, and the throw away Slicks were decades ago, back then they were cheap, so much so that a new one wasn’t much more than an overhaul, but they ain’t cheap anymore. You overhaul them now I’m told. Nickel is much better than SS

-

KOXR Mooney blade failure

A64Pilot replied to ragedracer1977's topic in Mooney Safety & Accident Discussion

It’s also not necessarily real definitive, the defect must be present at the surface for dye penetrant to discover a crack, then of course the test is only valid for the time the test was done, unless your willing to strip and rest yearly or whatever the interval the experts determine is less than the time between a discoverable crack and failure is. I couldn’t even hazard a guess. A better test would be eddy current as it will find sub surface defects, and I think doesn’t require paint stripping, but don’t quote me on that My SWAG is this prop had an inclusion in it, and that was the defect that the crack propagated from, or possibly if it had an avoid range that the pilot ignored it, in short I hope this was a one in 100,000 kind of thing and won’t effect the series. If it was an inclusion they will find that pretty quick. -

Part Problem for Engine Continental TSIO360SB2B

A64Pilot replied to Stefan Moehringer's topic in General Mooney Talk

Issue I believe is they can’t just take a part off of an old engine and use it, it will have to be overhauled IAW the manufacturers overhaul manual, unless the FAA allows otherwise which I doubt. I did build several crop dusters with customer supplied yellow tagged engines and props, but only because the FAA specifically allowed those two items, a customer could have given me a brand new set of wheels and brakes and I couldn’t have used them.- 14 replies

-

- tsio360sb2b

- throttle body

-

(and 2 more)

Tagged with:

-

KOXR Mooney blade failure

A64Pilot replied to ragedracer1977's topic in Mooney Safety & Accident Discussion

Believe it or not but a few of us did on long distance cruising sailboats. Reasoning was that God forbid but the weather was so bad that the boat rolled you didn’t want the engine coming loose in the cabin. What could you chain it to in an airplane though? It’s not just the rubber that breaks on an aircraft, it’s the tubular engine mount itself. We did it only on the left side of drag cars if memory serves because torque pulls the L side up.