A64Pilot

Basic Member-

Posts

7,977 -

Joined

-

Last visited

-

Days Won

21

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by A64Pilot

-

If the gauge confirms good and if that’s below the green I’d be concerned, but personally before I started tearing into things I’d fly it with both gauges to be real darn sure the ancient stock gauge isn’t flakey. I’ve seen tens of thousands spent when all the problem was the gauge, it was a temp gauge but still it read incorrectly. If it’s in the green, then well sort of by definition it’s OK.

-

Time to replace alternator?

A64Pilot replied to Teddyhherrera's topic in Vintage Mooneys (pre-J models)

Shouldn’t, they usually last decades it seems When you fix it please report back, I think it helps the next person who has your problem -

Time to replace alternator?

A64Pilot replied to Teddyhherrera's topic in Vintage Mooneys (pre-J models)

Being as it’s intermittent I’d be more likely to suspect the voltage regulator than the alternator. If memory serves and being older it’s not what it used to be but the voltage regulator is powered from the backside of the master switch, it uses spade terminals and they are prone to being loose, cleaning and a slight squeezing of the female spade (wire side) is all it takes if that’s the problem. Also check the field wire on the alternator for condition etc, but they usually break and of course that’s not intermittent. -

Successful 201 Forced Landing

A64Pilot replied to Mooney in Oz's topic in Mooney Safety & Accident Discussion

I’m not sure what it’s called, maybe parallax error? But think of how someone wants to make the fish they caught look big, so they hold it out in front of them closer to the camera as an example. I think it’s just from a wide angle lens, and not a faked or doctored photo, maybe that’s what we are seeing here? A wide angle lens distorts the image -

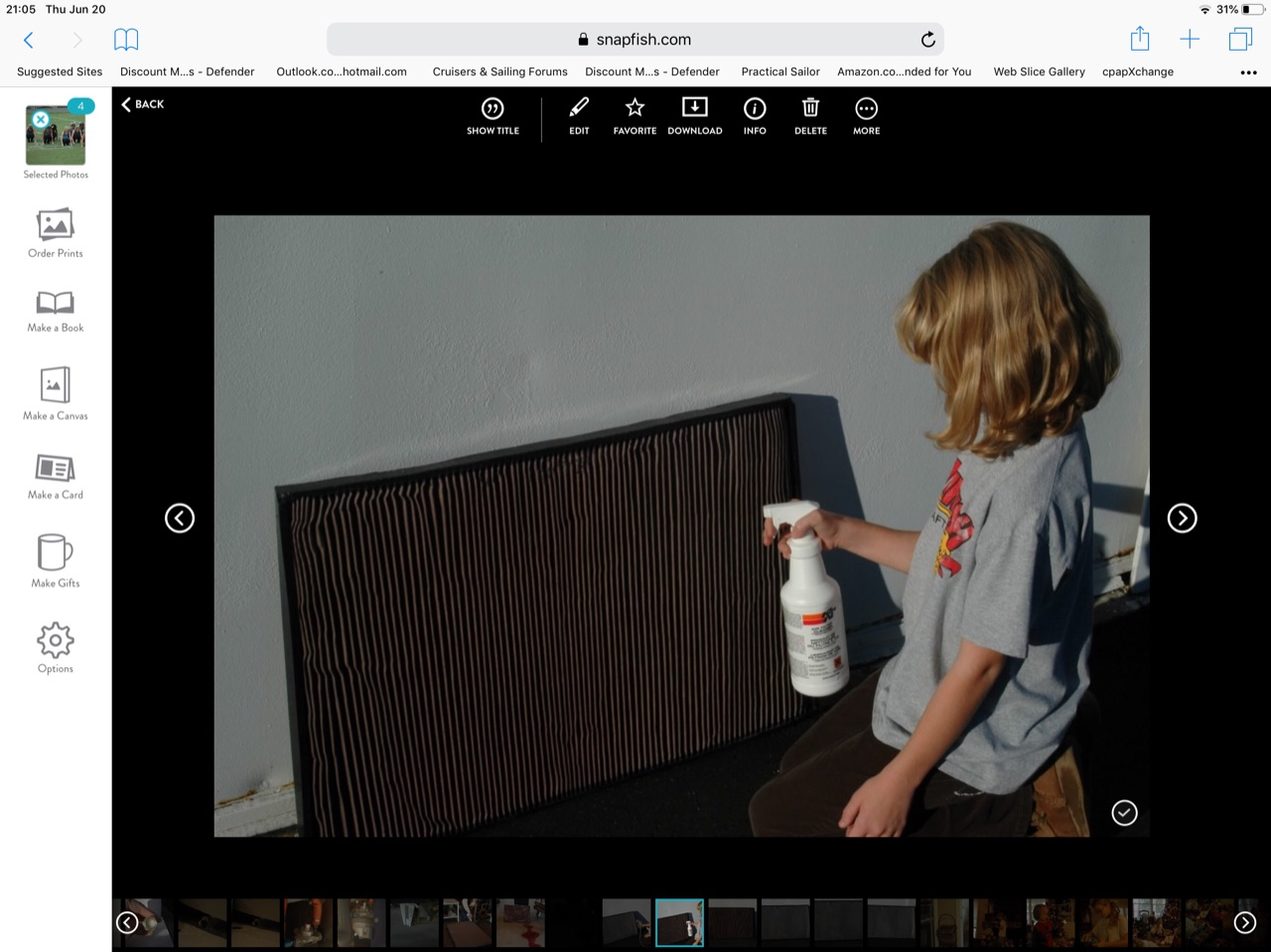

K&N’s also don’t filter very well, they have less restriction because they don’t filter as well. TANSTASFL It isn’t hard to properly service a K&N, but it can’t be done in one day as it takes 24 hours to completely dry before it’s oiled, plus it shouldn’t be dried in the sun as it’s cotton and that shrinks cotton, we used ones that were about 12 sq ft on the Thrush because for that application they were about the best thing going. You really don’t want to restrict the airflow to a turbine. Really cleaning and servicing a K&N is one of those things that’s so easy that it’s just foolish to pay someone else to do. ‘Pic is my Daughter years ago showing how to clean a Thrush intake air filter for a class I gave.

-

Just saw a video of the main XMSN and rotor assy. They were attached to a big chunk of the cabin roof, the 206L XMSN and it’s mounts are a little different than it’s little brothers but very similar, Seems the mount didn’t fail, the cabin roof did. So did the cabin roof failure cause the accident or was it a result of the accident? The cabin roof on the smaller 206 is a honeycomb assembly of aluminum and was very prone to voids, we had to shoot filler in the voids on Military OH-58’s, the voids significantly reduce the strength of the honeycomb, I assume the bigger L model is the same.

-

I know that but apparently what he has is a box or boxes of parts, case already split etc., lifters are out and not segregated as to where they came from, so no way to ensure they go back on the cam lobe they came from. You may get away with mixing lifters, to be truthful I have never tried as I’ve always heard it will eat the cam, lifters and the cam wear into each other, you can put new lifters on a used cam. but not used ones. So he either needs to buy new lifters, hopefully DLC ones or have what he has reground and renitrided. My advice would be to put new DLC lifters in. If a case is split DLC lifters seem to just be logical. I reread his post I assumed it was for an Experimental, but apparently not, he is going to have to have an A&P involved with this, and of course follow the Lycoming manual.

-

Do NOT mismatch lifters and the cam, if you don’t know which hole they came from they need to be reground. New or reground lifters can be put on a used cam It’s no different than a pushrod car used to be. Your not supposed to but push rods can be shortened by removing the tip, shortening it and reinstalling it. On assembly lubriplate the snot out of everything and ideally pre-lube it by putting pressurized oil into a galley before starting. Difference in breaking in an aircraft engine as opposed to a bike or car is you do not baby the aircraft engine, you run it full rich and hard.

-

Hovering is the trick, if you can hover you have it licked, flying it’s just like an airplane without the inherent stability is all

-

Looking for a Gear Motor PN# LA11C2114

A64Pilot replied to Paulie's topic in Vintage Mooneys (pre-J models)

@DCarlton https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC_23-27.pdf This AC applies to ALL Mooney’s regardless of date of manufacture. Ref “supervision” the FAA would prefer me take an exhaust system to a professional welder and have it TIG welded than say for me to use my Oxy Acetylene torch and do it myself. A problem can be if I held out that I Overhauled say an electric motor as that’s beyond my capabilities as an A&P/IA, however a repair is likely acceptable, to the FAA language is everything. -

I would like to have a Hughes 269/300. It’s what I learned on in flight school, we called them LOB’s for little orange bastards. Slow as a Cub and about as powerful, but they were very responsive and fun. All Hughes helicopters are pilots aircraft, the 206 is not, it was made for the guy in the backseat.

-

One actually, it holds the rotor head on. I’ve never head of one failing, but if it did, it would be bad. There we’re a few Swashplate failures on the AH-1 Cobra, came from the Army installing Kaman 747 semi symmetrical rotor blades to increase useful load, problem is the center of pressure moves aft with increase in angle of attack on a semi symmetrical rotor blade, this back fed pressure into the swashplate that it wasn’t designed to handle. The rotating portion of the swashplate would stop rotating, the Pitch Change links would break, most likely blowback would have the rotor pitch up heavily, the tail boom is cut off and of course everybody dies. Except for the fact that the mast isn’t broken off, this NY 206 crash looks very much like the AH-1 failures, difference is I think that your not ripping out the main transmission of a Cobra, but there isn’t much holding in one on a 206, perhaps one of the inverted V braces that hold the tranny in broke? Or unlikely I think but the transmission seized?

-

A few things, the transmission on a 206 is held in by two inverted V braces, one on each side, then there is an elastormeric “box” right behind the transmission that dampens movement, connected to this link is a round pin that sits in a square hole, excessive movement cause the pin to hit the hole and is called “spike knock”, we dreaded spike knock, usually got it in a touchdown auto by not leveling the aircraft on touchdown, at Ft Rucker if you got spike knock you got to wear a RailRoad spike hung around you neck for all to see. It wasn’t common I never saw anyone wearing the spike. The engine isn’t connected to the transmission except by a driveshaft and it’s pretty much like a auto driveshaft, no structure to really hold the two together The instant the engine quits, you immediately lower the collective to maintain rotor RPM, then at the bottom of the Auto you first decel which adds energy into the rotors, then finally use collective to cushion the landing. Having said all that the Bell products generally have more mass in the rotor system than others meaning they are much more forgiving in an autorotation, it’s possible the pilot could have been completely stupid and not put the collective down, but unlikely if they were decently trained being a Commercial pilot surely they were. Two bladed rotor systems are semi-rigid underslung, meaning simply that neg G or low rotor can destabilize the rotor and it tester back and forth and “mast bump”, mast bumping may or may not tear the mast off, I believe newer Civilian Bell’s have big springs in the Hub to help prevent mast bumping, mostly during shut downs etc from wing gusts, and I think that could have help prevent the mast from being broken off, but if a swashplate fails, it sealed and the PC links break and the rotor will come off, maybe breaking the mast or maybe just tearing the transmission out. Yes the blades most certainly took the tail boom off, if they were at full RPM they had plenty of energy to do that likely without breaking. UH-1 Transmission is completely different, to begin with it’s about 8 feet tall, held into the Huey with four “candle sticks” and a Lift Link at the bottom, you can’t get “spike Knock” in a Huey and as such you don’t have to level the aircraft before a touchdown Auto, the 206 tranny sits on top of the cabin top where the Huey one goes almost to the bottom of the aircraft. I was a 67V, an OH-58 Crew Chief for five years and flew them in flight school, an OH-58 is essentially a 206

-

I’ll start the speculation based on no facts. I think either Swashplste failure or Pitch Change links failure, either would sever main rotor control which would lead to mast bumping and that means everybody dies.

-

1. It should be good enough, it might not be perfect though, depends a lot on where and how the aircraft lived. If in Arizona tied down is way different than hangar living. 2. It’s the best way to go, but an auto paint may be good enough, depending on your goals. If it’s just to get through a year or so before the repaint the auto might be OK. 3. Sand lightly and paint. Avoid any stripping if possible. 4 No experience with spray bombs, my recommendation is avoid them, get a decent air brush or touch up gun. I don’t pretend to be an expert, but know a few, my advice is if you want a near perfect job, hire it out, Auto guy is fine. I think Auto jobs are usually of better quality than Aircraft jobs myself. I treat paint like I do fabric, as an IA I’m allowed to do fabric but never have so I’m no expert, but I know several that are Nothing wrong with hiring a job out if your after perfection, you might be a true artist and hit one out of the ball park first try, but it’s unlikely. However if you’re just after good enough, why not give it a shot? What do you have to lose, you can always hire it out if you can’t get it good enough. Do some reading, lots of it. Your asking what to thin it with seems to indicate you need some education.

-

What type of stem is on this tube? Goodyear Flight Mate

A64Pilot replied to dkkim73's topic in Modern Mooney Discussion

@dkkim73 That is pretty much word for word what I have read the recommendation is from every manufacturers books I’ve read. But of course they have everything to gain if you never reuse a tube. I have seen several that have been reused but have never myself seen a failure attributed to it. I have seem tubes that were worn and had creases that wore telling me they needed to go in the trash, so I suspect those were reused and the manufacturers have a point. Your milage may vary. -

I doubt he took them anywhere, unless there was an investigation of some kind. I don’t think they are allowed to just walk off with records? I’m surprised maintenance records (historical) are even allowed to be on the airplane, Military they aren’t, if we had to, we put them on another aircraft while we carried theirs, reason is of course if there is an accident you don’t want the historical records destroyed. Would kind of upset the investigators and set fire to the conspiracy theorists I bet. But Inspectors are from all kinds of backgrounds and I don’t think many are even A&P’s one of the ones for my Repair station’s background was an Avionics tech for instance, he was the PIA, the one that found obscure rules type.

-

You know my goal is the middle of the green, what that is in degrees I have no idea, but unlike many I don’t think Lycoming are idiots, there is a reason why the green arc has a bottom to it and it doesn’t go all the way to the bottom of the gauge. I almost always run LOP and sometimes in Winter which isn’t real winter where I live I have to run richer to get temps up. I can only imagine that up in the great white north they have to run peak or ROP to keep temps up? The only thing I differ on being in the middle of the green is oil pressure, I like it being in the higher end of the green arc myself.

-

I have 8 ply’s on both my Mooney and my C-140, reason is the Thrush S2R-T660 uses a 10 ply 6.00-6 tailwheel tire, we ordered 8 plies once by mistake and couldn’t use them or send them back I guess. This is my last sets of “free”tires though as I Retired 9 yrs ago.

-

Yes and they even have a quota of some number per month per inspector, or so I have been told by a Senior Inspector. Where I used to live they ramp checked often at the end of the month at Falcon Field near Atl, where AC Spruce is. I think it’s real close to the FSDO hence it got more than its share of “business”. I got ramp checked once and told the inspector who wanted to see the Airworthiness Cert. that I was sorry but as it was I was late for a meeting, jumped in put my belt on and called clear, he backed up and I left. He was looking hard at the prop though I suspect with the plan of red tagging the airplane. I have been told, but do not know that they cannot detain you without some kind of probable cause maybe? Just like I have been told to not turn loose of your Certificate too, doing so could be considered you surrendering it? Maybe both are BS, I’m no Lawyer. But where I did most of my flying I never saw one, but they do often conduct surveillance on shops and I’m told will check out things that they observe that just don’t look right when they are there. Many have their pet things like the data plate or maybe a chromed spinner or whatever that they always look for. Ref the nose wheel ply rating, very often as in most always what’s in the TCDS is what they tested with drop test wise, if a 4-ply passed why check a 6 or 8? More testing than min you don’t do, nothing to gain and it’s expensive. Hopefully they are smart enough to test what’s most commonly available and or least expensive first. Ply ratings and surprisingly even tire pressure can make a big difference in passing the drop test. I suspicion that’s why my J models nose wheel tire pressure is so high. it shouldn’t be for prop strike because you have to have a min distance with a flat tire. Doesn't matter why really, just my suspicion is all.

-

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

Should, if it has the wire in the hose like it should and the wire doesn’t have an open circuit, but also believe it or not but static builds from fuel falling in the air, that is why the tanker trucks that top load have the dip tube https://www.chevronwithtechron.com/content/dam/external/chevron/en_us/marketing-support/all-other/Static_Electricity_Hazards_and_Prevention_from_CBT.pdf8v https://docslib.org/doc/12963317/petroleum-loading-and-unloading-procedures-top-loading As I said probably over cautious and when was the last time you heard of a GA aircraft catching fire being fueled, so probably not real necessary, but why not do a couple of things that require nothing special like be sure you touch the wing to dissipate static from you before you stick that nozzle in the tank? I refuel inside of my hangar so I guess I’m overly paranoid. But if you care when we refueled from a truck, (Military) the truck had to be grounded, the truck bonded to the aircraft and the nozzle bonded to the aircraft before being attached to the aircraft, we never open port refueled too, because of the danger from vapors, and that was Jet fuel which is harder to ignite than gasoline -

@Ragsf15e No, ALL mooney’s are CAR3. I have never heard of anyone wanting burn certs for a pre-buy, but they aren’t expensive or hard to obtain, most anything will pass as the reg pretty much says if it doesn’t burn vigorously it’s OK. Surely Airtex can or will supply burn certs on request, it’s just not tough or expensive to meet Certs so why wouldn’t they? From memory your supposed to placard the airplane no smoking if you don’t have burn certs, but even if you have certs if you don’t placard it you have to have an ashtray for each seat, there is no way if I were paying big bucks for an interior that I would have ash trays, so I’d placard it anyway. For anyone who is replacing the foam in your seat I strongly recommend Oregon Aero cushions, Maule has absolutely horrible seats, couldn’t fly an hour without my back killing me, Oregon aero seat foam transformed the seats, it’s not so much the foam as it’s the foams shape that made the difference. It will seem like a lot of money for just foam, but it’s worth it.

-

I had no idea they cost that much to overhaul. I’ve been an A&P for a long time, I remember thinking about 1990 or so while I was still in the Army that my cost in parts and services that I would have to farm out to overhaul an engine was less than $2K a cylinder, meaning 8K for a four cylinder engine, new cylinder kits complete with everything were I think about $500. I think I spent about $10K to overhaul my IO-540 in roughly 2007 or so and I cut no corners, actually spent more than I should buying new Millenium cylinders rather than having mine overhauled, that was a mistake. In truth I don’t keep track of costs as if I did I’m sure I couldn’t logically justify owning an aircraft. I prop struck it at about 1800 hours or so and I decided that if it was coming apart for inspection that I was going to overhaul it. It was so cheap to overhaul largely because it was low time and I didn’t have to replace anything except bearings etc. I did send the rods off to be rebuilt, crank to be inspected, it still met new tolerances and only needed polishing, cam and lifters to be ground and nitrided, I had the counterweight bushings replaced. Cases went to Divco, they found a crack to weld, but you could not find the repair, I looked. Its a lot like your brakes on your car, if you change pads when they are about half gone and flush the fluid, it’s easy, takes only a few min per wheel and is cheap, but if you wait until it’s metal to metal, well then your buying new disks and pads and as it’s been years since the calipers were flushed maybe calipers too. I’m a strong proponent of preventative maintenance. If you run your engine until it’s making metal, best I think to buy a factory overhaul and turn in yours as a core, because once it’s making metal, it’s very likely your crankshaft, cam, oil pump etc are gone, your oil lines, cooler need replacing, and your prop and governor need overhauling as well, anything that oil touches is contaminated

-

100K MORE to overhaul than to top? You must be flying a Twin and wanting to do both? Nothing says you have to replace all accessories, hoses etc. When I overhauled my Maule I didn’t, and didn’t have any real issues from not doing so. If I were 300 from TBO, I’d either nurse the thing or more likely IRAN the cylinders and start saving for an Overhaul. If they are as worn as you say you can most likely have them honed to next size, new pistons and rings, have valves at least inspected and refaced and get at least another 500 hours out of them. The fear of removing cylinders is way overstated, really all that’s needed as a min is remove a cyl, place spacer or I have seen a few fender washers and torque them down, go to next cylinder. The torque plates for Lyc are cheap, surely the same is true for a Conti. Too cheap to justify fender washers. One of I’m sure many sources for Lyc torque plates https://flyboyaccessories.com/products/cylinder-torque-plate-for-lycoming-engines

-

OK so nothing has changed then, only Rebuilt gets new tolerances. Overhauled gets serviceable limits. Only the manufacturer or their designated representative can Rebuild an engine, the rest of us can only Overhaul or of course repair. https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC_43-11.pdf