-

Posts

259 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Mooney-Shiner

-

Crankcase pressure measurement

Mooney-Shiner replied to Mooney-Shiner's topic in Vintage Mooneys (pre-J models)

Wow, your oil use actually sounds great! I will try to use 20W50, even though I live in pretty warm climate (Florida). Parallel to this, I need to find a good way to completely degrease the engine bay and use baby power to locate the oil leak. -

Mixture Rich or Best for ground ops

Mooney-Shiner replied to Mooney-Shiner's topic in Vintage Mooneys (pre-J models)

Just to update. I think I solved my marginal run-up due to fouling, thanks to this board. Right after start I let the engine warm up for 20-30 sec. Then with throttle setting at 1000RPM, I lean my mixture until my fuel flow reads 1.5 GPH (I'm at sea level at KTPF). Every time I do this, I get solid run-up (@1700RPM) without left mag dropping my RPMs significantly like it used to. Thank you for all of the help, guys. -

Crankcase pressure measurement

Mooney-Shiner replied to Mooney-Shiner's topic in Vintage Mooneys (pre-J models)

The underbelly next to the breather drain pipe has some stickiness to it, but not excessive like some report (oil mess all the away to the spar or tail). The vernatherm makes perfect sense. I will check my cooler after the next flight. Thank you -

Crankcase pressure measurement

Mooney-Shiner replied to Mooney-Shiner's topic in Vintage Mooneys (pre-J models)

Thats what I figured...I was able to put my hand on the cooler fins without any issues. Maybe because I didn't run the engine long enough to get the oil con enough. It was showing 160-170F on the oil temp gauge on the cluster. Perhaps, I should measure the oil cooler temp after my next flight. -

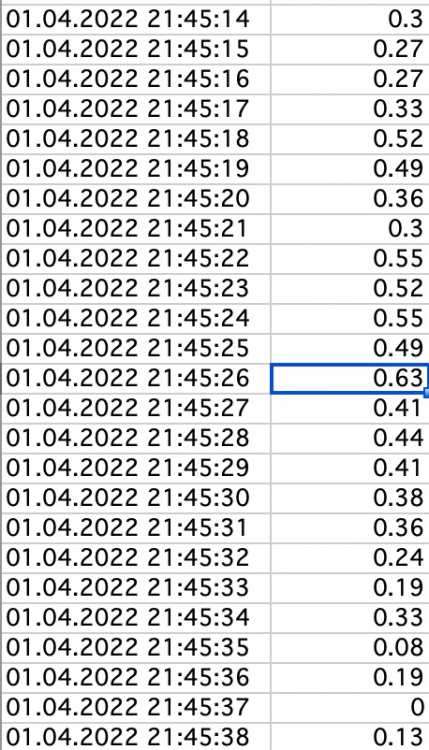

Since I started flying more often, I recently began noticing the oil consumption. Losing about 1 qt every 5-6 hrs and my engine bay is messy (muffler is dry). So I began suspecting a blow by and wanted to test the crankcase pressure before I started considering anything more drastic and expensive. Since I didn't have a spare oil filler cap to repurpose as pressure outlet for my Bluetooth manometer (https://www.amazon.com/gp/product/B07JYXR24F/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1), I build a depicted contraption seal off the oil filler tube best I can. The Lycoming doesn't have a guidance on pressure reading, but Continental does have SB M89-9. There it prescribes the maximum crankcase pressure at 4.0 inches of water pressure (or 0.144365 PSI). I did several ground full power runs. My resulting reading were nowhere near this number during the ground full power run. At the highest, it was 0.63 in H2O. So I ruled out the static excessive crankcase pressure, and thinking of possible ram-air from the front propeller seal leak? Parallel to this effort I will clean the engine bay and try to find locations of oil leaks. I know for sure that I'm losing some oil from the top spine connection on the engine halves (possibly break out the old JB weld epoxy?). Anyone found the way to test the overpressure in flight? One strange thing to note: after running the engine for about 30-40 min, my oil cooler temperature was only 84F. Not sure what temp should I expect?

-

"Positive Control" button

Mooney-Shiner replied to Dan Lawler's topic in Vintage Mooneys (pre-J models)

Open the inspection plates around the aileron connections and see if they have Britain servos. -

What's the street price for a used KX 155?

Mooney-Shiner replied to corn_flake's topic in Vintage Mooneys (pre-J models)

Keith Peshak fixed my MAC 1700 for $500. https://www.barnstormers.com/classified-1588254-King-KX-175B-NavCom-Repair.html?catid=16683 He gets your eqpt and tells you outright if its repairable. -

Vacuum equipment and Edo Aire DG

Mooney-Shiner replied to FlyingDude's topic in Avionics / Parts Classifieds

Jeez, my apologies for missing the post and not responding to the message, which I meant to respond. I went ahead and bit the bullet by buying a brand new tempest… -

Yes, I have this one installed as my main filter in the tail end of the system, but I also was thinking that some here advocated to have an in-line system between the pump and instruments to protect them from carbon.

-

Do I see it correctly? These inline filters are not meant for installation in the F Model? I know the IPC doesn't require any inline filter, but I thought that this would be a good idea to have added protection between pump and DG/AI instruments. Sorry about highjacking the thread.

-

Vacuum equipment and Edo Aire DG

Mooney-Shiner replied to FlyingDude's topic in Avionics / Parts Classifieds

Do you still have any of these? -

Parting out a 63 C model...

Mooney-Shiner replied to Alan Fox's topic in Avionics / Parts Classifieds

How about one of those ancient Rheostat for Right Dome Light? Mine is getting hot and kicks the breaker. Any King 170s radio? Any boots for aileron servo for old Brittain system? Outboard RH fuel sender for fuel tanks level. -

Thank you, ShuRugal! Looking through the records, it appears that it hasn't been changed since 2013. I removed it and will replace. Fingers crossed that its the culprit. I would like to get 50-100 hrs from this plane before I will decide to start avionics conversions, although I do see the point of losing the vacuum system.

-

I remember us disconnecting fuel lines in the area marked with crude arrows to drop the whole assembly out. Ended up pulling the curbed aluminum fuel line, along with the pump. Pro tip: video record the initial set up, so you can put everything back together the same way. Particularly, note the locations of the electric connections. You might have to drop the control rod (depicted on the left the pump). You will need a thin 1-1/4" wrench to tie the bronze safety nut depicted on the right of pump (between the pump and the pivoting bronze elbow) whenever you will finish the reinstall.

- 1 reply

-

- 1

-

-

Hello, Esteemed board. I really appreciate the continuous stream of valuable opinions of MS as we are working on repairing our aircraft to get it to the tip-top shape. New chapter in our (my A&P and my) journey is fault with the AI and DG that all of the sudden starting acting up. My CFI and I were doing some pattern work, when we noticed that the DG is doing a continuous spin and the AI card had sagged and didn't show any accurate readings. Neither Low nor High Vacuum light was lit though. We played it safe and landed back to the field. I did some taxiing around the airport and noticed that DG no longer responded to any changes in plane's orientation and AI continued to sag. Now my A&P and I are trying to figure our what could this be. From reading past threads, it seems that we should get a vacuum gage and check the "plumbing" for vacuum at various points to id a potential break in the line. Are there any other troubleshooting suggestions? Note: I recently had avionics shop do a VFR check on my transponder, so they may have interfered with something.

-

Mixture Rich or Best for ground ops

Mooney-Shiner replied to Mooney-Shiner's topic in Vintage Mooneys (pre-J models)

Nice summary of PP thoughts only, A. I totally forgot that I have JPI450 fuel flow scan. I wonder what GPH should I look for for my IO360A1A at taxi, runup, take off? Happy Thx-giving! -

Mixture Rich or Best for ground ops

Mooney-Shiner replied to Mooney-Shiner's topic in Vintage Mooneys (pre-J models)

Thank you, PT20J. This is an excellent explanation. I began wondering why would Lycoming built their IO-360 so inefficiently...Now I know that they built IO-360 with totally different fuel in mind. In totally unrelated note, makes me wonder if this means that low compression IO-360s are prime candidate for a regular car gas STC or just blanket use approval since they would be right at home with lower octane number of car or marine gas. Happy Thx-giving! -

Mixture Rich or Best for ground ops

Mooney-Shiner replied to Mooney-Shiner's topic in Vintage Mooneys (pre-J models)

This is an interesting note... How an excess air in the fuel system causes overly rich solution and flooding my bottom spark plugs with fuel causing a misfire? -

Mixture Rich or Best for ground ops

Mooney-Shiner replied to Mooney-Shiner's topic in Vintage Mooneys (pre-J models)

You are not wrong. I'm Ukrainian-American, who lived in US for 22 years and serve in USMC. When I set up my account I mistook the user name for the email (I'm not good in the computer things). Of course this is an email that I used back when I was 17 back in late 90-s (jeez!), and now using it for all unofficial business. All the Ukrainian tail numbers start with UR-.