dzeleski

Verified Member-

Posts

505 -

Joined

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by dzeleski

-

360A Slaved problems: Rebuild or replace (and then what?)

dzeleski replied to sy308's topic in Avionics/Panel Discussion

This is not accurate. Every quote I got for 275s was several thousand more on labor. The 275 is basically a G500 and the connector is 5x the size of the G5. My installer specifically stated that a G5 install is way easier and way faster then a 275 and they do both types of installs on a regular basis. That on top of the fact that garmin forced a square interface into a round screen pushed me to G5s, and after flying in a dual 275 airplane I do not regret it. That is obviously personal preference. The ONLY thing I miss on the G5 is being able to set a minimum for an approach. G5: GI-275: It also doesnt look as bad as described on a stock J panel: -

She just slides the seat all the way back and then slides forward on the seat. Its similar to just sitting on the toilet. There is a 0% chance diapers are ever an option lol

-

We use these: https://www.amazon.com/Travel-John-Resealable-Disposable-Urinal/dp/B07Y5QSXQZ Whether or not its acceptable for her I have no idea but my other half uses these without any problems. I limit my legs to 3-4 hours as I personally like to see 2 hours of fuel left in the tanks after landing.

-

The pressure from the intake/box needs to feed pressure to the injector bleed lines and the fuel pump. If your fuel pump and injectors are simply connected together that is effectively doing nothing. You basically have an extension cord plugged into itself and expecting a light to be powered. Those two open lines should be connected to something otherwise you have a massive boost leak/intake leak. I cant find a better diagram for you so the text is blurry but it does show it: http://www.kellyaerospace.com/articles/ContinuousFlow.pdf

-

https://www.lycoming.com/content/hard-facts-about-engine-break "The first careful consideration for engine run-in is the oil to be used. The latest revision of Lycoming Service Instruction 1014 should be consulted for this information. The basic rule which applies to most normally aspirated Lycoming piston engines is simple: use straight mineral oil of the proper viscosity for the first fifty hours or until oil consumption stabilizes. Then switch to ashless dispersant (AD) oil."

-

I stopped running camguard. Had two stuck valves and one starting to show issues, one that required a complete cylinder replacement due to a bad seat that couldnt be lapped. All of which started after using camguard. Once the second valve guide was reamed I stopped using camguard and my issues have since disappeared. My engine was a low time engine as well at around 300 hours SMOH. All of these valves had to be hammered out they were so tight. I fly ~100 hours a year and I usually dont have more then a few weeks of non use. As you said anecdotal evidence but I stopped using it and dont worry about engine corrosion considering I fly it enough. I use Phillips XC multi weight as im up north where it gets too cold for single weight.

-

CDW, FRG, and ISP are you best bets. Most of the schools are booked out however so I would just start calling and see if anyone has openings. It’s about an hour to each local train station but then you still need to get to the FBO as well.

-

Where in NYC? Manhattan? Mornings are gonna be tough if you don’t have from 7am to 12pm. Lots of schools are booked solid and won’t take a new student for a few days. A private instructor might be your best bet but even many of them are slammed.

-

The wing is one piece but the cockpit can come off as well. I dont know the details of that but Air Mods has some pictures on their site showing it: https://www.airmodsflightcenter.com/shop-project Dave at AirMods is probably a good call to make as well, they seemingly are always working on some wild project every time I go over there.

-

https://publicapps.caa.co.uk/docs/33/NERL Major Incident Investigation Preliminary Report.pdf The flight plan delivered to FPRSA-R by IFPS had been converted in the usual way into ADEXP. Following the IFPS processing of the flight plan, the ADEXP format of the flight plan contained the original ICAO4444 flight plan plus additional waypoints relevant to its route. The ADEXP waypoints plan included two waypoints along its route that were geographically distinct but which have the same designator. ....... Although there has been work by ICAO and other bodies to eradicate non-unique waypoint names there are duplicates around the world. In order to avoid confusion latest standards state that such identical designators should be geographically widely spaced. In this specific event, both of the waypoints were located outside of the UK, one towards the beginning of the route and one towards the end; approximately 4000 nautical miles apart. ........... Once the ADEXP file had been received, the FPRSA-R software commenced searching for the UK airspace entry point in the waypoint information per the ADEXP flight plan, commencing at the first line of that waypoint data. FPRSA-R was able to specifically identify the character string as it appeared in the ADEXP flight plan text. Having correctly identified the entry point, the software moved on to search for the exit point from UK airspace in the waypoint data. Having completed those steps, FPRSA-R then searches the ICAO4444 section of the ADEXP file. It initially searches from the beginning of that data, to find the identified UK airspace entry point. This was successfully found. Next, it searches backwards, from the end of that section, to find the UK airspace exit point. This did not appear in that section of the flight plan so the search was unsuccessful. As there is no requirement for a flight plan to contain an exit waypoint from a Flight Information Region (FIR) or a country’s airspace, the software is designed to cope with this scenario. Therefore, where there is no UK exit point explicitly included, the software logic utilises the waypoints as detailed in the ADEXP file to search for the next nearest point beyond the UK exit point. This was also not present. The software therefore moved on to the next waypoint. This search was successful as a duplicate identifier appeared in the flight plan. Having found an entry and exit point, with the latter being the duplicate and therefore geographically incorrect, the software could not extract a valid UK portion of flight plan between these two points. This is the root cause of the incident. ........ Having raised a critical exception the FPRSA-R primary system wrote a log file into the system log. It then correctly placed itself into maintenance mode and the C&M system identified that the primary system was no longer available. In the event of a failure of a primary system the backup system is designed to take over processing seamlessly. In this instance the backup system took over processing flight plan messages. As is common in complex real-time systems the backup system software is located on separate hardware with separate power and data feeds. Therefore, on taking over the duties of the primary server, the backup system applied the same logic to the flight plan with the same result. It subsequently raised its own critical exception, writing a log file into the system log and placed itself into maintenance mode. ........ Now that the root cause has been identified further work needs to be undertaken to trace back through the development and testing of the FPRSA-R sub-system to understand whether the combination of events that led to the incident could have been mitigated at some point in the software development cycle. It is our understanding from the manufacturer that the specific area of software related to this investigation is unique to NATS.

-

Air Stop Tubes- backordered at AS for months?!?

dzeleski replied to 0TreeLemur's topic in Miscellaneous Aviation Talk

They are cheap too, I keep a few spare cores in everything that uses them. Another trick is to fully depress the valve several times in a row and then refill the tire. Sometimes some dirt gets in there and stops it from sealing all the way. -

Broken Mixture Control Cable - Field Repair

dzeleski replied to dzeleski's topic in General Mooney Talk

Didnt think about that I actually keep that in the airplane. I can definitely see that working though. I believe they were replaced during the OH a handful of years ago. Ill double check the books though and make plans to replace them if they werent. -

Engine preheat on the ramp - options

dzeleski replied to generalaviationguru's topic in General Mooney Talk

When I was tied down outside I brought a generator, a meal, and some music. Plugged it in and hung out for 45min to an hour. That was enough time to get the oil and cylinders into the 40-50s which was enough to get it started. I have a reiff XP system which works really quickly especially if you have a sealed cowl cover. You can see the heat times here: http://www.reiffpreheat.com/FAQ.htm#QA2 Do you know which system you have installed? -

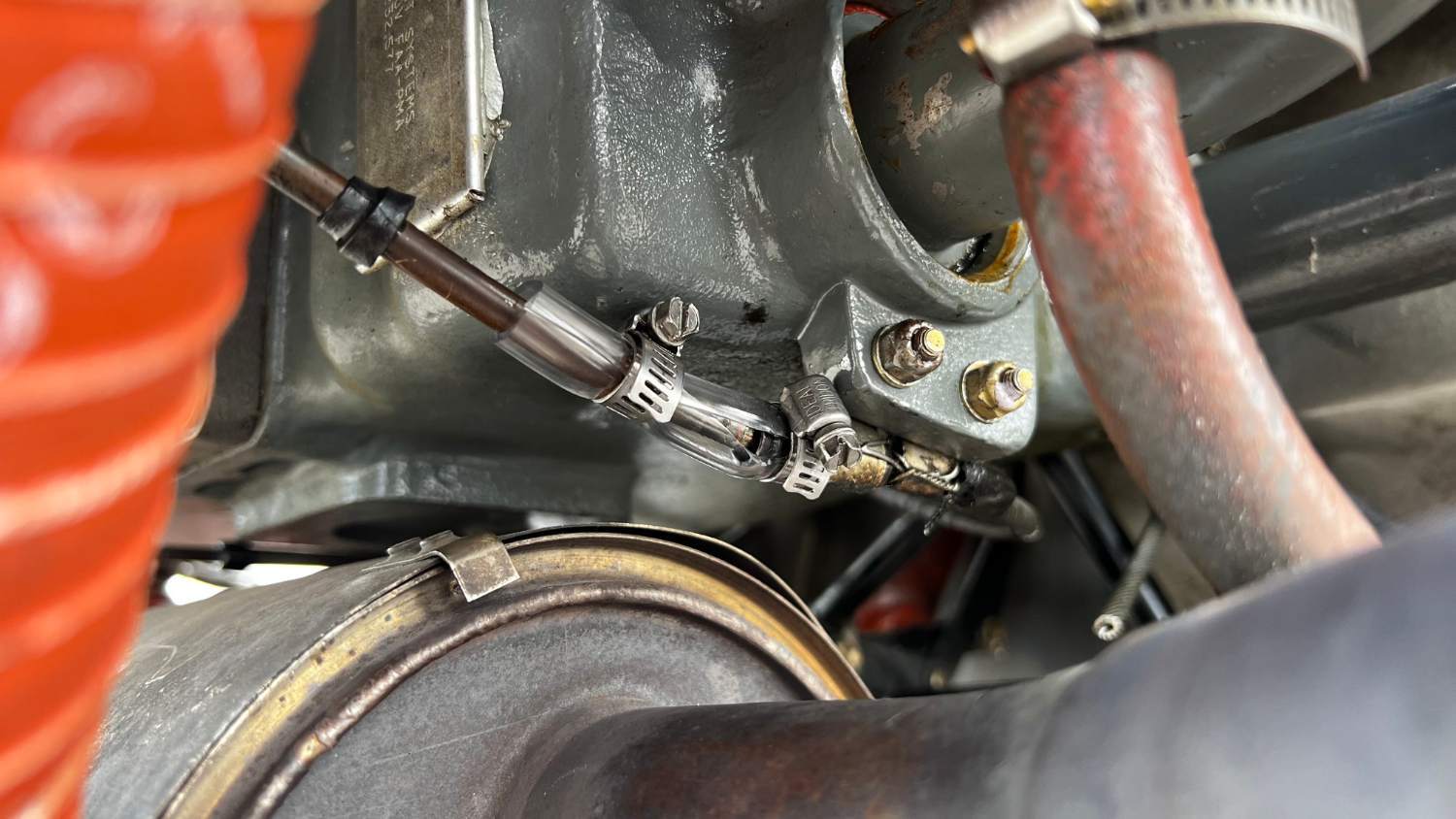

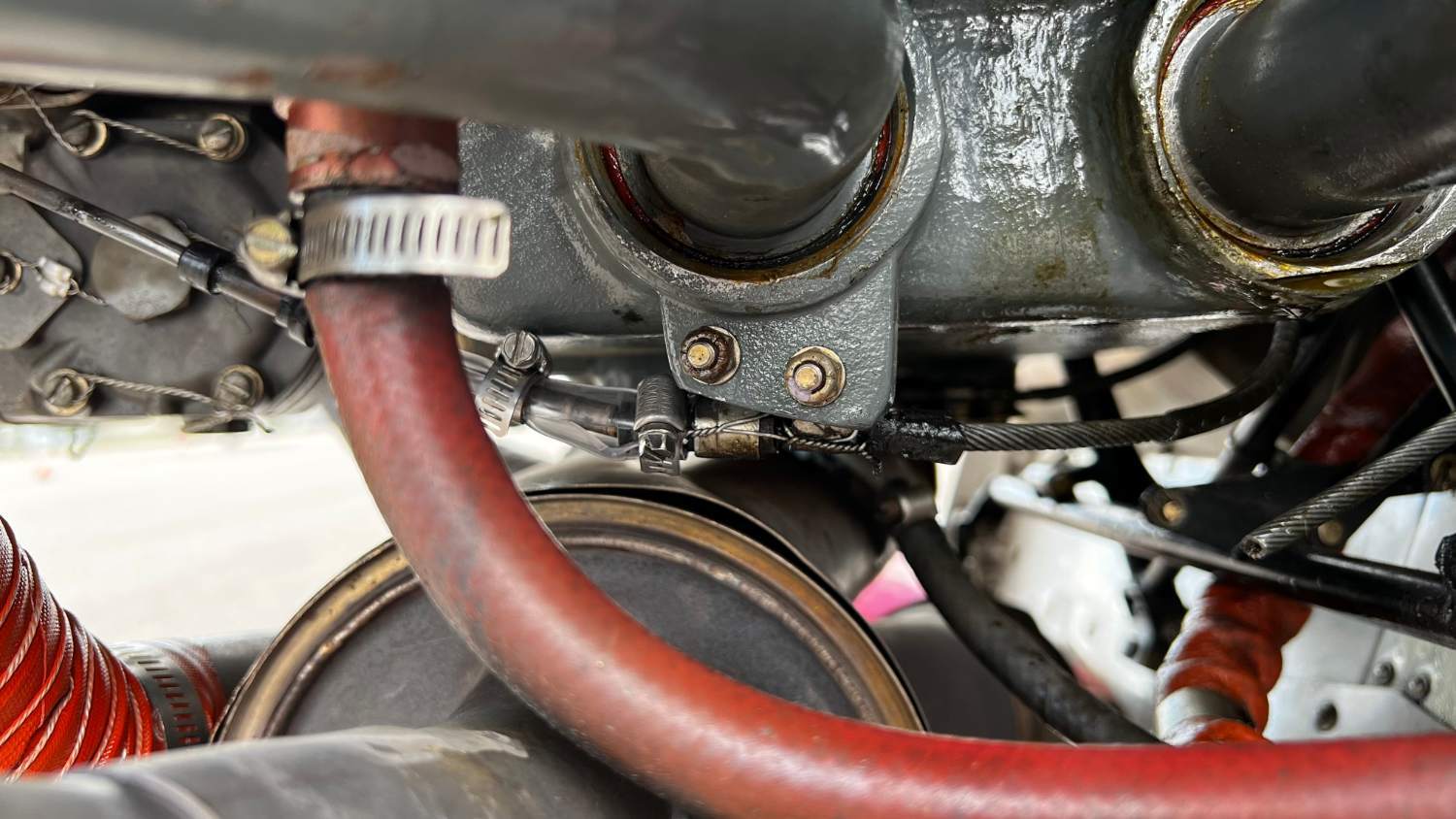

I recently flew from NY to CA and back, on our way back my mixture control on my 77 J started to have issues with ICO. After calling every shop at KAPA and being told they cant help me for 3 weeks or more I called my mechanic back home and asked for some help. He had an idea what it could be and he ended up being correct, the ball joint failed and the end of the mixture control which caused it to bind up before hitting ICO. He told me to run out and grab some tubing and hose clamps and push the ball back into its socket. Well the temp repair worked great and got us home without issues. I figured I would post up some photos of the issue and the repair in case this ever occurs to someone else. Looking back on this problem the engine slowly started to have larger and larger issues going to ICO over a few flights, and inside the airplane the mixture control visibly wasn't coming back far enough. You can see the cable, which you shouldnt be able to, and that ball on the left is supposed to be pressed into the black hole on the right. There is supposed to be a black plastic cover that is crimped over it to keep it in place and you can see that its completely shattered. Please note: This is not a permanent fix. A new control cable was ordered and installed once I returned home. Video of the issue: To fix the problem I bought some 3/8 ID tubing, cut it in half and slipped it over the joint. Then I used two hose clamps to help support the ball joint and keep it together: Video of the repair:

-

"Fine wire spark plugs normally don’t need much cleaning. However, if you do need to get the lead out don’t pry against the electrodes or insulators. If you blast the spark plug, use only high grade, new, spark plug abrasive. Use the lowest pressure possible and blast for only a second or two." Is what it states. It is completely fine to do it to them but its generally not required, lower pressure with the correct abrasive works just fine. The main reason to blast them is if you cant get them clean without requiring a prying effort. Generally when I inspect my plugs half way through the year I only need to blast a single plug, maybe two. Usually I can get everything clean with a solvent and a little pick tool, and even then there isnt much to do. I check gaps as well and will adjust them if they are not in spec but again its usually only one or two that need to be tweaked. Champion has similar instructions as well: https://www.wagaero.com/pdf/Champion-TB16-001-fine-wire-servicing-062216.pdf

-

I don’t know what the core is made of but it’s a coating of iridium which is why minimal blasting is important.

-

You can blast them but you need to use the correct material and the correct PSI on the compressor. https://tempestplus.com/wp-content/uploads/2019/01/Sparkplug-Cleaning-The-Right-Way-081412.pdf https://tempestplus.com/wp-content/uploads/2020/12/1710A_Rev-E.pdf

-

What is the useful load of your J?

dzeleski replied to 0TreeLemur's topic in Modern Mooney Discussion

Yep thats what happens when I try and do things a few minutes after waking up. Its 1731 EW. Thanks, ill update my post above. -

What is the useful load of your J?

dzeleski replied to 0TreeLemur's topic in Modern Mooney Discussion

Yeah the numbers don’t go high enough IMO. My 1977 J is 1009lb UL. I believe it’s empty weight is like ~1731lbs. My J is way to early for the GW increase as well. -

What is your Useful Load in your M20E?

dzeleski replied to Echo's topic in Vintage Mooneys (pre-J models)

I’ll bet someone messed up with the scales or math and it was never caught. Or someone installed a lead weight for fun! -

What is your Useful Load in your M20E?

dzeleski replied to Echo's topic in Vintage Mooneys (pre-J models)

That seems really low for an E. Most of them are somewhere around 900-1000lbs. What equipment does it have other then the tanks? -

Power settings and performance for rocket (Not cruise)

dzeleski replied to wombat's topic in General Mooney Talk

Shock cooling is a myth all together. You can prove it to yourself. Pull the power as far back as you want and descend. Then shut the engine off but leave your engine monitor running. Pull the logs and look at how fast the engine cools when you shut it down. https://www.avweb.com/ownership/shock-cooling-myth-or-reality/ https://www.avweb.com/ownership/shock-cooling-time-to-kill-the-myth/ -

Ideally $0. Contact the shop that did your panel work. They didnt do the job correctly and need to fix this. I would also ask them to check and make sure the rest of them are also correct.