1980Mooney

Verified Member-

Posts

3,510 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by 1980Mooney

-

Not familiar with them but I am well south of the Dallas metroplex. The owner is Robert Vondersaar. He also runs an aircraft maintenance school in Plano. See the details at the end. https://aircraftmaintenanceschool.com They have good online local reviews (14) https://nicelocal.com/carrollton/business/ae_aircraft_engines/ and a few Google - all good (9) BBB shows that they are in business 8 yr and A+

-

From the ICA - General Aviation Modifications, Inc (gami.com) GAMI REPORT 06-6460002, Rev. C, September 1, 2022 Instructions for Continued Airworthiness Page 4 of 6 "The G100UL fuel typically weighs approximately 6.2 to 6.3 pounds per gallon which makes it approximately 3.5 to 5 percent higher in weight per gallon than 100LL fuel (6.0 pounds per gallon). G100UL has approximately 1 - 2% higher energy content on a per volume basis. Therefore, fuel system setups based upon weight per time may continue to use the adjustment values as listed for 100LL fuel. Fuel system adjustments that are based upon EGT values rich or lean of peak remain the same even though the peak EGT when running on G100UL may be different than the peak EGT when running on other fuels. Fuel system adjustments performed on a bench using naptha or similar less flammable fluid should continue using those adjustment values without change."

-

Just to confirm what @PT20J stated, this latest gear actuator failure in 2022 was a Plessey actuator - they call it a torsion spring (not a "no back spring although it performs/grips the same way) and that the GEC (Plessey) actuator is no longer available.

-

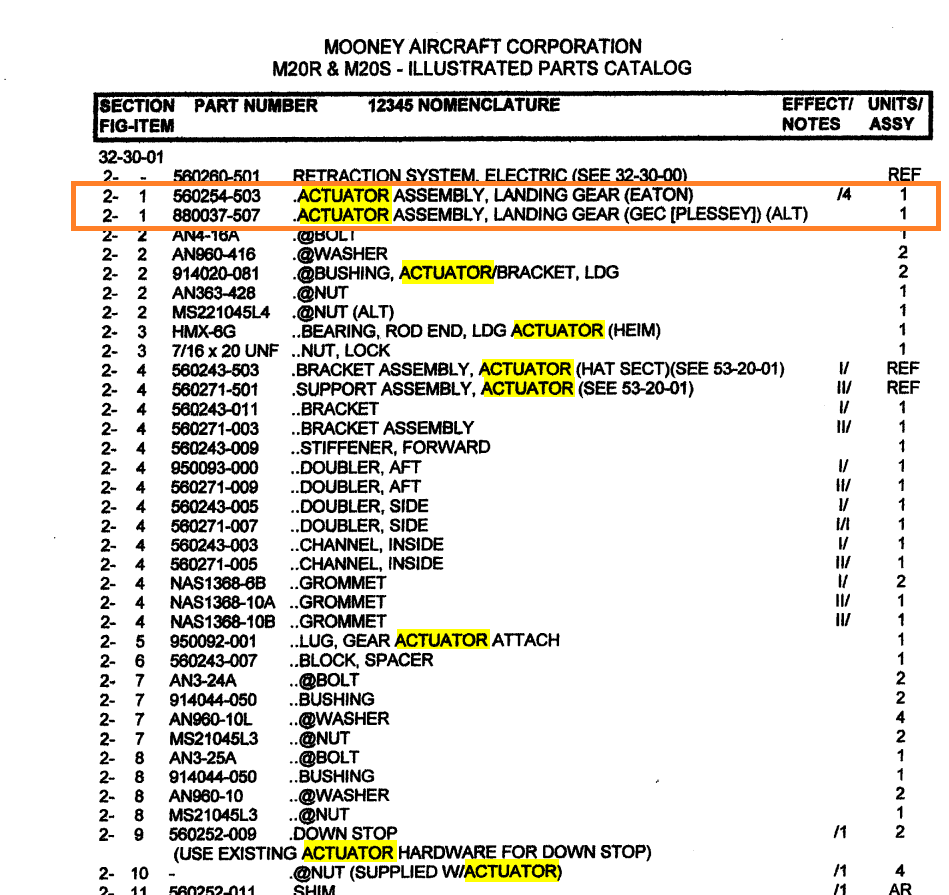

Hard to say. The report by the FAA in 2003 lacks detail. The Mooney M20R & M20S Parts Catalog shows the Eaton actuator first and the GEC (Plessey) as the alternate. FAA Accident and Incident Reporting System (AIDS) GENERAL INFORMATION Data Source ACCIDENT AND INCIDENT DATABASE Report Number 20031030030799I Local Date 30-OCT-03 City TOMS RIVER State NJ Airport Name ROBERT J. MILLER AIR PARK Event Type INCIDENT Mid Air Collision NOT A MIDAIR AIRCRAFT INFORMATION Aircraft Damage MINOR Aircraft Make MOONEY Aircraft Model M20S Aircraft Series NO SERIES EXISTS Airframe Hrs 960 Primary Flight Type PERSONAL Secondary Flight Type PLEASURE Type of Operation GENERAL OPERATING RULES Registration Nbr 2234X Total Aboard 2 Fatalities 0 Injuries 0 Aircraft Weight Class UNDER 12501 LBS Number of Engines 1 Environmental/Operations Info Primary Flight Conditions VISUAL FLIGHT RULES Secondary Flight Conditions WEATHER NOT A FACTOR Flight Plan Filed UNKNOWN Pilot In Command Pilot Certificates COMMERCIAL PILOT Pilot Rating AIRPLANE SINGLE, MULTI-ENGINE LAND Pilot Qualification QUALIFIED Flight Time Total Hours 1597 Total in Make/Model 689 Total in Last 90 days 64 Event Remarks (-23) LANDING GEAR WOULD NOT EXTEND. PILOT LANDED AIRCRAFT GEAR UP. AIRCRAFT RECEIVED MINOR DAMAGE TO THE BELLY PAN, BOTH NOSE GEAR DOORS, AND PROPELLER. THE AIRCRAFT WAS JACKED AND THE GEAR WAS TESTED IN NORMAL AND EMERGENCY SYSTEMS. GEAR WOULD NOT MOVE IN EITHER POSITION. DISCONNECTED GEAR LINKAGE FROM THE LANDING GEAR ACTUATOR AND THE GEAR FREELY MOVED TO THE DOWN POSITION. DISASSEMBLED THE LANDING GEAR ACTUATOR. FOUND THE TABS HAD BROKEN OFF THE NO BACK CLUTCH SPRING PREVENTING THE GEAR FROM MOVING IN EITHER NORMAL OR EMERGENCY POSITION. END REPORT

-

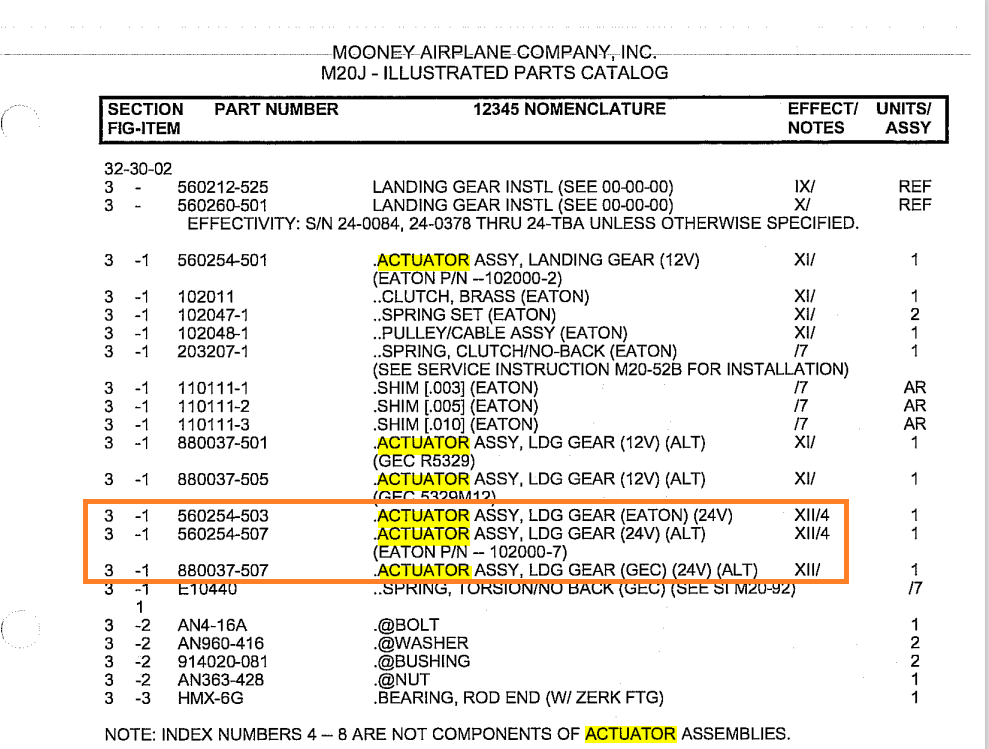

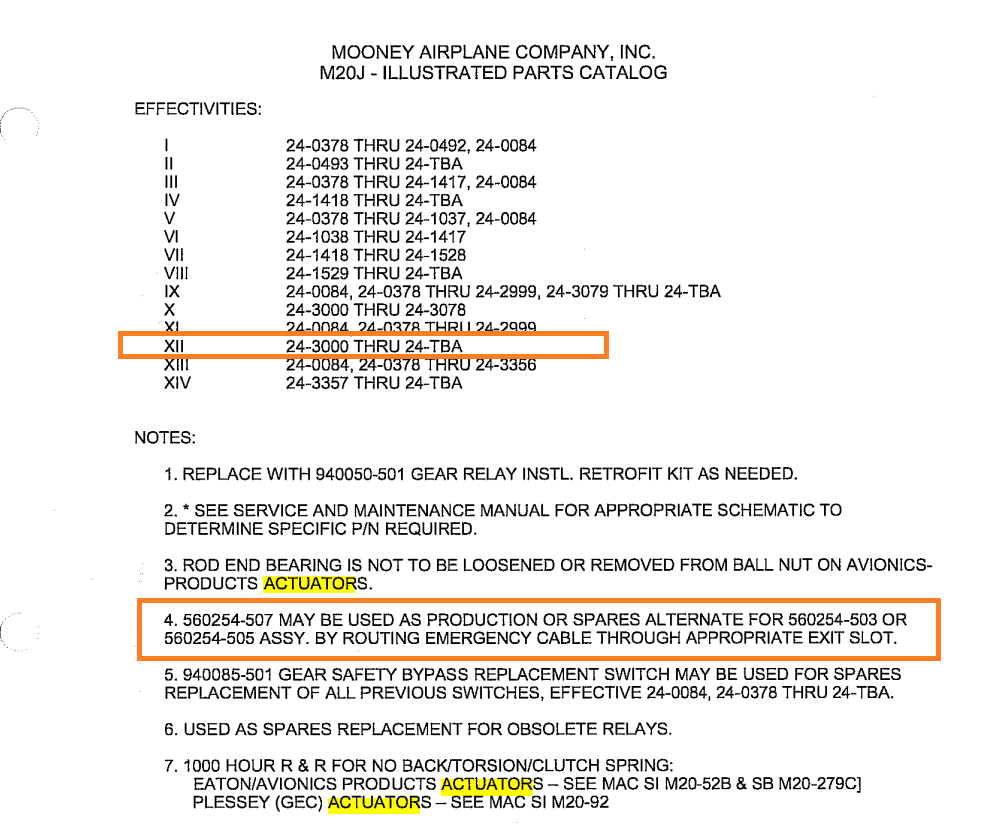

Good point. I mis-read the parts notes. 560254 -507 was originally made by GEC (Plessey) as 880037-507. Then Eaton made it. Confusing. I also had the parts notes highlighted wrong but fixed with edit.

-

NO. That plane is a 1992 M20J - Ser. 24-3261 - 24 volt actuator. Eaton made 3 different 24 volt actuators: 560254 - 503, -505 and -507

-

@StevenL757 Here is the latest No-back Spring "tang" failure documented by NTSB investigation. - November 2022 Report_ERA22LA319_105499_2_2_2023 11_04_56 PM.pdf Analysis After arrival to the destination airport near the conclusion of a cross-country flight the private pilot reported the landing gear circuit breaker (CB) tripped after he attempted to lower the landing gear electrically via the normal method. He reset the CB and again attempted to lower the landing gear via the normal method, but the same CB tripped. He overflew the airport then flew towards the coast where he reviewed the airplane’s Pilot’s Operating Handbook and attempted multiple times to manually lower the landing gear but was unsuccessful. He also contacted his mechanic to obtain assistance, but he was unable to lower the landing gear. At the suggestion of his mechanic, he diverted to a larger nearby airport where he performed a go-around on the first approach because the flight was too fast, then returned and landed gear-up. According to maintenance personnel associated with recovery of the airplane, lowering the landing gear required them to disconnect the push/pull tubes near the landing gear actuator for each landing gear. Further, the emergency cable activation lever would not move and was “jammed….” Following removal of the push/pull tubes near the actuator the emergency cable activation lever would only travel about 90%. Following removal of the actuator from the airplane, manual operation revealed the actuator turned freely in the retracted direction but would not turn in the gear extension direction. Disassembly inspection of the clutch drive assembly of the landing gear actuator revealed one “tang” of the torsion spring associated with gear extension was fractured. By system design the emergency extension system did not bypass the clutch and damaged spring; thus, a single point failure (torsion spring) precluded manual and normal extension of the landing gear. According to airframe manufacturer, the landing gear actuator and fractured torsion spring are no longer available or supported, but they do have a retrofit for the landing gear actuator. An airframe manufacturer service instruction specified replacement of the torsion spring in the drive clutch assembly of the landing gear actuator was last performed nearly 5 years and 427 hours earlier. The service instruction, due every 1,000 hours, was due again in about 573 Page 2 of 5 ERA22LA319 hours. The mechanic who performed the airplane’s last annual inspection nearly 8 months and 49 hours earlier reported that as part of that inspection he performed in part, normal and emergency extension checks of the landing gear and found no issues. He did not perform any maintenance to the landing gear except for lubrication. Probable Cause and Findings The National Transportation Safety Board determines the probable cause(s) of this accident to be: The failure of the torsion spring inside the drive clutch assembly of the landing gear actuator which prevented normal and manual extension of the landing gear. Findings Aircraft - Landing gear actuator - Failure Personnel issues - Use of equip/system - Pilot

-

“To lube, or not to lube, that is the question“

1980Mooney replied to Glen Davis's topic in Modern Mooney Discussion

Some use dry silicone, some tri-flow. See last thread - lots of detail. While you are under the panel don't forget to lube all the hinges and bearings on the linkages connected to the yoke control rod. - Tri-flow or LPS2 on the hinges/linkages/bearings. -

From our friends at BeechTalk : "This airplane was hangared across from me at CZL. It has been in that hangar for the last 20 years. The owners were just getting back into flying after their dad’s passing (he owned it for many years) awhile back. The right seater was an instructor. There is talk that there were some mag issues. After a high power run up, the mags checked ok, after that run up, a takeoff was made. The airplane has never flown very much, but these two brothers were hoping to change that. Very sad to see it in a burnt mangled mess, but glad no one was seriously hurt."

-

In 1967 Mooney introduced a "twisted" wing on the M20F. It lasted one year. I can't find any pictures showing profile comparison but in a MS thread that points out that the 201 M20J wing tips will not fit on a 1967 wing:: "A very clever greybeard at our local Mooney agent, that is a sheet metal expert and does magic with rebuilding just about any wreck, explained and actually physically demonstrated to me why the wingtip could not work. It does not have anything to do with altering the flight characteristics of the airplane or the wing, or anything along those lines. The leading edge on the twisted wing and that of the new style wingtip just don't match. Holding the tip to the wing, it fits perfectly all the way from the back up to about 8 inches from the leading egde. From here on, the shape of the wing is different to that of the tip and the leading edges don't match. The wings' being substantially lower." and "The washout helps improve control as the wing stalls, beginning at the root. The ailerons are the last part of the wing to stall. It could be seen as beneficial if flying too slow and get into an accelerated stall turning base to final, but I think the real world benefit wasn't really there. Some argue it costs a couple ktas. It's the only thing on my 67F that I don't care for, (for aesthetics), but not a big deal"

-

between January 20, 2022 and March 22, 2022. SAP also shipped individual affected intake valves between January 20, 2022 and May 18, 2022. It seems that the it was limited to a very narrow period.

-

Look what we found under the window….Corrosion

1980Mooney replied to c1tice's topic in General Mooney Talk

I didn’t have my coffee this morning… I can only imagine that the OP is sick right now….all excited to launch into an expensive avionics upgrade which has probably been derailed in the middle of the job. All the wiring needs to be detached from the tubulars. Sanding, painting, perhaps stripping exterior aluminum and welding. Additional cost - and replace all the glass fiber insulation. And how was this missed in the pre buy? - either by examining the logs and/or pulling panels. -

Look what we found under the window….Corrosion

1980Mooney replied to c1tice's topic in General Mooney Talk

The first line of his post says "Look what we found while installing a new GFC500". You don't usually pull side panels during an Annual. But the Avionics shop will pull the pilot side panel to run new wiring. And SB M20-208B was issued in 1989 - it is a well known problem that every Mooney should be inspected for and logged and should be checked during a Per Purchase Inspection. SBM20-208B.pdf (mooney.com) -

Yes - easy to say but the challenges that Eaton faces telegraphs that this is not as simple as it sounds. Like much of Mooney there is art to the science - much of which is being lost over time. Some of that knowledge was learned through trial and error - so let's not forget the potential liabilities for a new "supplier". How will it be tested over time? And if a tang fails jamming the gear mechanism leading to a gear-up I would expect everyone to sue the crap out of that supplier.....Unlikely anyone will show up to try this.

-

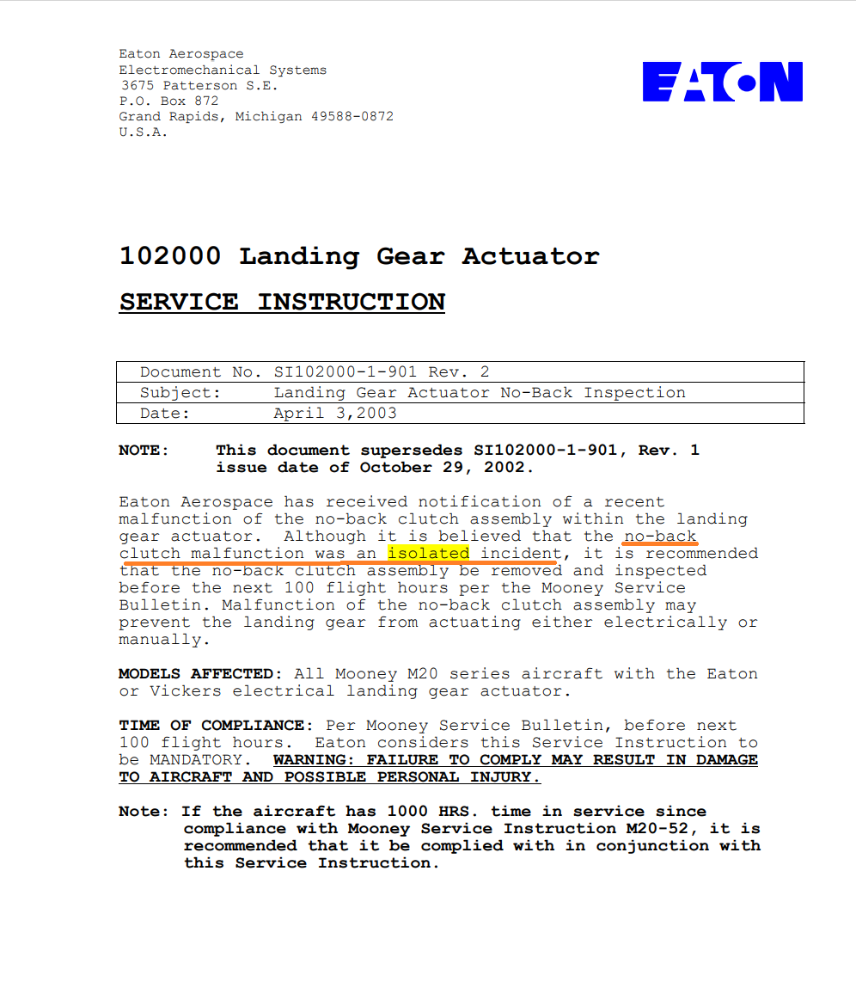

Mooney owners have been chasing their tail on this for 25 years. Back in 2013 on MS it was reported that a single failure in the late 90's led to the SB SBM20-282. Additionally on page 8 of the Service Bulletin (attached) Eaton states that they believe the failure was an isolated incident. And in 2003, the first Eagle M20S Serial number 30-0001 N2234X suffered a No-Back spring failure at 178 hours since compliance with the SB with a "new" No-Back spring. They are all probably Eaton manufacturing (heat treat or material ) quality defects leading to weak "tangs" on the springs that break off. FAA Incident Report: "IN FLIGHT, 178.3 HOURS SINCE COMPLIANCE WITH MFG SB AND MANDATORY REPLACEMENT OF NO BACK CLUTCH SPRING WITH NEW. BOTH TANG ENDS BROKE OFF OF SPRING INSIDE OF LANDING GEAR ACTUATOR WHEN GEAR WAS SELECTED DOWN FOR LANDING. ONE BROKEN TANG APPARENTLY JAMMED BETWEEN THE NO BACK CLUTCH SPRING AND THE NO BACK CLUTCH SPRING HOUSING MAKING EITHER ELECTRICAL OR EMERGENCY MANUAL EXTENSION OF THE LANDING GEAR IMPOSSIBLE. AC WAS LANDED, GEAR UP, UNEVENTFULLY BUT SUBSTANTIAL DAMAGE TOPROPELLER AND BOTTOM OF FUSELAGE WAS CAUSED BY CONTACT WITH RUNWAY. INVESTIGATION UNDER WAY, OTHER REPORTS OF IDENTICAL FAILURES." SBM20-282-A No Back Spring.pdf

-

"leave existing and proven NBC springs in service. " Exactly. What this means is that if your NB spring has not failed by now in the past 20+ years since Service Bulletin SBM20-279C was issued (Revised September 11, 2002) then it is not going to fail. And now we learn that owners which had actuators with perfectly good NB springs, at the cautionary recommendation of the SB, installed (at great expense) potentially defectively manufactured new NB springs from Eaton/Mooney. Apparently through all this Eaton (or its predecessors Eaton/Vickers and Avionic Products) was unable to trace the original 1994 manufacturing defects and is unable to trace and identify (or even recognize defects until others point it out) manufacturing defects in new NB springs that it has been shipping for who knows how long (years?). So now there is a new bad batch of NB springs that have been introduced into the fleet and in service. So that means that @ilovecornfields, or other owners that recently replaced NB springs, may need to "again" replace, as a precaution, the "new" NB spring that he replaced last year as a precaution to begin with...... What a cluster. What a waste of time and money. I have no intention of replacing my NB spring as long as I continue to own this Mooney.

-

Where can I get a replacement interior light switch?

1980Mooney replied to Glen Davis's topic in Modern Mooney Discussion

If you were considering changing those dim ineffective incandescent bulbs in the headliner to LEDs, then there is no need to change the switch. The high low dim feature does not work with the LEDs. - they are just on high all the time regardless of whether the switch is set on low or high. Not sure where you could that bezel other than salvage. -

More time? More surprises or More price?…or all three?!

-

True, On one of the other aviation forums there were comments that Garmin bumped prices twice in 2022. They said Garmin typically raises prices in Q1, but the price increase in June caught the dealers totally by surprise. They said the GPS 175 for example went from $4295 at dealers to $4895 during 2022, ~14% more. And there is an expectation that Garmin will raise prices again this quarter. Also shops have raised hourly rates. Per AINonline the Aircraft Electronics Association’s 2022 Rate and Labor Survey in December showed 8% increase on average. https://www.ainonline.com/aviation-news/business-aviation/2022-12-01/aea-survey-shows-optimism-increased-cost-business So @PT20J 's avionics upgrade today would probably be closer to $90K.

-

Bravo Structural Manual needed

1980Mooney replied to N252MK's topic in Mooney Safety & Accident Discussion

Also one here on MS in “Downloads” https://mooneyspace.com/files/file/184-1999-m20m-service-manual/ -

Bravo Structural Manual needed

1980Mooney replied to N252MK's topic in Mooney Safety & Accident Discussion

It’s online on Manualslib free scroll down to the second Manual https://www.manualslib.com/products/Mooney-M20m-10443462.html -

I thought with the new auto pilot and all the labor to pull the interior, pull all the old wiring out and new wiring to antennas etc. that it would be more. Thanks.

-

Don't forget shipping w/ insurance both ways.......another $80?...more?!

-

"Internal Clock Battery Low" warning and slow acquisition Either. Garmin does not want owners changing the battery and the Dealer provided procedures are not exactly easy to find. From our friends at Beechtalk: "My GTN650 was installed in 2013 and has now begun displaying the "Internal Clock Battery Low" warning all the time. Maybe its my imagination, but it also already seems to be a little slower in satellite acquisition on startup. I was surprised when my (small, but busy) avionics shop said "I don't know, I've never replaced one yet" in answer to my inquiries. They are checking with Garmin, but not yet getting any clear info about their ability to do the battery change vs. the need to send it back to Garmin ($1,000 flat repair fee if I'm not mistaken). The ICA states that we should expect around 10 years out of the battery, so that's one surprise. But it also says it can be replaced at an authorized repair shop or the factory. Of more concern is the lack of info I'm finding so far on what should be a routine maintenance item for a very common instrument. ICA also states that 1-2 months will pass after first appearance of the warning message before critical low state exists, and even then operational symptoms will be limited to slow acquisition only." "Dealer GTN 650 Maintenance Manual, 190-01004-01, Rev. 02 (downloaded from Garmin Dealer Resource Center) for full instructions for replacing the battery (page 5-6). The part number for the battery is in the Service Parts List on page 7-1. Only simple tools are required. No soldering." https://www.beechtalk.com/forums/viewtopic.php?f=21&t=152260

-

Here is the replacement on a GTN 650. It is larger. http://www.rvplane.com/?categoryid=10000&dayid=1456