1980Mooney

Basic Member-

Posts

3,142 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by 1980Mooney

-

In Foreflight go to "Aircraft" Go to "Aircraft Type" In the drop down type "Mooney" or scroll down Within "Mooney" scroll down to M20J You will see a "M20J 205" with your planes flight profile already populated.

-

1986 Mooney 252 w/Encore Mods N97NM

1980Mooney replied to William_Flood's topic in Aircraft Classifieds

Last recorded flight in September was near York, UK, about 200 miles north of London. https://www.flightaware.com/live/flight/N97NM -

Prop Strike and Engine tear down requirements.

1980Mooney replied to Schllc's topic in Modern Mooney Discussion

I am curious to know if you had a chance to review the entries in the engine and airframe logs. Rather than relying on broker hearsay what did the A&P and IA actually enter? And is there any written documentation from Continental attached to the logs or in the maintenance file? -

Although the knee-jerk reaction is to ridicule and blame the news media, "journalism" didn't have anything to do with it. Perhaps you didn't closely read @smwash02 's post above. He copied the the exact data entry that appears in the FAA Aviation Safety Reporting System (ASRS). The FAA intentionally "obscured/disguised" some of the identifiable information, which was self-reported by the pilot. The fourth line under "Aircraft" says Make Model Name : M-20 T Predator

-

Is that bare aluminum showing through in the picture or a gray primer under the white paint? I can't tell from the pic - your camera focused on the background and not the leading edge. If it is bare I would think that you need to alodine treat it and spray a primer. Have you considered a leading edge tape? https://www.aircraftspruce.com/catalog/cspages/leadingedgetape.php

-

Since you will need reliable dispatch Monday- Friday in the "cold Midwest" and destination now mainly in the "cold" Northeast, you will need a plane with FIKI - flight into known icing. The system includes dual alternator, dual pumps, fluid alone weighs 54 lbs. (6 gal x 9 lbs) That adds about 92 lbs. weight per @LANCECASPER - The turbocharged 252 and M will have an O2 bottle adding about 40-50 lbs. Your mission requires you to occasionally fly 3 passengers ... 800 nm.....I assume luggage. If you have 4 males on board - let's assume 200 lbs each (and that may be an underestimate now days) - add 100 lbs luggage. WITHOUT ANY FUEL, you will be near or above useful load of most Mooney's with FIKI. I have a hard time seeing how this fits your mission. Any one of the 3 Mooney's will be fine for pilot and 1 pax. Your other 2 collogues will have to fly commercial or drive.

-

Per @LANCECASPER the answer is “NO” - Not legal to fly

-

Since @Andrei Caldararu is in Wisconsin, here is a Backcountry Pilot pirep on wing covers outdoors. "Oh boy, been down this road so many times back when we had Winter in SE and no hangar. It’s a real pain in the ass, especially when you need to fly for something other than fun. We had the full on portable garage...windshield, tail, engine, prop...all covered. Piece of cake in cold snowy weather but a nightmare in the wet/freeze/rain conditions. Lots of years that way. Sometimes it was so bad that we would have to go hat - in - hand on bended - knee and ask a neighbor with a hangar for a quick defrost to get them off. Solid, frozen wing covers are the worst. Get the mesh ones with the spoilers on them as Mike suggested. I think Kennon makes them? When they freeze on its way easier to get them off. We carried a can or two of that windshield de-icer stuff or a small pump sprayer with diluted isopropyl alcohol. Works amazingly well on what’s left, if there is much left. Usually it’s clear enough. When they go back on they may be wet but at least it’s not solid wet like the nylon covers." and "Wing covers are usually used to keep frost off the wings. They don’t work well if you leave them on long term through snow/thaw/freeze cycles. If the covers are wet from an above freezing day, you need to take them home and dry them out well. Usually the problem isn’t ice on the wings from frozen covers, it’s trying to tear frozen covers off the wings. If you have lots of ice on them - take them home. Covers should be dry, just shake all the snow off and roll them up, should not get wet at all." Sounds like they will take more time than the commute to the distant hangar. Here is a video making them look so easy - it's a high wing but they have 2 people doing it and it is in a hangar - NO WIND. Geez you don't need them in a hangar. Let's see real world. And with a low wing you are crawling around on the ground trying to clip the straps.

-

I don't think it is "1 hour" difference. I believe you have overlooked some of the time that you will save with a hangar. You posed it as a 40 min. drive vs a 15 min. drive each way. That is an extra 25 min. commute each way and only an extra 50 min. commute in total to start with. But if you have it tied down, covered, engine plugs, pitot cover it takes some time to remove them and fold it up and stow it somewhere. And it takes longer to put it all back on - and if the weather changes as you land - i.e. windy or rain starts - it takes even longer. I bet you save at least 15 minutes total - maybe more What if it is a beautiful clear winter afternoon in Wisconsin, perhaps hovering around freezing, maybe slightly above? - in the hangar there will be no ice, slush or stubborn ice stuck in the shadows to clean off. What if you land after sunset? - you can push it into your lit hangar. There will be no fumbling around in the dark, losing time trying to put the cover on and tie it down. You will have lights, power and supplies handy to check/add air to the tires and check/top off the oil saving time. Depending on the airport and policy, you may be able to park closer with the hangar (or in the hangar) and save time. In the hangar, there will be less chance of rainwater/slush getting past the fuel caps - hence less time spent sampling/draining accumulated water out of the sumps. And there will be less chance of the unforeseen delay - animals in the cowling or making nests in the empennage, cleaning bird crap off the prop or antenna where birds have chosen to perch, etc. (when I was young my neighbor, who had his Bonanza tied down, had a small animal crawl out the front of the cowling as he revved the engine up for the first start on a cool day. - they lost a lot of time cleaning that mess up)

-

Spin on oil filter busted at the seams

1980Mooney replied to woodman86's topic in Vintage Mooneys (pre-J models)

It hasn't been mentioned but imagine if the seam/crimp let go as you were taking off or in some miserable IFR conditions. You might not be here to make this post. I find the initial response from Tempest to be unprofessional and irresponsible. Rather than dismiss it as "your problem", they should have been all over it and should have offered to pay you to send the burst filter to them for examination. If they have a manufacturing quality control issue, which they are failing to investigate even after being warned of premature failures, and it results in a crash then there will be a mega lawsuit. And this potentially isn't just a "Vintage Mooney's (pre J)" category issue. We should be reading about this on the next to last page of "Aviation Safety" in the "Squawk Box". -

Spin on oil filter busted at the seams

1980Mooney replied to woodman86's topic in Vintage Mooneys (pre-J models)

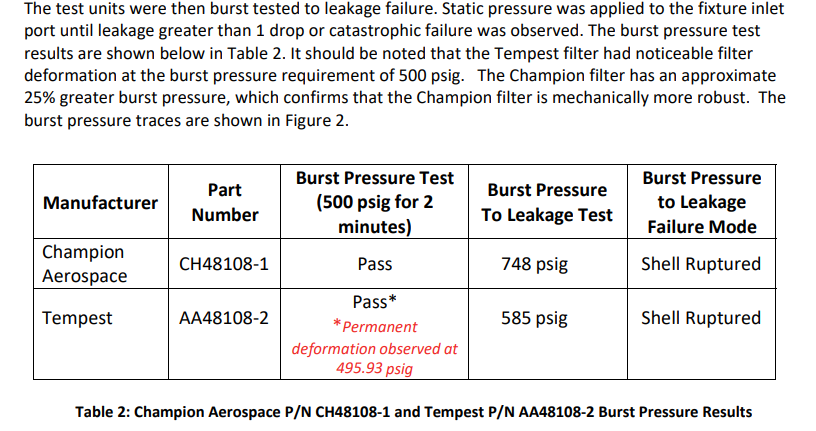

Right - the Tempest filter is structurally inferior to the Champion filter. But it still takes about 500 psi for 2 minutes to deform the Tempest filter (assuming it was manufactured to their normal spec). It is almost inconceivable to believe that your engine oil pump was at 500 psi for several minutes. That would mean you have a total solid blockage somewhere. More likely @RLCarter is right and it is just poor quality control in manufacturing at Tempest. Beechtalk noticed this before also over the last few years: BeechTalk - BT - Oil seeping at oil filter seam / crimp -

I see you just joined Mooneyspace (MS). @Parker_Woodruff is a MS member/pilot that is also an aircraft insurance specialist/broker. He can answer your questions and also arrange for your insurance should you purchase a Mooney.

-

@PT20J is right - there are quite a few salvage out there because the J and K used the same mid and outboard "Flap Hinge Fairings". A pristine set of 4 mid flap hinge fairings just sold yesterday by BAS Parts on ebay. From Section 53-50-00 in the Parts Manual 210379-009 Left wing - mid hinge fairings (2) 210379-010 Right wing - mid hinge fairings (2) 210379-011 Left wing - outboard hinge fairing (1) 210379-012 Right wing - outboard hinge fairing (1) The inboard hinge fairings vary depending upon serial number in both J and K but there is overlap between models. There are 2 different sets of inboard hinge fairings depending upon serial number 210398-001 and -002 210398-003 and -004

-

I am just going to put this out for information so that we "don't reinvent the wheel" and also remember what "advice" we have posted previously. Let's face it - we are mostly discussing how to fly/maintain planes of similar basic design that are mainly 15-60 years old. Avionics aside, there isn't much "new" that hasn't been questioned on MS before. Sometimes there are a lot of "best practices" which we have forgotten. Your question of how to lubricate fuel cap o-rings has been discussed in a topic that has been going for 10 years now on MS. Since 2013, many Mooney owners have been discussing in the same thread how to lubricate and replace the o-rings on the fuel caps. The thread also includes, on page 1, detailed instruction from our Beechcraft friends at CSOBeech on how to replace o-rings on the same type Shaw fuel caps. (It does require some disassembly of the cap locking mechanism) https://csobeech.com/files/O-RingChange.pdf https://csobeech.com/o-Rings.html I AM NOT ADVISING YOU TO CHANGE ANYTHING, but if, after inspection per SB-20-229a, that you discover that your o-rings are deteriorating, then discuss it with your A&P. He might allow you to change them "with supervision", inspect and sign off. After all, taking "preventative maintenance" action to keep water out of your fuel is a safety benefit. And the FAA Circular states "Owners and pilots must use good judgment when determining if a specific function should be classified as preventive maintenance." Lastly, in 2022 on the last page of that same thread, @PT20J shared his fuel cap lubrication recommendations. I assume these are still his recommended "best practices": "If you spray a bit of Tri-flow on the shaft and work it a few times every so often it keeps the center o-ring lubricated and pliable. If you keep some vasiline or DC-4 on the large o-ring, it also makes it last longer. I tried EZ Turn, which lasts longer, but it’s too sticky. A lot of mechanics take the easy way out and just replace them every year. I had the black ones on my first plane for 7 years and kept them lubricated and they never were a problem. You can tell when they’re shot — they develop radial cracks."

-

I noticed that @RescueMunchkin joined MS earlier this month and may be a new owner/aviation enthusiast. And I see that @PT20J followed up this post with guidance per Service Bulletin 229A. Just to be clear so there is no misinterpretation, this is the type of "Preventive Maintenance" which an owner can do. (and do it without having to first seek the approval of an A&P or having it observed/signed off by an A&P). AOPA summarized FAA P-8740-15. Among other things it states "6. Lubrication not requiring disassembly other than removal of nonstructural items such as cover plates, cowlings, and fairings." An owner can do a lot of things without A&P authorization including replacing seat belts, replacing non-structural fasteners, remove/clean/repack wheel bearings, grease the landing gear, replace fuel lines, remove and clean/gap spark plugs, replace cotter keys and safety wiring and more. However it is all prefaced upon the owner self assessing that "you have the ability to perform the work satisfactorily and safely." Although you don't need the approval of an A&P, it doesn't preclude or hurt you telling your A&P what you are planning to do. In fact if you are a new pilot/owner it is probably good to run it past your A&P but it is still a task that you can perform. https://www.aopa.org/news-and-media/all-news/2012/june/01/answers-for-pilots-preventive-maintenance https://www.faasafety.gov/files/gslac/library/documents/2011/Aug/56398/FAA P-8740-15 Maintenance Aspects of Owning Your Own Aircraft [hi-res] branded.pdf https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC_43-12A_CHG_1.pdf

-

Exactly. By filling the tanks you can easily add about 400 extra pounds of fuel that you don't really need right over the mains - and you will kill the shock discs even faster. You are right - a short body with 52 gallon tanks sits on the same shock discs as long bodies (most with 100 gal. tanks - even the early ones had 89 gal.), and anyone with Monroy's which have about 100 gal.

-

Geez - $800 for an appraisal? "You send them all the info and they do the appraisal without having to actually inspect" Seriously? Maybe Annuals will be like that in the future. We take our own compression readings, take some pics....send it all to your IA and he signs off without having to actually inspect....

-

Do you still have the original fixed prop? Or has the plane been converted to a "C"?

-

You may find this reprinted AOPA PILOT review of the 1984 Mooney M20K 231 interesting (April 1984). https://aeroresourcesinc.com/proj98-ci/WebContent/uploads/198404-1984 Mooney M20K 231.pdf

-

Pre-Buy is another hotly debated subject. Just make sure that they look closely for interior corrosion -

-

Sorry about that. Unfortunately, I can't find a 231 POH anywhere online free now. The old sites like Sparrow Flying Club, Delta Aviation, Monticello Flying Club, etc either no longer exist or no longer have a 231 and as a result took down their 231 POH pdf.

-

This is a great resource for all things Mooney: https://www.knr-inc.com/shop-talk-articles.html This may be too much too soon but the Continental engine has it's own quirks and additional manuals to supplement the Mooney M20K Service Manual. (operation, adjustment (especially the continuous fuel injection), overhaul) https://www.knr-inc.com/shop-talk-articles.html?view=article&id=94&catid=25 https://www.knr-inc.com/shop-talk-articles.html?view=article&id=98&catid=25 https://www.knr-inc.com/shop-talk-articles.html?view=article&id=38&catid=25 https://www.knr-inc.com/shop-talk-articles.html?view=article&id=118&catid=25 TCM SID97-3E (again) - Tennessee Aircraft Services, Inc. http://www.kellyaerospace.com/articles/ContinuousFlow.pdf https://pceonline.com/wp-content/uploads/2017/04/M-0standardpractice2017-01-15.pdf Continuous Flow Fuel Injection Systems Adjustment Specifications and Instructions (twincessna.org) Cont. Motors SID97-3G (Latest) https://www.scribd.com/document/433794061/TSIO-360-Overhaul-Manual

-

@Crawfish Also - The "manualslib" M20K Service and Maintenance Manual is the only one that I have seen that has the Electrical Schematics. You find them in 7 "Envelopes" after Chapter 91-30. You definitely want to download and save this one. You will find all the mechanical parts in the Parts Catalogue. You will find all the electrical parts in the back sections of the Service and Maintenance Manual. (Chapter 91) As stated above you will find all the wiring and electrical schematics in the Service and Maintenance Manual after Chapter 91 - referenced to Serial Number of your plane.

-

You can download the Service Manual for free here. https://www.manualslib.com/manual/1368102/Mooney-M20k.html#manual