1980Mooney

Verified Member-

Posts

3,762 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by 1980Mooney

-

The owner joined Mooneyspace last year. Getting service there is obviously a big problem. It’s not surprising that he is selling.

-

It may not be the primary cause but it chips away at and adds a bit faster rate of decline of the fleet. It's the loss at the small airports that rarely get mentioned. Here is a poor Mooney at Hendersonville Airport (0A7), NC that was submerged in 9 ft of water (video incorrectly states 3 ft. initially but it was 9 ft. of water) It floated up and pushed under the hangar door. You can see the water level in time lapsed pic in another hangar. The plane is covered inside and outside with silt. Other planes seen in the video shared the same fate.

-

Interesting article but it doesn’t seem to have anything to do with the OP’s question of higher observed fuel flow.

-

If the fuel flow is actually materially higher than you normally observe at a particular altitude/MP/throttle/speed, shouldn’t you also see a material difference in the temperatures that you normally observe? You say “cht, egt, tit, seem to be as they should.”

-

Looking for the owner of this plane N6817V

1980Mooney replied to Schllc's topic in Vintage Mooneys (pre-J models)

It appears to be at Moriarity Municipal Airport, Moriarity, New Mexico (0E0) (East of Albuquerque just off of I-40). It has great thermals and is a favorite for gliders/soaring. It flew from South Lake Tahoe to Moriarity on August 25, 2022. https://globe.adsbexchange.com/?icao=a90a4f&lat=38.027&lon=-113.028&zoom=6.3&showTrace=2022-08-25&trackLabels It flew pattern work a few times out of Moriarity Sept 25, 2022 https://globe.adsbexchange.com/?icao=a90a4f&lat=34.910&lon=-106.085&zoom=12.0&showTrace=2022-09-25&trackLabels Oct. 25, 2022 https://globe.adsbexchange.com/?icao=a90a4f&lat=34.910&lon=-106.085&zoom=12.0&showTrace=2022-10-25&trackLabels Nov. 12, 2022 https://globe.adsbexchange.com/?icao=a90a4f&lat=35.049&lon=-106.098&zoom=12.5&showTrace=2022-11-12&trackLabels Feb. 18, 2023 https://globe.adsbexchange.com/?icao=a90a4f&lat=34.982&lon=-105.982&zoom=13.4&showTrace=2023-02-18&trackLabels April 2, 2023 https://globe.adsbexchange.com/?icao=a90a4f&lat=34.982&lon=-105.982&zoom=13.4&showTrace=2023-04-02&trackLabels July 1, 2023 is the last shown flight https://globe.adsbexchange.com/?icao=a90a4f&lat=34.977&lon=-106.071&zoom=13.4&showTrace=2023-07-01&trackLabels I would call the FBO or the 2 businesses on the airport and ask around - phone numbers are listed. AirNav: 0E0 - Moriarty Municipal Airport -

The video is gone. It says "Copyright claim by Lycoming Engines"

-

Superior filed bankruptcy in 2008. The Chinese bought them. In addition to building up Lycoming licensed engines, they also tried to bring out their own 4-cylinder engine for the Experimental market: "In March 2019 the Superior Air Parts XP-400 and Superior Air Parts XP-382 engines were withdrawn from service and all customer engines were subject to a mandatory, immediate buy-back by the company to remove them from service. The company made this decision based on detonation problems found in some XP-400 engines that could not be resolved. Due to parts commonality, the decision was made to buy-back the XP-382 engines as well." There was a news story that they paid Vans $5 million in a settlement when the crankshaft broke on an XP-400 that killed 2 people. Just about everything Superior has touched in the last 15 years has turned to crap.

-

I think there was an AD in 2020 that recalled all the Superior built Lycoming IO-360 and O-360 engines due to bad crankshafts. FAA finalizes Superior Air Parts crankshaft AD - AOPA Between the Superior cylinder Airworthiness Directives in 2013 and 2019 and then the crankshaft problem: "Superior = Inferior"

-

Cigarette Lighter socket as USB power source

1980Mooney replied to PeterRus's topic in General Mooney Talk

My bad. I can't read..... -

Cigarette Lighter socket as USB power source

1980Mooney replied to PeterRus's topic in General Mooney Talk

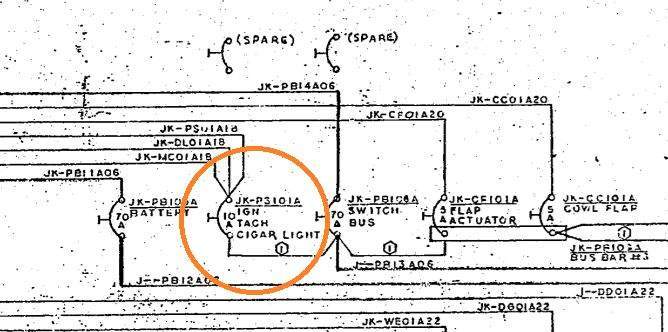

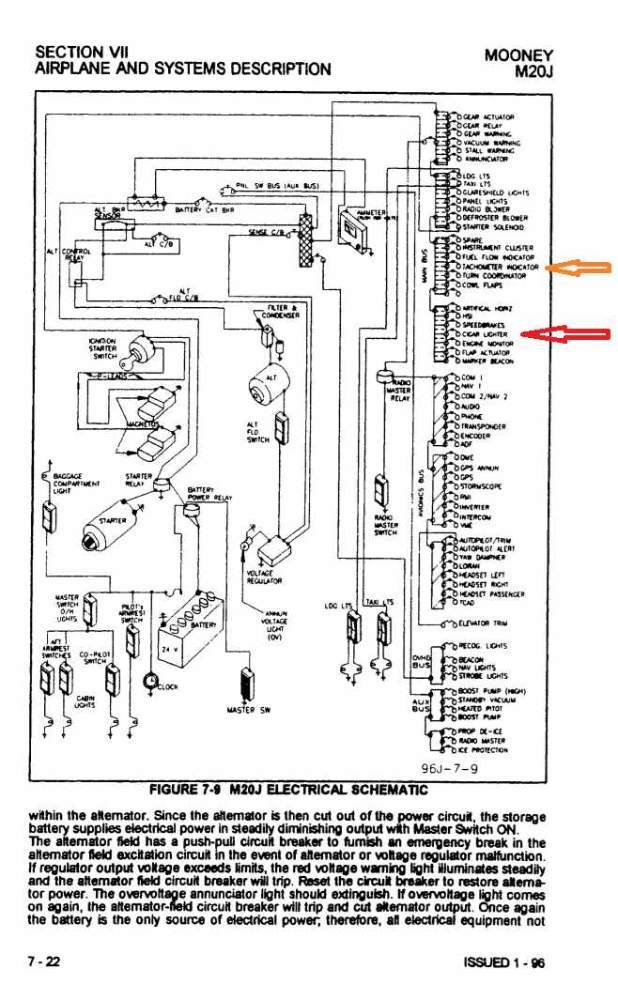

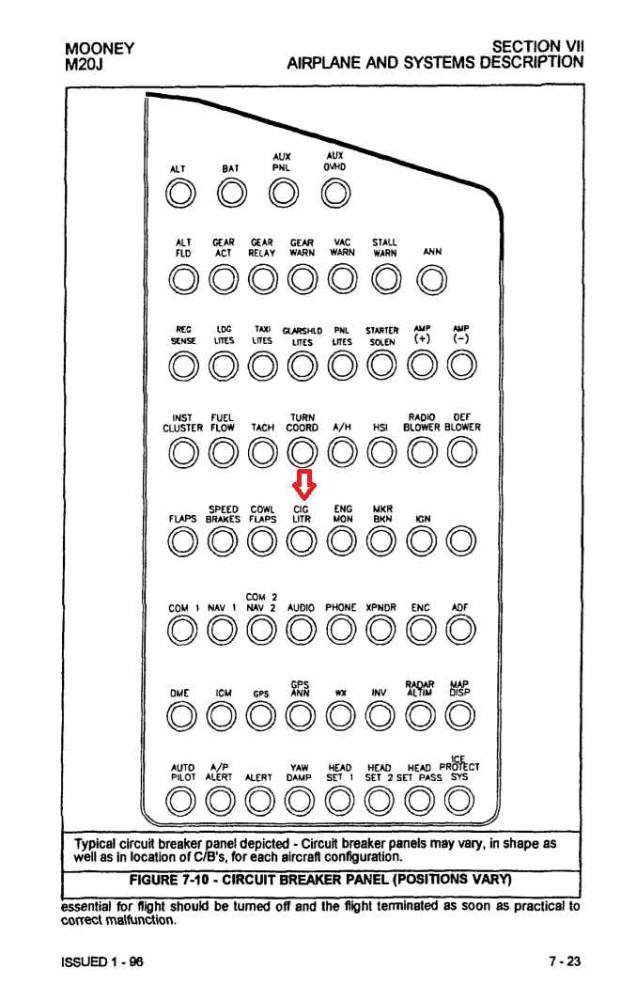

I don't know what year MSE you have, but the first ones starting with serial number 24-3144 had the "Cigar Lighter" on the same 10 A circuit breaker as the Ignition Switch (starter solenoid) and Tach. I believe the later ones were also on a 10A breaker. The POH (at least some of the later versions) showed the breaker labelled on the circuit breaker panel as "CIG LITR". You mention a multi port adapter with 20A per port - watch your load or you will be popping the breaker. Frequent tripping of the breaker will weaken it and make it trip more easily. If the circuit breaker was dedicated to the Lighter only it would be a non-issue but since it shares the Ignition Switch and the Tach, that is why some recommend putting the USB power supply on a separate dedicated circuit and breaker. Just be prudent. -

Yes that is correct - Thanks. My autospell checker is my enemy and I am terrible about proof-reading (I see what I meant to write and not what I actually wrote).

-

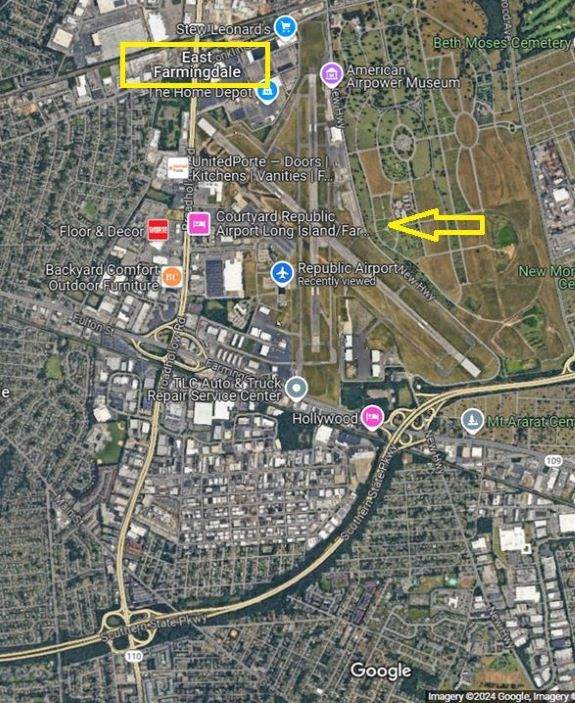

This is some ancient ATC tape that likely has been altered (compressed). I think this happened over 15 years ago and the graphics are just someone's "artistic creation" - maybe the whole thing has been doctored to enhance someone's Youtuber subscription following. The idiot can't even spell Mooney...."Moony". I bet it is just a machine phonetically trolling ATC tapes. AI at work! The Future..... N3277F last flew 7 years ago in 2017, before it was scrapped and deregistered following a gear up. Additionally the graphics depict Republic Airport (KFRG) Farmingdale, New York (Matches the controllers accent). The last time that particular Mooney was owned and based in the NY area was 2010 when it was sold to a Texas owner. N3277F, a 1967 M20F, had a gear up landing at Farmington, New Mexico (KFMN) in July, 2017. If was then scrapped, auctioned, purchased by Texas Aircraft Salvage and deregistered upon dismantlement. This plane did not appear to be ADS-B out compliant. On the salvage form this hapless F had only "Narco MK12D, Narco AT150, Narco 890 DME, King KMD 150" for avionics. http://www.kathrynsreport.com/2017/07/mooney-m20f-n3277f-incident-occurred_7.html http://www.avclaims.com/N3277F.htm http://www.avclaims.com/n3277f_photos.htm

-

Can you elaborate?

-

What can cause a magnetized cage in the Ovation?

1980Mooney replied to Ed de C.'s topic in Modern Mooney Discussion

Are you talking about this? https://mooney.com/wp-content/uploads/2020/12/SBM20-150A.pdf -

What can cause a magnetized cage in the Ovation?

1980Mooney replied to Ed de C.'s topic in Modern Mooney Discussion

Been discussed before. Everyone in old topic below says an AC cord cannot magnetize anything because it keeps alternating and reversing fields. DC power cords will magnetize the steel frame. Your 28v wires either zip tied across or along the tubing are more likely to cause magnetism. In 25 years of the same plane, I have had corded vacuums, lights, power tools in the cabin - sometimes for long periods like while replacing cabin insulation. One especially humid Gulf Coast winter in a crap hanger without sealed concrete I had a low wattage incandescent light with a small fan running continuously in the cabin for a while. Never a problem. As @Hank says, a canister on the wing with a hose may work better given the limited space. Also the motor heat blowing into the cabin is unbearable most times. I generally also just set on the wing. -

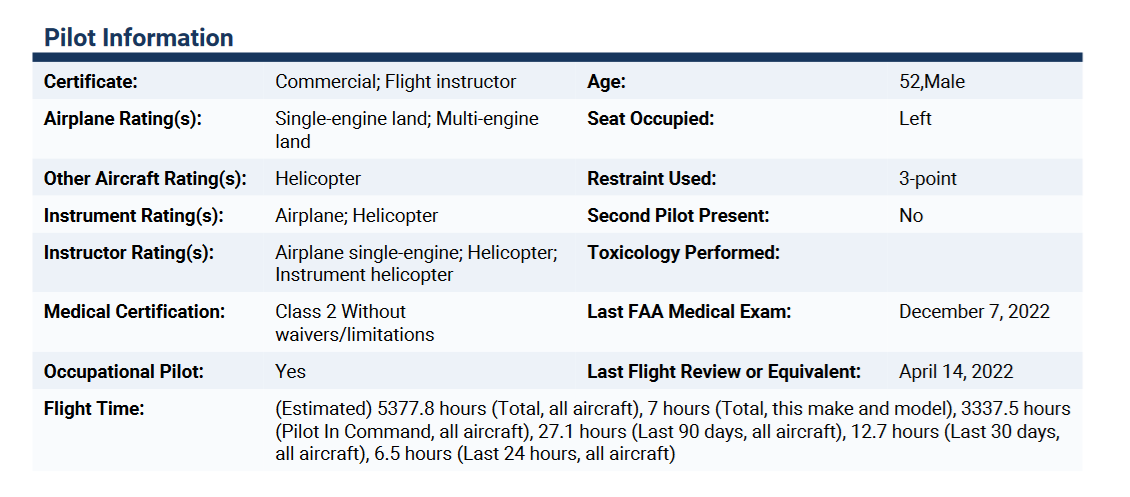

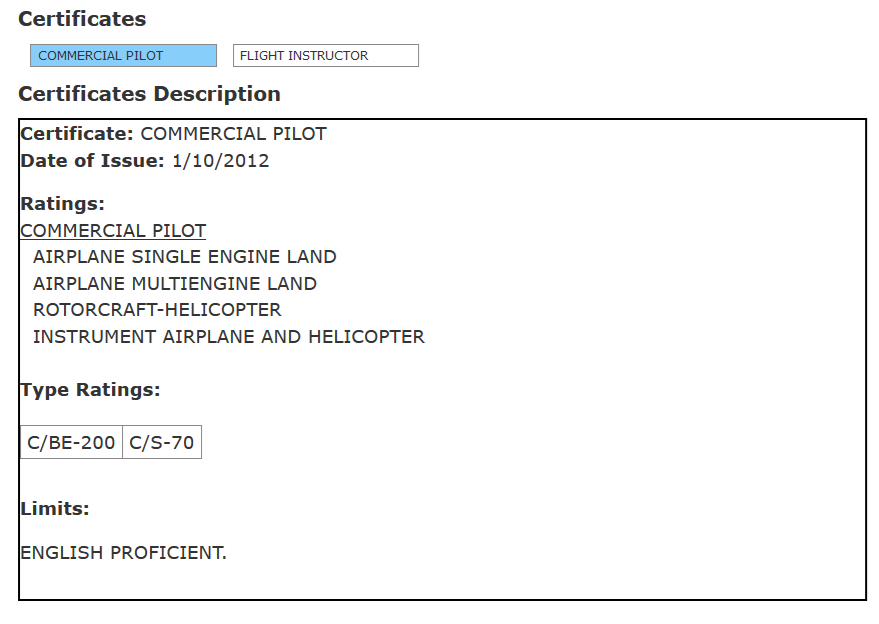

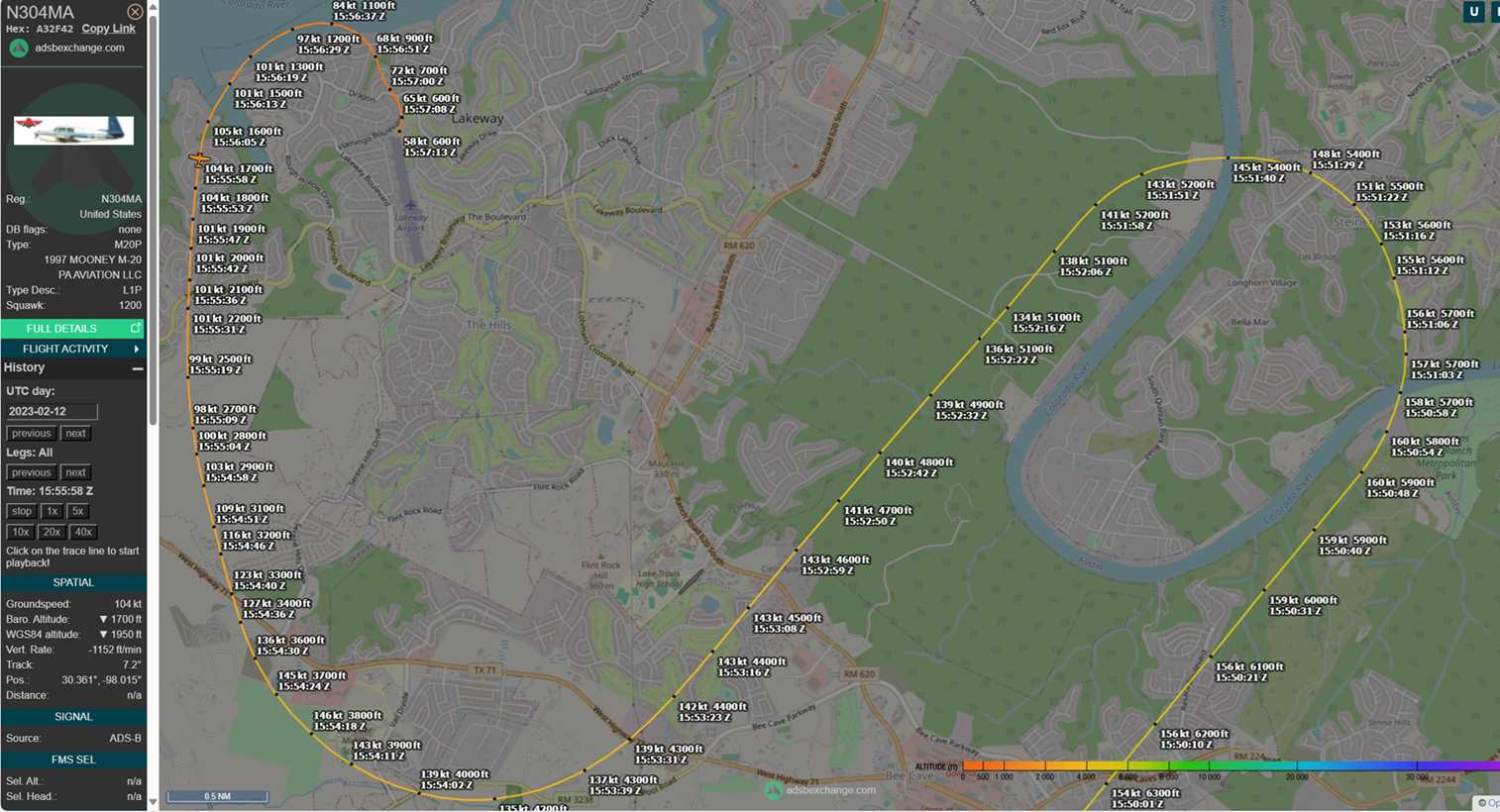

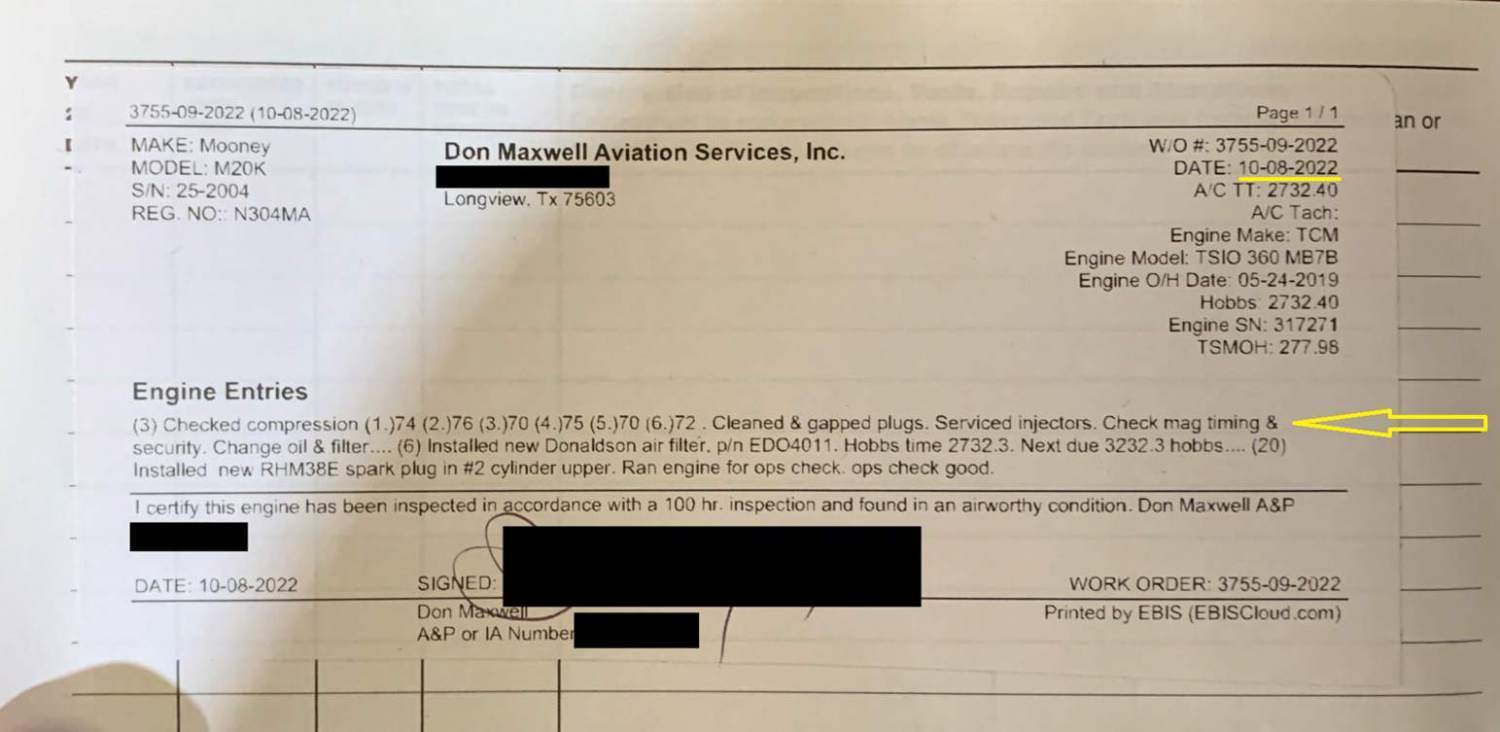

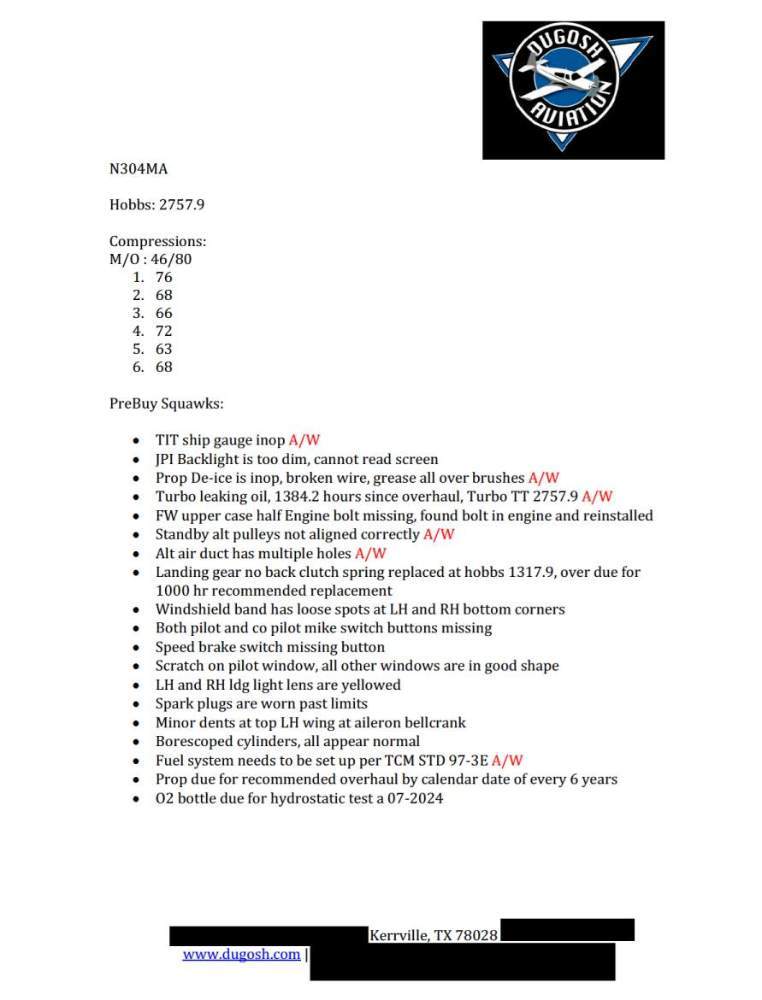

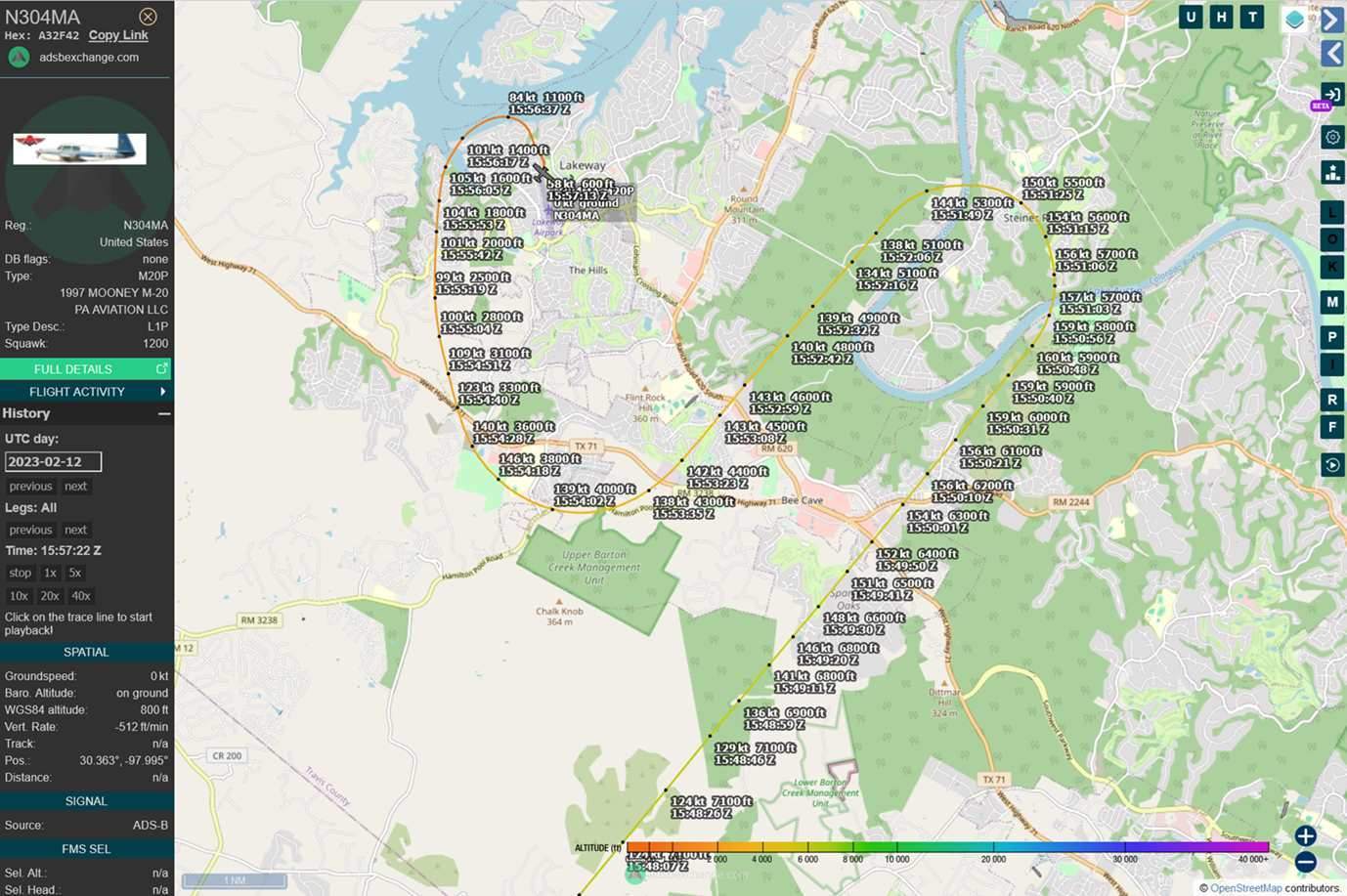

All interesting. The Aircraft, Engine and Prop Logs are in the Docket from 2018 on to the time of the accident. This Encore was owned by PA Aviation LLC in Burleson, TX from 2012 to just before the accident on February 12, 2023 The plane was in Kerrville (presumably Dugosh) from January 16-23, 2023 and then returned to Kestrel The new owner (Commercial & Helo Pilot/CFI owner and PIC during crash) appears to be flying transition training on February 11, 2023 - the day before the accident The plane flew from Kestrel in 6 legs eventually back to Kestrel - total duration 6.5 hours ADS-B Exchange - track aircraft live (adsbexchange.com) While owned by PA Aviation LLC, the owner seemed to have mostly the "best of the best" work on the plane All Annuals were done by Maxwell during the entire period (before and after the Overhaul) In July 2019 Maxwell performed the Overhaul with the engine done by Jewel In August 2019 LASAR in California worked on the plane - entry says " tightened most of the induction clamps. Set MP to 39" @ Full Power" "replaced TIT probe and OPS check normal on JPI" In September 2019, for some reason, Maxwell worked on the TIT probe again In February 2021, Maxwell installed Garmin G5's and GFC500 autopilot and removed the vacuum system. https://data.ntsb.gov/Docket/Document/docBLOB?ID=17141507&FileExtension=pdf&FileName=Engine Maintenance Records - 2018 to Accident_Redacted-Rel.pdf https://data.ntsb.gov/Docket/Document/docBLOB?ID=17141169&FileExtension=pdf&FileName=Airframe Maintenance Records - 2018 to Accident_Redacted-Rel.pdf https://data.ntsb.gov/Docket/Document/docBLOB?ID=17141070&FileExtension=pdf&FileName=Propeller Maintenance Records - 2018 to Accident_Redacted-Rel.pdf Although not in the Logs, Dugosh performed the Pre-Buy January 16-23, 2023 This did not appear to be a neglected plane. Maxwell and LASAR are not "bargain basement" providers. A lot of really experienced Mooney mechanics had their eyes and hands on this Encore right up to the time of the accident. How could this 300+ hour engine be in such bad shape?

-

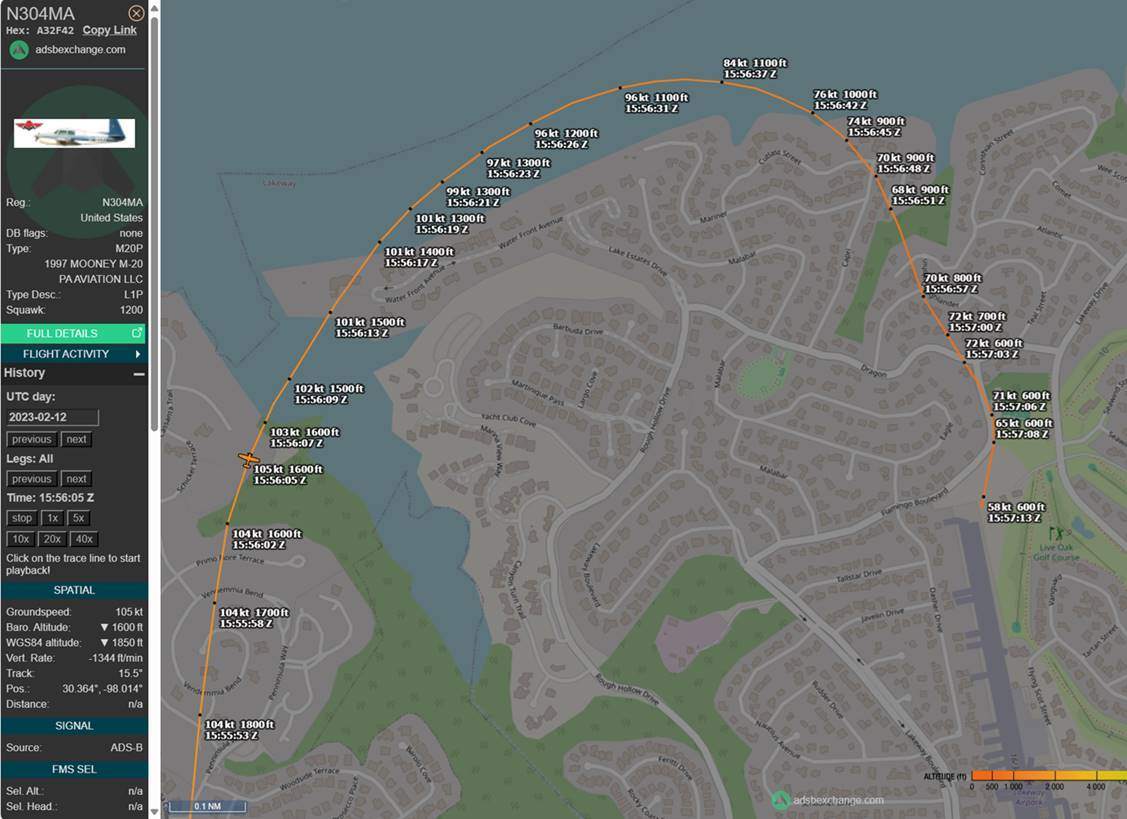

You may be right. Although a 5,400 hour Commercial pilot that is a Helo pilot and a CFI, it is possible that he mismanaged the recip engine to the point that a piston disintegrated. In his statement he said that he did not trust the JPI. See his statement the last 2 pages. https://data.ntsb.gov/Docket/Document/docBLOB?ID=17057139&FileExtension=pdf&FileName=NTSB Form 6120_1_Redacted-Rel.pdf It also unfortunate that he was not able to manage the engine out. I have landed at Lakeway and it is a bit unnerving the first time under the best conditions. This experienced pilot had so much energy - altitude, speed and still partial power within 5 nm of the Lakeway. He turned towards Lakeway and said oil pressure went to zero on downwind but the the engine was still turning until he was on base for short Final. When he was downwind for Runway 16, he said lost oil pressure, About midfield he was at 1,500 ft. AGL and 101 kts descending at -1,155 fpm. Later he was descending at -1,340 fpm and 105 kts while at 1,000 AGL By the time he was turning Base to Final he had lost too much energy and gotten too low and slow. This highlights how difficult and dangerous an engine out is. It is an event that killed Richard McSpadden. This pro pilot survived. We mere amateur weekend pilots may not be so fortunate. https://data.ntsb.gov/Docket/Document/docBLOB?ID=17057139&FileExtension=pdf&FileName=NTSB Form 6120_1_Redacted-Rel.pdf ADS-B Exchange - track aircraft live (adsbexchange.com)

-

ABSBExchange shows that the plane was in Kerrville for nearly a week in late January. Presumably it was at Dugosh doing the Pre-buy. That is plenty of time to address discrepancies. This should have been the best of the best of the best. The pinnacle of Mooney mid-body development managed/inspected by arguably 2 of the most experienced Mooney shops in the world flown by a 5000+ hour Commercial/ Instructor pilot. Instead this pilot came within about 4 feet of killing himself, crushed against the generator station. It’s amazing that the gash in the wing didn’t strike the fuel tank (full for the long relocation flight) and vaporize into an inferno. I think luck played a bigger role than skill that day. And one of the few Encores wound up as scrap metal.

-

Final is out on the crash of the 1997 M20K Encore, N304MA, near Lakeway Airport on February 12, 2023. The engine broke the #6 piston presumably due to detonation. Causes listed are spark plugs worn out of spec, magneto timing out of spec, running lean. The engine had a major Overhaul with new CMI cylinders May 24, 2019 by Jewel Aviation. Don Maxwell Service Center inspected/gapped plugs and checked the magneto timing as part of the Annual on October 8, 2022. Engine 278 hours since TSMOH. (Aircraft hours were 2732) Dugosh did the Pre-Buy Inspection the week of January 17, 2023. Engine hours were 304 (Aircraft hours were 2758) 26 hours after the Maxwell Annual - Dugosh claims that plugs are worn out The accident was on February 13, 2023 Engine hours were 309 (Aircraft hours were 2764 .) 31 hours after the Annual by Maxwell The new owner/pilot (Commercial, Instructor and Helicopter rated) did transition training At about 6,000 AGL and about 5 nm from Lakeway Airport he noticed Fluctuating cylinder temperatures Manifold pressure dropped to 26 in. He could not increase manifold pressure He had partial power and flew towards Lakeway, declaring an emergency While on Final for the runway he lost all oil pressure. He crashed short of the runway So, we are to believe that only 31 hours and about 3 months later after Maxwell had their hands on the engine, the spark plugs wore out and the magneto got so badly out of time that it destroyed the engine? I am having a hard time believing this. The Right Mag was 22 degrees (only 2 degrees advanced over spec) and the Left Mag was 15 degrees (5 degrees retarded below spec). The pilot commented that he had been running lean. Are we to believe that spark plugs will wear out in 25 hours? Are we to believe that Maxwell did not time the mags properly or that they went out of adjustment in 32 hours? If one of the last M20K Encore's made by Mooney, maintained by Maxwell, inspected by Dugosh, flown by a Commercial and Instructor rated Pilot can't reliably make it back to the runway without crashing, what hope is there for 20-40 year older Mooney's in the hands of mere amateur weekend pilots like most of us?..... N304MA | 1997 MOONEY M20K ENCORE on Aircraft.com https://data.ntsb.gov/carol-repgen/api/Aviation/ReportMain/GenerateNewestReport/106726/pdf

-

Another way to look at it is if he had only climbed 2,000 ft and was only 4 statute miles from the runway, then he probably was only in the air 3 minutes. What might cause an engine to stop and appear to be seized in 3 minutes? No oil ?? The safe thing after an Annual or major work is to first preflight exhaustively. (it will be interesting to see if there is airport video of that) Then fly the pattern a couple times. We don't know the experience of the pilot but the Prelim says it was the first time he had flown that particular plane. Generally the safe thing would be to fly the pattern and practice landings a few times. And then - at 2,000 ft AGL an experienced Mooney pilot should be able to glide 11.46:1. The Prelim says he was 1/2 mile short of the runway so he glided only about 18,500 ft or 9.25:1. If experienced and at the top of his game he should have made it. A lot of risks were stacked against the new owner - many that he could have influenced and maybe controlled.

-

Somehow missed this one at the beginning of the year. This was the first flight by a new owner which also the first flight after the Annual was completed. 1979 M20K, N231GG located at Tullahoma Regional Airport (KTHA), Tullahoma, Tennessee on January 3, 2024. During climb-out, at about 2,000 ft AGL and about 4 miles from the airport, the engine lost all power. The pilot turned back to KTHA to glide back to the runway. He attempted to restart the engine but he could not get the engine to turn over with the starter. He landed about a half mile short of the runway in rocky terrain. There are no ADS-B track logs. https://data.ntsb.gov/carol-repgen/api/Aviation/ReportMain/GenerateNewestReport/193598/pdf The plane was sold at a salvage auction last month. 1979 Mooney M20K, N231GG, S/N 25-0171 - McLarens Microsoft Word - Salvage Tender - N231GG (amazonaws.com)

-

Correct. It comes off the back of the engine. This video shows the gears on a 520 that has been pulled but it can be done in place.

-

This was a Rocket Engineering "Rocket 305" conversion of the M20K. The owner's Accident Report and Engine Examination in the Docket shows: Continental TSIO-520-NB17 (s/n 822302-R) (Rocket always put Factory Rebuilt Cont. Engines in the Rocket 305 and Missile 300 unless the owner specified and paid extra for New) The owner stated he owned the plane 22 years and had flown it 2000 hours. He also stated the engine hours were 2000, and that it had been 2000 hours since Overhaul so that means he bought the used K and had Rocket Engineering convert it in 2000. That means the engine had not been overhauled in 2000 hours and 22 years. Continental states that for TSIO-520 below ser. no 1006000, that TBO is 1600 hours and 12 years. Time Between Overhaul (TBO) Periods (captoscana.com) This engine was 400 hours and 10 years over TBO.

-

Yes Swift says "Swift 100R is a 100-Motor-Octane aviation gasoline designed to fully replace 100LL Leaded Avgas across the entire global piston fleet". The key words are "designed to" - that doesn't mean it actually works as "designed" and it certainly has not been proven so. UL94 did not work "as designed" at the UND flight school fleet. Swift Fuels’ 100-octane unleaded aviation fuel granted first STC - AOPA Swift CEO Acosta said to AOPA in the announcement “We’re following a very similar approach where we approve a certain set of engines and airframes and then we expand from that, just like we did nine years ago with UL94,” D’Acosta said. “It’s exactly the same architected program except that’s it’s for the 100-octane fuel." Exactly the same...and that worked out really well for the UND Flight School. Considering that the FAA approval is only for the newest C-172 Skyhawk R's and S's which almost all are found at flight schools, I wonder what flight school will want to risk engine damage for Swift (i.e. UND Ver. 2.0...) I find it really interesting that after the FAA approval, the stories by AOPA, AviaitonWeek, every aviation publication, that if you go to the Swift Fuels website, there is no mention of the approval or the limited STC. There is no mention in the "News" tab/drop down and nothing new on the R100 page. It is almost as if Swift is not proud of the milestone. I bet that Swift thought that they would get a broad sweeping approval - Instead only one engine on one Cessna model News — SwiftFuels