-

Posts

283 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by lithium366

-

Cylinder peaks way behind others

lithium366 replied to lithium366's topic in Vintage Mooneys (pre-J models)

Another interesting observation - even with 60 degrees LOP engine was not running rough -

Cylinder peaks way behind others

lithium366 replied to lithium366's topic in Vintage Mooneys (pre-J models)

I did. Not sure how to link a previous message but I posted earlier in a thread Savvy profile with 3 leanings followed by mag check -

Cylinder peaks way behind others

lithium366 replied to lithium366's topic in Vintage Mooneys (pre-J models)

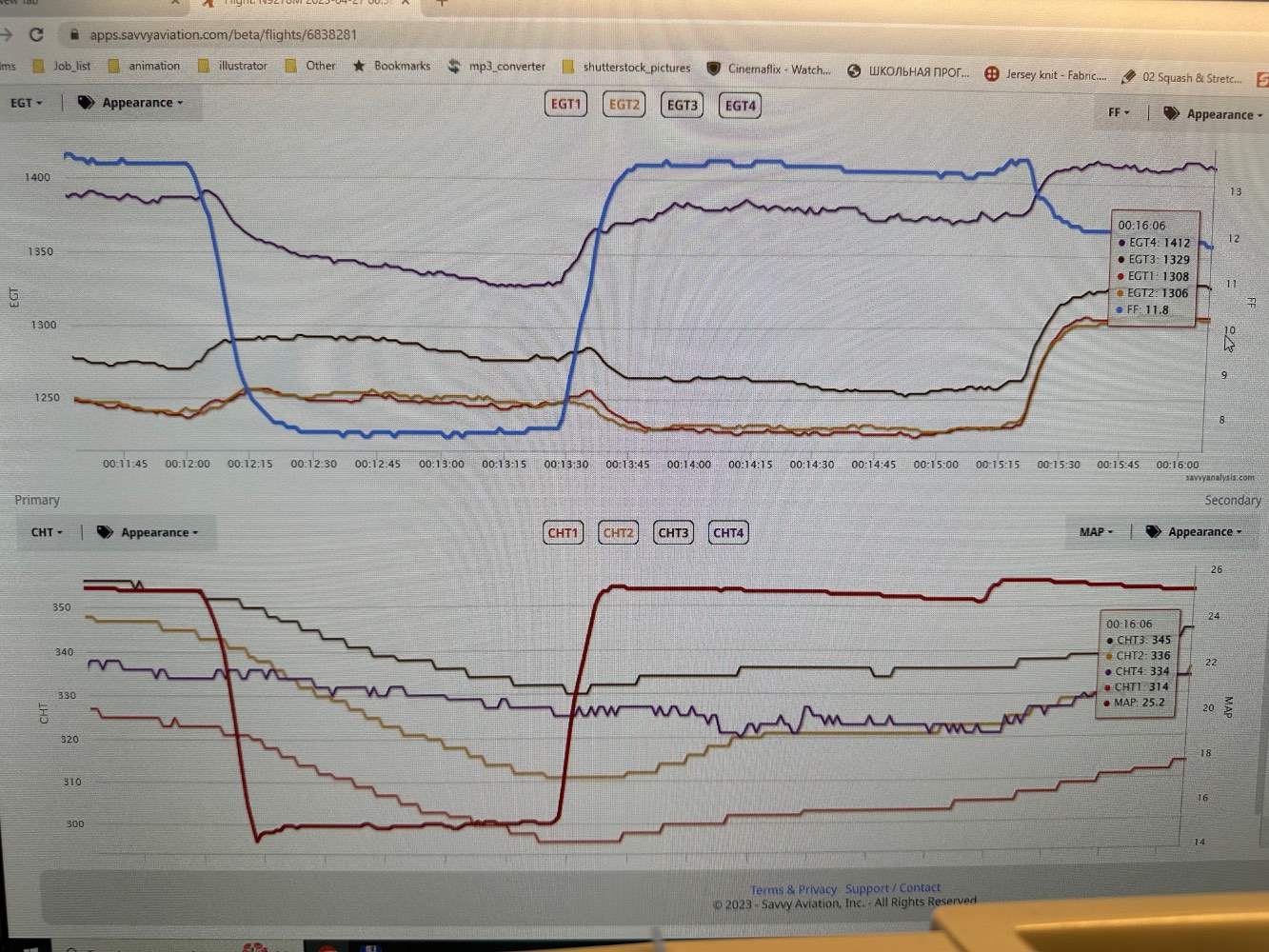

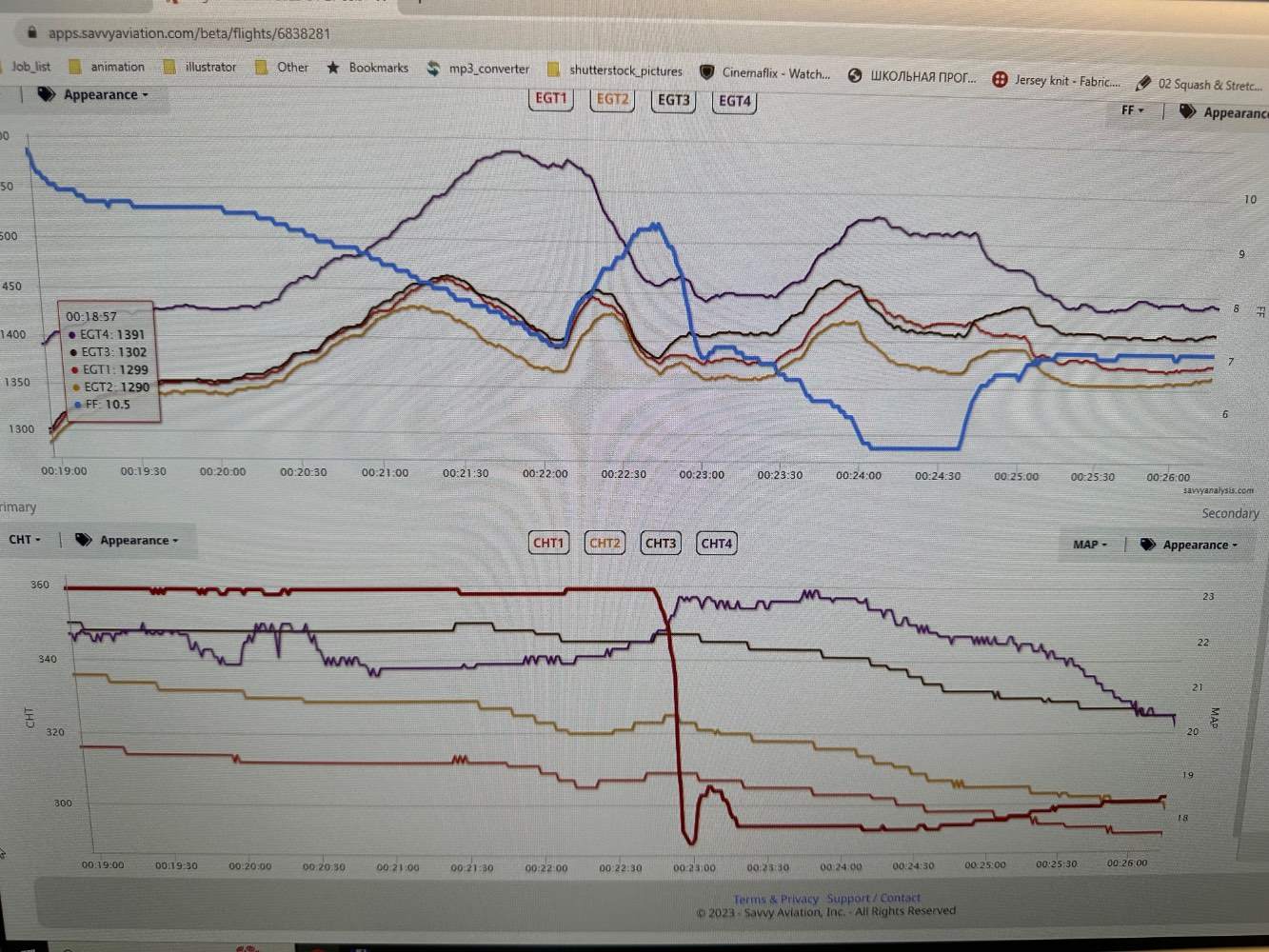

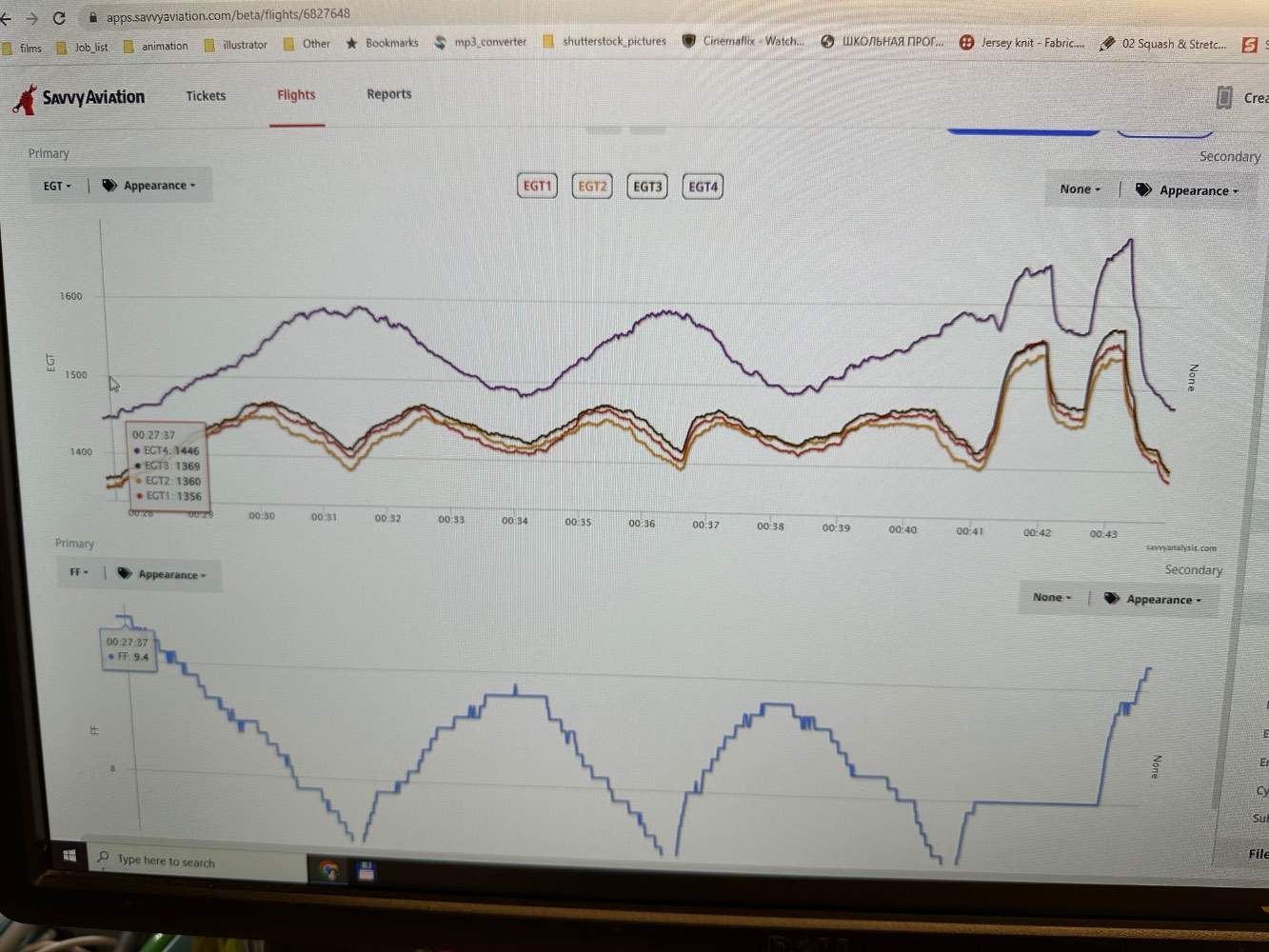

I just did another flight after rotating fuel nozzles (they all filled cups the same). As expected - no changes in EGT / GAMI spreads but wanted to share some data: Here is what I did with full rich mixture, 2600RPM at 4500ft: 12:15 set MP to 15 13:30 set MP to WOT (25.2) this was done to test for an induction leak. I would expect #4 EGT to go up, not down when power is decreased Then I climbed to 6500 and leaned to -60LOP with WOT of 23.1. GAMI spread was 0.8. This can be seen around 21:00 Then I reduced power to 18MAP and repeated leaning procedure - see 23:30. GAMI spread is better - 0.6 -

Cylinder peaks way behind others

lithium366 replied to lithium366's topic in Vintage Mooneys (pre-J models)

@A64Pilot my thinking is that if I eliminated fuel issues, then it is air. If intake valve does not open fully - less air, reacher cylinder. But why higher EGTs? Can a worn lobe change ignition so much on that cylinder? @M20Doc if anything it is IO-360-A1A with 1-2, 3-4 sitting on same intake lobes. Will setting TDC after shutdown un-pump lifters? What points on rockers you suggest to measure and compare to? Or it is a similar test to dry tappet clearance just without removing them? -

Cylinder peaks way behind others

lithium366 replied to lithium366's topic in Vintage Mooneys (pre-J models)

Attaching an image if Savvy profile flight - 3 leaning followed by mag check. GAMI spread is 07-08. Cylinders 1-3 have very little GAMI spread -

Cylinder peaks way behind others

lithium366 replied to lithium366's topic in Vintage Mooneys (pre-J models)

@M20Doc my nozzles are 1 piece and don’t have a separate restrictor. I don’t know if this is ok or not since when I google a part number different pictures came up - with and without restrictor. I am assuming if it is a problem I should expect issues in all cylinders -

Cylinder peaks way behind others

lithium366 replied to lithium366's topic in Vintage Mooneys (pre-J models)

@A64Pilot yes, cleaned, gapped and checked resistance -

Cylinder peaks way behind others

lithium366 replied to lithium366's topic in Vintage Mooneys (pre-J models)

@A64Pilot Lycoming manual says reading will be incorrect because of hydraulic lifters that need to be pulled, washed and dried. Is that true or approximation will be good enough? -

Cylinder peaks way behind others

lithium366 replied to lithium366's topic in Vintage Mooneys (pre-J models)

@wombat maybe a particular tappet / hydraulic lifter. That I can check, just putting it aside until I ruled out other obvious reasons -

Cylinder peaks way behind others

lithium366 replied to lithium366's topic in Vintage Mooneys (pre-J models)

@Pilot64 how do I use a dial indicator to check an amount of valve lift? @wombat I suspect there might be an excessive cam wear on that particular cylinder, I have other signs of cam/lifter issues too, but not to the point of needing an overhaul. What does not align is that if it’s an intake valve that does not open fully - how #3 is not having similar issues since it is sharing the same cam lobe? @Fly Boomer I did a magneto check and cleaned / re-gapped all spark plugs to everyone else, observations were uploaded to Savvy previously. The suggested checking if cylinder “breathe” normally. I will do another test flight and upload here as well -

I have a puzzle for you. #4 cylinder peaks when other 3 cylinders are 50-60 degrees on a lean side that cylinder EGT is also 100 degrees higher then other 3 when leaned ROP. borescoping #4 shows a lot of deposits (expected if it runs reach all the time?) So far I swapped EGT probes (cyl #4 still an outlier), did a fuel flow test, cleaned injector nozzles and also tried swapping injector nozzles. Checked in-flight ignition - ok. Next I would like to exclude an induction leak but weird part is that when I am WOT vs partially open #4 has most EGT changes. I would expect the opposite unless #4 is okay and the other 3 cylinders have induction leaks… Thinking about measuring dry tappet clearance but really don’t want to do this Any ideas?

-

Maxwell posted last week in FB that they have them

-

After switching to Challenger filter my oil temp is 10-12 degrees higher. My friend had the same issue. Switching back to a paper filter brings temperature back Will call Challenger tomorrow

-

Joining the party. Not urgent yet but keep me in mind if someone will start making these

-

Retractable Step Vacuum Replacement

lithium366 replied to 802flyer's topic in Vintage Mooneys (pre-J models)

Yeah I have one from when I replaced vacuum step with an electric. PM me -

Landing gear pressure switch.

lithium366 replied to M20E for me's topic in Vintage Mooneys (pre-J models)

Yes I have an airspeed switch and not a s squat switch. Speaking if high density altitude - this is exactly my limiting factor as I have to speed up in ground effect first and not being able to clear the obstacle by the book numbers. That said most airports have long enough runway to account for my nuance but still makes me uncomfortable. Good idea on adding a manual override switch if my problem will not be solved - easy to add -

Landing gear pressure switch.

lithium366 replied to M20E for me's topic in Vintage Mooneys (pre-J models)

Fine but if there is a leak I am assuming an airspeed safety switch will follow the airspeed indication because they are in-line and pressure is equal everywhere inside of the line. Like if airspeed indicator shows 60kts and safety switch calibrated to 60kts it will activate at this indicated airspeed while an actual airspeed can be anything because of the leak. I guess this can be different if problem is a static vent from an airspeed safety switch? -

Landing gear pressure switch.

lithium366 replied to M20E for me's topic in Vintage Mooneys (pre-J models)

My problem is that gear came up at 87mph instead of 80. Does the tube goes to an airspeed indicator as well? If so I guess 2 pilot/static certs rules out leak... -

Landing gear pressure switch.

lithium366 replied to M20E for me's topic in Vintage Mooneys (pre-J models)

Is there an adjustment on an airspeed safety switch or it has to be replaced? -

i recently pulled an interior for an inspection an coax cable replacement and noticed sheet metal edges covered with some sort of foam where they in contact with wires. Does anyone know what this is and where to buy because mine already deteriorated and compromise safety especially where they meet battery cable (my battery is in the back) Is this sort of protection still acceptable per modern standards? I didn’t see anything like this in FAA EWIS ACs

-

Hey Marc For gear and wheel wells they removed old paint mechanically where needed and painted over the old paint where it was holding well. You right they didn’t do any chemical stripping in delicate areas As for the windshield - i did not plan to replace it with one piece but wanted to ask ArtCraft to reseal it during the painting process. I changed my mind later when I realized that one piece windshield is not a bank breaker compared to a 201 windshield and asked them to replace it for me while they repaint

-

Not yet! Still looking for an antenna

-

Does anyone wants to sell an antenna like the one above? I would buy

-

How to cover hole from ADF Antenna?

lithium366 replied to Skates97's topic in Vintage Mooneys (pre-J models)

Are you talking about ADS-B out? I am installing Dynon’s Mode S transponder that will read it’s position from GPS never mind. Reading about it right now -

How to cover hole from ADF Antenna?

lithium366 replied to Skates97's topic in Vintage Mooneys (pre-J models)

I know this is confusing for me: GNS430W installation manual mention these combo antennas but at the same time in their IFR installation requirements they only specify 3 antennas: GA 35, 36 and 37.A&S also says I have to stick with these 3 models If I could install a combo antenna I would still have to repair a VHF antenna old holes first and then I will be left with an obsolete KA-92 that I will have to patch, too, in order to replace it with Dynon GPS. Finally my understanding is that FAA and avionics manufacturers prefer VHF antennas to be on the other sides of the fuselage. This is why I think I will just relocate an antenna to the belly