-

Posts

9,858 -

Joined

-

Last visited

-

Days Won

219

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by PT20J

-

Labor rates vary. Experience varies. My best advice is to get quotes from 3 shops you would be willing to do business with. Also, there are shortcuts some shops use to reduce the labor like reusing the B-K mounting brackets (not applicable in your case, but may make comparison with others unequal) and not removing old wiring.

-

In my case, by sacrificing itself, the stop probably reduced the damage to the tube so the dent was within the 1/32" spec to maintain airworthiness (you can see the dent in the upper portion of the gear leg tube where the paint is missing.) But the stops are not very strong and are easily broken off. You can see the remains in the upper right.

-

Alternator breaker keeps popping

PT20J replied to The Other Red Baron's topic in Vintage Mooneys (pre-J models)

Fascinating discussion, but I'm not sure we are helping the OP troubleshoot his issue. I think @EricJ's troubleshooting suggestion on the previous page made a lot of sense. If this were mine and it was tripping the big ALT breaker, I'd look for a short at the breaker panel (it's tight back there and mine had little pieces of sheet insulation material that could easily slip out of position separating breaker contacts). Next I'd consider a faulty alternator. Lastly I might question the circuit breaker itself although those are pretty reliable. It's a thermal device and any oxidation on the contacts might increase internal heating and lower the trip point. I might exercise it several times to clean the contacts. Actually, AC43.13 recommends exercising the breakers periodically and I usually do it at annual inspection. An alternator with a functioning voltage regulator is best modelled as constant voltage source. The voltage is a function of rpm and field current. The regulator adjusts the field current to maintain a constant voltage as the rpm and load vary. Let's keep the rpm constant and add load. Eventually we will get to the rated output -- say for example 60 amps. What happens if we add more load? At some point the field current will be as high as it can go and after that point the voltage will decrease and the current will decrease since with constant load the current is proportional to the voltage. How much more than 60 amps will it put out. It it is well designed, not much. Why? Without getting technical, it would cost more (heavier stator and rotor windings and bigger diodes). So, it's not going to be way over designed. Suppose we disconnect the voltage regulator from the field and connect the field terminal directly to the battery. What happens? Now the alternator voltage is solely a function of rpm and load. If the load is not the limiting factor, the voltage will increase and that will drive more current through the load. Maybe it will be enough to trip the ALT breaker, but more likely it will fry all the avionics due to the over voltage. -

Alternator breaker keeps popping

PT20J replied to The Other Red Baron's topic in Vintage Mooneys (pre-J models)

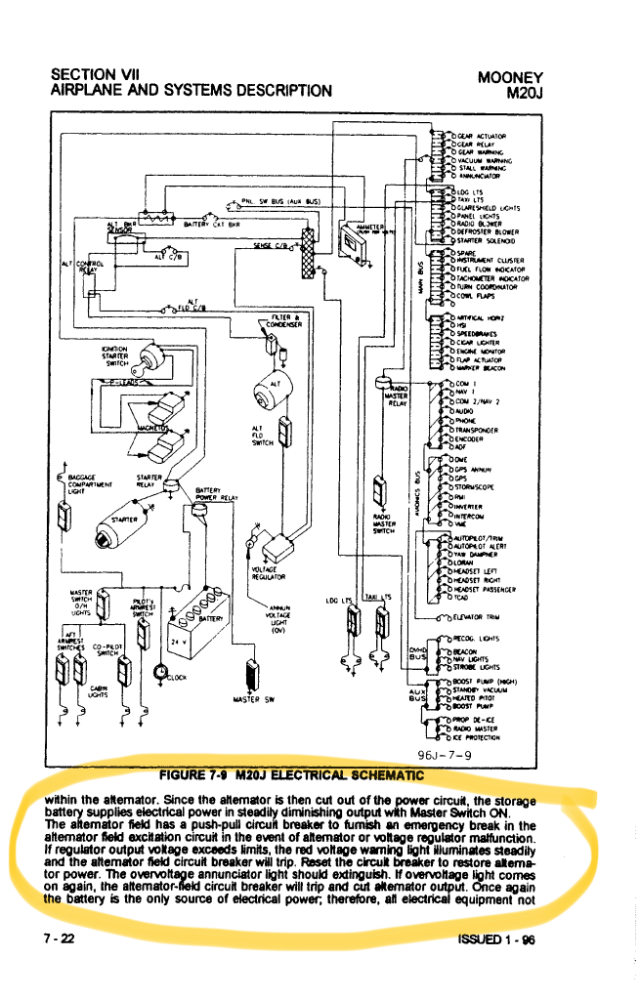

The current to pop the ALT breaker in the case of a short between the alternator and the bus (or more likely, within the alternator itself) comes from the battery, not the alternator. Even if the regulator fails and the alternator voltage increased (which would drive output current higher by Ohms law), the over voltage protection circuit would shut down the alternator by (depending on design) either removing the field excitation or crowbarring the field circuit (which would pop the ALT FIELD breaker.) From the M20J POH -

Alternator breaker keeps popping

PT20J replied to The Other Red Baron's topic in Vintage Mooneys (pre-J models)

If the field goes to bus voltage, the alternator voltage will increase, but the alternator is only capable of supplying so much power and the current will decrease. -

Alternator breaker keeps popping

PT20J replied to The Other Red Baron's topic in Vintage Mooneys (pre-J models)

That breaker is there to protect the wiring between the alternator and the bus. Unless the alternator has been improperly replaced with a larger one, the alternator will not put out enough current to trip that breaker. But, if there is a short somewhere between the alternator and the bus, the battery can supply more than enough current to trip the breaker. -

preventing FBO from damaging nose gear with tug - signage?

PT20J replied to rwabdu's topic in General Mooney Talk

Any MSC can order them. The part numbers are in the document. -

Alternator breaker keeps popping

PT20J replied to The Other Red Baron's topic in Vintage Mooneys (pre-J models)

Mags: In order to turn off a magneto, the p-lead must be grounded. The p-lead is a shielded wire to reduce radio interference. The shield can be grounded at the ignition switch end, at the magneto end, or at both ends. In some installations, the shield is grounded at the magneto only but connected to the ignition switch so that the switch can ground out the mag using the shield. If the shield is loose at the magneto end, then it may not be able to ground out the magneto. Wiggling the wire might temporarily improve the connection. Alternator: You didn't say which breaker tripped. There should be two: A breaker on the alternator output usually labelled ALT, and a breaker for the field usually labelled ALT FIELD. If the ALT breaker trips, there is a short between the alternator and the breaker. There are a couple of things that can trip the ALT FIELD breaker. It could be a short somewhere in the field circuit. Also, some voltage regulators use a "crowbar" circuit to intentionally create a short to pop the breaker and shut down the alternator when the regular senses an overvoltage condition. -

K vs. C Model Short Field performance

PT20J replied to bencpeters's topic in Modern Mooney Discussion

Acceleration is a function of thrust, (F=ma). So, the MT prop must generate more static thrust than the original prop. Vx is defined as the speed where the thrust available exceeds the thrust required (drag) by the maximum amount. So, a prop that is more efficient at creating thrust at low speeds will also improve Vx. Thrust falls off as true airspeed increases at constant horsepower. Vy and cruise speed are determined by available excess horsepower rather than thrust. -

Sounds plausible. It’s easy to replace. You could try taking it apart and cleaning the plunger in case it’s just the plunger sticking, but for a little over 100 bucks I figured I would just replace the switch and be done with it.

-

Not sure why you thought they would be new. Garmin never promised that. When you buy something from Garmin and it fails during the warranty they replace it with new or repaired/overhauled at Garmin’s discretion. It's always been that way. What you will get back is a servo that has been brought up to the latest specs and tested and has a 6 mo. warranty.

-

The POH spec didn't come out until 1975 and Mooney adopted it sometime thereafter.

-

GAMA Specification No. 1 (which is the industry consensus standard for the POH) says that, "Landing distance data shall be presented as landing distance versus outside air temperature, altitude and wind." Two examples are given: Tabular, commonly used by Cessna, and graphical, which Mooney used. The graphical example shows tailwinds up to 10 kts. The table example includes a note, "For operations with tailwinds up to 10 knots, increase distances by 6% for each 2.5 knots." So, apparently all the manufacturers agreed that tailwinds of up to 10 knots are acceptable. https://gama.aero/documents/gama-specification-1-specification-for-pilots-operating-handbook-version-2-0/

-

I don't see why not.

-

-

The alternator switch in my airplane is in the space between the master switch and the radio master. Maybe it went bad and someone just eliminated it, or maybe the alternator wiring is different than mine which is original from the factory. In mine, the Alt Field CB feeds power to the voltage regulator. The field output of the voltage regulator goes through one pole of the master switch and then through the alternator switch and then to the field terminal of the alternator. So, both the master and alternator switches have to be on to excite the alternator.

-

If you look at the pages after the diagrams there are callouts for Stratoflex 193-10 and 193-6 hose. 193 hose meets MIL-H-5593. The dash number is the ID in 16ths of an inch. Stratoflex 193 is black. The hose in your pictures looks kind of like surgical tubing.

-

Disconnect the battery because there is voltage at the master switch and clock. Then, remove the 4 screws you circled. There are spacers behind some of the screws that will fall out, so catch them to replace when you put it back together. If you need a clock, Skyman Avionics has the one I removed. kelsey@skymanavionics.com.

-

GI 275 - How to wire the external GPSS/HDG- switch

PT20J replied to NicoN's topic in Avionics/Panel Discussion

I believe Honeywell makes alternate action lighted square pushbuttons. Should be lots of sources for the machined crimp contacts. Aircraft Spruce lists them. EDIT: Steinair has the pins and a crimper less costly than the DMC. https://www.steinair.com/product/contact-high-density-dsub-pin/ -

How to pre-wire G430 and wing for dual G5s and magnetometer

PT20J replied to JoeM's topic in Avionics/Panel Discussion

Try https://support.garmin.com/en-US/?partNumber=K10-00280-01&tab=manuals -

The best thing is to make sure that the muffler is sound -- that's the main source of it getting into the cabin. In flight, the airstream should carry the exhaust away from the cabin.

-

Sometime in the mid-1980s Mooney switched to foam insulation, epoxy primed tubes and sealing the rivets that attach the window frames to the tubes. On those airframes, it it often a simple matter of checking that the pilot's storm window doesn't leak and removing the belly panels and checking for corrosion in the bottom tubes. A complete by-the-book inspection removing the belly, side panels, rear seat and tension bolts and putting everything back together is probably $1000 at a shop. @jetdriven would know. I might contact Frank Crawford at Mooney with the model and serial number and he should be able to look up the build records and tell if it has the updated insulation and primer. I bought bulk foam insulation that Mooney uses from a MSC for $475 and installed it myself. It took me maybe 4 hours to remove the old insulation and cut and install the new.

-

Last summer I noted a faint fuel odor in the cabin when the airplane had been sitting for a day or so closed up in the hangar. I traced it to a tiny seep from a screw attaching the right outboard fuel sender. The vapor travelled all the way down the leading edge of the wing to the cabin. So, it doesn't take much to be detectable by smell. A big leak will definitely be noticeable. And, BTW, if you think all that duct tape covering the gap at the wing root will keep CO out -- it won't.

-

It must be a lot harder on the K than the J. I bought new seals from Guy @Gee Bee Aeroproducts when we swapped out the engine. The hardest part was removing the hardened staples attaching the old seals to the baffles which I did with a Dremel cutoff wheel. It probably took me an hour or less. My A&P attached the new ones with the pop rivets that Guy supplied in less than an hour.