-

Posts

9,966 -

Joined

-

Last visited

-

Days Won

223

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by PT20J

-

My '94 J has the cap allowing replacement from the front. My '78 J didn't have that and the bulb had to be replaced from the rear which was a PITA requiring drilling out the pop rivets attaching the plastic trim on the right side of the console, disconnecting an aileron push pull tube and then removing a belly skin to disconnect the other end of the push pull tube to drop it out of the way to access the socket. I'm not sure when the design changed.

-

Well, part of the placard is missing but it seems to say INSTRUMENT SOURCE xxxxx INOP WARNING and it's next to the knob labelled PULL STBY VAC ON, so I'd guess it's a low vacuum warning light. Is that one of those manifold pressure vacuum backup systems? There should be some sort of supplement in the POH.

-

Might also try heating with a heat gun to soften the RTV.

-

Generally, all MEMS-based AHRS provide good short-term attitude solutions but suffer long-term drift. This is compensated for by using additional inputs, generally some combination of air data, GPS, and 3-axis magnetometers. Garmin goes into some detail explaining this in the G3X Pilot’s Guide, but not in the G5 documentation. However, we can reasonably infer that the products act similarly since they were designed by the same team (Team-X). So, you would have to lose both pitot/static and GPS inputs to the G5 before the ADI X’ed out. Most installations will also have a GMU 11, and that may add additional robustness. Skip

-

Less of that these days with modern CFD programs. Used to be pretty common to have to fix stuff after flight tests. And, the more original designs get stretched and grossed up, the more fixes get applied (ask Boeing about the MAX). https://kingairmagazine.com/article/why-do-the-ailerons-have-a-lump/

-

We just used standard pan head screws, painted them gray to match the new panel and put nylon flat washers underneath the heads so as to not mar the panel.

-

Modern electronics has gotten so much more reliable that I'm not as concerned about failures as I used to be. I want a VLOC backup, but I don't find the need for multiple GPS. When the GNS 430 came out, it was pretty standard for installations to have two, just as everyone used to have two Nav/Coms before GPS. Garmin must have loved that!. Over time, I see fewer installations like that. (Of course, Garmin would love to sell you a GTN 750 and 650 combo).

-

The panel screws that Mooney uses are pan head with a molded on plastic trim washer. Mooney uses them in various colors to match instrument panels and trim. They are made by Stake Fasteners. https://www.stakefastener.com/. I believe black is a standard color. When I contacted them a couple of years ago, the minimum order was $210. Skip

-

An 10,000 hour ATP corporate pilot I know bought a Bonanza and the insurance company made him get 10 hours dual. He asked why and they said they had many more claims from pilots going from jets to single engine pistons than the other way around. After the training, he said they were right.

-

Part number for door latch assembly insert

PT20J replied to RideOrFly's topic in Modern Mooney Discussion

You need to look at the indentations (. .. ...) in the 12345 Nomenclature column. These are used to indicate that a part is used in a next higher assembly. For example: INSERT 914028-005 is part of LINK ASSY 310304-013 which is part of LINK ASSY, LATCH 310304-503 which is part of DOOR ASSY, CABIN 340124-513. So, apparently LINK ASSY, LATCH includes two LINK ASSYs each with an INSERT. It's not clear from the drawing what these parts are and you don't describe exactly what you need. But in this case, the best approach is to contact Frank Crawford at support@mooney.com. Frank can access the engineering drawings and help you figure out what part to order through a MSC. -

It would depend entirely on your previous experience, abilities and comfort level in the Mooney.

-

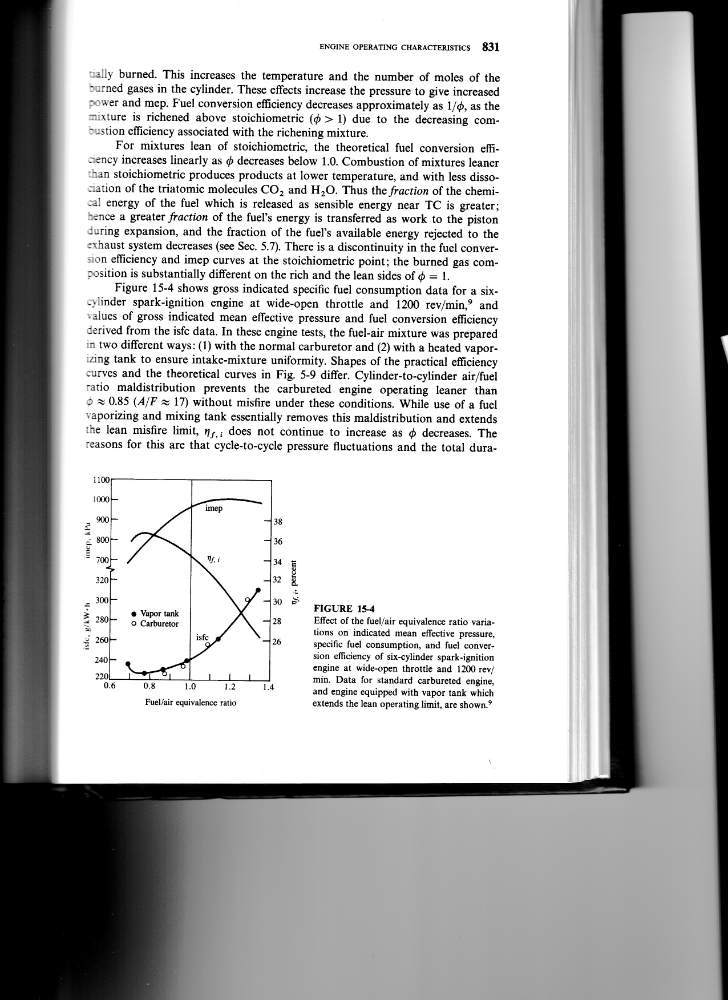

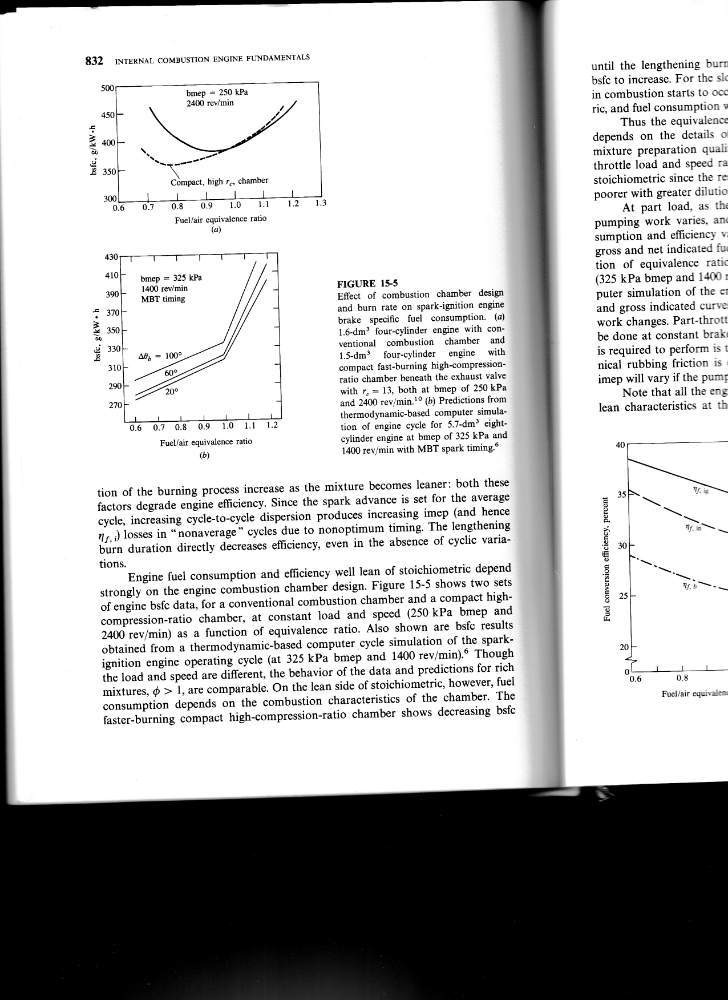

It is interesting to ponder why the BSFC curve has a U shape. Starting at stoichiometric mixture (peak EGT) as we lean the mixture the BSFC decreases approximately linearly. Why? It is because leaner mixtures burn at lower temperatures causing less chemical dissociation resulting in a greater percentage of the energy from combustion being converted to work. However, because there is less fuel available, the power decreases even though the efficiency increases. Theoretically, the BSFC would continue to decrease until the mixture was so weak that the engine stopped running. But, in a real engine, it doesn't; it levels off and then starts to rise. The reason is that very lean mixtures burn slower and also increase cycle to cycle cylinder pressure variations. Both effects decrease efficiency. The cycle-to-cycle variations between cylinders, and within individual cylinders, are what the pilot senses as "roughness." From, Heywood, John B., Internal Combustion Engine Fundamentals:

-

VGs are advantageous in reducing flow separation at high angles of attack. We all know that the speed of the air over the top of the wing accelerates which is one of the explanations for lift. However at some point, generally after about the 25% chord point (farther aft for laminar flow wings), the air begins to slow. This is because physics demands that an adverse pressure gradient build up on the aft portion of the wing. Within the boundary layer, the adverse pressure gradient can actually cause the flow to reverse and separate from the wing. At high angles of attack, the separation progresses forward along the wing chord reducing lift and causing a stall. Vortex generators create vortices (big surprise) -- little horizontal tornadoes -- which grab faster moving air from above and transport it down deep into the boundary layer which counteracts the reversed airflow and keeps the airflow attached to the wing. Originally, VG were dimensioned to be approximately as high as the boundary layer thickness. These did indeed create a small but measurable drag penalty. However it was discovered with modern CFD techniques that shorter subboundary layer vortex generators, or micro vortex generators, worked nearly as well at energizing the boundary layer and delaying stall without the drag penalty.

-

Lean it until it runs rough and then richen until it’s just smooth. That will put you at the lowest spot on the BSFC curve. If the airspeed is too slow, richen. If you are below 75% (Lycoming) or 65% (Continental) you are outside the red box at any power setting. If you are below 400 F you are outside the red box. Keep it simple.

-

I regularly fly my M20J into W10. The runway is 2470 x 25 with tall Douglas fir trees all around. It’s not a problem. A strip like that will teach you to be precise in speed and directional control. As long as you have nearby bigger airports for gas, maintenance, instrument approaches and diversion during unfavorable conditions, I wouldn’t hesitate.

-

Aircraft Magneto Service does excellent work. They quit doing the dual Bendix mags though.

-

It's good to remember that the pilot gets to select the approach regardless of what ATC is advertising. The only time you might not get it is if you ask for an approach to the opposite end of the runway that is in use because it messes up traffic flow, but I have even been able to get that when I wanted to land downwind to use an approach with lower minimums.

-

According to the FAA, NOTAMs are the official source. Both ADS-B and ForeFlight obtain graphical TFR data from tfr.faa.gov. That website contains the following disclaimer. This site is informational in nature and is designed to assist pilots and aircrews for flight planning and familiarization. It may be used in conjunction with other pre-flight information sources needed to satisfy all the requirements of 14 CFR 91.103 and is not to be considered as a sole source of information to meet all pre-flight action. Due to system processing delays, recently entered notams may not be displayed Skip

-

UREM37BY

-

Fine wires have gotten pretty pricey. The maintenance advantage is that the electrodes last much longer and don’t need gapping. The operational advantage derives from the electrode arrangement that places the spark deeper in the combustion chamber. I am trying out the BY plugs which should provide the operational advantage but not the maintenance advantage. I’ve got about 100 hours on them and they run great LOP and are also very clean when I rotated them twice so far.

-

The KAP/KFC 150 was digital with a microprocessor and thus software controlled. The GFC 500 is a distributed system. Some of the software is in the PFD, some is in the servos. Only Garmin knows exactly how it works. I think it was pretty much a clean sheet design. The servos often seem implicated when problems arise. I don't recall such problems with the GFC 600 or GFC 700; does anyone else? The GFC 500 was originally designed for the experimental market where airplanes are usually smaller with lighter control forces. Curious if anyone has followed the experimental threads to see if they have similar issues? Skip

-

Did they explain why? I wonder if most of the problems have been with J and K models? According to the FAA aircraft registry, Garmin International owns N430G (M20R) and N5272K (M20J).