-

Posts

10,166 -

Joined

-

Last visited

-

Days Won

231

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by PT20J

-

You can run the pick through one spark plug hole while observing through the other.

-

Me too, but I like the hacksaw blade idea. I scare myself every time I try to hold onto a slippery filter and wield a long, sharp blade!

-

The FAA requires that only approved parts can be installed on certificated aircraft. An OPP done correctly can be an approved part. It is not required that the part be unavailable elsewhere, although it is usually easier and less expensive to procure the part if it is available than it is to make one. But, sometimes it's easier to make one. For instance, the rubber tail pipe hanger was ripped halfway through and I removed it and used it as a template to cut one from an old tire. The OPP had the same dimensions and was made of material similar to the original. My A&P was fine with it; he gave me the tire. An OPP can only be produced by the owner (or operator) for their own aircraft and the owner must participate materially in the production although the owner can contract out the actual manufacture of the part. The OPP generally must be installed by an A&P. If the OPP is part of a major repair requiring a 337, then it must be signed off by an IA. Once the part is installed and logbook entry made, it is considered airworthy. A subsequent maintainer should only reject it if it somehow becomes unairworthy (say your new duct has developed a hole). If it is made correctly, the OPP should be virtually indistinguishable from the original. The difficulty in producing an OPP is that it must conform to approved data to be in accordance with the original type design. Since you are not going to get manufacturing drawings and material specifications from Mooney, the usual way to accomplish this is to copy an original. This is fairly simple with metal parts. At the museum, we had a brake caliper for a Bearcat machined to match the original unavailable cast part. Sheet metal parts are easily replicated. It gets more complicated when trying to replicate something like an intake duct. And, if you make it different than the original, even if it is "better", it might require a one-only STC. Skip

-

Kind of strange. I would call ECI and ask their opinion. How deep are the scratches? It's hard to tell from the pictures, but if they aren't deeper than the cross hatch then Lycoming told me that scratches are not an issue. Another test is to see if they catch a dental pick run across them. But, if it is running fine and not using oil and oil analysis is good and the filter is clear of metal, I personally wouldn't be too concerned about it. Skip

-

The Arrow II (PA28R-201) with the semi-tapered wing is a bit faster I think. I used to flight plan the Archer II at 120 KTAS and the Arrow II 140 and come out pretty close. On the positive side, Arrows are simple, with comfortable interiors and big windows. They are lighter on the controls and more responsive than Mooneys. Their stall characteristics are benign and they are not as speed sensitive on landing and the oleo struts make most landings greasers. On the negative side, they are less efficient than a Mooney. And, most Arrows have been used for rental and training and it is hard to find one that doesn't look pretty tired. And, there is the wing spar AD to consider. Skip

-

Portable GPS choice and synergy with database updates

PT20J replied to dkkim73's topic in Avionics/Panel Discussion

THIS^^^^^^^is what I do also. -

The problem with overhauled cylinders isn’t the steel barrels; it’s the aluminum heads. Every combustion event expands and contracts them slightly, especially if they were run at higher CHTs. Eventually, they work harden and crack. Some designs more than others. So heads do wear out.

-

GPSS does more than turn anticipation, i.e., not overshooting a Fly-By waypoint. It also allows a legacy autopilot to fly complex procedures in the GPS database such as missed approaches, DME arcs and holding patterns.

-

I have a Shapeways (no longer available) 3D printed ETA replacement cap for my avionics master that has gone through hundreds of cycles without failure. Given the number of failures of the original parts as evidenced by people frequently posting here querrying about replacements, I wonder if the 3D printed parts might not be better than the originals caps. Skip

-

A trick I learned from an A&P friend is to remove the media from the filter and compress the pleats and put it in a vice to squeeze the oil out of the media. (You might have to cut the media into 2 or 3 pieces depending on the opening of the jaws of your vice). This makes it much easier to see the metal trapped in the now dry media. Another check for fine ferrous material is to wash the media in a coffee can of clean solvent and then swish a magnet around in the solvent. Ferrous material will adhere to the magnet.

-

Ref Lycoming Service Bulletin 480 for guidelines

-

Probably anything is OK as long as it doesn't contain graphite which will weaken stainless -- the reason never to mark on the exhaust parts with a pencil. I have used copper anti-seize on the tail pipe ball joint. I have always used Aerokroil on the slip joints because that's what my IA likes. But frankly, I suspect that any of the penetrating oils will burn off quickly. My IA got a sample of DAM Exhaust Lube at the McFarlane booth at a trade show and I gave it a try this year. It penetrated the joint easily and seems like it would have some staying power. https://www.mcfarlaneaviation.com/products/category/exhaust-dam-exhaust-lube/description/ Skip

-

Something is haywire if the voltage is fluctuating with load. The function of the voltage regulator is to hold the voltage constant with fluctuating load. Also, the original problem was the OVP tripping. That would either be a regulator problem or something shorting the field wire to the battery bus. Since the regulator isn’t holding voltage within .1volts, it sounds like a bad regulator. But, I would check all the wiring to the alternator. A loose field connection could cause fluctuating voltage and it is conceivable that if the field circuit momentarily opened, the regulator could command max field current and if the field connection were remade this might cause a temporary over voltage and trip the OVP. I would check ALL the wiring in the charging circuit before messing with the regulator.

-

Should be the same. The logic was the same on my 200 and 150. GPSS is completely external to the autopilot and is just a converter to translate digital roll steering commands from a GPS navigator to analog heading for the autopilot.

-

With my Aspen/KAP 150/GNS 450W I used HDG for heading, HDG + GPSS for GPS Nav, NAV for VOR nav (rarely), and APR for approaches regardless of nav source.

-

An engine overhaul is only as good as the person doing the work. There has been a lot of turnover in most every industry during recent years. If I were going to have an engine overhauled, I would ask hard questions about who is going to do the work, and what their experience is, and how their work is inspected, and how the engine will be run in. And, I would visit the facility to see all this first hand. It's a lot of money. When I attended the Lycoming factory class last year we got a tour of the factory. Lycoming currently assembles all engines on the same AS9100-certified assembly line. That means that new, overhauled and rebuilt engines are all assembled by the same persons using the same procedures, and there is an inspection at every step. The engines are run in in a computerized test cell with a dynamometer rather than a test club and you get a printout of the results with your engine. This means that it is mostly broken in when you take delivery. Since all engines are assembled on the same line with the same process, the only difference between new and rebuilt is the parts. New is new. Rebuilt engine parts come from a stock of used parts that meet new tolerances harvested from returned cores. Cylinders are scrapped. Camshafts are scrapped. The main parts that get reused are crankshafts and cases because these usually have little wear. They always use new cylinders and pistons. I went with a factory rebuilt for three reasons: 1) At the time I did it (October 2018), it was the fastest option. 2) I wanted roller lifters and Lycoming now ships all non-turbo engines with roller lifters. 3) I felt that the AS9100 certification would reduce the risk of issues due to assembly variations. BTW, a rebuilt engine is zero time because Lycoming disassembles cores and puts all the reusable parts in stock and destroys the unusable parts. When a rebuilt engine is assembled, they pull all the parts from this stock plus whatever new parts are needed and there is no way to reconstruct any meaningful total time on the rebuilt engine. Since it meets new specs, it gets a new serial number (which indicates that it was rebuilt) and a new logbook. This means that your zero time rebuilt engine could theoretically have a crankshaft that has several thousand hours on it. This bothers some people. But I've never seen any evidence that rebuilt engines have a higher failure rate than new engines. Skip

-

Not sure about the non-Xi version. There was a software release a while back for the GTN Xi to allow it to show fuel data from the G3X. It also required changing a setting for a connection between the G3X and GTN. I’d check with your Garmin dealer.

-

Agree. My 78 J had it screwed to the firewall, up high under the windshield combing. It was an OECO and looked like this.

-

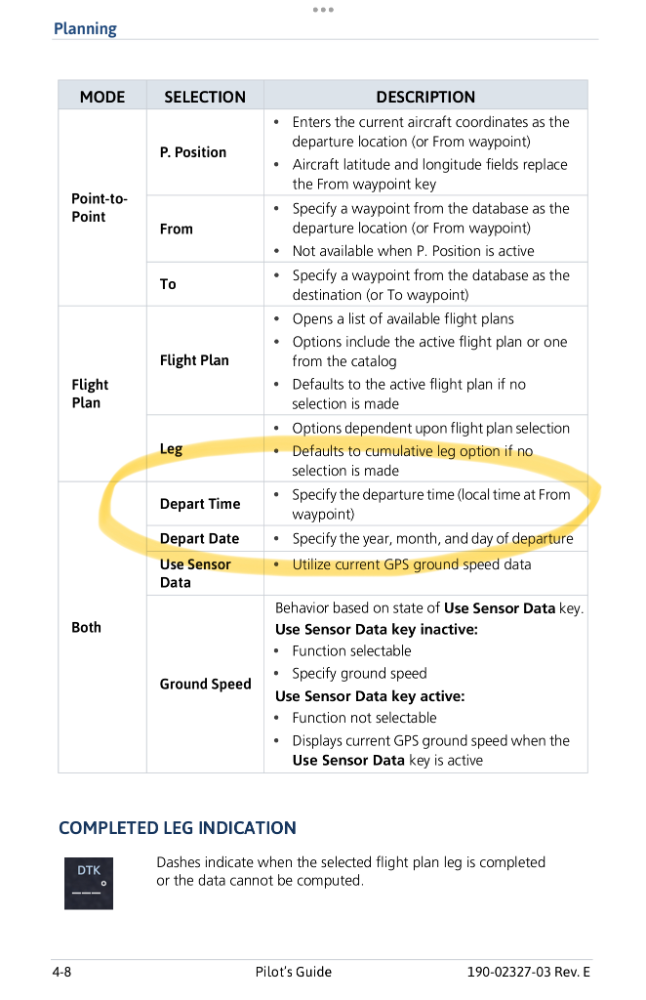

The manual isn’t terribly clear. It says ETA = Current Time + ETE … It doesn’t say that you have to enter the current time except for the sentence that says, “Departure date and time and ground speed data are required independent of mode selection.” Also, the table says it’s a manual entry. I agree it could be better designed, and it certainly could better described in the manual, but I believe it works as designed. Skip

-

Mine in a 1994 J are extrusions.

-

On mine the installer ordered some material that the vertical rails are made from, cut new rails to length, drilled them for the new trays, riveted the trays into the rails on the bench and installed the entire stack in the panel.

-

I like the flight plan page also on the GTN. It gives quick access if I need to change something. I have a G3X and have the map page up on that and I have a yoke mounted iPad running ForeFlight and I have the approach plate on that.

-

Time to buy new material and start fresh. That's what we did.

-

Tanis Cabin/ Avionics Pre-Heater?

PT20J replied to William Munney's topic in Modern Mooney Discussion

It probably depends on the insulation. Mooney long ago went to aluminized Mylar foam on the side panels to prevent moisture retention and corrosion of the tubular structure, but at least into the 1990s, it still used fiberglass elsewhere. I replaced all the fiberglass with the same material used on the side panels and it made it cozier in the cockpit. -

Tanis Cabin/ Avionics Pre-Heater?

PT20J replied to William Munney's topic in Modern Mooney Discussion

I keep a West Marine boat air dryer in the baggage compartment running continuously during the winter/rainy season in the Seattle area. It puts out a very small amount of heat. https://www.westmarine.com/west-marine-air-dryer-with-fan-dehumidifier-120v-ac-7867518.html?&utm_medium=cpc&utm_source=google&utm_campaign=PMax: GSC>Smart_Shopping>Plumbing & Ventilation2023&gad_source=1&gclid=CjwKCAiAjfyqBhAsEiwA-UdzJIgMRohFHXuGmp0j485jgUi6-W_5v5XRpUdxvM62pvVVFjjRqgcyBhoC4q4QAvD_BwE