-

Posts

230 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Jake@BevanAviation

-

Looking for KS179 Trim Servo 065-0052-04

Jake@BevanAviation replied to ddmooney's topic in General Mooney Talk

019-02362-0001 solenoid coil is still available but at a steep price form Honeywell. Units are still repairable pending part availability. -

Aspen PFD/225 auto pilot

Jake@BevanAviation replied to Mikey,,,,,,'s topic in Avionics/Panel Discussion

@squeaky.stow PM sent. -

Depending on the manufacture year of the computer it could be a unit that has capacitors leaking in the power supply (94-98). This cap leakage can corrode traces or even open up traces for the power supply circuit and voltage monitor circuit. Typically when this happens you get some interesting PFT results or the unit will not PFT. As the unit warms up or cools down it will randomly decide to work. This condition will only get worse over time. If the computer is working properly with sufficient power to the trim monitor circuit (NOTE: if there is no voltage to the trim monitor circuit the unit will not flash trim during PFT) when hitting PFT the unit will flash trim 4 times. . Two up trim pules and two down trim pules, the computer looks for feedback and does some other internal test with the microprocessor. If the test are successful the unit will flash AP approximately 12-14 times. Also, on a side note pay attention the the left side of the MET rocker switch if it is not in a neutral position it can cause the PFT to fail. If you are going to remove the unit from the rack use a 3/32 allen tool for the removal screw and be sure to remove the static line to the transducer on the back of the unit before pulling it all the way out. On the unit there should be a red 4 digit stamp (1497) the 14 is the week and 97 is the year. Check to see if you fall in the year range listed above for cap leakage.

-

Aspen PFD/225 auto pilot

Jake@BevanAviation replied to Mikey,,,,,,'s topic in Avionics/Panel Discussion

So if the KI-256 is still in the aircraft without a EA100 the KI256 is providing the roll and pitch reference to the KC225 for sure. As for the FD bar issue the drive can be paralleled from the KI-256 to the Aspen ACU. See print below for details. However, the parallels for FD commands can not be used if a EA100 is installed (see note 3). If the FD bars are moving correctly on the KI-256 the representation should be mirrored on the Aspen, if they are not I would have to check the voltages to the ACU and then maybe replace the ACU. Also, are you saying that moving the heading bug out from under the lubber provides no correction from the flight computer? -

Looking for a KFC200 trim servo

Jake@BevanAviation replied to aviatoreb's topic in Modern Mooney Discussion

A KFC225 will have completely different servos KS272C (trim) which are not interchangeable with older KFC systems. -

Looking for a KFC200 trim servo

Jake@BevanAviation replied to aviatoreb's topic in Modern Mooney Discussion

My email is Jake@bevanaviation.com Based on the N# in your signature it looks like it should be a KS272 or KS272A PN 065-0029-28 or 065-0061-28 per the install manual. -

Looking for a KFC200 trim servo

Jake@BevanAviation replied to aviatoreb's topic in Modern Mooney Discussion

Would need to know what series of servo it is 100 series (KS179) or 200 series (KS272). The 200 are easier to repair as replacement parts are more available. The 100 series have a different drive motor from Pittman and can be a pain when the motor is bad finding a place that can overhaul it. I did find an authorize Pittman repair center that did a couple of motors for me about 2 years ago. If you can provide the long part number I can do some digging and see what I come up with. -

GI 275 and KFC150 - attitude source?

Jake@BevanAviation replied to elimansour's topic in Avionics/Panel Discussion

To my knowledge the answer is no as a standalone pre-selector option. The KAS-297B used baro correction, gray code, and part of the frequency oscillator in the KC191/192 to produce a summed pitch command for VS modes. You can refer to the GAD43E for additional information if needed. With the dual GI275 we did in a M20J with a KFC 200 there was no pre-selector function added with the install of the GI-275. If you currently have a KAS-297B you might be able to use the 275 for baro correction but would still need gray code from some other source. A blind encoder should work if you did not want the KEA-130. Also, you must do the calibration with the KAS-279B when changing the encoder/baro source. -

Who to send a KX165 for repair / evaluation?

Jake@BevanAviation replied to jetdriven's topic in Avionics/Panel Discussion

Give us a call Monday and ask for Mike or Bill. They will be more than happy to discuss any issues you have with the KX-165. They will be able to provide information on potential repair cost and lead time. 316-946-4870 -

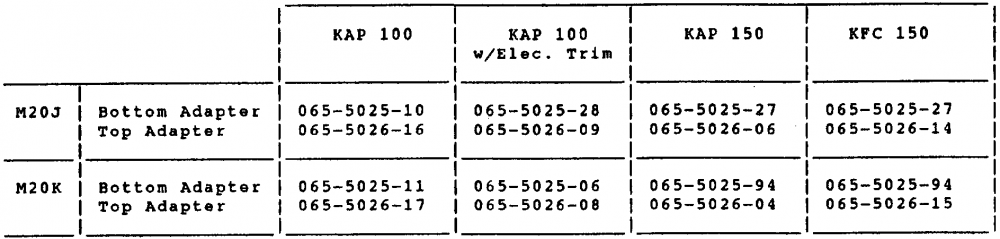

KAP/KFC 150 installation differences?

Jake@BevanAviation replied to Oldguy's topic in Avionics/Panel Discussion

Duncan Aviation is where I have to go to get new adapters made. -

KAP/KFC 150 installation differences?

Jake@BevanAviation replied to Oldguy's topic in Avionics/Panel Discussion

-

KAP/KFC 150 installation differences?

Jake@BevanAviation replied to Oldguy's topic in Avionics/Panel Discussion

I believe one of them needs to be change and I want to say it is the top module. I would have to look at the install manual to be sure. As for paperwork I think you could use the original stc install paperwork as it covers all the KAP/KFC for that aircraft/model. However, be sure to consult your local shop first just to stay safe. -

KAP/KFC 150 installation differences?

Jake@BevanAviation replied to Oldguy's topic in Avionics/Panel Discussion

To provide some clarification, the main difference from a KAP150 to KFC150 is the addition of FD bars and a different AI. There is additional wiring as others have mentioned but don't forget about the voltage of the unit or the adapter chips that are airframe specific. Depending on how the aircraft is optioned the KAS297B can be additional as well as a remote annunciator. Also, the KC192 flight computer needs to be married/aligned to the attitude source. This is easiest to do with the flight line tester or if the shop has built a extender harness as all of the gain pots are on the right side of the unit and you can not adjust them if they are in the rack. -

In smooth air alt hold should be within 10-20' from target. Depending on the severity of the turbulence it will increase but it should never go into continuous oscillations. Continuous oscillations are typically related to servo or trim issues, sometimes they can be related to the attitude source as well but are more prone to oscillate in smooth air. I checked the flight line book and the maintenance manual and neither give a reference for tolerance only the specs for the output error of 40mvDC/foot from the transducer. For the trim issues, the slip clutches are designed so they can be overpowered in a runaway condition so you can regain control of the aircraft and pull the breaker/remove power from the trim system. As others have mentioned, even with the system engaged you should never feel like you are going to break something in the attempt to override the trim. Any additional load or friction in the trim system has the potential to put the trim solenoid in a bind. With the solenoid in a bind even removing power from the servo will not allow it to properly release. There is even a test in the maintenance manual for the servo that requires you to put a load on the capstan at a preset torque limit, run the servo so the clutch will slip and then remove power from the solenoid. There should be a instant release with the solenoid and smooth operation by hand. If the solenoid does not instantly release, you adjust the alignment of the solenoid. I would suggest doing an thorough trim test/inspection of the system and replace/lubricate any parts that need attention. NOTE: do not spray any lubricant on the servo capstan or the slip clutch assembly.

-

I have seen an isolated issue with some Gamin navigators where the ILS energize ground does not go low enough to keep the computer happy. Older analog navigators do not show this issue. In the past the solution was to provide a hard ground to the computer with the associated navigator via a relay. The navigator triggers the relay and the relay provides the ground to the flight computer. However, having the ASPEN in the mix throws this theory out the window. I would like to see a apples to apples comparison of the 430W vs the 165 both shooting a ILS approach. Personally I think if you were to look at the ILS ground to the computer from the Aspen ACU and compare the two (430W vs 165) using a nav generator for ILS signals you will notice something different. Could be a different voltage reading or resistance reading but my guess is something is different. The computer was built around analog signals, this issue might be related to all the magic that happens when taking a digital source to the PFD, another digital signal from PFD to ACU, and then the ACU changing it to analog to keep the computer happy. The amount of digital to digital conversions is different when looking at the wiring for the KX165 to the ACU. From the ACU to the computer the wiring does not change, the only thing that does change is what source is providing the signal to the flight computer (digital vs analog).

-

If the aircraft is consistently off 4 deg from the heading bug when tracking HDG, check how it tracks with just wings level mode. If the wings are not level adjust the RN pot. Just be careful to not break the pot when inserting a small flat blade screwdriver. Adjusting the RN pot can potentially cause other modes to be off as this is a attitude trim pot. In theory if the aircraft can fly wings level with no issues adding in an additional nulled lateral command should produce no roll correction command. There are some internal adjustments for the roll servo null command but that would need to be checked on the bench or with the flight line tester before adjusting anything. NOTE: heading, course, nav deviation and roll cross-feed errors are all summed by the roll microprocessor. The only adjustment pot you get before the errors get summed is for NAV deviation. This is the reason why the unit needs to be checked with a test set prior to adjusting any internal pots. If you adjust the roll summed error it will effect all lateral modes.

-

KFC200 Autopilot or trim issues

Jake@BevanAviation replied to milotron's topic in Modern Mooney Discussion

After doing some additional testing on the KTS 151 with a KC295 flight computer. The computer will flash a trim fail if it sees the following condition. microswitch closed in the pitch servo. auto trim command sent to the trim servo no feedback from trim servo within a period of time flashes trim fail as long as the microswitch is closed. The test procedure says to wait at least 20 seconds for the fail to be issued and should clear within .82+/-.3 seconds after removing the command for auto trim. NOTE: the computer issuing a trim fail annunciation did not result in the system being disconnected. If I jumper the feedback to be the wrong polarity the trim fail is issued within 3-5 seconds of the microswitch being closed. Any shop experienced with using the KTS150 flight line tester should be able to quickly isolate the issue in the aircraft. If the aircraft was here, I would start troubleshooting the trim servo first. -

KFC200 Autopilot or trim issues

Jake@BevanAviation replied to milotron's topic in Modern Mooney Discussion

With the A/P system engaged the trim solenoid pulls in the trim servo and remains engaged until the system is disconnected and this is all normal. With the A/P system off you should be able to freely trim the aircraft by hand or you could used MET(manual electric Trim) on the yoke to trim the aircraft. NOTE: you can not have auto-trim and MET at the same time. If the A/P system is engaged and you trigger the MET function the A/P will disengage. Typically a flashing trim annunciation is due to the system detecting a trim fault. MET and auto-trim work independently from each other, you could have a failure for auto-trim but have normal operation of MET. There is a rare instance that it could be a component level failure for the flasher circuit inside of the KC-295 flight computer. When this happens you will have a random flashing trim annunciation that will vary in speed and consistency. Another possibility is the MET switch in the yoke specifically the left side of the split rocker. If the return springs in the MET assembly are weak or broken there is a possibility the left side of the switch is causing the system to disconnect in flight. -

Couple of things to note when the system is doing the PFT test. Closely watch the trim annunciation during the PFT, the trim annunciator should flash 4 times. This indicates the unit is sending 2 up pulses and 2 down pulses to the trim servo and looking for feedback. If you have no trim flashes this normally indicates that the unit is not seeing the regulated trim voltage from the trim servo. After a successful test the system will flash the AP annunciation approximately 12 times. If you don't see a flashing AP annunciation after the PFT, the system could be stuck in the PFT mode. There are some relays used internally to the unit for a attitude ramp test. If these relays fail the unit will not be able to finish the PFT. As others have mentioned always note the position of the MET switch on the yoke, specifically the left side of the split rocker. As the MET switch assemblies age the return springs can get weak or break and will not fully return the switch to a neutral position. If the computer sees that the command for MET is present it will not engage even if it has passed PFT. There are some other issues with the KFC-150 that will cause a PFT test fail like capacitor leakage but it is limited to a manufacture date range of the unit (1993-1998).

-

ASPEN stoped talking to my STEC55X

Jake@BevanAviation replied to Oscar Avalle's topic in Avionics/Panel Discussion

I would have to start at the ACU first and look at the signals going to the S-Tec. A ACU failure would result in the A/P system just maintaining wings level and maybe alt hold if it will pass its PFT. -

S-Tec offers 3 flat rate levels for repair, Minor, Major and Overhaul. Depending on where the unit falls you could be looking at 1K for a minor up to 4K for a overhaul. They want everything going back to the factory for repair and has to be sent in by a dealer. They give some field service memos for like fuse replacement and other small component replacement but no bench level repairs.

-

G5 HSI Installation and 1c388M AutoPilot

Jake@BevanAviation replied to KyleG's topic in Avionics/Panel Discussion

@JDPWithout a radio coupler you just wire per the print to the DG connector CD33. You can get a pre-made isolation box like the AIU-900D from Deklin Technologies that will help with the interface. See attached print for interconnect of a Century II. NOTE: without a radio coupler the G5 HSI will only function as a DG with the option of GPSS. Century IIB pin out.pdf -

M20K with KFC-200 Problems

Jake@BevanAviation replied to MooneyMuscle's topic in Modern Mooney Discussion

@tmo What I could find in the flight line MM is that trim should flash 4 times for a successful test along with all mode annunciations illuminated. Observations on the bench are. With no modes selected, holding the TEST button will light all mode annunciations as long as the TEST switch is depressed and trim will flash 4 times for a successful test. The computer will send a up trim command and then a down trim command for approximately 1 second for each direction. Up is always first, there is a small delay then down. When releasing the TEST button it will do the same test again as the caps are discharging on the adaptor card but, the time is drastically reduced. Attached is the POH for the KFC 200, page 27 outlines a ground and PFT test with results you should see in the aircraft. I could not find any mention of a beep as the system should be disengaged during the test. Disconnecting the system should give a alert pending you have the updated control head. A good rule of thumb is on the ground you should always test the system as much as possible. Modes like G/S capture or NAV/APPR ARM might be difficult to test unless you really know the equipment in the aircraft. However, the basic functions should always be checked like those mentioned in the POH. Those ground checks should be a very quick and easy test. For the ALT hold issue, does the aircraft ever level out after the descent or is it just a slow constant descent? There is a pot on the pitch card inside the KC-295 that might help with a alignment issue for alt hold but, it will not fix it if there is a constant descent with no level out. Alt hold cards are known to fail from time to time but, when they do it's normally a constant up or down drive that is fairly aggressive and they will never level out. A shop with the KTS 150 flight line test kit should be able to quickly tell you if it was a alt hold card issue. KFC 200 POH.pdf -

Autopilot! KAP-150 v/s KFC-150

Jake@BevanAviation replied to CharlesHuddleston's topic in Avionics/Panel Discussion

@CharlesHuddlestonKC-191 modules will have different straps/resistors vs modules for the KC-192. The IM for the aircraft will note what modules are needed for a KC-191 vs KC-192. If I remember correctly only one of the modules will have to be changed, the other can be re-used. Be sure to consult your local avionics shop to ensure they have the necessary equipment for the alignment. -

M20K with KFC-200 Problems

Jake@BevanAviation replied to MooneyMuscle's topic in Modern Mooney Discussion

Having a better description of the issue might help narrow down where to start looking. Some good questions to ask would be. What are the flight bars doing? Is the issue only related to alt hold? How large is the change from target altitude? Has the bridal cable tension been checked? Can the system hold a 5 deg climb or descent? If the static line is removed from the KC-295 is the issue still present? Has the attitude source (KI-256) been changed recently? If your friend has a video of the issue that might help as well. Just be sure to have the ADI and annunciator in the shot. Also, knowing what series of pitch servo would help. Depending on the serial of the aircraft it could have the KS-270 or KS-177 pitch servo. If your friend would like to chat about the issue they can always give me a call.