-

Posts

175 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Jake@BevanAviation

-

Wanted to buy - KC-192 replacement

Jake@BevanAviation replied to Stetson20's topic in Avionics / Parts Classifieds

@amillet It depends on the year the unit was manufactured. If it is the later revision of half surface mount / half through hole motherboards and if the leakage spreads too far it can damage the circuit traces and render the unit BER. The earlier units are more robust as long as they have been modded up. Units manufactured between 1991 and 1998 always have capacitor leakage and the older the units are getting the more common it is. There is normally a red or black 4 digit stamp on the back of the unit around the transducer assembly. This will tell you the year and week the unit was made. If for some reason the stamp is missing you have to open the unit and look at the ICs to get a year range. -

Wanted to buy - KC-192 replacement

Jake@BevanAviation replied to Stetson20's topic in Avionics / Parts Classifieds

I would try and find a high mod -02 for 14v or -03 for 28v. The -15 unit was 14/28 but its complete surface mount. Depending on the extent of the damaged the unit might be BER. The issue with the cap leakage is when it destroys the traces, specially on the surface mount units where the traces are so small you cant install a jumper. Not to mention the boards are multilayer PCB. I would avoid units manufactured between 1991-1998. They have the most problems with capacitor leakage. Also, I do not work on the -15 units due to it being surface mount. However, I can work on the -02 and -03 units. If you have any questions just give me a call. -

Thank you guys for all the kind words, I greatly appreciate them. If you or a friend need any help in the future just let me know. Also, I will say that Mooneyspace is an amazing community that is very helpful and responsive. I truly enjoy being able to add to it with autopilot help.

-

Very common issue. Use your favorite instrument shop if they support the KI-525 for evaluation and repair. Unfortunately, there is nothing we can do here for that system.

-

GI 275 /Century 21 - HDG mode fails after a while

Jake@BevanAviation replied to NicoN's topic in Avionics/Panel Discussion

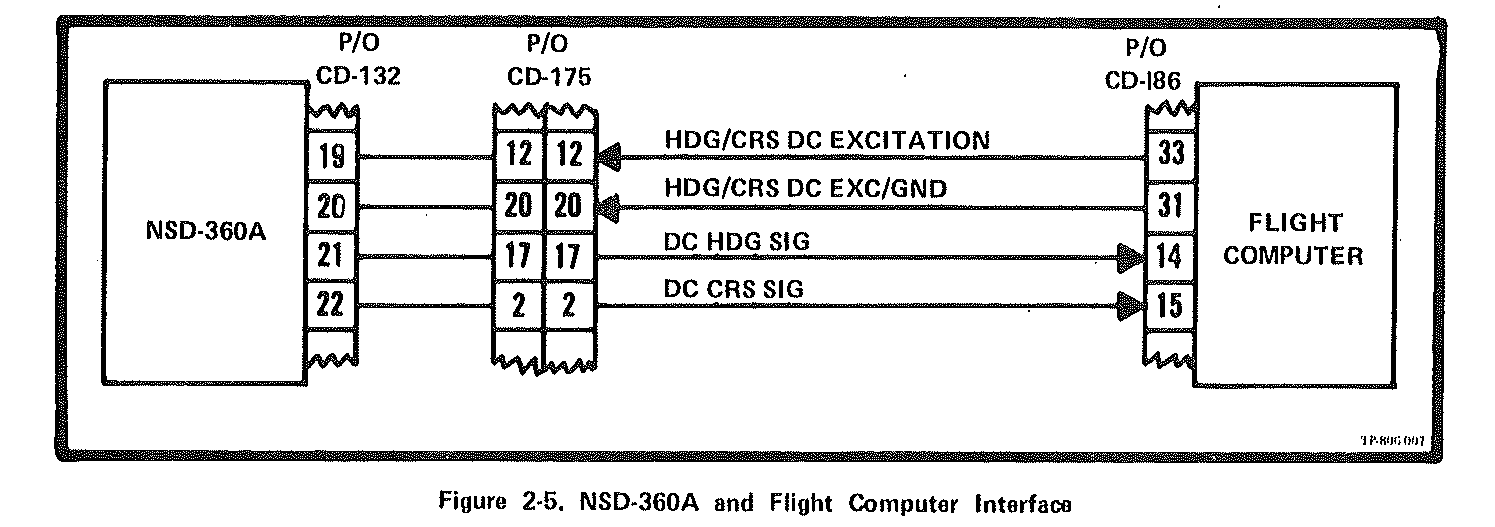

@NicoN for a HSI the most common was a NSD-360. Excitation to the NSD-360 would have been 9.6VDC. The output error under the lubber was around 4.8VDC as the Century 21 uses a half of supply for reference and the supply regulation is 9.6VDC. Going left or right of the lubber line should produce a heading error that goes above or below the 4.8VDC reference. Depending on how the installer wired the aircraft it could be to CD-175 or to CD-186. See print below for details. The Garmin IM show the GI275 P2752 pin 13 to CD-175 pin 17 for the HI and GI275 P2752 pin 52 to shield ground for the LO. No magic box would be needed for the GI-275 install, it should be a shielded twisted pair from the GI275 to the C21. If the installer followed the Garmin IM they should have wired it to CD-175. It might be worth it to have Garmin look at the logs for the heading error to see if it is dropping out over time. After discussing this with our installers we think if the system was failing the vibration test you would have several messages and the system would have to re-align. Another thing they discussed was what color is the heading bug text is? Do you know if the installer used a GMU-11 or 44? Also, if you have picture/video of the system when it is failed that might help. -

GI 275 /Century 21 - HDG mode fails after a while

Jake@BevanAviation replied to NicoN's topic in Avionics/Panel Discussion

@NicoN With the other lateral modes still working it shouldn't be a servo issue. You are down to checking the heading error from the GI275 for the C21 and possibly the IC's for signal processing inside the C21. Be very careful if you are going to open the unit as all boards are interconnected with ribbon cable that are known to cause issues. CD-175 would be the DG or HSI connector, CD-194 would be incoming power/ground, compass jumper select, and disconnect switch. CD-186 would be the connector at the back of the rack for the C21. What compass system did you replace with the GI-275? -

GI 275 /Century 21 - HDG mode fails after a while

Jake@BevanAviation replied to NicoN's topic in Avionics/Panel Discussion

Transformer isolation is not needed with the Century 21 system. -

GI 275 /Century 21 - HDG mode fails after a while

Jake@BevanAviation replied to NicoN's topic in Avionics/Panel Discussion

Odd question but when the system stop working and only does wings level have you ever tried to manual force the system off level and see if it returns to level flight? This would tell you a couple of things. The computer is still working for servo drive, attitude reference is still functional, and the roll servo is still responding to commands. The only thing you would be missing at that point is the heading bug error from the GI275. I am going to assume you don't have any messages on the GI275 indicating some type of heading failure. Also, when heading stops functioning have you tried to see if the other lateral control modes like NAV/APPR are functional? One last thing. Century used this analog gate IC's for signal routing and I have seen these become intermittent with time. Do you know if any of these IC's were replaced when the unit was worked on? Century P/N would be 48s114 or MC14016BCP. -

Garmin 430 repair rumors - Finally finished??

Jake@BevanAviation replied to Mark89114's topic in Avionics/Panel Discussion

I encourage anyone that has any issue with a GNS unit to please contact Bevan Aviation and talk to Mike or Zach to see if we can possibly repair the unit. -

King autopilot roll servo removal

Jake@BevanAviation replied to mooneyflyfast's topic in Avionics/Panel Discussion

@mooneyflyfast got the unit in today and have it fixed and ready to be shipped back. Give us a call when you are ready to issue payment. -

In some instances the KCS-55A system might have required a power inverter. See attachment for details. KCS-55A inverter.pdf

-

Century Trim Servo Motor Repair

Jake@BevanAviation replied to 231MJ's topic in Modern Mooney Discussion

Depending on the state of the armature wear specifically the commutator I might be able to fix it. If the commutator has excessive wear down to the insulator, the motor will need to be removed and sent to Globe for overhaul. I have new brushes and bearings but no new armatures. -

KAP 150 replacement suggestions

Jake@BevanAviation replied to Tmack201's topic in General Mooney Talk

To piggyback on what @LANCECASPER said, I would specifically ask the shop how they aligned the Aspen to the King autopilot and what method did they use. If they mention using the EA100 tool I have seen problems when using that method and I do it a different way. Normally when the alignment is off you might see a slight yoke pump. It's mostly an annoying yoke movement, very minor change in attitude from what I have seen. If it is a larger oscillation around 1-2 hz that could be a tach feedback issue. Typically, when the tach feedback is bad the system is overly aggressive in corrections causing oscillations and noticeable in all modes of flight. -

Check the disconnect voltage at the flight computer P2 pin B to aircraft ground. See print for details. KFC 150 M20jk 14-28v.pdf

-

KAP 150 Self-test pin missing

Jake@BevanAviation replied to PierreL's topic in Avionics/Panel Discussion

088-00762-0000 is the part number for the button. Shows active on Honeywell's website but only request for quote. I do not have any stock of this button. -

Century 4 AP oscillation Help!

Jake@BevanAviation replied to Tx_Aggie's topic in Avionics/Panel Discussion

Depending on the dash number for the flight computer it could have the electronic transducer assembly which is known to fail for alt hold functions only. -

Century Autopilot Service

Jake@BevanAviation replied to chuck459's topic in Avionics/Panel Discussion

Century is out of business, getting new parts for the 41 system is practically impossible without support from the manufacture for ribbon cable and other special parts. Unfortunately, any support you find for the system is going to be extremely limited due to part availability. Most common issues with the system was drive transistor failure for the servos, ribbon cables failing, and the transducer failing for alt hold functions. I would try and contact Executive Autopilots and see what support for this system looks like with the manufacture being out of business. -

KFC 200 will not engage

Jake@BevanAviation replied to willerjim273's topic in Modern Mooney Discussion

Pretty common failure, the control head needs a new lever switch. The plastic switch gets brittle with age and breaks. Hopefully, you found the little piece of metal that floats between the contacts. Trying to glue the switch back together does not always produce reliable results. The switch contact is designed to float for alignment to the electromagnet. When you glue the contact in place it can no longer self-align to the electromagnet and produces poor latching. The current list from Honeywell is $678.53 for the lever switch. I do have stock and will honor the old price of $241.00 plus labor. However, when I have to order more, I will have to go to the current list from Honeywell. My current lead time is 5-7 business days. -

Any time the attitude gyro is repaired or replaced, the system needs to be aligned to the attitude source. This requires the KTS150 test set, you can make an adapter to run the KI256 with the flight computer to be aligned on the bench. The KTS150 comes with harness to align it in the aircraft with the attitude gyro on a tilt stand.

-

New G-5 HSI and Autopilot Interface Problems

Jake@BevanAviation replied to bucko's topic in General Mooney Talk

Start with checking the S-Tec unit strapping for the compass system, it needs to be strapped for a KCS-55A (KI-525A). If this is not done the system will not work correctly. After that check servo rigging and start-up voltage. Ideally the start-up voltage needs to be under 2VDC, the lower the better. Also, depending on what was removed (DG/HSI) you might want to double check that the unit is still getting the L/R radio error. The GAD29B only provides the Heading/Course error. L/R radio deviation (analog) has to come from the primary navigator to the S-Tec unit. -

MET (manual electric trim) has separate circuitry vs autotrim. MET can be functional but have a issue with autotrim functions and still be related to the trim servo. Easiest way to see where the issue is by unplugging the trim servo and monitor the drive lines from the computer for autotrim functions with a DC volt meter. Do a autotrim test (can be push/pull or use the UP/DN switch in the KC290) and monitor the DC volt meter. Ideally without the micro-switches being closed in the pitch servo the computer should generate no drive. When a micro-switch in the pitch servo is closed and remains closed there is a 3-5 second delay before the computer will issue a autotrim command. The autotrim command from the computer will stop when the micro-switch is opened. If the computer checks out with the closing of the pitch servo micro-switches and autotrim drive being issued, the issue is with the trim servo. In normal operation if the computer detects a trim runaway condition (trim feedback) without a autotrim drive command being issued it will issue a trim fail warning. Copies of the IM can be found in the download section for interconnect reference.