-

Posts

932 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by skydvrboy

-

You know it's pretty straight forward to put a scale under each wheel and find out if there's an error. My A&P did this for me after installing my JPI 900 (without asking, but he told me if I didn't like the results we wouldn't log it). Turns out there was a calculation error, they forgot to subtract the weight when they pulled some avionics back in the 90's and I gained about 5 lbs of useful load. I know it normally goes the other way, but it will give you the actual number instead of just continuing to add rounding errors.

-

I'm pretty sure he's referring to high density altitude operations. If you know what your EGT's are during a sea level full power, full rich takeoff, then you can lean to that target EGT during your takeoff roll and ensure you are getting maximum power without hurting your engine. As you climb, continue leaning to that target EGT. It sounds like you are using a single probe EGT. If so, I would caution you about running a little LOP and certainly a little ROP. That only tells you when a single cylinder peaks and others may be running richer and and in a danger zone. Unless you have EGT's and CHT's for every cylinder, you just don't know. That said, I ran LOP with a single probe EGT for a few years until I got an engine monitor. However, I was very cautious to run very LOP to be on the safe side, as in 50 degrees lean of peak. You can't hurt your engine by running too LOP, but you can certainly hurt it by not running LOP enough!

-

I think you misinterpreted what I was saying, and reading it, I can see I didn't explain well enough. It would be dumb to drop it into ground effect and hold it off the runway, that negates all the work you did maintaining your airspeed on final. What I meant was, as you look out the window, just maintain power setting and airspeed until it's time to flair. As you said, that's when you slowly take the power out while you round out and flair. My point was that as long as you don't change airspeed or pitch attitude, your airspeed and rate of descent aren't going to change, so you don't need to keep looking at it all the time. Many of my best landings were after my instructor covered up my airspeed indicator. I wouldn't advocate doing that with a new student (and if the OP is struggling with landings, this certainly won't help), but all students should be able to land without their airspeed indicator before the end of their training. I also didn't list what airspeed I'm shooting for on final, which might have added to the confusion, and yes, correct speed is important. I've simplified it and use 80 mph when heavy, 75 mph medium, and 70 mph when light, so I'm not coming in with a lot of extra speed and just letting it float until touchdown. As you said, that would eat up a lot of runway and I like to be off by taxiway B (1,900') since that's where my hangar is located.

-

Maybe you're having difficulty with your landings because you are too concerned about your airspeed indicator. Sure, check it on each leg, but once you get 50-100 feet above the ground, just look outside the plane and fly it. Slowly add back pressure to round out just above the runway and then hold it there as long as possible. It will land when it's ready at whatever speed is right for the given weight. On the flip side, you can almost guarantee a bad landing if you are checking your airspeed while over the runway.

-

Which airport did you pick? I'm targeting the northern Arkansas or Southeastern Missouri area myself. Of course, that's all dependent upon the unpredictable weather forecasts we've been getting.

-

Help picking the right Mooney...

skydvrboy replied to enginenerd's topic in Modern Mooney Discussion

First, get on the hangar lists as soon as possible. The wait isn't nearly as long as they quote you. If a hangar comes up every month and there are 60 people in front of you on the list, they'll tell you it's a five year wait. In reality, when each hangar comes open, most of the people on the list either won't have an airplane or aren't ready to buy on right then, so they go to the next person on the list. When I got my hangar, everywhere around here said there was a 5-10 year wait list. Turned out it was a year and six months before my name came up due to all the people who passed. Second, if you really think you will wait a long time for a hangar, I think you'd be better off looking for something older than a J. You'll lose a lot less value leaving an "cheaper" older plane out on the ramp than you will a newer, more expensive, one. Third, do you think you'll still own this plane when the kids are teenagers? The kids and all your luggage are going to fit just fine in any Mooney right now, but they'll grow. If you still own this plane in 15 years, you'll be glad you got the longer model (G, F, or J). Last, and most importantly, find a the best maintained plane that is equipped with the avionics you want/need for the type of flying you will do. It's a good bet that one flying reguarly (100 hrs/yr) will be in a lot better condition mechanically than one that is rarely flying. Any of these planes will meet your needs (unless you plan on flying in icing conditions). There is far more difference between individual planes (equipment, condition, maintenance, etc.) than there is between different models. Happy hunting and let us know what you end up with! -

Base Cost of Annual - M20C

skydvrboy replied to Van Lanier's topic in Vintage Mooneys (pre-J models)

I just paid for my annual today. I was charged a flat rate of $1800 for the inspection, which is his normal rate. I received no discount even though I opened all the panels, cleaned and lubed everything, and closed everything back up. I'm not too disappointed that I didn't get a discount, even though I saved him hours of work while he was working on another annual, because his flat rate isn't too bad. I didn't help with any of the engine side of it because he was finished before I even knew he brought my plane in the shop. What I am a little disappointed about is that he thought the tires were too weather checked and just bought me new tires and tubes and was going to put them on without asking. I had absolutely no choice in what tires or tubes were selected. Last annual he replaced all 8 spark plugs because of the number of hours on them and this time around three of those tested bad is his plug tester (no idea what resistance they were). Again he bought me new ones and installed them without even discussing what type of plugs I wanted. Even worse, the old ones were thrown away without me being able to check the resistance. To be fair, most of this is my own fault because I didn't make it perfectly clear to him that I wanted involved in any repair discussions before those repairs take place. I wont' make that mistake next year as I'll have a document stating that "No repairs are authorized nor will be paid without additional written authorization." He will have to sign that before starting my annual or I'll get it done elsewhere. Last year the inspection rate was $1,200 (without any assistance from me) and his shop rate was $72/hr. This year he went up to $90/hr. Not bad compared to what some of you are paying but this is in the middle of nowhere where hangars go for $50 - $100 a month, so cost of living should be factored into that as well. -

If your airspeed or altitude change when opening the door (or pilot window), it's likely that your alternate static port is open. This happened to me during PPL training in a Warrior. After back on the ground, we flipped the valve the other way which caused the altitude and airspeed to remain constant when opening the door.

-

My Mooney specific transition instructor ripped my factory original door handle off trying to close the door in flight after he didn't get it closed properly. We tried slowing and slipping but nothing seemed to work, so he tried a "little" harder. Then I got the pleasure of custom making a new handle that is much nicer.

-

Unfortunately, they have already been thrown away.

-

A related question, is it common for relatively new plugs to fail the resistance test? Reason I ask, my mechanic replaced all 8 of my plugs at the last annual. This year, only 120 hours later, three failed the resistance test and were replaced. He said he's seeing this a lot lately in the various planes he maintains. Says if they pass the first year they seem to go a long time, but many fail in the first year. That seems odd to me and makes me wonder if his tester is faulty. I asked what resistance value he is using as pass fail and he said he didn't know, he just put them in the tester and it either shows a green light or it doesn't. That really surprised me because on most things he knows all the when, why, and how rather than just a pass/fail without knowing why. If it matters, these were Tempest UREM40E's.

-

It's been awhile since I did this on my bird, but we pushed fluid up through the system with a pressure bleeder and got it most of the way. I thought the brakes were still a little soft so the mechanic recommended I take it up to 10,000' or more to pump the brakes and cycle the flaps a few times. Upon landing the brakes were noticeably better and good enough that I thought they were acceptable. As I flew after that for awhile, I'd pump my brakes at altitude and shortly I found them to feel solid, at least for airplane brakes. They're never going to be as good as the brakes on a sports car, so you have to set your expectations accordingly. If you've seen the brake pads on each, you'll know why the sports car has so much more braking force.

-

I have the Johnson bar with the manual lever style seat belt from Hooker Harness and in six years it's never caused any issue or discomfort in any way. The only reason I wish I'd installed the inertia reel on the pilot side is for changing the fuel selector lever. The Hooker Harness seat belts is so adjustable that it simply never gets in the way of moving the gear lever.

-

I went with the manual Hooker harnesses and wish I knew a few things then that I know now. If you use the back seats for passengers any larger than children, go with the manual on the passenger side. Definitely get the inertia reel for the pilot side. If you get the manual belts, have them add the pull tabs to make releasing them easier. They were $2 each when I bought mine, but didn't know about them until the belts arrived. There are only two minor differences between the Alpha Aviation belts and the Hooker belts. On the Alpha belts the shoulder strap hooks onto a post coming off the lap belt, whereas the Hooker belts have a slot in the shoulder belt that the lap belt slides through before connecting. The only other difference is that Alpha has push button release and I don't think Hooker has that as an option. You could ask if it's important. Finally, check with your A&P as you may not need the minor change kit. My A&P just laughed at how much I paid for it as he had all of the hardware needed in his parts stash.

-

Redline aviation in Akron Colorado is $100 flat rate. Those prices are nuts.

-

I think they mean that they're not saving the history of your edits. I customized mine seven years ago and they are still the same as I entered back then. Like you, I wasn't impressed by the slowly decreasing fuel burn so I changed the first hour to reflect takeoff and climb fuel burn and the remainder to equal my cruise fuel burn. You have the choice to use the hourly fuel burn method or the more advanced fuel burn method that includes your climb speeds, rate of climb, etc.

-

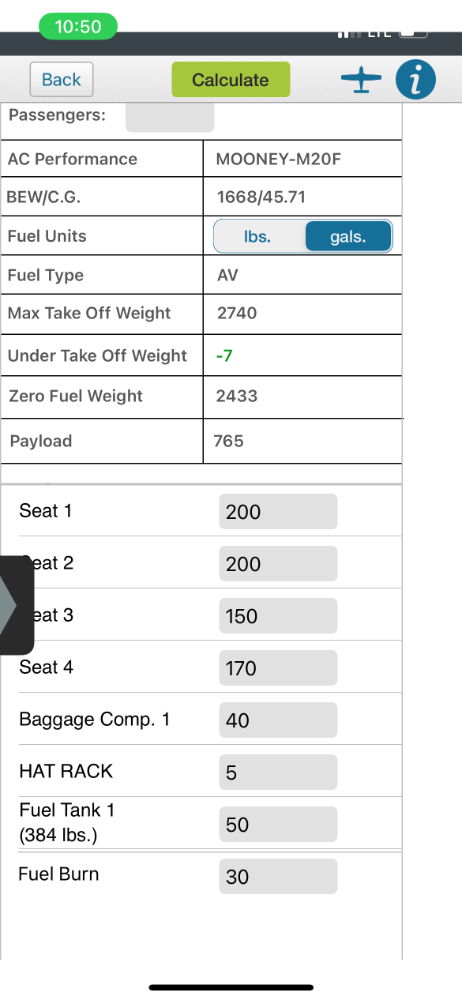

+1 for FltPlan Go. Especially if you already use the PC version. When you put it on your phone you can log in with the same username and it will automatically pull all of your online data through. That's nice for building and filing flight plans on the PC and then their already there on your phone when you go flying. If you really want to get into all the details, you can modify the performance criteria specific to your airplane. I did that, but kind of guessed at the numbers. Now that I have a JPI 900 engine monitor that tracks fuel burn, etc., I should go back and update it. However, I find that I'm usually not off by more than a few minutes and less than a gallon of fuel when I hit my destination, which is good enough for now. Here are a few screenshots from the phone:

-

At several airports in Colorado if you leave your mix full forward you'll just flood the engine. For high density altitude run up, you go full throttle, lean until max RPM, then enrichen the mix a bit and release the brakes. You can then adjust the mix a little on the roll, if needed, to hit your target EGT. Finally, lean in climb for target EGT just as you would anywhere else. Bonus answer: At high density altitudes all takeoffs should be no-flap takeoffs.

-

Switchblade: Kinda cool concept in progress

skydvrboy replied to hammdo's topic in Miscellaneous Aviation Talk

In case anyone wants to try out a Tesla, they have one as a courtesy car in Muskogee. -

Looking for advice on a new Tach for M20E

skydvrboy replied to nevadabandit's topic in Vintage Mooneys (pre-J models)

JPI 900. -

Can you take a handheld transceiver on a commercial flight?

skydvrboy replied to Yariv's topic in General Mooney Talk

Personally, I like to pull up LiveATC.net on my phone and listen in to the pilots that way. I've had other passengers ask me about it but never crew. I also often take my GPS and use it to track our flight on my iPad. The only time a flight attendant ever complained was when I stuck it to the window for better reception. -

I didn't expect to recognize other pilots, but clearly heard Buzz leaving as a two-ship at the 3:32 mark in your video.

- 1 reply

-

- 1

-

-

- m20r

- oshkosh departure

-

(and 3 more)

Tagged with:

-

My KX125 had the same symptom. Turned out it was a leaking capacitor that fried the circuit board. Hopefully that's not your problem, but if it is, Bevan Aviation in Wichita can fix it for you. I was quite pleased with their service.

-

Eddy current inspection in or around Vegas

skydvrboy replied to kechmant's topic in Vintage Mooneys (pre-J models)

Not really in or around Vegas, but Redline Aviation in Akron, CO is my go to shop. They last quoted me $150, but actually charged me less when all was said and done.