skykrawler

Supporter-

Posts

540 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by skykrawler

-

LOL.....I fly with guys like that, usually they fly jets that have yaw dampers and forget that rudder pedals are there except when taxiing.

-

Flat tire on landing

skykrawler replied to larrynimmo's topic in Mooney Safety & Accident Discussion

5 lbs ttps://hornblasters.com/products/88p-portable-air-compressor?currency=USD&variant=33793271617&utm_medium=cpc&utm_source=google&utm_campaign=Google Shopping&utm_term=&utm_campaign=&utm_source=adwords&utm_medium=ppc&hsa_acc=5574733909&hsa_cam=15487599817&hsa_grp=&hsa_ad=&hsa_src=x&hsa_tgt=&hsa_kw=&hsa_mt=&hsa_net=adwords&hsa_ver=3&gclid=Cj0KCQiAtICdBhCLARIsALUBFcGx97U6G95FpiI9DYG1FcTKe0DuA1Mt4Lu1AKjrBHqpequPDnIwiewaAi5lEALw_wcB https://hototools.com/products/hoto-portable-electric-tire-inflator?currency=USD&variant=40162042347726&utm_medium=cpc&utm_source=google&utm_campaign=Google Shopping&gclid=Cj0KCQiAtICdBhCLARIsALUBFcGFTBAqwlAP4sPFN8yujO0Ls4GLdQ-uFaZYTk1DTTSKL5xIIrwKoUwaAr4vEALw_wcB -

Coked up pistons, used oil excessively. Ran great.

-

The airplane is 40 years old. I have no regrets about my decision. New Lyc cylinders. I plan to have this airplane for a while.

-

These are from the overhaul on my engine completed last August for those who have not seen this sort of thing. This was an 1850 total time engine, so the original. I believe there was a prop strike tear down 35 years ago (650 hrs) and they replaced the bearings while it was apart. The airplane had very few hours on it the 4 or 5 previous year before I purchased it.

-

Assuming any reasonable operation management and maintenance this seems to be the most likely basis. But there are plenty engines that aren't run and don't get oil changes when they should.

-

FAA Extends Aircraft Registrations to Seven Years

skykrawler replied to midlifeflyer's topic in Miscellaneous Aviation Talk

And ordered a case of oil filters, too. -

And the gyroscopic affect is often omitted in the analysis. It comes in to play when you flare to land. Imagine the affect on yaw when in a careless power on stall the nose drops suddenly 20 or more degrees. PARE is for spin recovery. I think stall recovery is elevator first. If you dropped a wing, you stalled it. The skid/slip indicator is not just a 'level' - it indicating a force.

-

False ADS-B traffic targets around Everett WA

skykrawler replied to PT20J's topic in General Mooney Talk

The TIS broadcast by the GBT potentially includes traffic from UAT, 1090, and secondary radar. The secondary radar targets will not have a mode-s ID - these are typically displayed with a different symbol on a CDTI. It's possible the ground station does not receive your airborne transmission or fails to associate it with the secondary radar target. The target is added to the TIS-B without an identifier. The airborne receiver typically notices a target with it's own identifier and does not add it to the display bus. Receiver/display equipment is a factor. I'm on the east coast and have had this happen - but it is rare. Love my traffic display in the panel. This is one way this can happen. https://support.foreflight.com/hc/en-us/articles/205482188-What-do-ADS-B-ADS-R-and-TIS-B-refer-to-when-displayed-with-a-traffic-target- -

>> About a month ago, we started burning an excessive amount of oil (almost a qt an hour). The issue seemed to subside, but last week we did a compression test with our local >> mechanic and 2 x cylinders were in the 50s. It hard to imagine a mechanic not noticing an oil leak at the cooler on a Continental that eventually became that catastrophic. If it was in fact high oil pressure - it may have contributed to blowing out that gasket.

-

Dual Bendix Magneto for IO-360 A3B6D

skykrawler replied to Dsolly's topic in Avionics / Parts Classifieds

I don't understand why ElectroAire didn't get the impulse ring electronic ignition certified to work with the D mag. Just disable the one side of the D mag with the p-lead. -

Gascolator Empty Mystery

skykrawler replied to Oklahoma Mooney's topic in Vintage Mooneys (pre-J models)

What he said. And you might consider turning the fuel selector to OFF after shutdown until you find your leak - at current gas prices. -

I think the champions are from Brazil. Has anyone with a F/J tried to install the longer 48104? Will it fit?

-

Somebody else probably knows more.....the Garmin architecture typically has the analog I/O connected to device/unit (GIA?) which performs the conversion and then a digital bus to the G1000 display unit. So the poor connection, if that's the problem, is likely to this I/O device. Your A&P should be looking at the wiring diagram. You said: I've had a flaky oil temp situation for some time now, where it will mysteriously drop out for awhile and then come back. but haven't qualified "for awhile" or when. Only in flight? Also on ground? Engine running, not running.

-

You speak with such authority. But this contradicts the anecdote of @PT20J. What are m-spacers to think or believe? It seems plausible that the FAA has required remedial training in such a case and the individual wisely chose to not fight it.

-

Seems like it should be a thermistor - changes resistance based on temp. I would try to verify the sensor is bad by connecting an ohmmeter between the sensor terminal and a ground on the engine while the oil is hot or by removing the sensor and using hot water. When you say it "drops out" do you mean the indication drops to zero? If so, this implies an open in the circuit. Generally these sensors lower resistance as the temp goes up. An analog gauge will read full scale if you ground the sensor wire.

-

Have any of these posters with complex electronic avionics installations - factory or otherwise - performed an electrical load analysis on their aircraft (empirically using an ammeter)? It can be an educational. And don't forget to check the additional current when transmitting.

-

Correct, a significant design change to the longitudinal control system. That down spring design seems similar to the C182, King Air and other aircraft. Used to add stability for the widest possible CG range. Stability in the sense that the nose down tendency is retained with an aft CG condition when a nose up pitch is applied.

-

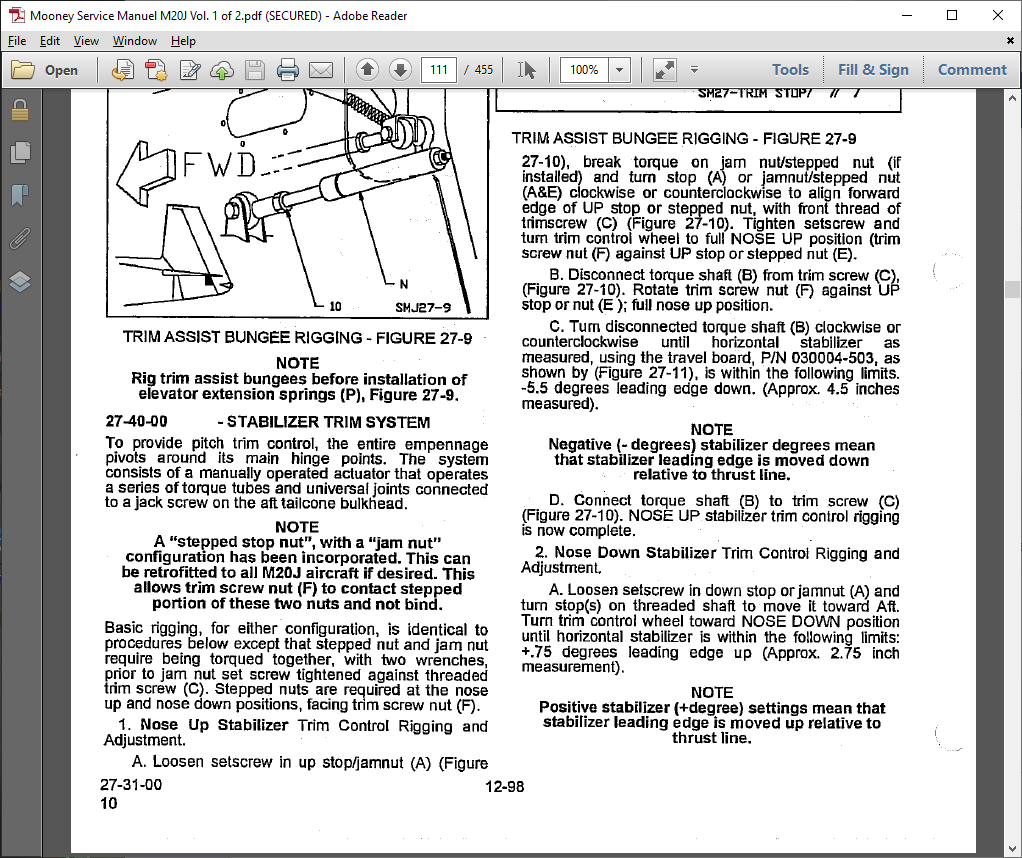

Sound advice. It gets harder to do every single day. On your first point...it may depend on the model. The procedure in the M20J service manual does say disconnect the shaft. This particular section also references the stepped nuts that are supposed to help prevent a jammed condition if one runs the electric trim into the stop (a previous post incorrectly identified this as a run away trim)

-

I think a lot of these airplanes have maladjusted trim indicator systems. In order to correct it the trim shaft must be disconnected somewhere and the indicator set to the correct position. PT20J had a good suggestion for when maintenance was being performed to run the trim to a stop and mark the stab position - then make sure it goes back together just like that. The difference in the OPs picture could be one full turn of the jackscrew. There is a procedure in the maint manual that calls for leveling the airplane and using board on the stabilizer. I found raising the airplane on jacks high enough to make the avionics bay opening level to be uncomfortably high. The thing to worry about is if the indicator hits the nose down stop, it prevents further nose down trim. If you've loaded an aft CG you can run out of trim at a high airspeed. This is sort of self correcting - but probably uncomfortable.

-

-

CIRRUS DOWN AT KMYF TODAY

skykrawler replied to DCarlton's topic in Mooney Safety & Accident Discussion

Are you saying the King Air has a castering nosewheel? Not true. Also, Aerostar's have electric trim only.