toto

Supporter-

Posts

2,843 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by toto

-

The rebuild vs reman distinction is very interesting, and I wonder how many aircraft owners understand the difference. There is definitely a warm fuzzy to getting a brand-new engine log, but I suspect that a lot of owners are paying more for perceived value beyond the logbook. This reminds me of the Mike Busch piece on the "zero-time" moniker for factory remanufactured engines (see below). This piece predates the FAA circular, and Busch mixes the "rebuild" vs "reman" terms, so I wonder if this no longer applies to the current FAA guidance. The AC clearly says that if you're going to give an engine a new logbook, it needs to be overhauled to "rebuild" standards. Lie #10: A factory reman is better than a field overhaul, because only the factory offers a true "zero-timed" engine. While it’s true that a factory rebuilt engine comes with a zero-time logbook while a field overhauled engine does not, it’s not for the reason you may think. When you have your engine overhauled by Mattituck, RAM, T.W. Smith, Victor, or whomever, that engine retains most of its original parts, as well as its serial number, data plate, and engine logbook or other maintenance records. The overhauled engine you get back is legally the same engine you sent in, all cleaned up with lots of new parts. On the other hand, when TCM or Lycoming receives a runout core from a customer, that engine loses its identity. The data plate is removed and destroyed. So are the logbooks.The case halves are cleaned up, inspected, and added to a big pile of reusable case halves. The crankshaft is cleaned up, inspected, and added to a big stack of reusable cranks. The same is true of camshafts, rods, accessory gears, and so forth. Those reusable parts become "anonymous" because they’re no longer associated with any particular engine serial number. Now, when TCM or Lycoming builds up a factory rebuilt engine (colloquially but incorrectly referred to as a "factory reman"), it pulls some"anonymous" case halves from one pile, an "anonymous" crankshaft from another pile, and so forth. When the engine is completely assembled, it gets a new data plate, a new serial number, and a new logbook. The logbook starts out at zero time-in-service. Why zero? Because there’s no other reasonable figure to put in the logbook. The case halves are certainly not zero-time, but there’s no record of how much time they’ve accrued. The crankshaft may not be new, but there’s no record of how much time is on the crank, either. And so on. In short, the "zero-time" logbook that comes with a factory rebuilt engine in no way implies that the engine is "newer" or "better" than a field overhaul. All it implies is that the reused components in the engine are of unknown heritage…nobody knows how long they were in service prior to the time then were cleaned up, inspected, and reused in your engine!

-

Several people on this board have recommended the P2 system. https://www.p2inc.com/audioadvisory.asp

-

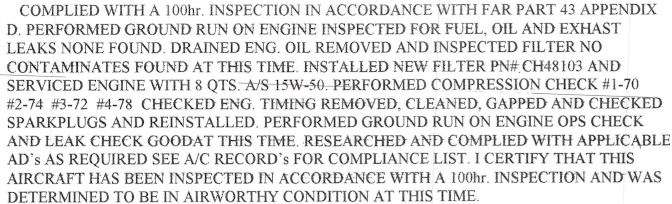

Yes, that image was from the engine log. For what it's worth, the airframe log for this date uses the identical language (same author, same signature, same "100hr" notes in the same places). But it's a fair point, and it's a nuance that I definitely missed as I was going through. I'll start lining up the engine log entries with their corresponding airframe entries and see whether they're all the same..

-

-

Reading through my mx logbooks, I've found several cases where an annual inspection was signed off as a 100-hour inspection. Some of these were from before I owned the aircraft. From my read of 91.409, an annual can substitute for a 100-hour, but a 100-hour cannot substitute for an annual unless it is specifically noted in the log as an "annual" inspection. The aircraft has never been used in any commercial operation, so there is no scenario where it would have needed a 100-hour inspection. These are all just incorrect annual inspection entries. (I've seen plenty of cases where an inspection log just has "100-hour / Annual" language and the inspector doesn't circle one or the other. But the examples I'm looking at now say "100-hour" without the word "annual.") I imagine that this is a very common mistake, since my logs show at least three different shops using more or less the same language. Is this so common that no one ever makes an issue of it?

-

Sorry, I didn't mean to say that it's not a good idea - I think it's clever. I was just responding to the question "what will the offset interfere with?" and was pointing out that in certain airport environments there are obstacles on either side of the extended centerline.

-

At some airports (e.g., my airport), there are commercial buildings on either side of the extended centerline, and nothing but approach lights straight ahead. So if you're not high enough for the turn, landing straight ahead could be far more interesting if you're offset than if you're aligned.

-

Understood. If the airplane is out of commission for whatever reason, there are lots of different ways to get stick time. But if *you're* out of commission due to external stress, then it makes sense to hangar fly until you're in a better place. If at all possible, you need a more gentle introduction next time Book a block of time at a flight school with a well maintained aircraft that has no open squawks. Get the rust knocked off your basic skills, then turn attention to your plane after you're up to speed. Being the test pilot in an aircraft with recent maintenance is a lot to take on - especially if you're not proficient yourself. Having a CFI along is a great idea, but if your CFI isn't very familiar with the aircraft, s/he can be yet another distraction for a rusty pilot. And honestly, if the CFI *is* very familiar with the aircraft, I might ask the instructor to fly left seat for a little while just to get the flows down and shake some cobwebs out of my head.

-

Why only five flights in five years?

-

I just learned in the other thread that Kelly now produces brand-new Bendix D-mags under PMA. Details from Kelly below and at http://kellyaerospace.com/airplane-engine-products/aircraft-magneto/. BENDIX D2000/D3000 SERIES MAG Kelly Aerospace Energy Systems is the only OEM to provide new manufactured and service parts for D2000/D3000 magnetos installed on thousands of Lycoming engines. Our overhauled magnetos are high quality, using a combination of new parts and In 2018, KAES introduced the completely new manufacture D2000/D3000 magnetos featuring 100% new parts. Kelly takes pride in that we support 25,000 owners of engines with the Dual magneto and we provide a magneto with numerous key improvements over the original D2000/D3000 magnetos. All aluminum frame to replace troublesome magnesium frames. The aluminum frame is stronger, longer lasting and far less likely to crack or corrode like the original magnesium frames. All new distributor block and gears. Thousands of these parts have been installed with tens of thousands of flight hours accrued over the past 20 years. All new coils, condensers and contact points.

-

I'm not sure that I have ever suggested this before, but it might be a case where a high speed taxi or two is a good idea. After aborting takeoff #2 and seeing a good second runup, you could exercise various power settings on the 6000 foot runway without rotating. I think I'm in the camp that would say "if it doesn't feel right, put it to bed and call the mechanic," but a high speed taxi could tell you a lot about how a third takeoff roll would feel - with minimal risk of an emergency. If the high speed taxi still feels wrong, call it a day. (I'm definitely not judging here - just throwing out an idea. You're safe and the airplane isn't bent - that's the best possible outcome under the circumstances.)

-

+1 A failed mag check for me has only ever been caused by a fouled plug.

-

Found some discussion on the Kelly mags here: https://www.shortwingpipers.org/forum/archive/index.php/t-8487.html This is just from random Googling, so .. H

-

+1 I’d love a pirep on these too. I’m due for a 500-hour this year, and I’d be very tempted to go with a new unit if they’re better.

-

Any chance you could make this the subject line? This could be a great discussion topic but the subject is sort of vague

-

Interesting, thanks for that. I didn't realize that it was possible to buy new Bendix dual mags today.

-

On behalf of all dual-mag owners, I hope this isn’t true

-

It would be better to redirect to Mooneyspace than to have the site throw up an error page.

-

Yeah it's been that way for years - the site only ever worked on the 'www' subdomain.

-

You can add on a separate annunciator pretty inexpensively.. something like this https://www.aircraftspruce.com/catalog/inpages/vacuumwarning.php (I have no experience with that particular product, so ymmv - just an example.)

-

Honestly, this sounds like an experience that more people should have. In a safe environment, VMC with an instructor, you've seen first-hand what happens when an instrument fails. And you're starting to think seriously about personal minimums (including about minimum equipment for instrument flight). I suspect there are quite a few instrument rated pilots flying around in IMC who have never experienced a real equipment failure, and have an inadequate appreciation for how quickly things can go to hell. Doing the debrief in your head, with your instructor, and with others on MS or elsewhere is the right way to go. But don't be too hard on yourself. You'll be a better pilot for having seen this first-hand.

-

PVT INSTRUMENT Computer Based Training Courses

toto replied to V1VRV2's topic in Miscellaneous Aviation Talk

It's been a little while since I used one of these courses, so I don't want to recommend a particular publisher. But I'll just note that there can be a big difference between knowledge courses and test prep courses. If you take a good online knowledge course, you may actually get a lower score on the written but have a better understanding of the material than if you take a pure test prep course. Since it sounds like you're primarily interested in knowledge, go with one of the long-form video publishers. -

Inspection panel come loose during flight?

toto replied to SantosDumont's topic in General Mooney Talk

Yep. The only time I've seen this was after an annual, with finger-tight screws that weren't followed up with a screwdriver. -

Right, but capping liability to 18 years for certain claims could have a major impact on the manufacturer’s total exposure.

-

Back when US single-engine piston production ground to a halt in 1986 or so, manufacturers were saying that ~50% of their cost was liability insurance. That’s my vague recollection, anyway. After the GA Revitalization Act (1996ish) and later, it may well be that labor costs represent a much higher portion of the purchase price.