Aerodon

Supporter-

Posts

1,242 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Aerodon

-

I'm sure it varies by year. Some switches are on the busbar that is fed any a 70A Aux CB. The Primer button is not on this busbar and is protected by an inline fuse off this busbar. The Trim on the KFC150/200 autopilot is completely separate. You are probably correct, a trim switch that is not part of an autopilot is probably on the busbar. Aerodon

-

The Trim switch is not on the busbar, so you should be OK. Aerodon

-

Same happened to me, I smiled and used it as an excuse to get a discount on the installed cost of Aveo wingtips. You can help me with a further discount by buying one of my old wingtips. I elected to give up on the recognition lights and used those wires to sync the strobes on the Aveo wingtips. We also used it as an opportunity to clean up and paint the inside of the wingtip. The Aveo wingtips are nice, required a bit of trimming and sanding. Make sure you have a bunch of 'rightsize' and 'oversize' Avex rivets on hand. Oh, and we had to add a LED Strobe / Nav light to replace the aft facing Nav lights. A bit tedious, but I used the old 'standby vacuum pump' wire from the panel to the aft fuselage for the new Nav light. Aerodon

-

Andy, I'm prettier sure I have a spare one, will go look in the hangar tomorrow. Aerodon

-

I decided to go in a different direction, bought a VHF/XM antenna for my GDL69A. So have a spare new GA37 GPS/XM antenna, these sell for over $600 new. I have a CNC'd double to go with this if you need one. Or if you need this or any other doubler, I have several shapes and sizes on the shelf. This disadvantage of having a CNC machine, I can't help myself, make all these doublers because I can. Aerodon

- 1 reply

-

- 2

-

-

-

EDM830 Systems $2100 (four) or $2300 (six cylinder)

Aerodon replied to Aerodon's topic in Avionics / Parts Classifieds

Still have one used EDM830 (2019 display unit) with new harness and probes for sale. -

EDM830 Systems $2100 (four) or $2300 (six cylinder)

Aerodon replied to Aerodon's topic in Avionics / Parts Classifieds

Yes I can order EDM900's - these are 'airplane specific' orders and can take a few weeks to get. I can also do a a new pilots side panel to make everything fir nicely in your MSE. -

The EDM800 has almost all the features of an EDM830 without the colour display. It's a relatively easy upgrade from an EDM700, the display is the same size, just add the transducers required. If you have an EDM700 with fuel flow, you will need OAT, MP, RPM to calculate percentage power. I have several EDM700 and 800's in stock, along with all the probes and harnesses needed for upgrade. Pricing will depend on unit being traded in and the number of transducers and harnesses needed to get a full house EDM800. And, when you have all those probes and harnesses, its just plug and play to get to an EDM830. Contact me for any JPI products, especially if you need an upgrade package, new display etc. Aerodon supercub180@gmail.com

-

Hate to say it, but even if you are well insured it sound like the insurance company will write it off. There are too many 'out of stock' parts, and very long lead time items. Also sounds like you might be self insured? Normally you insurance company will have already explained the process to you. I would expect them to recover the aircraft, take it to a nearby airport or storage facility and then figure out what next. The difference between taking it out properly and just hailing it away could be $20K, and that will figure into their decision to write it off? Post some pictures, there are some well informed guys on this site that could chime in. Don

-

EDM830 Systems $2100 (four) or $2300 (six cylinder)

Aerodon replied to Aerodon's topic in Avionics / Parts Classifieds

Hi Billy, nice panel (your other posts). Looks like you have an EDM700 and an FS450. Also looks like you are a bit short on available space. An 830 might fit where your current JPI is, with minimal work, but it is quite far out of your line of site. It would consolidate your 700 and 450, and even your OAT (above the FS450?). My recommendations in order of price: 1) add oil temp and OAT to your EDM700 - approx $300 2) consolidate EDM700 and FS450 into one EDM700 with both. Preferably pilots side. Add Oil T and OAT. Replace factory OAT with clock / USB power supply? - approx $800 3) same as 2) but use EDM800 - look the same as EDM700 but adds RPM, MP and percentage power. - Approx $1500 4) EDM830 (same functions as EDM800, but nice 4x3" display). I think the RHS is too far away. - Approx $2000 - need more transducers 5) EDM900 - this would fit nicely where your current engine cluster is. A little far away, but minimal panel work and the current EGT/CHT harness will probably reach. Your panel is 'nice enough' to go all in with the EDM900. Aerodon -

EDM830 Systems $2100 (four) or $2300 (six cylinder)

Aerodon replied to Aerodon's topic in Avionics / Parts Classifieds

I have one new system left at OSH pricing. $2575 for 4 cylinder, $2875 for 6 cylinder. Aerodon -

Garmin G5 with battery and connector $1950

Aerodon replied to Aerodon's topic in Avionics / Parts Classifieds

I also have a GMU11 (heading) and GAD13 (OAT) to go with this. Aerodon -

All the ones I have done - remove the small setscrew on the font side of the carb and replace with the probe. I don't think the thread pitch of the JPi probe and the setscrew are the same but it works. Maybe epoxy it in to be safe? Aerodon

-

Flap position indicator not longer visible

Aerodon replied to redbaron1982's topic in General Mooney Talk

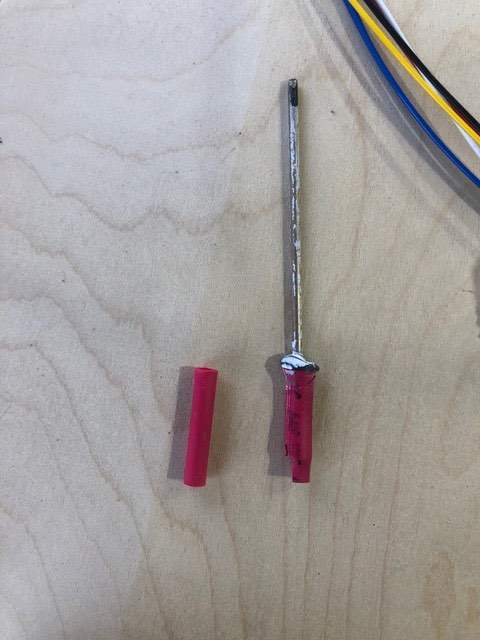

This is from a 252, does it look original? Looks like the metal rod is just a painted brass welding rod glued into an electrical splice? I've experimented with using a Nicopress 'end stop' swaged onto the spring steel cable, will also try crimping this electrical connector onto the cable for a 'pull test'. Anyone got any pictures on how the spring steel is fitted into the hole on the flap actuator? This is where mine broke, need to figure out how best to attach the new one. Aerodon -

Garmin G5 with battery and connector $1950

Aerodon replied to Aerodon's topic in Avionics / Parts Classifieds

Still available -

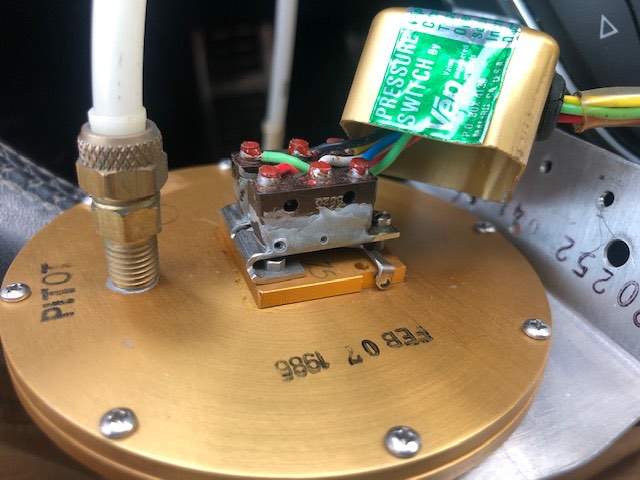

OK, Scott, you sent me down a rabbit hole. A person can 'blow' up to 2.8 psi A party balloon is 0.25 psi The pressure switch is rated to 50" water, or 1.8 psi 65 knots is 0.2 inHG or 0.1 psi So yes, be careful with the switch. Aerodon

-

If you look at the picture I posted above, you will see each microswitch has an adjustment screw. One side was working fine, the other side was 'always open'. About a turn of the adjusting screw, and I could hear the microswitch close. I had to grind about one thread off the adjusting screw to get it to work. Aerodon

-

This is what the switch looks like inside the box. Two micro switches epoxied to a plate. The diaphragm pulls the actuator away from the micro switches. My main micro switch works, the auxiliary switch does not. I am trying to use the auxiliary switch for both a flight timer clock and an airborne sensor for a transponder. It looks like I might be able to get the auxiliary working by adjusting the micro switch ‘further away’ from the actuator with the small set screws. aerodon

-

I had to think about this for a moment. I guess it is fair that your insurance company pays out what you were insured for, and then goes after the other party. If you don't give up your right to pursue the other party, you could have the situation that both you and your insurer are filing a claim against the other party. A good recipe for confusion. So you have to pick a route, either you file a claim against the other party for the full value, to take the money and run. Aerodon

-

Here are some pictures of a helicopter one piece belly. Note the copper backplanes for the transponder antennas, and the neat cables for partially dropping the panel until you have disconnected the RF cables. I've been wanting to move the transponder and DME antenna away from the Mooney side by side location, and also install a belly mounted VHF antenna. Aerodon

-

JPI EDM 830 programming - Fuel Flow at takeoff

Aerodon replied to blaine beaven's topic in Modern Mooney Discussion

I think the issue is that JPI have three fuel flow transducers and want to make sure that the smallest one (201?) is OK with the maximum fuel flow at takeoff. You can look in the lycoming manual for your engine, they usually have the max full rich fuel flow. I don't think you will be far wrong with 25 or 30GPH. (this value is not entered as an alarm anywhere on the 830. EDM900/930, it is if its in the AFM. Don -

https://www.woxikon.com/abbreviations/en/cb, I see circuit breaker made the list, but Cheap Bastard did not.

-

SOLD - THANKS! - Garmin GI-275 Basic - $2650

Aerodon replied to byork's topic in Avionics / Parts Classifieds

Mmmh, new member, good deal posted. Saw same ad on VansAirforce. Could be a scam. But a little due diligence, Bill York has been registered on Vans for a long time. N1ZL (shown as Bill's plane above) is registered to a Frank in Mesa (not Bill). Mesa / Chandler / P19 are all close together. Can verify that Bill York is a pilot, and that phone number appears to be matched to Billy York. Bill works in Aerospace. But lots of information posted, so a little bit more due diligence could raise my thoughst from scam > looks OK > send money. Bill, I'm not sure if I am helping or hindering, but this is the process I would go through. Don -

I'm not a fan of insane jury awards, but if my plane was written off through no fault of my own, I would expect my insurance company to replace it. I don't underinsure, and I don't care if they try recoup their losses, that's their business. I had a hangar fire, my insurance fixed it and filed a claim on the local utility who were the direct cause. They reached a settlement pretty quickly and recouped 80% of their outlay. I'm pretty sure the owner of the Piper M600 that got chewed up by a P51 got compensated and the insurance company would have gone after the P51 pilot? I am aware of one local pilot / owner that flew into a high rise after a medical issue. The residents were relocated and repairs ran into millions. The building owners insurance company filed a claim against everyone and anyone involved. Some guys were dropped fairly early on (no assets or insurance), but the estate was wiped out and his family was left penniless. One avionics shop insurer that had worked on the plane settled for a significant mid 6 figure number, just to avoid a trial. Aerodon

-

1977 M20J Windshield shipping cost & shops

Aerodon replied to Maxx's topic in Modern Mooney Discussion

I see airline windows are nicely milled to make them flush. I think it takes really good machinery and knowledge to machine plastics in a way that does cause them to break during the process or future. It takes special drill bits that 'don't grab', and all edges need to be nicely sanded and polished. The RV guys have endless problems with cracked windshields, the Evolutions that popped their windshields were traced back to scratches left over from sanding. A local C414 is currently having multiple side windows replaced due to cracking. Early Pipers have thin (1/8") windshields and I think replacements up to 1/4" are available. I have witnessed the last screw being tightened on a Cherokee and seeing the windshield crack. My friend's Lancair has a 3/8" windshield (maybe even 1/2"). What I am trying to say is make sure you do you research properly to ensure a thicker windshield will fit, and make sure your installer knows what he is doing with drilling, cutting, fitting, sanding, milling, sealants etc. It's very nice getting a new thicker, tinted, UV protected windshield, but get it done properly. Shipping is the least of your concerns...a lot of labour goes into this, and a lot can go wrong. Aerodon