Aerodon

Supporter-

Posts

1,315 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Aerodon

-

The older Mooneys are a bit short of panel space to do a nice clean installation of additional circuit breakers. In theory the existing single row of switches on the LHS and RHS should be enough for all the OEM electrical equipment. If a new engine monitor is installed, then the old Garwin instrument cluster makes a nice location for an additional 18 circuit breakers. One row could be for all the stuff that comes on with the master switch (GI-275, JPI etc.) and the other two rows could be setup with a 35A breaker switch for avionics master. Next time I fire my CNC machine up, I'll cut out a sample and take some pictures with it fully loaded with circuit breakers. I'd be happy to send a sample to anyone who can help me refine the design and dimensions. There seem to be a few variations in mounting holes. Aerodon @flyingdude @JoeM M20C_CB2.pdf

-

So it sounds like this centre console was originally for an ashtray. My 252 had the vacuum gauge. It's deep enough for just about any instrument. So I made a simple bracket to slide in from the front, with U shaped slots for the mounting screws. It's quite hard to access the screws from the back with a right angle screwdriver drive. So I put two 3/4" holes in the bottom so you can use a regular screwdriver to tighten the top screws. The bottom screw can be tightened with a right angle driver. The attached pdf is an iteration of this - longer bottom shelf and slots to support an O2D2. The yellow rectangle has the dimensions of the faceplate of the O2D2, the green rectangle is the footprint of the side of the O2D2. I prefer mounting things 'centered' in spaces like this, so it will need some form of spacer to raise the O2D2. And I could put slots on the sides of the bottom tray so that velcro straps can be used to hold the O2D2 down, Thanks for the dimensions @pinecone. Give me some feedback and I'll cut it out next time I have my CNC machine fired up. Aerodon Console_O2D2.pdf

-

New GI275 install; problem with KAP150 integration

Aerodon replied to Alangj's topic in Avionics/Panel Discussion

I might have a spare 28V KFC150, is there any merit in replacing a KAP150 with the GI275? Aerodon -

Here is my simple replacement panel. There are 4 mounting screws on the plane that are quite hard to get to, but they just need to be loosened so that the plastic panel slides out. My aluminum panel has holes on the bottom to stick a screwdriver through. I am mounting 'prop amps', vacuum gauge and Aux power complete with 2 post lights. There are no obstacles behind this panel, could easily accommodate a 12" deep instrument. I have the CAD file, could easily make more with whatever instruments you would like to mount there. Don

-

Standby for a pictures. I have made a simple aluminium cover on my CNC machine that replaces that and uses the original mounting screws. Aerodon

-

Apart from the 14/28V issue, they are the same engine. Either may or may not have the dual alternator. But the 231 cannot get the the Encore gross weight increase. Aerodon

-

I was totally confused on a cessna project once, getting continuity to ground when there shouldn't. I eventually discovered the flap switch was partially down providing a path to ground even though everything else was off. Aerodon

-

I have made up a few of these for wing mounting GMU11's. I did a fuselage mount similar to the one above, but with a support. I don't like what I see there, it's like mounting the GMU11 on a tuning fork. Also, I don't like drilling new holes in stringers. It worked for the calibration, but from time to time I'd get an error because of loss of signal. Wing mount works good, but plan on running light and strobe grounds to well inboard of the magnetometer. Aerodon

-

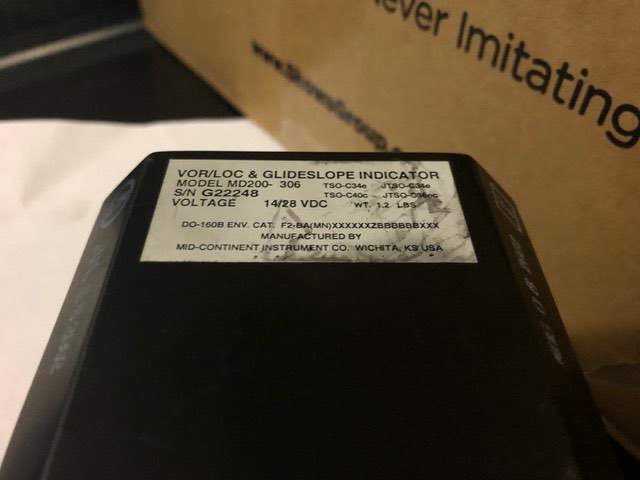

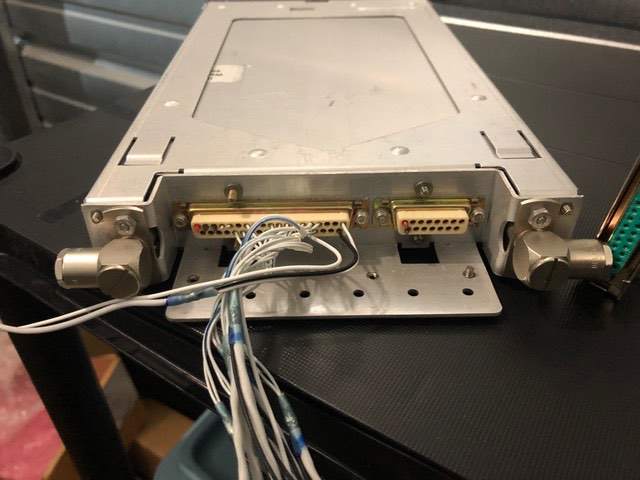

Mooneys are short of panel space, the SL30 is a full feature NavCom only 1.3" tall. I have a spare SL30 and MD200 with a wiring harness. The SL30 is a very high serial number in excellent condition, the MD200 is also very nice with no fading of flags. Already wired together to make an easy addition or replacement to your stack. Aerodon

-

I removed these from my 1986 252 and are available individually or together. With tray and connectors. Aerodon

-

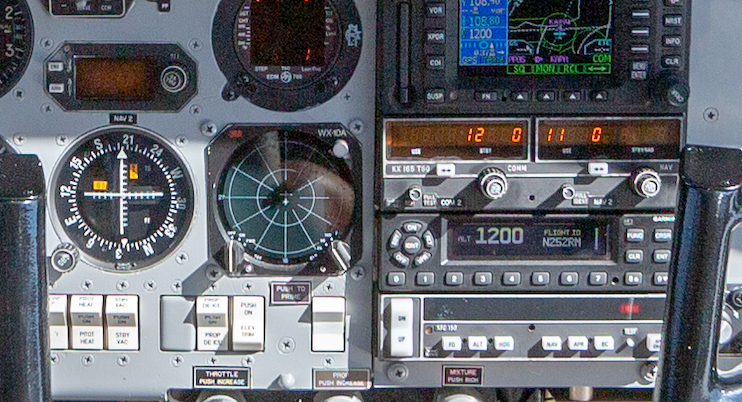

I think the EDM900 along with a GI-275 on the RHS of the G3X is functionally better and looks really good. Attached is a panel for a 252 with a G500. Aerodon Mooney_M20K_N252RM_V6_600.pdf

-

I have this nice 2019 EDM830 display that I can provide with a good used harness and probes for a 4 or 6 cylinder aircraft. 4 CHT/EGT, OAT, Oil T, MP, RPM & FF transducers. P1,2,3,4 harnesses. Aerodon

-

Max, I've installed several EDM900's and figure about 30-50 hours. Sometimes it can take a lot of time cleaning up previous installations removing OEWM transducers, getting new hoses for pressure instruments etc. And depends what else is happening, to make it easier or more difficult. If the cowls are off and the instrument panel side does not require a lot of modification it makes it quicker. There are some things I like about a GI-275, wider selection of transducers, ability to set and change your own alarm limits. Smaller footprint also helps but makes it harder to see numbers. I think a GI-275 for flight instruments is a dealer install, I think the engine or MFD is an IA install? Don

-

Look at the warbirds over wanaka yak 3 crash. The pilot specifically asked if the grass runway was in use at the briefing and was told that it was. He was uninsured and successfully sued the organizers and the guys responsible for placing the cherry picker on the runway. Read about the P59 and B17 crashing Texas, there was no real horizontal or vertical separation plan discussed at the briefing, and look at the end result. The thing about liability is you have to prove the other party was liable. In this case the organizers came up with a rule, and the pilot ignored it. Not to say a jury wouldn't somehow find the organizer partially liable. And then the waivers. The local ski hill has several 'issues' a year (I won't call them accidents), some of them escalate to settlements and some eventually escalate to lawsuits and damages awarded. Aerodon

-

Twice other spacers have been scammed by someone masquerading as me. Once for an item I was not even selling. The private messaging system is fairly secure, but at some point a seller has to provide a phone number, email address or real address for payment. I think what happens is the scammer sees someone posting interest in an article and then jumps on your user name to provide an email to take the correspondence offline. Please use caution and do some cross checking before sending money. Aerodon Donald Hague

-

I've been going through my stock on the shelf and can put together a nice system for a 4 cylinder system: 1) EDM700 with data and fuel flow, new display. Comes with factory return to service documentation. 2) Good used transducers - EGT, CHT, OAT, Oil T, FF - all the data you need to record for engine trouble shooting and analysis 3) Good used harnesses - P1 (Power, data, OAT, Oil T), P2 (CHT/EGT), P4 (fuel flow, GPS, FF switch) 4) Pilot Guide I'll get this ready for installation, making sure you have all the harnesses, sleeves, terminals etc. And I will make sure all the wiring harnesses are long enough and good enough to reuse. And I'll warranty all parts for 3 months. Other systems available - EDM800, 6 cylinder, EDM830 etc all the way through to EDM930. Aerodon

-

My vote would be for a GNX375 - combined GPS transponder. Start with a low cost insta and a standalone, save up for G5's or GI275 later? Remove and sell the DME and KT76A.

-

Audio panels PMA450, PMA8000B, PMA7000B,SL15 $1000 +

Aerodon replied to Aerodon's topic in Avionics / Parts Classifieds

Yeah, the FBI C182's had 2 KMA24H's with intercoms, always confused the heck out of me. I used to get get one radio and the intercom working then don't touch anything. Eventually we did a panel makeover and got rid of them. -

I have too many audio panels on the shelf. The PMA450,8000B and SL15 are new old stock, complete with install kits. The PMA8000B and PMA450 are forward compatible with the PMA450C and various Garmin audio panels. The SL15 is still a very nice audio panel and is a nice way of adding a stereo audio panel with intercom to an existing KMA24 audio panel. I have a guy that can make a harness for the intercom side. The PMA7000 is in excellent condition, has the DRAWS (digital recorded audio warning system?) that can give voice annunciations like 'check engine' 'check vacuum' etc. This was in my Mooney, kinda neat, but will take some figuring out how to connect. Can sell with or without install kits, so priced at US$1000 through US$1600. I also have Approach Systems hub and cables to go with these. Send me a PM and let me know which you prefer. Aerodon

-

I've seen them split.

-

I recently sold some pedal extensions and some other loser tried to get payment directed to him. And a month ago I sold some brake masters and the buyer got scammed out of a deposit. There are bad guys amongst us, sometimes its easy to spot, sometimes not. Don

-

both sets of 1.5" extensions sold, thanks.

-

Sexy New Aveo LED Wingtips for Late Model Mooneys

Aerodon replied to RoundTwo's topic in General Mooney Talk

Me too, if it wasn't for all the holes and permanent rivets I used I'd consider upgrading. You did nut plates, so go for it? Aerodon -

post a picture of your speed brake switch. I have drawings showing the 2 or 3 different types. Aerodon