All Activity

- Past hour

-

Landing flap setting for "normal" landings in a J

Ftrdave replied to Ftrdave's topic in Modern Mooney Discussion

Thank you to all for the great and thoughtful replies. As a pilot with 4000 hours in tactical fighter jets but barely 40 hours in single engine prop planes, I feel like a shiny new penny when flying my J. I'm absorbing every bit of knowledge and wisdom I can get my hands on regarding everything I never knew about flying "low and slow." Here are my big takeaways: 1. Absolutely have to be proficient in landing the aircraft in every flap configuration. Totally makes sense given all the reasons stated....and exactly what we did in fighters... 2. Choose the correct flap configuration for the conditions. This is where my experience falls short as Tomcats, Hornets and Super Hornets are always landed with the same flap setting (unless you have an emergency). I appreciate the discussion provided that lays out reasons for when to use each flap setting. 3. I need go slow flight and stall the aircraft in every configuration (not just full flap) so that I can document Vso for each and calculate 1.3Vso for each. 4. Have already learned the hard way that you have to fly this thing on-speed or just take it around! Thanks again for the discussion. If any of you are ever near KJNX, please stop by and visit (I'm the airport director)! Dave - Yesterday

-

Why isn't he using the old one as a template?

-

All, A&P is installing a new headliner from a two piece solid mold that has to be not only trimed but the holes have to be cut as it's a solid piece. Hes asking that any pictures of a complete headliner that could show exact placement of horns and lights would be appreciated. Can anyone with a 84j please share the layout of the headliner where the horns and lights are mounted and which ones go where?

-

Retract Gear or Flaps First in a Go Around ?

1980Mooney replied to donkaye, MCFI's topic in Modern Mooney Discussion

Since this was posted on the Modern Mooney forum, we have not heard from our J-bar pilots. I bet they would say that they are not wasting any time messing with flaps and that they want to get the gear up ASAP so that they don't have a wrestling match with the J-bar. -

Retract Gear or Flaps First in a Go Around ?

1980Mooney replied to donkaye, MCFI's topic in Modern Mooney Discussion

I think it means "Full 33 degree flaps reduced to take-off (I think it is 10 degrees on the Long Body), then raise Gear, and then reduce Take-off (10 degrees) to 0 degree Flaps". It has been discussed before and the consensus was that mid-body Mooney's don't climb very well with Full Flaps. Perhaps with more power in your Bravo it would not be as noticeable but still degraded. -

I was advised that I am nearing the sb to replace the spring. I am not going to do so. I believe there was a bad batch at some point in the past and that the SB was an over reaction. no guarantee that the “new” spring will not have issues. the life cycles of these springs is pretty light in our airplanes and I see no reason to spend $3k for a $10 part that is unlikely to fail. At least that is my opinion.

-

You only need to fly to Oregon to save that $145.....

-

It switches depending on whether it is driving the gear up or down. Wire per the diagram for the airplane to the appropriate relays. If it goes the wrong way, switch them.

-

Got this in the email the other day from Lasar: Why is the No-Back Spring so important? Per the Mooney Service Bulletin, the failure of the No-Back Spring in the Landing Gear actuator renders both the normal (electrical) landing gear inoperative as well as the emergency (manual) mode. The potential for physical harm and expense of a belly landing far outweighs the cost of safety. Take advantage of our No-Back Spring Kit installation – in accordance with Mooney Service Bulletin - M20-282. Purchase your kit (SB 20-282-001 - $2575.00) Standard install price: $895.00 Labor Day Special Installation for $750 that's a savings of $145!

-

JohnSmithxx joined the community

-

Hi all, Selling my Garmin Aera 760 setup, going to try the Uavionics Sky Sensor/Ipad. This is all you really need to get ADS B in, traffic and weather. It includes the following: Aera 760 in excellent cosmetic and operational condition. Includes yoke mount, cradle, and cigarette lighter power cable. Garmin GDL 39 with battery, also working as it should. Includes two charger cables, one with wall wart &n one with cigarette lighter. The GDL 39 communicates with the 760 via bluetooth. It can also be hard wired ( cable not included). Please note, 760 database is out of date. $1300 shipped in Cont USA. If there is no interest I will list on the auction site, thought I would try here first.

-

Retract Gear or Flaps First in a Go Around ?

1980Mooney replied to donkaye, MCFI's topic in Modern Mooney Discussion

Complicating this discussion is the fact that prior to 1987 (24-3000), M20J's did not have a "take-off" preselect on the flaps. I think it is the same with the M20K but have not looked at all the wiring diagrams. Late J's & K's and Long Bodies have the takeoff preselect. The POH states that if balking a landing with full flaps deployed the pilot should Retract the flaps to "take-off" position before Retracting Landing Gear and then fully Retracting Flaps (from "take-off" position to 0 degrees). This means that the pilot has to look down at the indicator while toggling the flap switch and watch until it centers at the "take-off mark. This fumble farting around looking down can spell disaster when forced to execute a go-around while trying to land possibly in the clag or with an animal popping out on the runway. @PT20J and others are right that full flaps deployed while landing can provide maximum landing performance (except in some conditions like strong winds, etc) but the lack of take-off flap preselect on most "modern" Mid-Bodies creates a sub-optimal (I would argue unsafe) situation to be dancing "flaps, gear, flaps" during a forced go-around. I think it better in Mooney's without a "takeoff" flap preselect to compromise and set up to land with "take-off" 15-degree flaps. That way you are set up to go around without thinking about it - without having to fumble/bumble looking down at a hard to see indicator (especially at night) to raise from Full Flaps to the Take-off Flaps mark on the indicator before raising Landing Gear. If set up with "take-off" flaps, once you break out or know the runway is clear, you can throw in the remaining flaps with a single press of the flap actuator switch (and not having to look) if you think it is needed. Everything in aviation is a compromise. I have no idea why Mooney did not have a "take-off preselect" or a stepped flaps actuator (like all Cessna) all along. Just my 2 cents. -

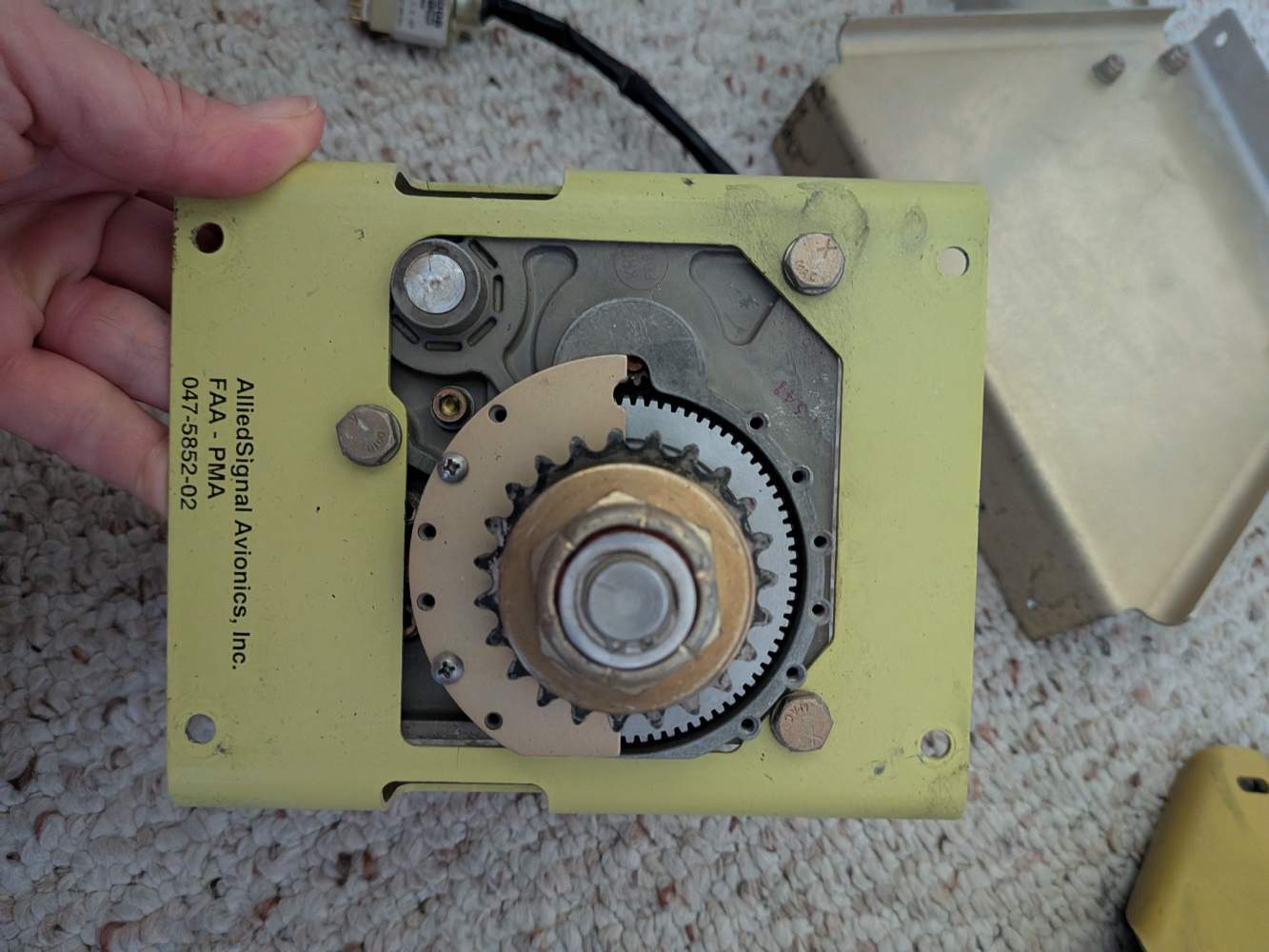

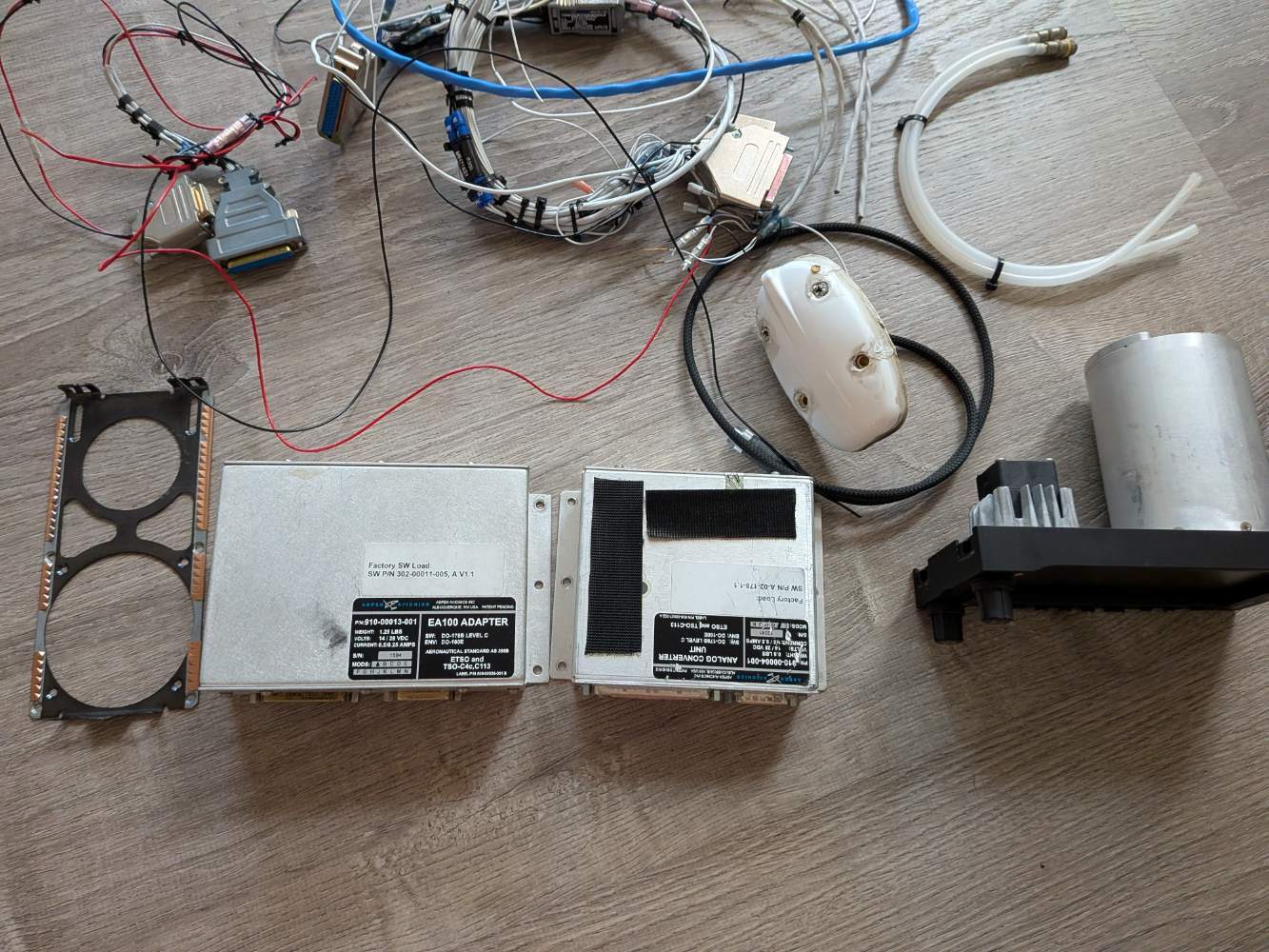

Selling a King KFC 150 Autopilot System and a Aspen EFD 1000. Both units were fully functional when removed from a 1995 Mooney Ovation M20R in May of this year for a Garmin GFC 500 autopilot upgrade.King KFC 150 Autopilot System King KFC 150 Autopilot System This complete system includes the King 150 autopilot computer, Bendix King mounting bracket, and all three servos (pitch, roll, and trim) with their mounting brackets. The system is in working condition, with all functions operating correctly, with the exception of the glideslope capture, which works intermittently. We had this issue looked at, and while it briefly improved, the intermittent nature of the glideslope capture returned. Additional components included: KAA Aural Alerter KAS 297B altitude preselect/vertical speed selector Mid-Continent DC-AC Inverter (Volts: 14-26) We prefer to sell the KFC 150 unit as a package, but are willing to sell individual parts if needed. Aspen EFD 1000 Pro This unit was in perfect working condition when it was pulled from the aircraft. The EFD 1000 was replaced with two GI-275 units for better integration with the new Garmin autopilot. Components included: Aspen EFD 1000 display EA 100 adapter Analog converter Remote sensor module (top mount) Prefer to sell the Aspen in its components as a package. But can sell individual parts if needed. Please contact us for more information or pricing. More pictures upon request Phone: 408-455-4031 Email: juliannechalupa@gmail.com

-

Is green or black positive on motor?

-

Don had me send a couple pics. A tiny screw was holding it on. Job done. Thanks Don!

-

takair started following No Back Spring Update

-

I know SB is not mandatory for part 91, but this shows up in at least some of the Maintenance Manuals… The Ovation manual shows it as mandatory. It’s not an AD, so I guess it may depend on the vintage of the aircraft if this manual applies to a specific airframe or not.

-

PSA for anyone coming to Tampa area

Grant_Waite replied to Grant_Waite's topic in General Mooney Talk

Yeah it’s a luxury to have that option these days. For a lot of us, we are forced into having to go elsewhere which is the worst thing unless you have a very good relationship with the shop. I always found that unless I was present, the work would take twice as long to get done. -

I learned big things air brakes in college driving the campus buses. There is an initial slow to make sure you still have brakes. The fun days with the fire truck are the driving course days. I pretty much have the go pedal on the floor most of the time. The key is when the rear tire passes the cone. going forwards or backwards. The steering wheel needs to be moving fast. They should figure it out when I tell everyone to strap in.

-

Pirep - Gee Bee Aeroproducts Baggage Door Seal

Gee Bee Aeroproducts replied to Z W's topic in General Mooney Talk

I will always answer the phone and questions if need be. Iam either in Jaco Costa Rica or in Hawaii. Cheers -

Pirep - Gee Bee Aeroproducts Baggage Door Seal

WilliamR replied to Z W's topic in General Mooney Talk

Thanks -

I’ve always found Guy to be very friendly and helpful on the phone.

-

That's the European racing school method. You can beat them by trail braking into the corner, although I don't think I'd advise that in a fire truck except as a last-ditch measure.

-

kortopates started following No Joy on Landing Gear Extension - J Model

-

G3X Touch + EIS Owners - How is your tach wired?

Ryan ORL replied to Ryan ORL's topic in Avionics/Panel Discussion

Thanks guys! That seems to be the most straightforward solution then... switch to the hall effect sensor for the G3X and ditch the P-lead pickups entirely (except for the R1). I think with that setup, there's no need for the Tach2. -

G3X Touch + EIS Owners - How is your tach wired?

PT20J replied to Ryan ORL's topic in Avionics/Panel Discussion

I used the the Hall effect sensor on my G3X also. -

Yesterday 2100 feet in non aggressive braking. No speed brakes. If I had braked earlier I could have not had to do a U turn for the 2000 foot turn off. Lht to variable winds. About 14 landings. The trick being to hold off a little longer which shortens the roll out.

-

No Joy on Landing Gear Extension - J Model

N201MKTurbo replied to Brent's topic in Modern Mooney Discussion

I’ve told this a few times. I think people think it is silly, but it is not. In your situation, if it is a contactor, they are mounted to the floor under the pilots seat. If the gear does nothing, stomping on the floor or bouncing on the seat may knock it loose and get the gear going. I also had this happen once and found one of the motor brushes fell out.