All Activity

- Today

-

I also looked up Brown Aircraft you mentioned in another thread and thought this might work on the back of the glareshield. It’s pretty small. https://www.brownaircraft.com/Black-Trim-Lok-Edge-Trim-1-64in-by-3-8in-p/trim-lock-0-b.htm

-

Whats the shortest strip you will land at?

varlajo replied to Niko182's topic in General Mooney Talk

My personal minimums are 2100x30 ft day VFR, 2500x40 night VFR. -

Whats the shortest strip you will land at?

skydvrboy replied to Niko182's topic in General Mooney Talk

Finally got the opportunity to attend a local fly-in that I've been wanting to get to at 1KS3 Leo's Place (1100' published, but later lengthened to 1400'). I reviewed this thread extensively last night along with my POH which was helpful to set my mind at ease, so a big thanks to the guys with MUCH more experience than myself. I did a couple power-off stalls on the way over so I knew the plane was stalling at 59 mph. Overflew the field to check the windsock and landed into the wind. Turns out, the "wind" was about zero and that set me up for a downhill landing. Started final at 1.3 Vso, realized I was a bit high, so I slipped it down and then slowed to 1.2 Vso. Just enough energy to flair but not much more, not a whole lot different than a normal landing other than very precise speed management. Flaps up and back pressure for aerodynamic braking and weight on the mains. I could see I had plenty of room so used very little braking. Stopped in about 900' in spite of the downhill runway. The stall horn chirped once on final, then blared as soon as I started my round out to flair. For takeoff, I chose to accept about 5 knot tailwind so I could takeoff downhill. Did my run-up into the wind, then applied full power about 90 degrees through my turn to final. Kept it on the runway until I knew I had sufficient speed to lift off. Then gear up, flaps up and climb away. The terrain fell away after the end of the runway so no need to worry about clearing obstacles. Lift off was about 950', probably could have yanked it off the ground sooner, but again, could see I had plenty of remaining runway. I don't think I was far off the book numbers for either the takeoff or landing given the conditions (grass, downhill, tailwind, etc.) Of course I went light, about 530 lbs below gross. There was a lot of discussion on here about whether to have a steeper approach or a normal 3* approach. With no glide slope indicator, I couldn't really tell you what I did. It felt like a normal approach, but I almost always use a steeper approach than the glide slope indicators. Sorry, I can't help settle that argument other than to say, don't change your approach substantially from your normal approach. All and all, quite fun, but don't do it without a bit of practice at a longer field. My hangar is 1700' from the end of a 12,300' runway, so I do a lot of short field landings to make my turnoff. -

They seemed pretty easy to get until shortly before the most recent factory ownership change. When Jonny took over, one of the things people were asking for was availability of the NBS, and I know this was on his short list of things to shore up. But it never really seemed to happen. Prior to 2020, iirc you could get one of these through a MSC for under 1AMU.

-

The way I was interpreting it was that the spring breaks when the lever goes up, and the gear remain down and locked. So no gear up landing, no report filed. I don’t pretend to be an expert in these actuators or the sequence of events, so I may be way off base.

-

I believe that's Trim Loc which is pretty thick. I haven't tried this, but I think it's a possibility https://www.glapinc.com/Cessna/misc/misc.htm

-

Have you got the “bravo” style glareshield in your MSE? I thought that didn’t come out until the Allegro in ‘96? My ‘91 isn’t bad to remove. I do put some gaffer tape on the center post to avoid scratching it, but otherwise remove the two screws, disconnect the glareshield lighting, and pull straight back while bending it at the seam in the center. Slides right out no problem.

-

Jaeger no longer sells it; they've lost their supplier. Vantage has some and this MM Seal looks to be an option https://mmseals.com/collections/edge-trim/products/gray-edge-trim-standard-size-u-extrusion-u-height-17-32-grip-range-3-64-9-64

-

I replaced the windlace in the baggage compartment area today; it was much easier than I thought (and that's without having the old one to match the cut/hole placement). I also re-installed the overhead piece in the baggage area so I got a first view at the colors and I'm very happy with the color combo. I'm glad to have gone a custom color (even if I means waiting a few weeks to get the last piece painted because the shop ran out of on ingredient). The only downside is that it will show dirt much easier. I'm leaving town tomorrow morning for a week so no more progress but it gives me time to order a few odds/ends I didn't expect to be issues like the window beading.

-

When I was there, runway 5 was open, I landed on it. Taxiways A and E were closed so I departed on 23, no traffic or wind. Rwy 5-23 was in great shape when I was there. No idea why it is closed. I just looked it up, they are building a larger GA parking ramp and redoing taxiways A and E. I imagine the runway is closed for the taxiway work. https://www.facebook.com/hsairport/posts/here-are-the-latest-updates-on-the-airport-construction-project-at-khot/1168719931956240/

-

Well, with my Mooney now out of annual, it's time for an update. In an earlier post I wrote "The cable as well as the housing are as far as I can tell firmly fastened to the mount and not slipping." My mechanic ended up finding that the mounts were loose, and squawked it on annual to replace. Flew today and the issue is resolved. I'm glad that even though I over-thought the issue, and missed the simplest solution, the professional I trust to find these things didn't. I hope the learnings in this post will go on to serve someone else well in the future! I definitely enjoyed reading the replies.

-

kortopates started following IAS Airspeed In a Bravo and No back spring

- Yesterday

-

wac007 joined the community

-

WTH -- seriously, is this what the algorithm thinks of me

IvanP replied to McMooney's topic in Miscellaneous Aviation Talk

Did your "mooney" space get invaded by bugs? AI at its best -

My guess would be shortly after the SB was published, pure conjecture, though. Similar to the turbo V-band clamps. Before the recent AD, they were somewhat available. Shortly after the AD was published, they became unobtainium.

-

I was there a couple of months ago. Runway 5 was open then. If it’s IFR it looks like the circle to land option is going to be the only option. Weather looks a bit sketchy for Monday. I can understand why 13 is right traffic as the mountain is rising quickly to the east.

-

Does anyone know when the springs stopped being readily available?

-

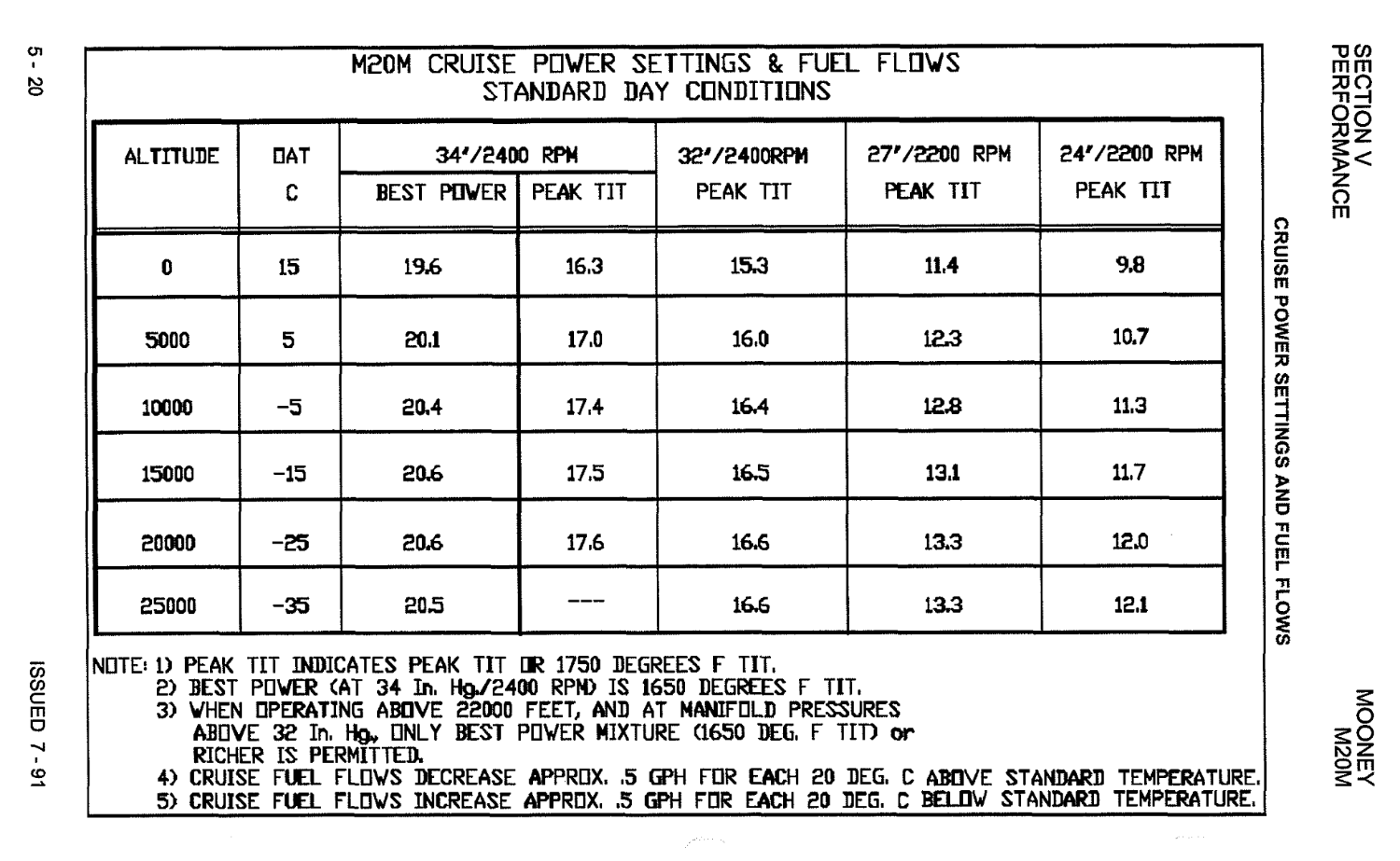

Several things catch my attention here. First, your TIT is 1644 and your highest EGT is 1517. That's unlikely. The TIT is nominally 70-100Fº higher than the average of the EGTs, and yours is 126Fº higher than your highest EGT. This COULD be accurate depending on the placement of your EGT probes, but doesn't track with what I've seen in my airplane or in a couple of other Bravos. Second, 17gph at 31.7/2380 is very close to the book values for peak TIT, and at that high of a power setting the CHTs should be in the neighborhood of 400º. Your hottest CHT shows as 349º, which also seems unlikely because your power setting is right in the middle of the "red box". Third, as Paul pointed out, your EIS is indicating 65% HP which is definitely incorrect. The generally accepted "safe" ROP power setting is ~18gph at 29/2400, which nominally yields a TIT in the mid to upper 1500s and CHTS in the high 300s. With that as a baseline, your indications appear suspect. I'm sure you've spent some time looking at it but I'm including the POH power chart for reference within this thread so others can see what the book says. And we know that we don't want to fly these numbers.

-

Not only that, perhaps people actually change the spring according to the SB? I mean if there's an SB and people follow it then it would be logical to not see any failures. People saying "we haven't seen massive amounts of these springs fail" just ignore the many owners that actually change them. Or are these people saying no owners follow the SB??

-

Hi all, Just to circle back on this - I was able to find the bulkhead and the spinner from Hartzell. After about 6-8 weeks of waiting for it to be made... It showed up and it works great! I think it gets better air around and into my intakes because it has a way better gap between the spinner/bulkhead combo and the actual cowling, which makes me obviously feel a lot better from our previous conversation and feedback about how close it was.

-

Private sector yard. We built mostly work boats like tugs and ferries, and large yachts. One of the yards did build a few Coast Guard cutters with deck guns though! My composites experience was outside of the shipyard and for a really interesting, but niche special project run through a high performance sailboat component manufacturing place. I learned so much there, it was such a cool place. Unfortunately they went under, and I hopped ship early as the writing was on the wall.

-

He’s probably flying that high power setting believing his engine monitor saying it’s only 65% power! Yet it’s over 80% depending on altitude. one generally can’t use the %power displayed on their engine monitor till they calibrate it. Sent from my iPhone using Tapatalk

-

The glareshield on my 1994 J is a royal pain to remove. The one on my 1978 (without the hump in the center) was a breeze. You are right that it is a tight fit and most of the u-channel I found is too thick. My painter buys his from Textron because Cessna uses it and it's the only source he's found for it. But, I think the silicone window beading that Jaeger sells would work as it's pretty thin. I use a couple of tricks I picked up from other MS posts when removing my glareshield. First, I remove the compass from the center post. Then, after removing the glareshield screws, I slip a couple of thin plastic sheets on either side between the A pillars and the glareshield to make it slide more easily. Lastly, I lift the front edge up towards the top of the windshield and pull rearward which seems to give the most clearance with the least flexing of the plastic.

-

Did the glareshield still fit ok? Mine seems pretty tight and I don’t think there’s anything along the back protecting the window (which looks bad there). Also when you take out the glareshield do you take off the trim pieces between the front and side windows? Those seem to block complete removal.

-

I admit to using SS screws because I like the way they look and I've never had an issue. But there are disadvantages. Stainless is softer than carbon steel, and it it easier to cam out the head if you overtighten. Stainless will gall. Heat and friction cause this. There is also the corrosion potential. I have never had an issue with corrosion around the fasteners, but my airplane is in a hangar. If it was outside on the gulf coast, I would probably use cad plated steel screws. To avoid the camming and galling, I tighten and loosen screws with a ratchet screwdriver rather than a power driver to avoid turning them too fast (galling) and overtightening (camming). I also soak the screws in ACF-50 before reinstalling which provides lubrication for the threads and perhaps some corrosion protection.

-

I’ve flown in there on the ILS and RNAV 05 and circled to land on 31. 31 has rising terrain and looks high but np in taking off. I usually do a downwind departure to the southwest if taking off 31. VX climb then VY to traffic pattern… 13 is right traffic btw… -Don

-

Subs? The folks in Portsmouth were the planning yard for the program I supported. Thanks for the refresher.