All Activity

- Past hour

-

Over Center Gear Link bushing 914020-017 bushing

Fritz1 replied to BrianL29's topic in Modern Mooney Discussion

excellent! -

jeremyc209 started following Mooney pilot draws an A-10

-

It's not about skill, it's about having a little fun.

-

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

Fritz1 replied to cliffy's topic in General Mooney Talk

during annual in March we discovered a small elevator bellcrank that caused excessive play between the elevator halves, small handmade part riveted together from three sheet metal plates, bushing, bearing the whole thing about 4" long. As a quick and legal fix we replaced the loose hylock fastenters with monel rivets. Consensus was that this part would be $2500 to replace if it were a Beechcraft part. The Mooney part had a lead time of 13 weeks and a price of $800. When I got the part I was amazed, Mooney had re-engineered the part to be integrally milled in one piece. No doubt they lost money on that part. Soo, parts prices will go up because they have to. About the same time I was approached by an MSC wondering if I was ready to fund parts production at Mooney with a fixed amount per year, lots of questions, nothing ever came of it and now Lasar stepped in. Problem still remains, parts production needs to be funded to build up inventory, by how much? probably by the amount of 6 months of parts sales. So, instead of moping, who is ready to step in? 300 owners at $3000 a pop makes $900k, enough the get things moving funds to be released to Lasar and/or Mooney for inventory buildup by a board of the the 3 largest donors? The whole thing blows up, guess what fonds perdu as the French say. In the end gotta pay the piper! Whoever is interested in being part of the solution, please pm me. -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

Rick Junkin replied to cliffy's topic in General Mooney Talk

Once you take the time to research the process, and the FAA requirements and involvement, it will make more sense to you. What "should/could be" and what "is" are two completely different things. Change/streamlining of the FAA process will not happen quickly or through actions or abilities of the users of the system. Until the FAA formally changes the PMA requirements and approval process, no amount of technical savvy on the part of an applicant will make any difference in the time or expense required to accomplish the process. -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

hazek replied to cliffy's topic in General Mooney Talk

Sure that makes sense. This less so. In today's age with computers, especially now with quite useful AI this paperwork stuff should be an easy problem. Perhaps it's not attempted by people who excel in this sort of stuff but by people that are savvy in other relevant areas. Hopefully Lasar knows how to get these steps done cheaply enough so that the manufacturing process itself can be feasible. This parts problem is another huge concern of mine regarding the future, like AVGAS phase out, that makes me very motivated to only think about how I should find a way to drive a turbine Piper asap. -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

WheelPantsOff replied to cliffy's topic in General Mooney Talk

Parts support, combined with the aging out of the ownership population, will be the death of this brand. - Today

-

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

1980Mooney replied to cliffy's topic in General Mooney Talk

That sounds exactly like what Arcline/Hartzell and other various Private Equity that are consolidating General Aviation businesses & FBO’s think and say…. -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

Rick Junkin replied to cliffy's topic in General Mooney Talk

If you do an internet search on "what does it take to receive FAA PMA authority" you'll find the information and reference data that will help answer your questions. In addition to cumbersome and slow, the process is expensive, especially for a shop that doesn't already have a documented formal quality assurance program. And that assumes the shop can obtain the production engineering data from the original manufacturer, or have the capability to reverse engineer the data to the FAA's satisfaction. Then there is the cost/benefit analysis that accompanies any business decision. Economy of scale is difficult or impossible to realize in our niche market, so a business needs to recoup all of the administrative, testing, tooling and setup costs in the price they charge for the limited quantity of end product. This price needs to allow the manufacturer to be profitable while remaining affordable for the end customer. We've just seen this with new production of no-back springs for the gear actuators. Affordability is in the eye of the consumer. And altruism isn't a trait commonly found in significant measure in a successful business, so if in the C&B analysis the part(s) can't be produced at a cost that allows for an affordable price, it doesn't get produced. -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

jamesyql replied to cliffy's topic in General Mooney Talk

For an “in current production” example- my friend’s SR22T was AOG for 1 YEAR when he needed a new nose gear strut. Nobody is completely safe from parts availability issues. We should support Lasar’s goal to keep our planes in the sky! -

I just sent mine to aero accessories based on what I've been reading here. I get my plane back on Monday, so we'll see how it goes. http://aeroacc-vny.com/

-

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

cliffy replied to cliffy's topic in General Mooney Talk

Its calle Its called "traceability" and PMAs And yes it is cumbersome and time consuming and costly to get the approvals And the market for the investment is only 7000 possible customers I see it took 9 months to get PMA approval for the SRS Beech skins plus 10s of thousands of dollars And the approvals came just last July. Learned something new. Up until then Bonanzas were paper weights if the ruddervators were junk. Less$$$$ maybe but still $7100 just for the part - A piece of stamped magnesium sheet metal If its so easy to make parts why did it take so long. ANY decent stamping plant should have been able to do it - right? If we don't have parts how will we get a "stretch formed" wing leading edge skin if we bang into a fuel truck? Who will pay the $$$$ involved to set up a PMA SYSTEM to stretch form wing skins for a few airplanes every year? How much do you think those would cost? -

IO-360 ‘warm engine’ start on M20J

Fly Boomer replied to Tiny18Driver's topic in Modern Mooney Discussion

This is Maxwell's hot start procedure, but it may suggest an approach: https://youtu.be/jbRYqS-fRo0 -

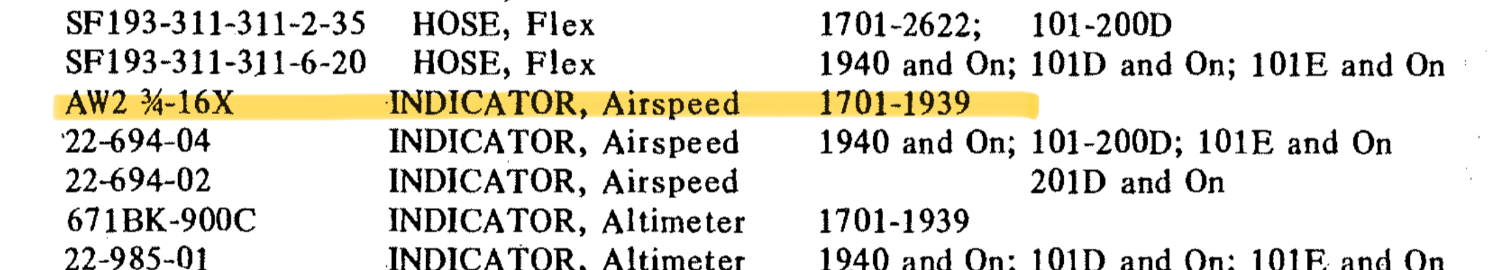

Several available on controller.com… https://www.controller.com/parts/search?PartNumber=AW2-3%2F4-16

-

There are three Mooney's based at TCL. I haven't yet met the owner of the plane that flew this mission, N7132V.

-

I think that getting the FAA ‘stamp of approval’ can be a very cumbersome process. Look how many hoops LASAR had to jump through when they moved to Oregon and had to start working with a new FSDO. My guess is that they had to reaccomplish FAA approvals on every part they touched. The ‘F’ in FSDO might be a pseudonym for Fiefdom.

-

And the 8130 is signed by the 17 year old behind the counter :-)

-

Crankshaft Seal (split or not?)

WheelPantsOff replied to bnicolette's topic in Miscellaneous Aviation Talk

To close the loop on this, the one-piece seal the A&P installed seemed to solve the leak. I did notice that the oil return tube rubber couplings on the bottom of the engine were very loose and could be spun by hand. The hose clams holding those in were tightened and a noticeable decrease in belly/gear door blow-by was evident after a few hours. -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

hazek replied to cliffy's topic in General Mooney Talk

How can it be so difficult to transfer manufacturing to modern practices? Are regulations really that stiff and the process to obtain approval that cumbersome and slow? I'm pretty sure any decent shop manufacturing parts could manufacture any part for our planes. Where's the catch? And why doesn't someone just do this? -

Bumping this back from the dead. Where are people sending their D4LN-3000 magnetos for inspection/repair nowadays? Thanks in advance.

-

National Aircraft Parts Association has many parts for our Vintage birds!

-

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

Sabremech replied to cliffy's topic in General Mooney Talk

@cliffy ruddervator skins are now available for V-tail Bonanzas from SRS Aviation. They are also selling them for LESS than when they were last available from Beechcraft. Hmmm?? What? Less? How can that be? -

Nice description! This will help someone else with less experience.

- 63 replies

-

- carbon fiber

- fiberglass

-

(and 2 more)

Tagged with:

-

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

Matthew P replied to cliffy's topic in General Mooney Talk

UNTIL you realize that that 30% increase DOESN'T include LASAR's 500% markup.. -

Mystery oil pressure indicator switch

skykrawler replied to Flyler's topic in Avionics/Panel Discussion

Did you buy the airplane from a person with no name or phone number?