-

Posts

1,696 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by exM20K

-

Back-cylinder (#1/#2) CHTs in Ovation IO-550.

exM20K replied to Jeff Uphoff's topic in Modern Mooney Discussion

How are the baffles, and are all the through-the-firewall grommets in place? definitely swap two probes to confirm it’s not an instrumentation issue. If the baffles are old and floppy, they can make a poor seal against the top cowling at the rear of the engine compartment, spilling cooling air out the back. Mine is currently a bit bimodal: #1, which is indicating cooler than #2, has excursions up and down about 15* as the baffle sags and goes Back to its seated position. It has done this for a long time, doesn’t keep me up at night, and I’ll eventually replace at least the rear baffle. How big is the delta between #1 and 2, and do they track each other and the other CHTs? -dan -

A dab of this stuff will prevent the seals from sticking https://www.amazon.com/303-Rubber-Protectant-Conditioner-Weather/dp/B00T44D1R2 -dan

-

Dunno if I’d call them similar: TSIO520 is bottom induction and single (?) turbo. TSIO550 dimensionally a stroked TSIO520 but with top induction and 2 turbos and intercoolers vs 1 (?). The top induction seems to make the 550 more easily capable of LOP OPS. TBO is also higher for the 550 for those that care about such things as TBO. Which leads to your questions….. it is the received wisdom of enlightened piston aviators that LOP is kinder to the top end than ROP. If there is a higher percentage TSIO 550 hours done LOP vs the TSIO520, then “our” liturgy favors 550 cylinder life. Here in the real world, disuse probably kills more engines or top ends than how you operate it. My one datapoint is the disuse-induced corrosion on my cylinders when I bought the plane. When oil consumption fell below 4hrs per quart, I had all six cylinders overhauled. CMI has had issues with improperly ground valve seats in the past. This is probably the same for both the 520 and 550 and has lead to many a cylinder coming off for leakage past the exhaust valve and burned valves. I dunno if their fancy new machine tools have corrected this deficiency. I did and would again overhaul one or more jugs on condition. They will tell you when they are done and usually without catastrophic failure. Burnt exhaust valves and low compression, corrosion and high oil consumption, cylinder/ring wear with high oil consumption, a pressurized crankcase blowing oil out of the breathers. These are all good reasons to fix one or more jugs. A borescope and careful attention to changes in oil consumption are your ally here. How to make sure the shop does it right and doesn’t kill you with a spun bearing after leaving a through bolt finger tight? Good question. Showing up a few times in the morning with a box of donuts or a pizza lunch can’t hurt. After my top, I found a dead EGT probe, a wrench sitting on top of one of the intercooler, and chased a MAP lapse issue that was finally diagnosed as as a cut in the MAP line going to the G1000 sender. It was cut when the tech snipped a zip tied bundle of wires sitting on top of it. oh, and I hit a bird in the pattern on the first test flight. Obviously that wasn’t the shop’s fault, and we’re still friends. Me and the shop, not me and the bird. bake a mid time top into your cake economically, and maybe you’ll be pleasantly surprised. The cost and downtime aren’t nothing, but neither are they life-changing. -dan

-

Good grief. I deleted that post almost immediately after making it as I find the drift into insurance and liability for hypothetical events icky, given two airmen perished, people on the ground, including children, were likely traumatized, and one of our members lost his plane… I really didn’t want to contribute to the ickyness. There are two families dealing with the loss of loved ones. They may happen along here. Im trying to be a decent human being, so I deleted my post, which you quoted within seconds. Please do the same to yours, and I’ll delete this one. My comment, which I immediately deleted was in reference to yours: “And if you are underinsured you are screwed for no fault of your own.” That is simply not so. It is the owner’s responsibility to adequately insure their plane. Why would you suggest Im suggesting anything beyond that? But, seriously: this is a tragic event for all involved. I’m thankful that the OP and family are OK, but mostly saddened by the loss of life. -dan

-

Very glad to hear you and family escaped injury. Sorry about your plane. Any word on the involved pilots? -dan

-

It is worthwhile to practice an “icing conditions” approach. Minimum airspeed in icing conditions is 120 KIAS. Maximum flap extension if icing has been encountered is 120 KIAS. Practice would be something like an ILS or GPS approach flown at >120 KIAS, takeoff flaps only and a full stop landing also with takeoff flaps only. Do you know your approach and stall speeds in this configuration?. It’s very different from SOP for me and good to perform in benign weather before trying it “in anger” -dan

-

Unfortunately, these dates coincide with my daughter's college parents' weekend. I would like to support the event, though. Are there other ways to contribute? -dan

-

Craig Fuller was interviewed on a sporty’s podcast a couple of mo the ago. He talked about the Flying Magazine purchase in terms of the content library being the most valuable piece along with the brand. This is not so different than Sportys buying the rights to Air Facts. But Sportys is using content for inbound marketing, which I think is smart. Content for content’s sake is hard to monetize. Probably the vast catalog of Aviation Consumer content is what he’s after. While it’s not obvious to me how he will make it all pencil, he doesn’t appear to me to be a dumb guy, and if he makes a go of it, then I think that’s a win for all of us in GA. It is also not obvious that the current Belvoir / AvWeb model could continue, especially with Sporty’s turning into a content engine. Things change.. -dan

-

CHEETAH VS BO; MOONEY WATCHES IN HORROR...

exM20K replied to DCarlton's topic in General Mooney Talk

Hangars protect a plane from more than just the environment. I can’t imagine what a hangar costs or how long the waiting list is in Sandy Eggo, though. -dan -

@Pmaxwell have your ears stopped ringing yet? -dan

-

looking good, team Mooney. My YouTube skills don’t include cueing it to a time stamp. Starts at 1:40 -dan

-

Disuse is the death of engines. If there is corrosion on the cylinder walls, then expect oil consumption to be elevated, if it is not already. If you can get a $17,000 concession from the seller, you should be safe financially. Mine was topped 800 hours ago, and I’ve had no issues since. There was a history of disuse and corrosion on all six jugs. IIRC, the top was $2000-2500 per cylinder six years ago, and that was with a re-honing of the cylinders, not replacement. LOP/SOP/ATT since, and compressions, borescope, and oil consumption are all good. -dan

-

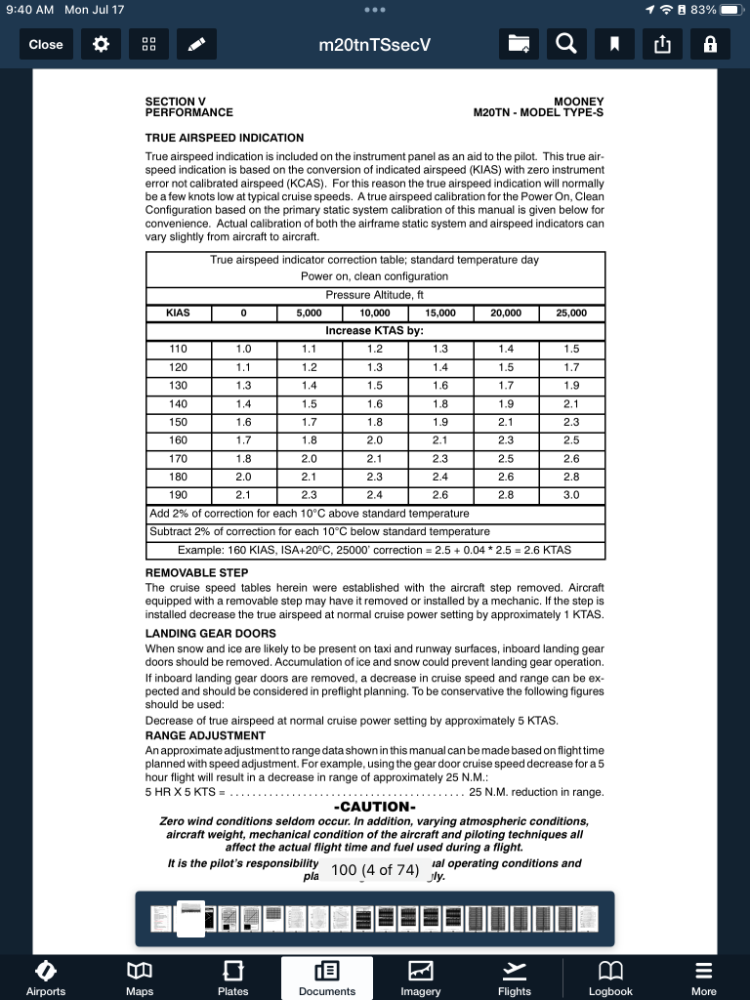

Your observed speed shortfall sounds about right to me. Does the Ovation POH have this note which is in the Acclaim’s?

-

Sure it would: Just throw a Kelly Aerospace air conditioner in the back. very little weight or CG change.

-

The Kelly Aerospace built-in unit for the Mooney is 11,500 Btu/hr, so your math seems about right. I use the B-Kool mostly on the ground and approach/landing, say 12 minutes (0.2 hr per flight). It is maybe half or 2/3 exhausted after that (using cubes), so 2000 btu's per .2 hour or 10,000/hr though you can't sustain it for an hour. Used for taxi, approach, landing and taxi, it is putting out approximately the same cooling as the Kelly unit, just with limited duration. I'd still consider the Kelly unit if I could get the lithium battery people's attention for an STC. I have an evaporative vest for use on a motorcycle, which is similar but worse. Once the water is fully evaporated, I have a nice, warm vest around my core! -dan

-

How would you handle a "bad" electrician, plumber, doctor, or lawyer?

-

The B-kool is fine. I had a breaker-protected outlet installed on the back bulkhead f the baggage compartment, which is a short run to the batteries. +1 on the remote. I find that block ice sloshes around and dislodges the bilge pump, so I stick with cubes. Considering the factory A/C cannot be used for takeoff, this is a 95% solution. Get a chest freezer in the hangar to store ice, and you’re good to go. -dan

-

It’s hot and CHTs are a problem! Solution??

exM20K replied to Utah20Gflyer's topic in General Mooney Talk

I have never observed more than a few degrees drop in CHT when flying in the rain. -dan -

Precise Flight Mic Mask - Weak Microphone?

exM20K replied to PhateX1337's topic in Modern Mooney Discussion

Same. No issues with either the factory masks nor the ones set up for O2D2. -

There’s a third camp of at least one: the total cost of servicing the O2 semi annually doesn’t even register in the total cost of ownership, it can be done along with an oil change for convenience, and I’m too busy/lazy to mess around with a cascade tank setup. -de

-

Gotta love the Mooney efficiency!

exM20K replied to gmonnig's topic in Vintage Mooneys (pre-J models)

@Pinecone impressive range. I assume that was powered back and LOP? 130 KIAS is, I think, a very favorable spot on the L/D curve of the Mooney wing. I find very little degradation in cruise climb going from 120-130 indicated. -dan -

I want some kind of aviation performance table.

exM20K replied to aviatoreb's topic in Miscellaneous Aviation Talk

probably applicable only to NA aircraft. Your turbo gives only a few poops about DA on takeoff. Even no wind and MTOW, the 280HP acclaim is at 3400 ish ft over 50' Acclaim Type S 50ft TO.pdf -

I want some kind of aviation performance table.

exM20K replied to aviatoreb's topic in Miscellaneous Aviation Talk

take off: yes. Landing? dunno. But that is the extent of the performance notes in the STC IIRC. Same deal for the 310HP Acclaim. -dan