-

Posts

11,926 -

Joined

-

Last visited

-

Days Won

163

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Shadrach

-

I wrote Mr. Fitch this morning outlining my concerns that AD 77-17-04 and the instructions for continued airworthiness therein might contribute to an inspection/maintenance induced failure of the components depicted in the recent Airworthiness Concern Sheet. I would encourage anyone else that has shared these concerns to send a comment. I think that there are more effective and far less invasive ways to mitigate a potential yoke/yoke shaft failure.

-

Good catch. I too have always thought that any sealant/gasket maker on the cylinder flange was a no no. I don’t see how the bolts achieve the proper torque (stretch) with that crap on the flange.

-

I am pretty sure that the piston, like the cam, relies on splash/spray lubrication from the crank and connecting rods. My guess is that if the piston isn’t getting sufficient “splash” lubrication then it’s not likely that the proximal cam lobes are either.

-

Takeoff Trim Setting - New to me 1970 M20F

Shadrach replied to ProtoFly's topic in Vintage Mooneys (pre-J models)

Yup. Same here. The only time I hit the aft trim stop is when landing with minimum fuel and two up front…and then only on short final…and then it’s only likely because I fly slower approaches than most. Loaded as described I’m crossing the fence at <60KIAS. -

Perhaps they fired the marketing manager from 1967…. My standard WOT @2500 and 7500’ shows 187mph in 1967 but only 173 in 1968. Notice the 1967 poh allows for leaning to 100ROP at 76%hp (10.8gph) but in 1968 it’s full rich (14gph). M20F POH cruise data from 1967: M20F POH cruise data from 1968:

-

I would have zero concerns about issues with tank sealant and o-rings with mogas. Many many STC holders operating in the field with the same gaskets, adhesives and seals. Peterson had to demonstrate compatibility to get the STC approved. Avgas is blended to exceed shelf life specs. Technically, it’s required to meet production standards after 12months in storage. In reality, 10 year old samples that have been properly stored have shown to meet production standards. It’s lasts a long time…

-

If I go by the 1967 owners manual, my plane is slower than book. If I go by the 1968 owners manual, it's pretty close on speed and efficiency is slightly better because I use more sophisticated leaning practices. Be better if we knew what "about the same" meant. The delta between similar HP models isn't tat far off even if every one is making book speeds.

-

I agree. The 210 driver I knew was not based at an airport. He had high octane in a tank at a farm strip (this was before Ethanol was pervasive). The Mooney driver that did it was a member here who confessed his sins privately. Another downside mentioned was that he could smell the mogas in the cockpit when he switched tanks.

-

Not legally but I know of a few scofflaws that have done so. One tank of 100LL and the other 93 mogas. Climb, take-off, and landing on 100LL, cruise on mogas. I was told that switching from 100LL to Mogas increased CHTs by 30-40° all other things being equal. ROI seems low just to save a few bucks. I know of someone who operated an NA C210 this way quite a bit, but for them it was more of a fuel availability issue rather than economics.

-

Mooney has not been doing “well” for quite some time. I think that they are cash poor. This has led to a more reactionary and transactional approach. They don’t seem to have much of a support strategy beyond “keeping the doors open”. Fabricating obscure parts in low quantities does not serve their current financial situation.

-

O360s handle mogas just fine. It’s the fuel system design that presents a challenge. Peterson offers a mogas STC for all of the following Lycoming engines, but their approval is airframe dependent. Lycoming 0-145-A1, 0-145-A2, 0-145-B1, 0-145-B2, 0-145-B3, 0-145-C1, 0-145-C2, GO-145-C1, GO-145-C2, GO-145-C3, 0-235-C, 0-235-C1, 0-235-C1B, 0-235-E1, 0-235-E1B, 0-235-C1C, 0-235-C1A, 0-235-H2C, 0-235-C2A, 0-235-E2A, 0-235-E2B, 0-235-L2A, 0-235-L2C, 0-235-M1, 0-235-M2C, 0-235-M3C, 0-235-N2A, 0-235-N2C, 0-235-P1, 0-235-P2A, 0-235-P2C, 0-235-P3C, 0-290-A, 0-290-AP, 0-290-B, 0-290-1, 0-290-C, 0-290-3, 0-290-CP, 0-290-D, 0-290-11, 0-290-D2, 0-290-D2A, 0-290-D2B, 0-290-D2C, 0-320, 0-320-A1A, 0-320-A1B, 0-320-A2A, 0-320-A2B, 0-320-A2C, 0-320-A2D, 0-320-A3A, 0-320-A3B, 0-320-A3C, RAM 160 Conversion, 0-320-B1A, 0-320-B1B, 0-320-B2A, 0-320-B2B, 0-320-B2C, 0-320-B3A, 0-320-B3B, 0-320-B3C, 0-320-C1A, 0-320-C1B, 0-320-C2A, 0-320-C2B, 0-320-C2C, 0-320-C3A, 0-320-C3B, 0-320-C3C, 0-320-D1A, 0-320-D1B, 0-320-D1C, 0-320-D1D, 0-320-D1F, 0-320-D2A, 0-320-D2B, 0-320-D2C, 0-320-D2F, 0-320-D2G, 0-320-D2H, 0-320-D2J, 0-320-D3G, 0-320-E1A, 0-320-E1B, 0-320-E1C, 0-320-E1F, 0-320-E2A, 0-320-E2B, 0-320-E2C, 0-320-E2D, 0-320-E2F, 0-320-E2G, 0-320-E2H, 0-320-E3D, 0-320-E3H, 0-320-E1J, 0-360-B1A, 0-360-B1B, 0-360-B2A, 0-360-B2B, 0-360-D1A, 0-360-D2A, 0-360-D2B, 0-360-A1A, 0-360-A1AD, 0-360-A1D, 0-360-A1F, 0-360-A1F6, 0-360-A1F6D, 0-360-A1H, 0-360-A1H6, 0-360-A1G, 0-360-A1G6, 0-360-A1G6D, 0-360-A1LD, 0-360-A1P, 0-360-A2A, 0-360-A2D, 0-360-A2E, 0-360-A2F, 0-360-A2G, 0-360-A2H, 0-360-A3A, 0-360-A3AD, 0-360-A3D, 0-360-A4A, 0-360-A4AD, 0-360-A4D, 0-360-A4G, 0-360-A4J, 0-360-A4K, 0-360-A4M, 0-360-A4N, 0-360-A5AD, 0-360-C1A, 0-360-C1C, 0-360-C1E, 0-360-C1F, 0-360-C1G, 0-360-C2A, 0-360-C2C, 0-360-C2E, 0-360-C4F, 0-360-C4P, 0-360-F1A6, 0-360-G1A6, 0-360-J2A, H0-360-C1A, 0-435, 0-435-A, 0-435-C1, 0-435-1, 0-435-C1, 0-435-11, 0-435-C2, 0-435-13, 0-540-B1A5, 0-540-B1B5, 0-540-B1D5, 0-540-B2A5, 0-540-B2B5, 0-540-B2C5, 0-540-B4A5, 0-540-B4B5, 0-540-A1A, 0-540-A1A5, 0-540-A1B5, 0-540-A1C5, 0-540-A1D, 0-540-A1D5, 0-540-A2B, 0-540-A3D5, 0-540-A4A5, 0-540-A4B5, 0-540-A4C5, 0-540-A4D5, 0-540-D1A5, 0-540-E4A5, 0-540-E4B5, 0-540-E4C5, 0-540-F1B5, 0-540-G1A5, 0-540-G2A5, 0-540-H1A5, 0-540-H2A5, 0-540-H1A5D, 0-540-H2A5D, 0-540-H1B5D, 0-540-H2B5D, R-680-E3, R-680-E3A, R-680-E3B, R-680-9, R-680-13, R-680-E1, R-680-E2, R-680-6, R-680-B6, R-680-D5, R-680-D6, R-680-B2, R-680-BA, R-680-2, R-680-4, R-680-B4, R-680-B4B, R-680-B4C, R-680-B4D, R-680-B4E, R-680-5, R-680-7, R-680-8, R-680-11, R-680-17, R-680-B5, 0-540-F1B5 (Derated for Robinson), 0-320 Series (Derated for Robinson), 0-360 Series (Derated for Robinson)

-

I have had it overheat but not from usage. Always a result of sun exposure.

-

Josh, I think you’re over reading this. Potential vendors often have a single profile with multiple employees posting. For example, EarthX has had both the CEO and a sales executive post from a single profile. Also his reply was directly related to Rich’s post about annual bushing lubrication. It may not have been worded as eloquently as it could have, but I don’t get the sense that Juan is a bot. I would be interested in seat rollers if they significantly reduced friction. My seats move fine but it’s still a two handed operation.

-

Fuel Burn 4 Cyl (200hp) vs 6 Cyl (300hp)

Shadrach replied to GeneralT001's topic in General Mooney Talk

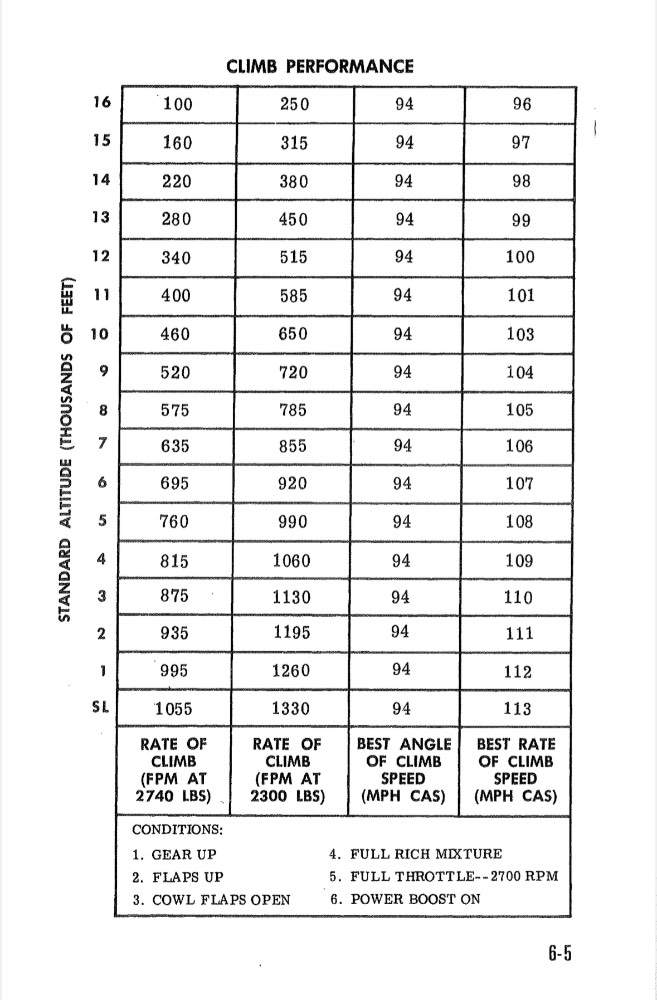

It’s not so obvious. You need to run the numbers. The higher horsepower makes for a faster plane, but also quite a bit heavier. In terms of runway and climb performance, it’s not so black and white. My bird weighs 1681lbs. With 50gal, me, and 20lbs of bags, my op weight is around 2200lbs. At that weight on a standard day I can average >1000fpm from SL to 10,000’ Book numbers below. -

The intake boot is a challenge for the vintage aircraft. They can be had but are not made in large quantities and sometimes require a lot of searching to find a source. Gear up and down locks have also been a challenge. The locks would be pretty easy to have fabricated at a local machine shop with a CNC machine. I kept my old blocks so that I can use them as a template for OPP if needed in the future.

-

I think it is easier to go electric if you haven’t spent a lot of time in a manual gear aircraft. Having owned and maintained a manual gear F for 20 years, it’s likely a bigger deal to me. For me it’s not just the inherent reliability of the system, it’s also the tactile feedback in every swing that tells me the gear is functioning as it should. I enjoy the same sensation with the manual wing and cowl flaps. Every inch of pump handle movement translates into a pitch change as if there were a jack under the tail. The cable operated cowl flaps are simple and easy to operate. Any binding in the system would be immediately obvious. Overtime one develops a sense of how these system should feel. It gives me great confidence in the systems to feel their smooth operation on every flight.

-

Strongly suggest Aeromotors for overhaul. They make a number of modifications to the pump that improve its reliability and function a great deal. They’re also very reasonable. I think less than $500. They often have an exchange pump on the shelf, but if they don’t, turn around as fast.

-

Im pretty sure that I have been verbally cleared into the SFRA many times; sometime direct to my destination within the SFRA and others via the filed entry gate. Clearance was usually accompanied by instructions to remain clear of Bravo. I have not had a need to file a SFRA flight plan for many years so perhaps things have changed.

-

SureFly with EAREM37HE plugs? Slick failure?

Shadrach replied to John Mininger's topic in General Mooney Talk

Has anyone verified the timing by observing spark at the lead? The Lycoming IO360 was certified at 25° of advance. 20° of advance was added to the TCDS at a later date. Many of us are running 25° with cool CHTs. I can envision no scenario where 20° of advance would produce the symptoms you're experiencing. It seems unlikely that the increased spark energy of the Surefly would increase flame front propagation sufficiently to cause an increase CHT, ergo I would ensure it is properly timed. As for the Slick failure. Any magneto can fail. The question is what component failed. There are a number of component failures that would cause the scenario you describe. If you ever again find yourself operating in on a single mag in flight, it is perfectly fine to adjust the mixture to increase the speed of combustion (flame front propagation). This would entail leaning the mixture if ROP or enrichening the mixture if LOP. This will help to recapture lost power and reduce any roughness until the flight is completed. Note that losing a mag while running LOP is more likely to result in noticeable power loss and roughness. While it is getting harder to find A&Ps that will open a mag, there are still many that are willing. For future reference, a repair kit is available for the Slick 4370 through airpower for $175.00. Kit includes the following: Contact Point Kits Double Sealed Bearing Bearing Cap Assembly Condenser Rotor Gear Cotter Pin Coil Distributer Block and Gear Woodruff Key Oil Seal Washer Impulse Coupler