-

Posts

11,903 -

Joined

-

Last visited

-

Days Won

163

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Shadrach

-

If it doesn't seem right, it probably isn't

Shadrach replied to donkaye's topic in Vintage Mooneys (pre-J models)

Just to be clear, did the tube fail due to the slow leak becoming a major leak or did the tire fail from being operated below specified pressure? -

I sort of understand that policy, but the pilot is the responsible party here. My prop had 18 months to go before reaching calendar TBO and only about 600SPOH. Shops are liable for the work that they do, but not for the pilot’s decisions about compliance with manufacturer recommendations. It’s not really a grey area legally.

-

Good for you. The last time I had a seal fail, the shop refused to reseal because my prop was 18 months from calendar TBO. They said this was for liability reasons. They only charged $1800 for the overhaul, so I agreed.

-

Glazed Cylinder Borescope Images

Shadrach replied to TheAv8r's topic in Vintage Mooneys (pre-J models)

Cold compression checks are the norm for us at annual given that when my IA arrives the plane has typically been on jacks for a day or two with panels removed. I have never noticed much difference between cold and hot. That being said we have gotten compressions of 80/80 on several occasions. A few years ago we got the trifecta on a cold engine that had not run in 6 weeks. Next year, none of them were 80/80 but all were above 77. I put no stock in such things… 80/80 compressions are good for little more than bragging rights on an Internet forum. -

Aft Spar Web SB Doublers M20-217

Shadrach replied to TravelingIA98's topic in Vintage Mooneys (pre-J models)

Good deal! Sounds like you’ve got everything on the proper trajectory. If you’re able to fab a doubler and feel like making a second while you’re at it, I’ll buy it from you. It’d be good to have on hand. -

I like everything about the 730/830 except the fuel totalizer functions, the UI sucks.

-

Were you trying to test it? I would expect it to detonate at that setting. I have always assumed that MP redlines were based on limiting output to rated horsepower. It could, under some scenarios, be useful to have the option of running MP >30" while on the lean side of peak allowing for close to max rated power on less fuel. Do you think this would be feasible with your set up?

-

Aft Spar Web SB Doublers M20-217

Shadrach replied to TravelingIA98's topic in Vintage Mooneys (pre-J models)

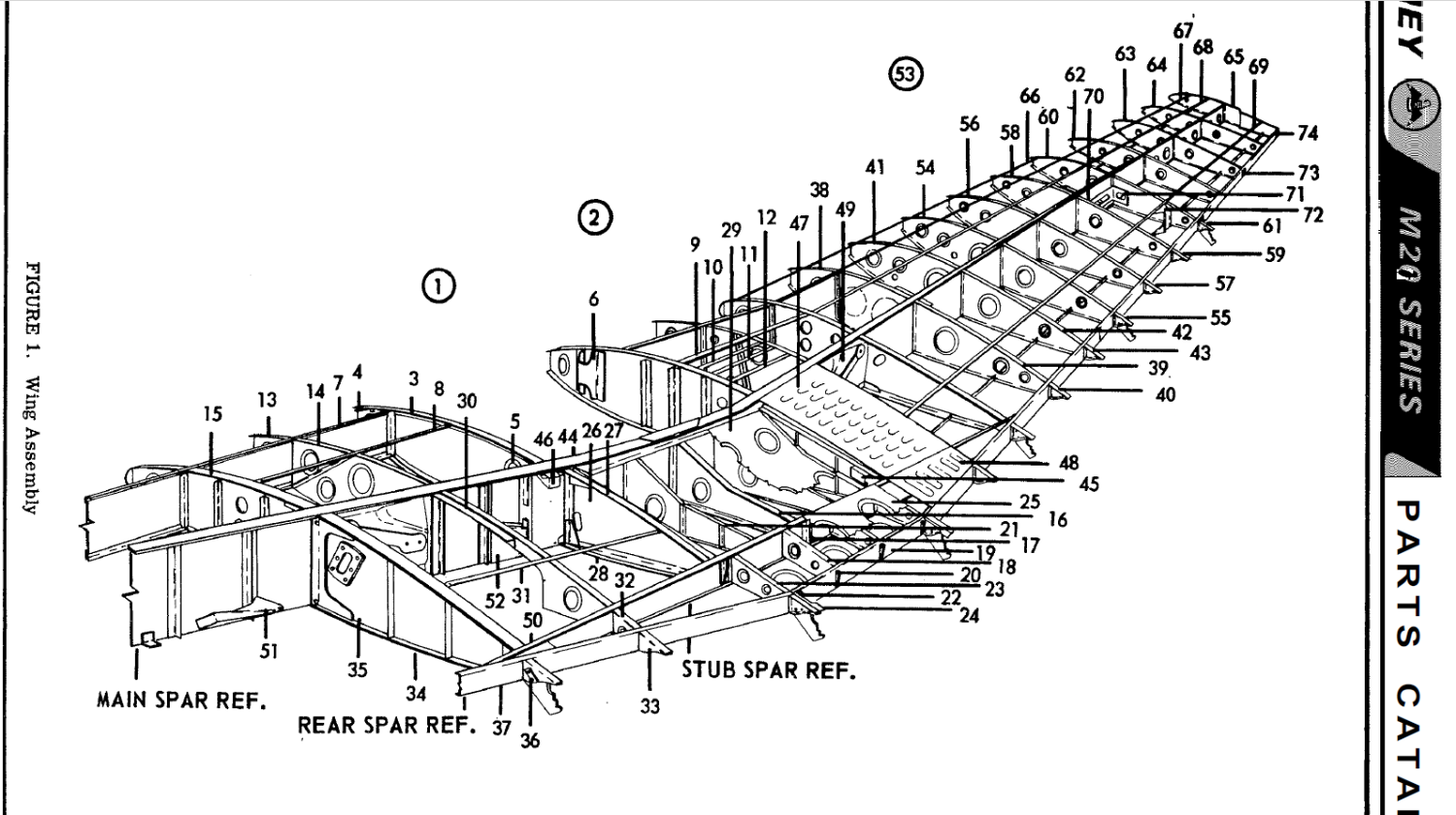

Thanks for the clarification Andy, I could not find an easily viewable copy of SBM20-217 perhaps I have the wrong number. A cursory look at the IPC diagram could lead to mistaking the stub for the rear spar. I have seen it written so many times that I just adopted the terminology. After reviewing the IPC, it's clear that the flap actuator is attached to the rear spar center splice. I will edit. Thank you! -

Aft Spar Web SB Doublers M20-217

Shadrach replied to TravelingIA98's topic in Vintage Mooneys (pre-J models)

Understood. Just throwing out some unsolicited advice from someone who has also been maintaining a nearly 60 year old M20 airframe for the past two decades. If the rear spar has not cracked in 59 years of service, it seems unlikely that it's going to any time soon...unless abused. I believe that these cracks develop as a result of multiple overspeed events and that once a crack is initiated, it propagates under normal usage. It's a good sign that it yours is still in good shape. Installing the doubler is a 10 to 12 hour job that will require removing the rear seat as well as re-rigging the flaps. Have you considered all of the other things that might benefit from 10-12hrs of your time? When was the last time the elevator trim gear box was disassembled, cleaned and lubed? Have you removed the wing root fairings to ensure everything is still sealed? The interior compartments of the trailing edge of the wings at the root tend to accumulate dirt and debris which holds moisture. The same for the bottom, inside of the empennage. Every year I check these areas and if needed pressure wash them with mineral spirits and finish them with a vacuum (after fumes dissipate). It's not on the annual checklist, but these are extra things that I do to maintain the integrity of the airframe. If this airplane was not previously A&P owned or owner maintained, I can almost guarantee these areas have seen little attention. Also, If it has a Brittain wing leveler/autopilot, there is a better than 50/50 chance that the vacuum hoses are rotten, but will only appear so when stretched. It's likely that SBM20-208 has been complied with, but have you removed the interior and put eyes on steel tubing from top to bottom, inside and out? I say all of this not to deter you from complying with the SBM20-217, but because in my experience there are areas of the airframe that are often neglected and prioritizing them might yield a better return on your maintenance efforts than installing a doubler on what seems to be a healthy rear spar. If all of those other things have been addressed, then please disregard. -

It’s mostly about reducing workload. Once rpm is set, there is one knob to contend with. The airport I departed from is fairly busy and is less than 2 mins from the DC SFRA, the expanded area of P40 (Camp David) and lots of Bravo airspace. The procedure is to level, set rpm and pull mixture until slight speed loss then continue the business of navigating and communicating. Check CHTs once things are settled. If they’re too cool, add a little gas, if they’re warmer than desired, take a little away. Less to do than screwing around with “Key numbers” or setting the power at “24 squared” and then leaning. It’s simple, marginally faster, and burns less gas. That being said, I don’t begrudge anyone their desire to make setting power more complicated or to simply leave the throttle and mixture in and puke 15gph through it per the POH.

-

Aft Spar Web SB Doublers M20-217

Shadrach replied to TravelingIA98's topic in Vintage Mooneys (pre-J models)

Is your stub spar cracked? We inspect ours annually. In 3300hrs, no visible cracks as of yet. -

I've been doing it this way for nearly two decades. It was born out of a regularly scheduled 48NM trip over the river (and the woods) to Grandma's (RIP) house. My IO360 runs really well LOP at high MP. At DAs of 3000' or less, I see speeds just over 150kts. There is little to doubt when seeing over 150 across the ground when westbound into a known, light headwind.

-

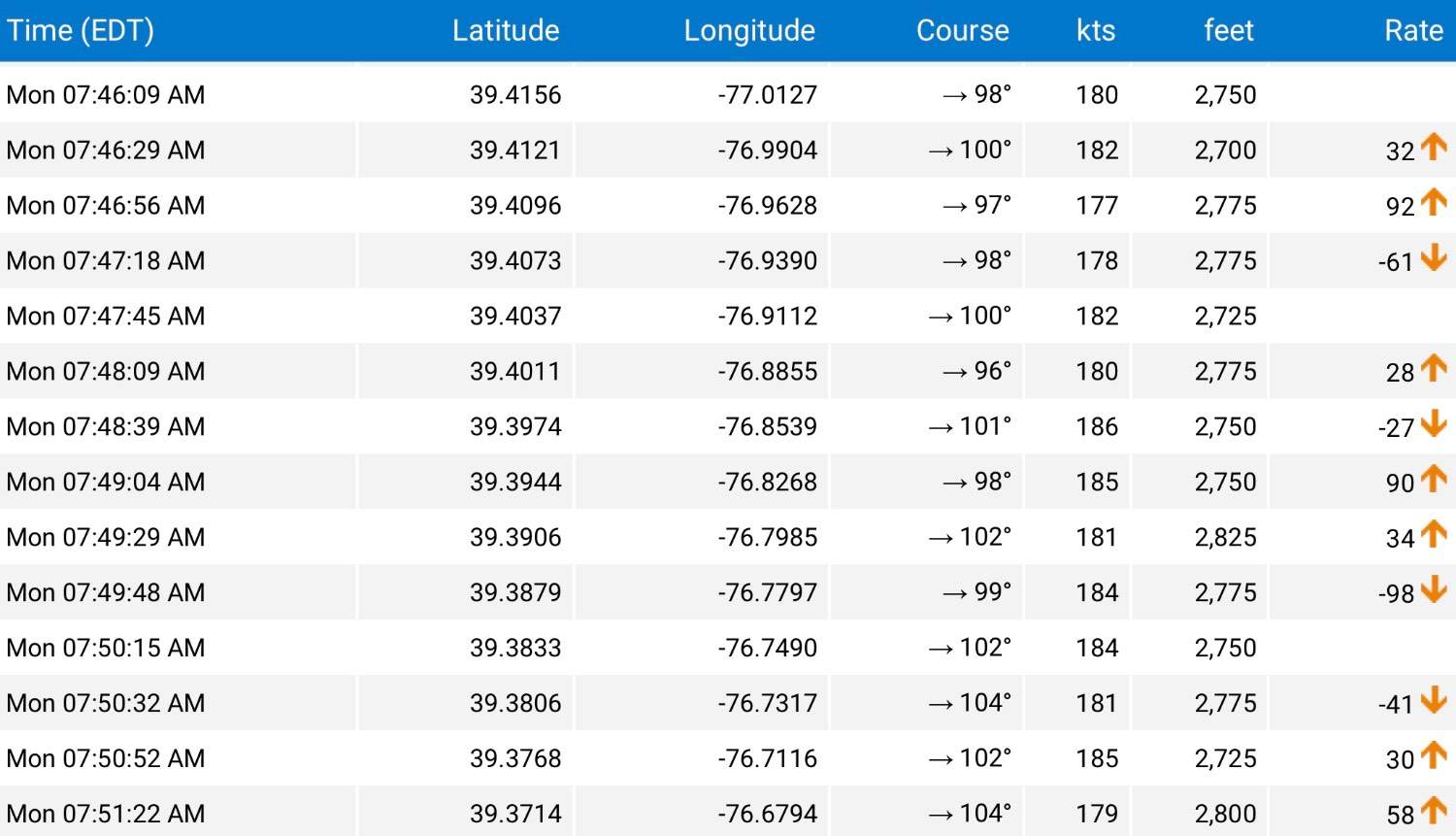

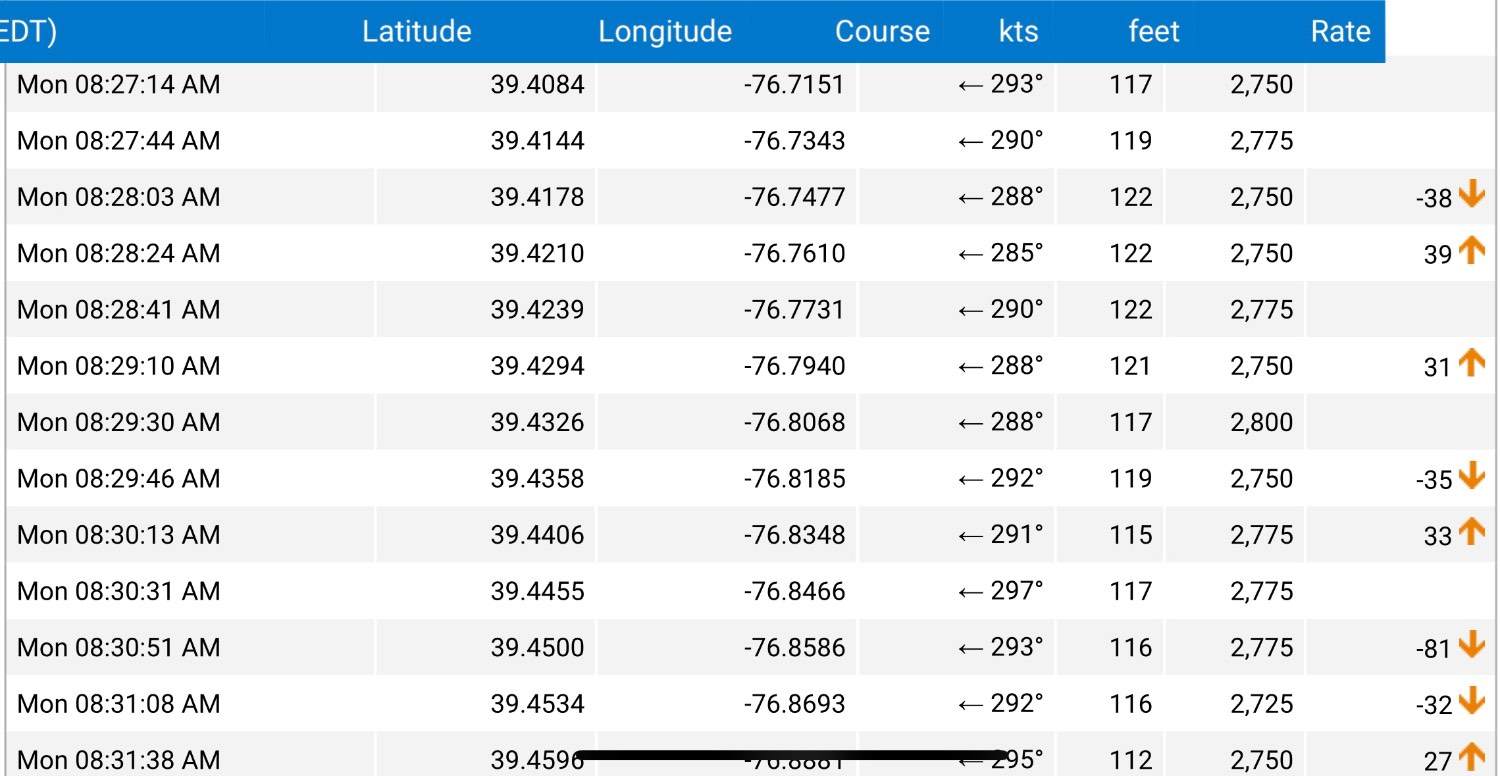

@Medflyer to build on my earlier comments. The type of flying I was doing yesterday morning illustrates why WOT LOP power settings down low are an excellent option, if one understands how to do it properly. For the most part I was cruising at 2500’, wide open throttle, ram air open and 2500rpm. At 2500’ I enjoyed ground speeds in cruise of 178-186kts when eastbound but fighting the winds on the return trip still yielded 112-122kts. All while burning less than 11gph with CHTs <330°. I’m increasingly convinced that this is the best way to run an IO360. YMMV.

-

1963 M20D/C Nose Gear Truss Dents

Shadrach replied to BrettC113's topic in Vintage Mooneys (pre-J models)

Are you saying that this was not identified by the technician performing the prebuy? The dents are common and easily rectified issue. However, if they were missed during prebuy, I’d have concerns about what else might have been overlooked. -

Once you know an airframe/engine combo well, you can just about lean it in your sleep. I am a big proponent of engine monitors. However, I can easily lean an IO 360 to LOP without an engine monitor by using airspeed and engine roughness. Could I get the very best out of it, no…but plenty adequate. It would be much, much, harder and more dangerous to lean to best power without a monitor.

-

Temperature is my top priority for power settings. I manage temps almost exclusively with mixture. I find the IO360 A1A in my 67F feels smoothest if not the quietest at 2500rpm, so that is where I run it in cruise. I run all the air through the engine that it will take unless I am trying to land. I use mixture to keep temps in a range that is appropriate for the OAT. For instance, this morning, I flew 3 short legs of 26nm, 50nm and 67nm. Shuttling around the DC metro area. I did each leg at 2500msl except for a brief stint at 3000 to get over a ridge. OAT at cruising alt was just over 40°. For each leg I was leaned to about 10.6 GPH in cruise. That translates to about 80% power around 25° lean of peak., CHTs all <330°, oil at 180°. Good speed, good economy, good temps and simple operations. This method is easy, only one knob to manage.

-

That’s how things ended at Moa, sadly. It was also kind of underground. We always felt welcome there, even though we were usually the only people ordering in English.

-

The best place to go in MoCo used to be a place called Moa. it was nestled in an industrial park in Rockville almost entirely staffed by Korean grandmother types. Service was hit and miss, but the food was fantastic. No K-pop. Unfortunately, it closed a few years ago.

-

Multiple locations. It’s far from the best Korean around. You have to go to Annandale Virginia for really good Korean. https://www.honeypigbbq.com/ there is a new place in Frederick that I it’s just as good if not better than honey pig. https://www.gogigokoreanbbq.com/frederick

-

That seems like a very useful air frame/power plant combination. Too expensive to certify it a higher useful load? It obviously had enough wing and certainly enough power. 900lbs is pretty piss poor considering it’s actual capabilities.

-

I am decidedly not a fan of K-pop. However, I do love international cuisine. My favorite Korean Restaurant has multiple screens playing Korean pop music. Imagine my surprise when I looked up from my spicy pork belly to see a Mooney towing a banner across the screen.

-

F model is set up the same. No clearance issue. I’ll take a peek tomorrow.

-

Given the number of conversions, I’d say the market agrees with your analysis.

-

-

What are the odds that multiple hamburgers showed up in the pattern at the same time? It sounded like there was a delay in his radar feed. He kept screaming at Reliant 379 (at Citation that likely had an ATP at the controls) to start the requested 360. The Pilot responded that they were half way through the 360. Controller’s response? “Turn harder”. I have seen lots of ATC sequencing hiccups over the years in all levels of airspace. I have been involved ATC sequencing Aircraft in the exact opposite order that seemed practical to me and it worked out just as I thought it would… with lots of low altitude, turns and extensions for spacing. What I have never heard is a controller come completely unhinged like this guy. He sounds like Bernie from The Incredibles…