A64Pilot

Verified Member-

Posts

8,000 -

Joined

-

Last visited

-

Days Won

21

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by A64Pilot

-

In all honesty I cant think of ever shooting an ILS to a short field, ILS as I’m old was my default in “hard” IFR. I don’t fly IFR anymore, I don’t have the need or desire and don’t maintain proficiency, so I just don’t. I’m one that believes proficiency and currency differ. Are there any ILS equipped short fields? I guess that depends on your definition of short? I normally land with full flap, because that gives me the lowest landing speed and a lower deck angle, but I think you should be comfortable landing with no flap, because eventually you will have to. A Mooney or any other GA aircraft will go around with gear down and full flaps, if nothing else an electrical failure is possible even if unlikely. But it won’t in every possible scenario. You can’t cover every possibility, if you try you will end up with a dog with no real range or useful load. However every GA aircraft I can think of climbs best with NO flap. Many won’t use flaps on takeoff because of this, rather than getting wrapped around the axle on something that likely isn’t real important, I use T/O flaps because the POH calls for it. I’ve participated in several accident investigations, both Military and Civil. If your the aircraft Commander it’s far easier if you were following the POH as opposed to give a convincing argument why the POH is incorrect. But in truth under normal circumstances it’s truly difficult to get a Certified GA airplane in a position it can’t fly, yet of course some do every year, we have all seen the videos of the airplane that gets off the ground but can’t climb because it’s in the region of reverse command. You just can’t build an idiot proof anything, there will always be a “better” idiot. As with everything else all this is opinion, there are many ways to skin a cat, and no single way is always the best, that’s why in my opinion you should be comfortable with every possible way. For example if light weight and near sea level the shortest T/O in my Maule was with 48 degrees (full flap), but my normal T/O was no flap. I think it was 48 degrees anyway, point is depending on conditions maybe there is no one best flap position, which flies in the face of always follow the POH. In my opinion you should do a couple of practice go-arounds full flap and gear down, learn it’s not anything to be afraid of, if you weren’t shown that then you should have, eventually you will need to go around on short final and scrambling to get gear and flap may not be prudent, possibly getting the aircraft climbing and you to settle down, then getting gear and flaps is a better idea. Watch some videos of Corsairs take off of a Carrier if you want to see a lot of flap, or watch the T/O film of the Doolittle raid, those guys did a lot of practice with getting a heavy B-25 off short, I’m sure they tried everything.

-

Observation about takeoff flaps and full aileron deflection

A64Pilot replied to AJ88V's topic in General Mooney Talk

That’s an old bush / Ag pilot belief. It’s predicated in the belief that an Aircraft manufacturer knew what they were doing when they set max deflection of the ailerons. Idea is they are set to cause the most lift as possible and that more travel adds more drag than lift, drag of course causes adverse yaw and that’s not desirable. Often with flaps there are three settings, first is mostly lift, second a mix of both increased lift and drag and full is mostly increased drag. However if there is enough thrust to overcome the additional drag takeoff roll will be reduced with full flaps, there are no absolutes, however if your really heavy first notch, or usually 15 deg will often match max down aileron deflection is best to get a struggling Ag plane off of the runway. Full flap on turbine Thrush aircraft was only 15 deg for this reason, with a turbine you can get drag from the prop so no need in flaps for drag. Oh, and for Certification at max gross weight an aircraft has to demonstrate capability to go around with full flaps. But hot day, high altitude etc., maybe not. On edit, don’t do what your CFI tells you, do what the POH says. -

A problem with introducing something new is that often as much as you try it’s not possible to test for every possible interaction. I’m not saying that the Gami fuel has or will cause any problems, perhaps for example the seeming new leaks are actually from the change in weather. But while I can’t quote specific examples off of the top of my head other than from the Military but it’s really not at all uncommon for a new fuel or oil etc once it gets into the field to cause problems in a small percentage of aircraft, especially when they are operated in environmental conditions that are unusual or who knows what all the possible combinations of who knows what are. The only way to honestly know is to field something and cross your fingers. I was listening to a class sometime ago where a fuel cell manufacturer claimed that the aeromatics in some auto fuel was causing problems with fuel cells for instance.

-

The first Bose aviation headset was a heavy clunky thing with clear sections that you could see the electronics in, it had clear gel filled cushions, not black. Don’t know the model, that was maybe 20 years ago? The box was of course the first lemo type connector and the power supply. Not big about the size of an old fashioned match box. Heavy thing but comfortable, and it was a decent passive headset with ANR. It was in my opinion superior to what they sell now. There are several things I don’t like about Bose but primarily it’s that they don’t protect your hearing, the reason is because ANR at least Bose anyway only works from about 40 Hz to 300 Hz or so, yes that cuts out most of the annoying drone from our aircraft, but it’s not the frequencies that cause damage. Don’t believe me, I’m just some anonymous guy on the internet, look it up yourself. If you want to protect hearing you need to block primarily high freq’s, thats probably best done with a good passive headset, then add in ANR and you have a headset that knocks out the fatiguing drone, and protects your hearing. Bose quickly abandoned that for I think a couple of reasons, both marketing based. First for lightweight, but also if your headset doesn’t block much if any noise with the ANR off it’s magic when it’s turned on, I’m sure we have all been to a Bose booth where they are playing the low freq drone and you turn the headset on and off to experience the magic. But also largely because way back in the 70’s I have been an Audiophile, and Bose has always been in truth pretty poor speakers, using processing etc to give what seems like good sound, but it’s not, if you can set up an A+B switch to good speakers so you can switch back and forth you will hear how much is missing, then take a good look at many if not most of their Auto systems where they quote huge power numbers, but what they don’t tell you is that their speakers are 2 Ohm, not 4 or 8.

-

I bought my Maule years ago, it came with the original Bose headset and had a “box” installed in the panel that the single plug plugged into providing comms and power. Soon one ear stopped working, called Bose to see about getting it repaired, they said they don’t support it I would have to buy the new model, I asked well will you give me a trade-in or a little off? Bose said no. I asked well will the new model plug into the box mounted in the panel? Bose said no. I asked well will the new box fit the same hole in the panel? Bose said no. Ended up making a cover plate to cover the hole. Threw the Bose in the trash, which was a shame because it was the best working Bose made as it was a decent passive set with noise cancelling, newer models don’t have much if any passive attenuation. Last Bose I ever bought. I do have an A10 that I inherited I think it is, stored it for a few years, bought about the same time as my Zulu. Started flying again, both headsets needed new plugs etc as the rubber had deteriorated, called Bose, Bose said we don’t support that you’ll have to buy the new model, same song and dance about trade in etc.. Called Zulu and they said sure, for xx dollars we will rebuild it and upgrade it to the new model, which they did, but did so, so well that it just might be a whole new one, I’m not sure. Which one do you think was the better buy? Batteries are just too cheap and easy to carry spares plus my headsets will work in almost all other aircraft because of the standard plugs.

-

Ref parts, Thank God we can make our own via OPP, there really isn’t much you can’t build or have built, $$$ and time would be the issue. I have a friend that “restored” the only flying XP-82, takes money, time and skill, but one man built it, another can rebuild it. Not me though

-

Mine looks like that, on mine I think it’s a push rod tube leaking One day I’ll do something about it, and I second the 6 qt recommendation. Can be coming from the bottom of the filler tube too, lots of potential leaks

-

I don’t know if Cat will do aircraft engines, but in the rest of the world they are known as pretty much the best analysis people out there, but in truth I think there are all good from what I have seen. I don’t know what they cost either, currently I’m using Amsoil to determine a change interval on my motorhome based on soot load, because my engine pumps an abnormally large amount of exhaust into the intake for emissions and they include soot in their base analysis where many it’s an additional cost. A Diesel is very similar to aircraft in that you don’t change oil based on the oil breaking down you change it to get the junk out, Diesel is often soot but sometimes fuel, aircraft it’s often lead, but do any of the oil analysis companies tell you how much lead is in the oil? I’d be curious to see if LOP reduces it. I’m not necessarily a big fan of oil analysis as a tool for determining engine condition which is what it’s being marketed as, but it IS the best too in existence for determining the condition of the oil for determining oil change interval etc. It is after all called oil not engine analysis. The reason I’m not necessarily a fan of analysis is because for example your sample has elevated bearing metal, what is your course of action? What it usually is is excessive worry, but I’ve never seen an engine torn down based on analysis, but I’ve seen a great many from metal in the filter. It’s the filter in my opinion that’s the bird in the coal mine, not analysis.

-

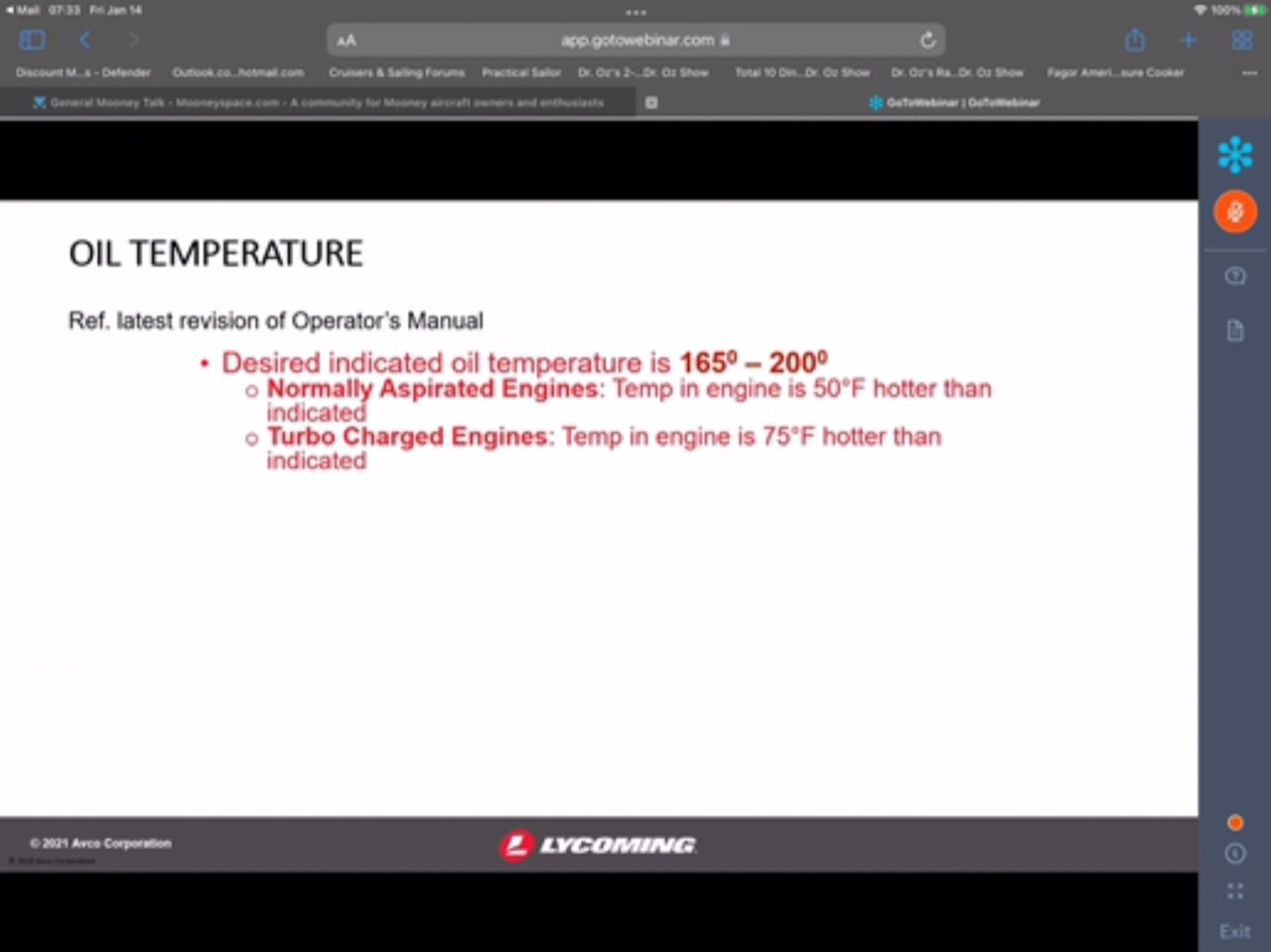

The purpose of running an engine until the oil is hot before draining is to mix the sludge and junk that settles out over hours so it will drain with the oil. The drain is not at the absolute bottom, if it were then it might not be as important to get the oil hot first. Anyone that has ever pulled a constant speed prop has seen the sludge, unfortunately as the oil in the prop is a dead end without any flow the sludge builds up over time. Probably because of the lead, sludge is a real thing in our engines, even with a short change interval. 180F is plenty hot, because we don’t measure where the oil is hottest. This is what Lycoming says about oil temp. Remember everything in the engine excepting the heads and possibly the cylinder is oil cooled. Temps above 200 is not desirable

-

A few comments, do NOT use any kind of ferrous steel, brillo pad, regular steel wire brush etc to clean stainless steel, it will imbed ferrous steel in the SS and that will rust. Very often good grades of Stainless like 316 wire rigging on sailboats for example will appear to rust, but it’s from the steel tooling that was used that leaves steel behind that rusts. The answer is to “passivite” the stainless, that is use an acid that removes the ferrous metal and voila the rust stops. I’ve not read tge article but think considering the source it’s probably pretty good, Most any piping is drawn through a steel die and that contaminates it, then any bending process is another way https://www.mmsonline.com/articles/how-to-passivate-stainless-steel-parts. I’ve had decent luck with believe it or not but Citric acid on a sailboat, but usually nitric acid is used, but that’s nasty stuff to put on parts that can’t be removed like on a boat. The process is to remove the iron contaminate physically as much as possible, scratch brite on a die grinder is good, then passivate Titanium isn’t as expensive as you may think, I had Allied Titanium in Washington I think make me grade 5 Titanium chain plates on my boat for not much more than the 304L ones Island Packet used. Pic is one of eight chain plates made from Grade 5 Titanium, business card is just for scale

-

Anyone have any idea what happened to this airplane?

A64Pilot replied to Ethan's topic in Mooney Safety & Accident Discussion

I don’t think it’s necessarily just a temp, it’s a temp PLUS how much water is in saturation in your fuel, unfortunately you don’t know that amount. If I were concerned, I’d add the alcohol, I don’t think it hurts, but I wouldn’t add it until pre flight myself. I’m suspicious of it sitting in there long term for a couple of reasons -

Anyone have any idea what happened to this airplane?

A64Pilot replied to Ethan's topic in Mooney Safety & Accident Discussion

IPA and Methanol, Ethanol and water all are completely miscible, within limits, exceed those limits and the water drops out Those limits are I believe temperature related. From this website https://petroclear.com/resources/dont-be-phased.php “As noted on Chevron's Web site, while conventional gasoline can dissolve up to 150 parts per million of water at 70°F, the situation is different for gasoline oxygenated with 10% ethanol. This 90% gasoline/10% ethanol blend can dissolve up to 7,000 ppm of water at 70°F. When this blend is cooled, both the water and some of the ethanol become insoluble. Contacting the blend with more water also draws ethanol from the blend. The result, in both cases, is two layers of liquid, an upper ethanol-deficit gasoline layer and a lower ethanol-rich water layer.” For example ever tried to dissolve sugar in ice tea? Good luck, but for some reason people North of the Mason Dixon line don’t understand that. However for some reason O2 saturates at a lower temp in water water than cold, that’s one reason fish die in warm water, there isn’t enough O2. So things always dissolve better in warm temps apparently isn’t an absolute. -

Anyone have any idea what happened to this airplane?

A64Pilot replied to Ethan's topic in Mooney Safety & Accident Discussion

I believe so, but we add alcohol to make the water combine into an emulsion and mix with the fuel in our aircraft. Other than water trapping filters and recirculating fuel I don’t know of any other way, filtering your removing the water, adding alcohol your making sure that there will be no free water dropping out of solution in cold temps. Phase separation occurs when the fuel gets saturated and the water that can no longer be contained drops out of solution, it gets saturated because alcohol is hydroscopic, that is it readily mixes with water and will absorb water from the atmosphere over time, as the fuel temp drops and I believe maybe as atmospheric pressure drops the amount of water that can be held in solution decreases, not sure about dropping atmospheric pressure but remember reading that years ago. By adding alcohol to our aircraft fuel prior to flight, we are alcohol “rich” that is we have a mixture that can absorb more water than is present, get alcohol rich enough and fuel won’t phase separate in cold temps. I’d follow the POH, if it said 3% then that’s what I’d add if I was concerned I know it’s probably obvious, but there is a specific alcohol that you must use, you can’t or shouldn’t use any other. Years ago I went on a mission if you will to find the number of aircraft crashes from aircraft burning E10 gasoline, in short I couldn’t find any, but I know for a fact that many, many aircraft are burning it. I’m not abdicating burning it because it’s dis allowed, but it was interesting that at that time I couldn’t find any crashes attributed to it. -

Anyone have any idea what happened to this airplane?

A64Pilot replied to Ethan's topic in Mooney Safety & Accident Discussion

I’ve heard this all the time, it seems to be a opinion of most. But here is the thing, the fuel pickup is fixed, it’s drawing from hopefully the very bottom in order to reduce unusable fuel. Assuming we are talking about contaminates that don’t float in fuel they sit on the bottom and are suctioned up the fuel line whether the tank is full or empty, emptying one has no effect on sucking up water or other heavier than fuel contaminates. Now anything that floats of course won’t be until the tanks pretty much run dry, but how much “stuff” floats in fuel? Sumping the tanks if they are well designed will alert you to any contaminates, especially water and eliminate them. “Free” water only of course, water dissolved in fuel it can’t, and that’s in my opinion another reason to not add the alcohol until your ready to fly, if it sits in the fuel over time it’s absorbing the water from the atmosphere. The atmosphere gets into the tanks from temperature changes, as temps drop the tanks inhale if you will and exhale when temps rise. An exception to this is possibly some bladder tanks, I had a C-210 that had apparently a wrinkle in the left bladder because you could sump it and get nothing, rock the wings and then get a little water. I was taught by a very experienced ferry pilot that running one side dry isn’t to increase range, because of course it has no effect on range, but rather so that you know there is nothing left on that side, otherwise you’ll think worst case I have a little left that you may not. -

If I understand the procedure and I don’t as I don’t own one, but plugging in the dehumidifier and plugging up the holes are different things? Done at the same time yes but different plugs. By that I mean you can remove the dehumidifier and leave the holes plugged? I just don’t see the downside to pumping air in through the oil fill tube, it’s connected to the same place, and as an old arthritic guy not having to get on the floor to remove the thing would be a big plus

-

Often, and I think this is the best way they are described as a whistle slot, that puts the top part that’s flat bent in so as any oil drips off it goes out the tube and not inside of the cowling. What happens if you don’t have one and it’s cold is the end of the tube freezes shut, pressure builds up and the front crankshaft seal blows out, the windshield gets covered in oil so you can’t see out and if you don't quickly shut down the motor, it will seize. Of course first the engine over revs as the prop goes to min pitch stops from loss of oil pressure, so bad day If you plug that hole (s) be darn sure you unplug them before flight, personally I wouldn’t plug them but go thru the oil fill tube.

-

I’d go this route, I can’t see how it would matter how the air gets in, so long as it does. consider dehumidifying the whole hangar, that protects everything even your tools. Last couple of years I ran one 50 pint dehumidifier, on cold wet days RH would get into the mid 60’s or higher, so this year I got a second one. I think next month I’ll replace my old one with another like this, my old one is not energy star and from 2017, it pulls four times the current of the new one. But both keep RH in the mid 50’s even on a day like today in N Central Fl it’s gotten cold and been raining for hours RH outside has been 99% all day, in the hangar it’s 55% and for the moment both dehumidifiers are off, meaning of course that two of them is a little more than I need. The new one pulls 175 Watts and if I did the math right with electricity at 17C a KWH that even if it ran 24/7 for 30 days it uses $21 or electricity. My hangar is 3,000 sq ft with a 12 ft ceiling, it’s 50 X 60 ft. $189, but you can get one that’s 150 pint for $300

-

I like a happy ending

-

Anyone have any idea what happened to this airplane?

A64Pilot replied to Ethan's topic in Mooney Safety & Accident Discussion

For what ever it’s worth the 777 that had the dual engine roll back, the ice clogged the entrance to the fuel heater, very common with turbines for the fuel to be used to cool the oil, this also has the function of heating the fuel before it gets to the fuel control. The ice built up in the fuel lines and assumption is when fuel flow went up and maybe with higher temps, the ice came off of the lines all at once and blocked the oil cooler / fuel heater. Rolls fix was to make some tubes longer so it would take a stupid amount of ice to block both the short and long tubes. Point is that sometimes the fix is more involved and harder than we would think, but before you can fix something you need to be real sure of the complete problem, which is very difficult with ice as the evidence pretty quickly disappears. I agree alcohol is not really a fix, it’s a band aid, but until there is a fix I would apply the band aid myself. I think possibly the fix is what the Army did decades ago, measure the entrained I think it’s called water and if it’s above some number, remove it before the fuel is dispensed. Think that could happen at the self serve fuel pumps? -

Anyone have any idea what happened to this airplane?

A64Pilot replied to Ethan's topic in Mooney Safety & Accident Discussion

Personally I wouldn’t add the alcohol until just before flight as I’m suspicious as to it’s long term effects on sealant and bladders. I know alcohol will mix with free water and form an emulsion that mixes with gasoline, it’s why E10 etc can contain so much water dissolved it in. But I don’t know what alcohol does for water dissolved into fuel? Perhaps help keep it in suspension? Problem is of course you can’t sump out water dissolved into the fuel. -

Anyone have any idea what happened to this airplane?

A64Pilot replied to Ethan's topic in Mooney Safety & Accident Discussion

Ref it can’t happen in jets. https://en.wikipedia.org/wiki/British_Airways_Flight_38 ALL fuel has some amount of dissolved water in it, you can’t drain it out, it’s possible that low temps can precipitate it out as ice crystals. In the Army we had to test fuel before using it for the amount of dissolved water, if the fuel failed we recirculated the fuel in the truck etc through its filter that had I think the same stuff Baby diapers have in it. it absorbs water and turns into a gel, but anyway recirculating it through the filter would absorb the water until it would pass the test. Test was called Aqua-Glo test. I know of no such test for Avgas? -

O360 high power, intermittent stumble…

A64Pilot replied to Jakes Simmons's topic in Vintage Mooneys (pre-J models)

If you can’t get anywhere with ignition, my next suspect would be a sticking exh valve. Having said that high manifold pressures do require higher voltage to fire and very often a weak ignition works fine until manifold pressure is high then it begins to miss. -

This is the SB your referring to, read through it and if using it you can get your mechanic to buy off go ahead, but this isn’t owner level maintenance. I don’t have a dog in this, just in my opinion using a mag switch not specifically approved requires a 337. Apparently so do several manufacturers or they wouldn’t have an AML for the part. https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC_23-27.pdf Ref the aircraft that has toggle switches installed by “Avionics” I almost guarantee you that a 337 was filed as they almost always are for Avionics installations, Why I can’t fathom why removing one brand of VHF radio and replacing with another requires a 337, but almost always one is filed, so add the toggles and Starter switch. In this instance I’m certain a 337 is required and the POH should be changed too as starting and run up procedures etc have changed, and that’s a major. My FAA inspector joked that according to FAA records the average GA airplane is flying around with four or more radios as they file a 337 for installation, but don’t file one for removal. Oh, and my 1946 C-140 came from the factory with toggle switches and a pull handle starter. I prefer the toggles myself, I think being completely independent is safer and don’t see the need for a cover myself. It does however make the airplane easier to steal. The Crop duster I used to manufacture had no keys of any kind, not even a door lock, after 911 Homeland Security had a hissy fit, but I think the FAA told them to pack sand

-

Corrosion may not be visible, but it’s almost certainly the cause, why else would it seize? Penetrant can’t hurt so certainly give it a try, but I suspect as pipe threads are an interference fit that nothing will penetrate, not allowing a leak is of course what pipe threads are for. But it can’t hurt and maybe it might get into a thread or two and who knows maybe that’s the straw? Often significant heat will break loose that corrosion bond. I’d try a heat gun first and after trying everything else first graduate to propane. Idea is to heat only the fitting causing it to expand or try to anyway and that might break the corrosion bond. Try getting it to wiggle just a tiny by tightening and loosening, just trying to get it to wiggle. Let it cool completely and try again with it cool. I’d honestly go ahead and order the fitting and use a vise grip myself, squeezing the snot out of it may even help it break free, it’s a hollow part after all. In the Army we would use liquid Nitrogen sometimes to shrink a part to get it to let loose, but that may be beyond your capabilities, but maybe your local Airgas of whatever has a small dewer like Dr’s use they will rent? Never asked myself.

-

Any recip engine four or two stroke has what’s caused reversion, that is a little reverse airflow at times. It’s easily felt by removing the air filter on a lawnmower or whatever and putting your hand by the carb and feeling the pulsing air flow out, as it’s a carbureted motor it’s likely your hand will get some fuel on it too, so carbon etc build up on intake valves is normal. Valve timing is interesting with valves opening when it doesn’t seem logical, but a lot of it’s based on the air having inertia meaning that air continues to flow even when you would think it’s not. It’s even possible with valve timing to get to greater than 100% volumetric efficiency without any kind of compressor, rare and only at certain sweet spots of load and RPM, but possible.