A64Pilot

Verified Member-

Posts

8,000 -

Joined

-

Last visited

-

Days Won

21

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by A64Pilot

-

Noticed today doing the annual when I pushed on the Alt belt the Alt moved slightly, I thought this odd, Where it’s getting the movement is from the two pivot bolts being loose, now they are cotter pinned so obviously they were intentionally installed loose obviously to allow the alt to rotate freely for tightening the belt. Is this normal for a Mooney? I don’t see it as a safety issue, just seems odd is all.

-

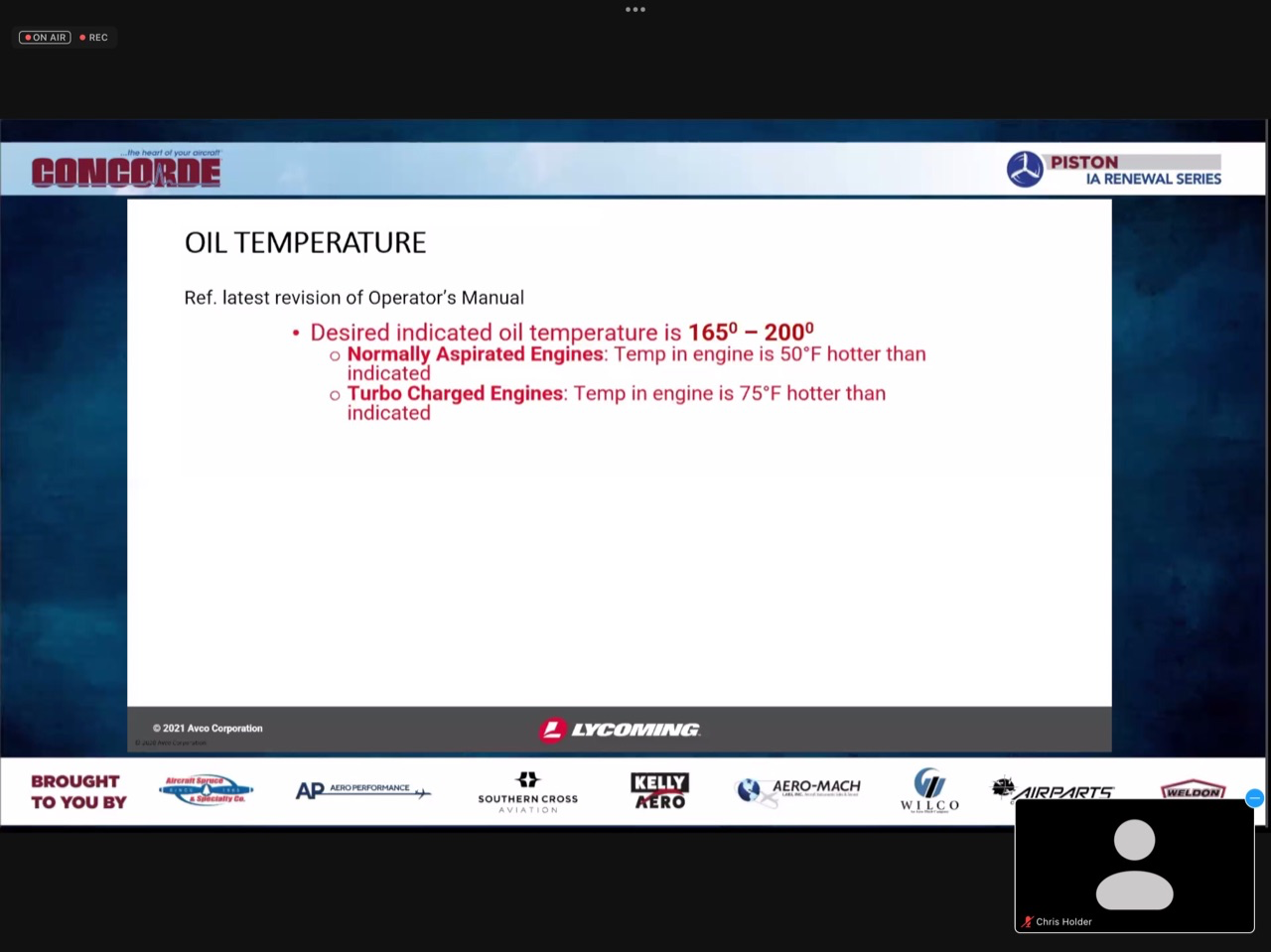

Ref oil temp, Lycoming published maximums and what Lycoming recommends. Think of it like that 500F Cyl head max temp, sure they say you can, but in several other pubs they recommend 400F max for engine longevity This from last years IA renewal. This is what they recommend, sure higher is allowed, but not recommended. As far as what to do about blow-by and possible stuck rings, Mike Bush has a ring flush procedure that I’m not a fan of, but several are. Every case of stuck rings I have seen shows up in low compressions, sometimes not stupid low, but definitely a number that has me researching why. In my cases it has resulted in cylinder removal, I’ve even disassembled everything freeing up the rings etc and putting things back together, but didn’t seem to fix the problem (My C-85) and will result in cylinder removal and an IRAN or maybe overhaul depending on what the shop suggests. Just have to get a round tuit. Oh, and on edit, rings wise listening for leaks at the oil fill tube or blow-by tube is more important I think than the actual compression number, obviously if there is a loud hiss from the exhaust but not the crankcase, then it’s likely your low compression is not from rings,but the exh valve.

-

An indicator of high oil temps in cruise if everything else is fine is excessive blow-by, blow-by unfortunately doesn’t always show up in a compression check like you think it should. If the oil turns coal black within a few hours of being changed you might have a stuck ring or similar. Personally I climb my J at 120+ kts indicated primarily to keep cyl head temps where I like them, but of course it keeps oil temps low too. If anything I have an issue getting the oil warm enough, it’s never beyond the half way point on the gauge, but then I won’t let me cyl head temps get very high either. This was cruise the other day at 60% power or so LOP. It was cooler than average being Dec, but it was also in Central Fl and 4,500 so it’s not real cold.

-

Very often STC’s are not free, depends on whether or not the owner is trying to sell their product or make money from the STC, or both maybe. Often the STC cost is small, sometimes not. For instance if the STC is for modifying the aircraft with readily available parts so the STC holders only profit is from the STC, then of course that STC can and should cost more. As an IA, in my opinion anything that doesn’t require any modification to the aircraft should not by definition require an STC. For the owner an STC is a pain, and even if it’s free they still have to pay an IA to fill out the 337, make logbook entries etc., so free isn’t. From my understanding this fuel requires no aircraft modifications or changes to operation, is a simple drop in, is completely miscible with other existing fuels, so why does it require an STC? Just one man’s opinion.

-

I’m pretty much there myself, my dilemma is that I have the single drive mag, and I think it’s gotten so that people seem to specialize in them, many or maybe most won’t even do them, so I think the answer to your question may depend on which Mags you have. Personally I don’t think any perceived advantage of electronic is worth the expense myself

-

Germany at least in the 90’s was that way too, but Frankly I find it more Civilized, I think of those people who have to work nights and weekends in order for me to get what I want 24/7, and think the sacrifice they have to make just so I can get a doughnut or whatever at all hours is more than they should be asked to do.

-

In 1989 we flew 2 AH-64’s, 2 OH-58’s and 2 Lynx’s from Germany to Dax France for their helicopter school’s airshow, we met up with a French Gazelle at the border to escort us, which was a good thing because all ATC calls were in French, sure you could usually make a call in English and they would respond in English, but all other calls were in French. It’s amazing how much info you get from hearing the other calls. That was an eventful trip, took way longer than we expected, refueling wasn’t center point refuel, but open port like we do our Mooney’s, and we had to reposition each aircraft one at a time to the pump to refuel. Ended up getting dark and we landed at some little grass strip, seemed the whole town turned out and cooked us Supper at the pilot lounge. Two Chinooks also went in another flight, I can’t imagine how their refueling went. On edit it was probably 93 or 94 I was still at Ft Hood in 89

-

I think it’s because you and I live and probably either always or mostly have lived in the “sticks”, for me it’s always, but I like it that way. For me an absolute horror story would be a cruise ship, 5,000 people stuffed into a boat, even or maybe especially a large one would have me breaking out in hives. I just don’t like crowds. The traffic and congestion in Orlando for me is insane, I will only go near there if there is no other option, and I’m certain it’s Hicksville compared to what I have seen on the news about some of California. I did attend a class at the Navy base in San Diego years ago though and don’t remember the traffic being horrible. Where I live the town has one traffic light, but it’s real close to “The Villages” in Fl, I could not live there, or like that. Pics of new construction in The Villages, it’s not all like this, but even the nicer areas the houses are stacked on top of each other, the open areas are the golf courses etc.

-

Scoring on cylinder wall found during annual

A64Pilot replied to Guillaume's topic in Modern Mooney Discussion

I would be more concerned about the ferrous metal in the filter. I personally have never found any in a piston engine. Only ferrous metal I have ever found was stuck to the magnet in the filter and was so fine it passed right through the filter, looked and felt like a small bit of grease. I don’t think cylinder scoring is going to carve off bits of cylinder wall to get caught in the filter. What did the chips look like? I think I’d sacrifice an oil filter in a few hours and likely would put preservative oil in the engine just before the Winter freeze this year if it’s not already happened. I don’t think the cylinder scoring is a big concern myself. You can still continue to do ground runs if you like with the preservative oil if you choose to. Some who go home every Summer where I live put the preservative oil in, leave for the Summer and in late Fall when they return drain it and keep it for next year. -

Now you can get a sort of sweet spot with altitude, for my Maule that was 10k to 12k, flaps at -7 at 10K and 0 at 12K at 12K and above reflexed flaps slowed you down. I’ve not done much long distance flying in my Mooney and to get the gain from altitude the distance flown has to exceed the fuel and time you burn climbing to get there, so I don’t know what that spot is for my Mooney, I suspect it might be lower than the Maule though, in this instance I’m calling the sweet spot to be the fastest speed obtainable, at a power setting that’s kind on the engine. As you climb airframe drag at first falls off faster than engine power decreases, but at some altitude that reverses and you lose HP faster than airframe drag. That’s where forced induction comes in of course, you get to continue to go faster as airframe drag decreases but don’t lose as much power.

-

Respectfully efficiency isn’t really what is most often meant and Bob probably was using it to mean best speed as you state, but that’s not efficiency. I ASSUME he said 2500 instead of 2700 for the reduced NVH at 2500, I believe he was selling airplanes who’s niche was speed after all, but the increase in speed at 2700 probably wasn’t worth the extra noise and vibrations, a 4 cyl engine has many advantages, but smooth isn’t one of them. Think of it this way, best speed for example is 100 ROP, I think that’s generally accepted, but best efficiency is low engine RPM and about -25 LOP, it’s most efficient, but quite a bit slower than best power mixture and 2700 RPM. That gets you best engine and prop efficiency, but there is more to be had, the airframe becomes more efficient as it slows down with its peak at L/D airspeed. But who could stand that? I couldn’t and I don’t mind slowing down quite a bit, But if max time aloft was for some reason what you needed that’s how to get there. But other than hangar talk it’s often just not relevant, if we accept that at 2500 the prop is most efficient it’s really sort of irrelevant in the real world, if you want to go faster turn up the RPM and lowering it decreases speed, any increase in efficiency just really isn’t measurable, trust me I’ve tried. It’s dead easy to try just roll back RPM and increase throttle until indicated A/S is identical, check fuel flow. Most often you will find that rolling back RPM you don’t have enough throttle to fully recover the A/S though so you have to try this experiment at lower than most cruise A/S. Many years ago I was certain that there was a sweet spot, that is an RPM/ mixture/ throttle setting that gave the most speed for the least fuel. I spent significant time trying to find it by graphing different combinations and while admittedly I was in an inefficient airframe I just couldn’t find one. Want to save fuel? Slow down, sure yiu can get small gains from RPM and mixture, but the big savings come from reduced A/S. Years before that I tried the same thing in a twin engine Sportfishing boat that had flo scan fuel flow meters, I was certain that once you broke onto plane that the boat would accelerate at the same fuel flow and there was a sweet spot, so I went out and graphed speed and fuel flow, and while the graphs curve did reduce the steepness there was never a point where you could go faster with less fuel burn. Even cars many people swear their car, usually higher HP ones have a sweet spot, a point that the engine is most efficient at and this efficiency more than makes up for the higher drag at speed, many think for example their Corvette or whatever gets better fuel milage at 80 than 70 or 60, but it’s unfortunately incorrect. To continue the rambling I can remember even as a boy flying with my Father that many, particularly Mooney drivers swore that you could get one on step, that was a point where the airplane accelerated and would maintain a higher airspeed than one that wasn’t on the step, usually they said to get on the step climb a couple of hundred ft above desired cruise then slowly descend picking up speed, they were certain that the final stabilized airspeed was faster than if they just leveled off and let speed stabilize, they were even convinced you could tell if the airplane was on the step because the deck angle was slightly lower. I’ve even spent some time trying in vain the find this step, why not? sometimes tribal knowledge is correct, not often but sometimes. The Gurney flap comes to mind.

-

People want to poo poo Lycoming without trying to understand what motivates them, they have to write procedures that an idiot can do and not hurt the engine because they will be paying if they do, secondly they don’t want to publish procedures that degrade the engine performance. Anyway their recommendations are worth reading. Lycoming is well aware that LOP is where best BSFC is and if you read this they do tell you to lean as much as it will continue to run smooth but contradict themselves at times saying best economy is peak, but also remember they are having to keep it simple and cover every model of engine they make. They know LOP is better BSFC, but they also know the majority of their engines won’t run LOP, and power drops off rapidly when LOP, and peak is pretty close to -25 LOP once you factor in speed difference. What is interesting that over several different pubs they state for max engine longevity cruise at 65% or less. https://www.lycoming.com/content/leaning-lycoming-engines Having done quite a bit of instrumented flight testing myself I can tell you that 99% of expert recommendations can’t be backed up by testing, and statements like props are optimized for xx RPM etc just isn’t possible, due to huge variations of density altitude, power etc. You can optimize a prop for a narrow density altitude and speed for a set power. For example Hartzell designed a prop for me for a 800 SHP engine that turned 2080 RPM on takeoff at sea level and the goal was short takeoff roll, it performed much better than their existing prop, their motivation was me informing them that Avia had a better performing prop and I was considering going with the Avia, unless they could meet or come close to it. Pumping losses etc are real, but so small it’s nearly impossible to back them up in testing, perhaps it’s because the charts just aren’t that accurate because they are most certainly interprelated not every point is a test point. High RPM is an increase in friction of both the engine and prop, but if everything else is equal higher RPM = higher power. As a general statement at least at normal altitudes the lower the RPM the more efficient the prop, efficient as in most thrust per torque applied, this isn’t usually what is meant by “optimized” though, especially from the manufacturer that means best speed without too much noise and vibration, aircraft are rarely sold for MPG, they are almost sold based on speed. What usually happens is for a NA engine you can run LOP below say 9000 ft or so at a speed that you can live with, above that you have to start increasing RPM and or fuel flow until you get to 100 ROP, then no matter what else you do you can’t get any more power. Now 9000 ft is just a statement, some can be happy higher, others say I didn’t buy a Mooney to go slow and can’t, personal preference. At least we have a choice, if we were FADEC we wouldn’t, you lose speed increasing efficiency and lose efficiency to increase speed TANSTAAFL. Now when I was flying the C-210 as the Company paid the bills I fire walled it at takeoff, and reduced power to land, I flew it at best power for max speed and 2500 RPM for noise and it was smooth there. Now that I’m retired and only fly for fun and pay all the bills, I don’t fly my Mooney that way, but understand the I want speed, nothing wrong with that but it does cost more. Most of the CFI’s I’ve had experience with have essentially no maintenance experience, and often have very little if any aircraft ownership experience so other than the POH they don’t often have any real experience, and every POH to include the few I wrote emphasize performance, because performance sells. Very few people that can buy a new airplane are more concerned with fuel burn than speed. The reason most engines can be run past TBO if well treated is because TBO is set for the guy that flies like I did the C-210, always as fast as it could go. If you do as Lycoming recommends and forget that 500F head temp redline and your redline is 400F and oil temp between 165 and 200 and fly at or below 65% power the engine will most likely go way past TBO safely, probably, unless the cam goes or you let it sit too much or etc.

-

What race car is front wheel drive? I haven’t raced cars for 40 years but then it was only two, old mini-cooper which had its own series and the Renault R5, the Le-Car, which was only technically a race car as it was raced in SSCA C class show room stock against the mighty Chevy Vega. Renault handled better until it rolled but the Vega had more power, in other words they were both turds, but they were fun because all cars were evenly matched. Rear brakes while it’s true do very little braking yet they are important, they do help in stopping and sometimes will keep the back end where it belongs, some motorcycle road racers put thumb brakes on the rear on the left handle bar, when braking in a hard turn without a tiny bit of rear brake the rear would step out, even if they do no braking at all they absorb the inertia of the drive train that will act to push the vehicle forward under hard braking.

-

Most of the lights I have experience with are timed as in once you get the cadence right then you will make every, or almost every one, the timing doesn’t vary from 3am with no traffic to rush hour. Every so often you hit lights that there seems to be no timing at all, they seem random, I’ve always assumed those are not networked Apparently none of the ones I’ve been around have the ability to adjust timing based on traffic density either, because the length of time the light stays green is the same whether there is one car waiting, or 20, when it’s 20 you may have to wait several cycles, when it’s like that I often go past and turn around. I suspect most of the US thankfully is not like S Cal. I couldn’t live in that kind of density myself. I don’t expect to ever have to put new pads or rotors on, car I just sold had 50K on it, and the brakes were worn maybe 10%? Except to hold the car once stopped they were only rarely used (regen braking does all normal braking)

-

You will also save a BUNCH of fuel too if you lift the throttle when the light ahead turns yellow. Drives me nuts to watch these people who accelerate until they hit the brake, it doesn’t save them any time, nobody is going until the light turns green, so why do they do it?

-

This Personally I delay gear down until top of the white arc, because my airplane is geriatric and as I have Certified a few CAR 3 airplanes myself I know that there is no consideration for aging components in Certification, I believe there is some verbiage that fatigue of the airframe must be considered without any definition of what that means. I also retract gear at the slowest speed possible, in fact I think maybe retraction is even harder on the actuator and linkages etc than extension, but I don’t have any proof of that it comes from an opinion, and we all know what those are worth. Other than being taught to do it by CFI’s that have zero mechanical aptitude or experience I can’t figure out why a person who won’t pull max G’s every flight or push to VNE on every descent etc thinks nothing of hitting that gear switch the instant it’s allowed. Now if I could purchase a new Eaton actuator and the rest of the parts were readily available, then maybe I’d relax my attitude some. Oh, and it’s honestly not at all hard to slow a J model down, you just start a little earlier is all. On edit, I’ll often descend 100 ft lower than pattern altitude, then climb the 100 back, the climb when at low power really drops speed of course.

-

That’s what I was saying, but also they are reporting they must be very high tech because we can’t intercept any control signals to them. So if we have even rudimentary frequency monitoring equipment listening, then why not cameras taking pictures? A drone at 200 ft looks nothing like a 737 on approach at 3,000 ft. Surely there are lots of cameras in civilians hands that would do the job. https://www.amazon.com/s?k=night+vision+camcorder&crid=1JZW9YKPAUDBP&sprefix=night+vision+camcorder%2Caps%2C167&ref=nb_sb_noss_1 But there was a report of a police helicopter hovering over one, so either completely false or a drone? However you slice it, if it’s full sized aircraft that’s so easily busted, why hasn’t the Feds busted the story so they don’t continue to look like inept fools? None of it makes sense to me, why don’t the Feds do something, what’s gained by letting it continue?

-

While I agree that many of the few videos I’ve seen were manned aircraft it has me wondering a few things. 1. Surely there have been manned aircraft flying over NJ for years, so why now all this drone concern if there aren’t drones about? 2. Where are the night camera’s? I know for certain that the FLIR in an Apache can certainly tell the difference, and as that is now over 40 yr old tech, certainly there is a whole bunch of Commercial FLIR that’s at least as good, probably better in Sheriff’s helicopters if nothing else, so why no video from them? Same for Night Vision cameras, News had bunches of them in DS 1, and that was what, 35 years ago? I’d bet maybe you can buy a Sony video camera with a low light camera good enough to tell the difference between a drone of a 172, 737 whatever. So where is the video? With all the craziness on Youtube trying desperately for views, where are the videos confirming or denying drones? 3. What idiot if trying to be covert or having nefarious motives flies at night with the lights on? Or assuming if they were dumb enough to have, why are they still? If your up to no good, fly lights out and no one would have known, if your not going to fly lights out, just fly in the middle of the day.

-

Observation about takeoff flaps and full aileron deflection

A64Pilot replied to AJ88V's topic in General Mooney Talk

What causes that excessive pitch attitude is flaps AND excessive up trim, if you don’t trim up so much you won’t have that excessive pitch up. It’s not just Mooney’s either, my Maule was much worse, the difference was a Maules flaps were manual and you can lower them in an instant, but a Mooney’s take time, plus a C/B could pop. I learned in my Maule to not trim full up for landing, works in my Mooney too. By the way, as bad as it was for you with I assume by yourself or one other, it’s much worse with people in the back, especially if there is baggage too, because of tge CG of course. -

Observation about takeoff flaps and full aileron deflection

A64Pilot replied to AJ88V's topic in General Mooney Talk

Piston 1340 Thrush had I think 40 degrees of flap, Thrush flaps are like a Mooney with electric flaps in that they are infinitely adjustable. Anyway when the Turbine was installed by the Ayres Corp flight testing showed an excessive nose up pitching moment when doing a go-around at light weight so that is where the turbines 15 degree flaps came from. When they installed the Garrett’s the rudder would lock if you did a stupid excessive slip, so rudder deflection was reduced. On the K my guess and it is just a guess but mine is that maybe they are just a little more nose heavy and that might cause a little more trim change with flaps? The Thrush of course has a few STC’s for turbine installation, none of which call for flap travel reduction and I never heard of an accident from it so apparently the average pilot can handle 40 degrees of flap. Two different test pilots can fly the identical airplane and come up with different opinion on handling qualities, as much as we would like to think it’s purely scientific, but aircraft handling qualities are somewhat subjective, then add in the fact that many test pilots have to find something, they feel that if they don’t it looks like they aren’t doing their jobs, and I learned eventually that if the change they wanted was minor and didn’t hurt aircraft performance to just thank them, make the change, save who knows how much money and get the aircraft Certified months earlier, and possibly I made a friend as I WILL see that FAA check pilot again. I’m saying that just maybe Mooney did it at the request of the FAA for some reason we will never know, because fighting to not make the change just wasn't worth it. I promise you the darndest things get changed and you just can’t make sense of it, but as Paul Harvey used to say “and now for the rest of the story” -

Last years Concorde I A renewal seminar, I only screen shot screens that are of a particular interest to me. The presenter worked, maybe owned Eagle fuel cells, and has it seems a long history with fuel cells, his point is that aeromatics are hard on fuel cells, and my take on that is it’s likely hard on sealants as well. On edit, I think his point was that ALL fuels are relying more heavily on aeromatics than they used to. He seemed to indicate that they are hard on fuel cells and I’d assume he would have an educated opinion. If you search aeromatics in auto fuel you will get some interesting reading. I would suspect you would get only a few hits on a search of it in aircraft fuels based on just how little piston aircraft fuel is manufactured.

-

What do you bring on long flights?

A64Pilot replied to DC_Brasil's topic in Modern Mooney Discussion

I carry an RON bag, because well I may have to remain overnight for Wx and who knows, just underwear and toothbrush, cell phone charger etc. and my wallet. You should hydrate, air at altitude apparently is dry and that causes dehydration. Gatoraid bottles work well but I also have a travel John. Wife refuses such a thing so we make more stops when she is along than when I’m by myself. I’ve been told that Gatoraid isn’t good for rehydrating, can’t speak to that myself. -

I would be real concerned with a discharge rate of 290 amps, even at 20V (hit a battery hard and voltage drops), that’s still 5,800 Watts, which is an awful lot as in enough to cause a fire. A bad battery should not have anything to do with a discharge, once running the alternator is providing current, not the battery, so in my opinion it’s most probable that you still have a problem, and I doubt the -290 amps is real or you would have smelled burning wires. A loose ground can cause all kinds of illogical problems, lots of things that just don’t make sense.

- 22 replies

-

- 1

-

-

- electric

- electrical

-

(and 3 more)

Tagged with:

-

Oh, and one of my helmets has the Oregon Aero upgrade kits, which are WAY more comfortable, much better cushions, and I think the foam they use in the ear cups absorb even more noise than the stock foam does. They make their kits for headset too apparently, but I’ve not put a kit on any of my headsets, I guess you have to call and find out which kit fits your headset? https://www.oregonaero.com/helmet-upgrades/military-aviation-helmet-upgrades#!/~/search/keyword=headset+upgrade+kit

-

Roughly I’d guess about 8,000 of my hours are in noisy turbines, AH-64’s and Crop Dusters, Crop Dusters are loud as they have zero insulation, it’s all sheetmetal with a hole in the floor, that way you can hose it out every so often like old work trucks, and of course any Military helicopter is loud, but an AH-64 has an engine intake behind each shoulder and the intake is where the high freq comes from, and the transmission right behind your back. What works best is take a good passive system and add ANR, that gives you the best of both worlds. Attached photo is three of my helmets, one SPH-4B and two HGU-56P’s all three have ANR kits, one the battery box is on the back of the helmet, which didn’t work out as well as I hoped, the other two the box is between the two plugs. Headsets Inc makes the ANR kits, have them install them or install them yourself. https://www.headsetsinc.com Give them a call, they have been doing this for a long time and they can customize most anything. What Sux is they use 9v batteries that are expensive, to combat that I use rechargeable Li-Po 9V’s that recharge from a USB plug There is also a Headsets Inc headset, they used to take Peltier headsets and modify them, not sure if the newer ones are still Peltor or not but if not they are a clone, one of the new ones is in the Pic One good option is to take a good David Clark headset and put an ANR kit in, if you like David Clarks. If hearing protection is your concern, you’re not getting protection from ANR alone because it doesn’t block the harmful frequencies, but I don’t think our Mooney’s produce high freqs like a turbine can either. The low frequency drone that they do produce is fatiguing over time but probably not all that harmful, but a good passive set with ANR gives the most noise reduction as if ANR is faced with lower volume of the freqs it cancels it of course does an even better job, but there just isn’t the major difference between ANR off and on of course because the passive is so good. If you really, really want to protect your hearing have an Audiologist take a mold of your ear canals and make special tuned ear plugs, that’s what I did in the Military because ANR in my Military IHADDS helmet wasn’t an option then.