A64Pilot

Basic Member-

Posts

7,988 -

Joined

-

Last visited

-

Days Won

21

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by A64Pilot

-

You do know, even back in the day there was a light that came on if water pressure dropped below set point when system was on, I think you got a green light when system was on and you had water flow and a red light when system was on and limited or no flow. I know Rob Roberts owner of EI very well, I’m certain that his “box” monitors pressure and turns on the second pump if necessary and alerts the pilot, but I have not seen the new system. In truth you really can run premium car gas without harm most times, it’s only if you get that stupid high cyl head temp that Lycoming allows that you get detonation, but Cert rightfully so requires a healthy margin Way back in the 70’s I think University of Tennessee ran a C-310 on what then was called Gasahol in one engine for hundreds of hours. Dr Ralph Kimberlin who was my Civilian Test Pilot mentor was part of the program. It may have been a 421 not sure. Without ADI you do have to have a very different Cyl head temp redline though, and I’m sure you don’t have the margin 100LL gives you, but with ADI that margin is even larger that without ADI but running 100LL.

-

In the 140, it’s was an $85 STC, there are a couple of STC’s Peterson charged $1 per HP I think. I think you’re supposed to have a label by the fuel filler that says MOGAS is OK, but I don’t. In truth most little airplane guys just run it and don’t bother buying the STC No modifications to the aircraft, although some aircraft do require mods. Maule has to have a fuel pump and I think a vent to prevent vapor loc. So it differs by airframe

-

It’s an extraordinarily simple system, if you have ever played with Nitrous Oxide in cars it’s very similar, simple plate that goes between the carb or servo and intake “four bolts” and one hose that connects to the plate that I’m sure has a spray bar in it, the hose connects to an automotive electric fuel pump that connects to a tank. The “brain” made apparently by EI now monitors two things, cyl head temp and manifold pressure, either or both above set point, pump is turned on. That’s it. Other than not being approved of course I could build one myself in a day. Many Ag guys do it in particularly G6 Garrets, in the Garret it’s EGT that’s the limiting factor, it’s why yiu can’t keep pushing the power lever forward, inject water and yiu get an instant drop in EGT so yiu can push the lever further forward making more power for takeoff. Car guys, ones that run high boost anyway have been doing it for years, apparently they often run windshield washer pre-mix, seems the cheap blue stuff is just the right mix of alcohol and water https://www.dragzine.com/tech-stories/engine/get-schooled-water-methanol-injection-101/ https://www.holley.com/blog/post/the_science_behind_why_water-methanol_injection_works_so_well/

-

I’ve been burning 87 Octane car gas in my C-140 for years, the 140’s fuel vent system is 2 small holes drilled into the tractor style fuel caps, as such if you fill them up they will siphon fuel out in flight. Both my fuel tank covers that are painted with Jet-glo are stained a yellowish brown, but it will polish out, or did a few years ago the one time I did

-

As a kid in Albany Ga, Turner Air Force base I used to watch them scramble B-52’s and they would do “wet” takeoffs, that is water injection, I don’t know why, but it did make them smoke like trains

-

I keep bringing this up, but all this angst of “we must have an unleaded 100 Octane fuel” just isn’t the case, not at least for non forced induction aircraft anyway and I suspect turbo aircraft would be fine too in cruise. It’s been done widespread since WWII, called ADI or anti detonation injection. It’s simple alcohol / water injection, trigger points for injection are often manifold pressure above 25” or cyl head temps above 400F https://www.avweb.com/features/the-return-of-anti-detonation-water-injection-adi/ https://generalaviationnews.com/2012/05/22/adi-bridging-the-octane-gap/ https://www.autofuelstc.com/news.phtml/E2F118E7/anti-detonant_injection With it you burn car gas, no big deal, no melting paint, swelling O-rings etc because people have been burning car gas for decades, I have anyway, but on low compression engines OR just remove the lead from 100LL and burn it with ADI, why not do that?

-

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

Actually we were still using Trich we called it up until I retired, mostly cleaning cannon plugs etc. -

How many RPM per turn of the screw for I believe a McCauley governor? I need 100 RPM

-

We tightened it, that removed the looseness, that was there from wear from being loose, and that returned the belt to correct tension, so being loose obviously caused wear. What had me confused was as there were cotter pins, it was intentionally installed loose, and as that ran against my experience I thought I’d ask. Now onto the other thing that has been annoying me, that is the engine controls bottom out, there should be some “cushion” that is stops on the engine should hit leaving some travel on the cable.

-

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

When I joined the Army as an aircraft mechanic in 1982, we used Acetone regularly to wash parts. Eventually due to testing done and the results of what Acetone’s effects on the body was it was prohibited and replaced with Methyl Ethyel Keytone. Then years later due to testing that showed that MEK was bad for you it was replaced by Methyl Iso Ketone. MIK Now I’m pretty sure but can’t prove that in truth Acetone was the least “bad” of the three and while maybe well intended in truth the replacements were in fact worse than the chemical they replaced. Its my understanding that aeromatics are bad stuff health wise, at least if you search aeromatics effects in auto fuel that seems to be the general belief. -

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

Ref paint and “plastics” material compatibility with solvents, the two pics I attached are my Chinese made parts washer, that I feel pretty sure was likely meant only for water based cleaning fluid, but it’s lasted for at least two years before it failed, so effects if any may take a long time to surface, and if you test only new products they may be fine, but older ones exposed to other solvents may not, then add in every other possibility like 100+ degrees desert temps and deep sub zero temps, you’ll maybe concede that the only way to truly know is to field it and closely monitor it, or cross your fingers and hope for the best. -

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

It’s getting parts that are aviation approved that may be the issue, and that’s a tough call. For instance I know of no butt splices that are specifically approved, but the wire required has very specific qualifications. Thankfully the wire is readily available though so not an issue. Just as an example, Stat -O- Seals it seems are getting very difficult to find, but I can order them that aren’t approved aircraft parts readily and I can’t tell the difference. So what do you do? Reuse an obviously deteriorating seal because you can’t get the correct one, or replace it with a non approved one? Thats where in my opinion the FAA SB on aging aircraft parts helps, but then your using an Advisory pub to justify not following a Regulation, and that’s flakey, putting the responsibility and liability off of the FAA and onto the mechanic. FAA seems to be very concerned about liability or responsibility anyway, I guess admin types are concerned about their careers first and foremost? -

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

OK, I watched the video. I don’t think he’s a nut searching for hits or whatever they are called. Personally I wouldn’t put this stuff in my lawnmower if I had an option not too just based on that Video Paint I think isn’t a significant issue, but I have a LOT of experience with Jet-Glo, it’s one of the paints that tolerates chemicals used in Aerial application, and some of those even eat fuel tank sealer, we used fuel tank sealer in the chemical hopper and it would get eaten up and need replacing regularly, but we never found anything better, anything that dissolves or eats up Jet-Glo is something that will likely have adverse effects on just about anything. Paint staining is an annoyance but it won’t hurt you, swelling fuel system “rubber” components can There are seals, O-rings throughout many fuel systems, some you can’t change out, like fuel flow senders for instance, there are plastics in places you wouldn’t think of too. I’ve seen plastic bushings etc in fuel pumps for instance so add pumps to the list of fuel system “rubber” -

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

I think it’s likely that we have enough people burning this stuff that we will have a good indicator of problems before long, at least in California climate anyway. That’s the acid test in my opinion, I’m just too risk adverse myself to willingly participate -

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

I don’t either, and not to be insensitive as of yet I don’t have a dog in the fight. I figure by the time it’s forced onto me that it will have been well tested by lots of souls. As I said I have not watched the video, but I can’t imagine someone with a few jars has discovered an obvious defect in this fuel, something that any compatibility testing would have discovered the problem, and I’m certain that compatibility testing was done years ago, before it was ever put into an airplane surely. As far as the recommendation to upgrade the rubber in the fuel system, yeah that’s worrisome, but it could be argued as simply good advice too Viton where allowed and Teflon lines are superior products from my experience. O-rings etc could cause serious problems even engine failures, but I think the biggest $$$ concern is bladders and fuel tanks. Youtube is so full of BS, with all kinds of people claiming all kinds of nonsense, all seeking their 30 sec of fame that it’s just sad. I guess I’ll watch the video and give him another click or hit or whatever it’s called -

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

I’ve done hot fuel testing, it’s an airframe requirement, not I believe a fuel requirement. For example one of the tests I did was to qualify the S2R-T660 which is a turbine for 100LL, because Pratt allows limited use of 100LL as an emergency fuel. Having said that the STC process from my experience is pretty “flakey” for example at one time there was an STC to put a C-140 into LSA by putting a placard on the airplane restricting its gross weight to the LSA limited. FAA later rescinded that STC. The Auto fuel STC’s I believe did do specific testing to each airframe, because several airframes require modifications to run it, most I believe to prevent vapor loc, so there had to be airframe hot fuel testing to qualify that. I assume with no knowledge that Gami showed that their fuel due to vapor pressure was less likely to vapor lock than 100LL. -

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

There are many practices like that, like to replace a Goodyear tire with a Michelin etc. You can replace an AN bolt with a NAS etc, because the NAS is “better”. I believe Viton unless for some reason is disallowed is “better” But I believe that for whatever reason if the fuel is eating O-rings then there just might be an AD requiring O-ring replacement, then you have your paperwork. As an IA I would have no problem with Viton, I serviced my Gascolator yesterday, replaced the big O-ring and Stat-O-Seal and went to replace the tiny one on the pull to drain, noticed it was brown meaning it’s was Viton so I left it. I bet that Viton one will outlive me, I’ve never seen one deteriorate, I’ve only seen a few mechanically worn is all. -

Based on the G100UL fuel leak thread what's your position?

A64Pilot replied to gabez's topic in General Mooney Talk

Depending on the aircraft, I have bladders for instance there are more O-rings than we might think, I’m sure fuel caps have them too etc. I’ve not watched the video, but strongly suspect something isn’t Kosher with it, O-rings are surely about the first things you would check, and are among the easiest. I’d bet Lunch Gami tested both new and used O-rings many years ago, along with fuel lines and sealant. I can’t believe they missed that and suggesting they knew and drove on anyway is suggesting they are both crooks and stupid ones at that as of course that’s going to become apparent soon and kill their product, probably have them in many courts, bankrupt the company and kill any trust the community had in them. I don’t think they are that stupid myself. Having said all of that even if it were available to me I won’t be an early adopter. The Mobil 1 issue comes to mind, so even unlikely things are possible. I have become over the years very distrustful of the FAA overseeing anything, their stamp of approval doesn’t mean what it used to. -

Noticed today doing the annual when I pushed on the Alt belt the Alt moved slightly, I thought this odd, Where it’s getting the movement is from the two pivot bolts being loose, now they are cotter pinned so obviously they were intentionally installed loose obviously to allow the alt to rotate freely for tightening the belt. Is this normal for a Mooney? I don’t see it as a safety issue, just seems odd is all.

-

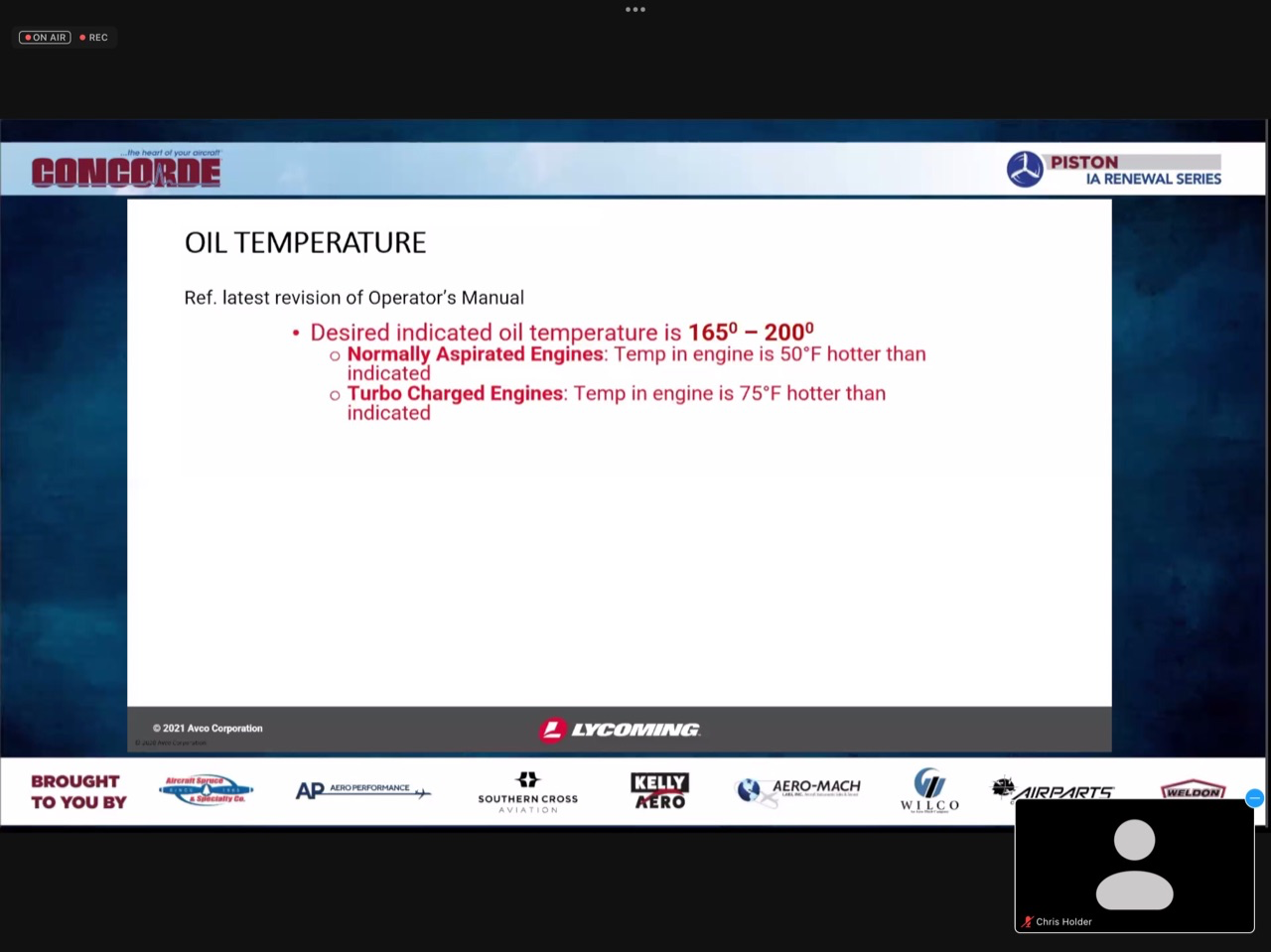

Ref oil temp, Lycoming published maximums and what Lycoming recommends. Think of it like that 500F Cyl head max temp, sure they say you can, but in several other pubs they recommend 400F max for engine longevity This from last years IA renewal. This is what they recommend, sure higher is allowed, but not recommended. As far as what to do about blow-by and possible stuck rings, Mike Bush has a ring flush procedure that I’m not a fan of, but several are. Every case of stuck rings I have seen shows up in low compressions, sometimes not stupid low, but definitely a number that has me researching why. In my cases it has resulted in cylinder removal, I’ve even disassembled everything freeing up the rings etc and putting things back together, but didn’t seem to fix the problem (My C-85) and will result in cylinder removal and an IRAN or maybe overhaul depending on what the shop suggests. Just have to get a round tuit. Oh, and on edit, rings wise listening for leaks at the oil fill tube or blow-by tube is more important I think than the actual compression number, obviously if there is a loud hiss from the exhaust but not the crankcase, then it’s likely your low compression is not from rings,but the exh valve.

-

An indicator of high oil temps in cruise if everything else is fine is excessive blow-by, blow-by unfortunately doesn’t always show up in a compression check like you think it should. If the oil turns coal black within a few hours of being changed you might have a stuck ring or similar. Personally I climb my J at 120+ kts indicated primarily to keep cyl head temps where I like them, but of course it keeps oil temps low too. If anything I have an issue getting the oil warm enough, it’s never beyond the half way point on the gauge, but then I won’t let me cyl head temps get very high either. This was cruise the other day at 60% power or so LOP. It was cooler than average being Dec, but it was also in Central Fl and 4,500 so it’s not real cold.

-

Very often STC’s are not free, depends on whether or not the owner is trying to sell their product or make money from the STC, or both maybe. Often the STC cost is small, sometimes not. For instance if the STC is for modifying the aircraft with readily available parts so the STC holders only profit is from the STC, then of course that STC can and should cost more. As an IA, in my opinion anything that doesn’t require any modification to the aircraft should not by definition require an STC. For the owner an STC is a pain, and even if it’s free they still have to pay an IA to fill out the 337, make logbook entries etc., so free isn’t. From my understanding this fuel requires no aircraft modifications or changes to operation, is a simple drop in, is completely miscible with other existing fuels, so why does it require an STC? Just one man’s opinion.

-

I’m pretty much there myself, my dilemma is that I have the single drive mag, and I think it’s gotten so that people seem to specialize in them, many or maybe most won’t even do them, so I think the answer to your question may depend on which Mags you have. Personally I don’t think any perceived advantage of electronic is worth the expense myself

-

Germany at least in the 90’s was that way too, but Frankly I find it more Civilized, I think of those people who have to work nights and weekends in order for me to get what I want 24/7, and think the sacrifice they have to make just so I can get a doughnut or whatever at all hours is more than they should be asked to do.

-

In 1989 we flew 2 AH-64’s, 2 OH-58’s and 2 Lynx’s from Germany to Dax France for their helicopter school’s airshow, we met up with a French Gazelle at the border to escort us, which was a good thing because all ATC calls were in French, sure you could usually make a call in English and they would respond in English, but all other calls were in French. It’s amazing how much info you get from hearing the other calls. That was an eventful trip, took way longer than we expected, refueling wasn’t center point refuel, but open port like we do our Mooney’s, and we had to reposition each aircraft one at a time to the pump to refuel. Ended up getting dark and we landed at some little grass strip, seemed the whole town turned out and cooked us Supper at the pilot lounge. Two Chinooks also went in another flight, I can’t imagine how their refueling went. On edit it was probably 93 or 94 I was still at Ft Hood in 89