hammdo

Supporter-

Posts

2,623 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by hammdo

-

BTDT.. don't think they’re interested but couldn’t hurt to contact Trio… -Don

-

Yeah, will ask AP about it at annual…

-

Well, started on oil change, found the quick drain won’t go up anymore. Tried to remove it and someone in the past seal those drain plugs forever. I tried removing the plug on the pilots side and BROKE my cheap wrench! So, had to resort to using the electric oil drain pump and that did the job. I’m not about to drop the sump - I have a feeling the sump would need to be replace since these damn things are in there for good. Not spending 3k to 4k on a new one — didn’t find a used one either. Electric oil drain pump worked just fine and a drip of oil occasionally from the quick drain. Would love to know who seal the drains shut… Anyway, change is done, filter on, run up with no leaks. Didn’t see the problem yet on the step - looked for the fuse but didn’t see one. May have to have the shop look at that during annual. -Don

-

Jack points maybe? — may have something they inset into… -Don

-

Looks like the oil leak is solved, did a flight today and the residual oil is pretty much gone. Doing oil change now to clear out the dye. Noticed my electric step stopped going up/down though - it’s attached to the beacon and that is still working. Sent a note to @takair about it. Will report back on it. Gonna give Maxwells a call on the control rods to see about changing those out. Never ending maintenance it seems… -Don

-

Favorite View Limiting Device with Noise Cancelling Headsets

hammdo replied to PeteMc's topic in Miscellaneous Aviation Talk

Icarus but not cheap — great trainer - simulates IFR pretty well… https://www.icarusdevices.com/ -Don -

Everything has gone great -- did some IFR approaches with low ceilings (400 ft). While doing some lubing, I realized the rudder and elevator controls need some love. I ordered some low time control rods from a 66 Mooney that look like new! My current ones look like this (below) so I think its time to have them updated. I'll see if Maxwell's have time -- wouldn't think it would take too long. I also purchases the dual elevator rods that are in the tail section. I'll have them replace the rudder heims and that should really get this in great shape.

-

He detailed his journey here on Mooneyspace - from when he found it… -Don

-

Mine has 2 ‘longerons’ if you will and the transponder antenna… -Don

-

W91 - Smith Mountain? I believe they too rent hangers… -Don

-

Good News! But is it part of the new political atmosphere?

hammdo replied to Schllc's topic in General Mooney Talk

Same response when they deferred it… -Don -

Hell of a racer too… -Don

-

Did another flight today in the pattern. Post flight check was great. I only see the residual oil left so cleaned it up. I’ll probably have to do this a bit more as it was really a mess before the fix. I’ll fly it one more time in the pattern then change the oil again. As of now, running great and I’m slowly getting the oil leaks taken care of… -Don

-

Io360 a1a cylinder blow by. Replace?

hammdo replied to Teddyhherrera's topic in Vintage Mooneys (pre-J models)

This should work ;o) -Don -

Congratulations! Well done! -Don

-

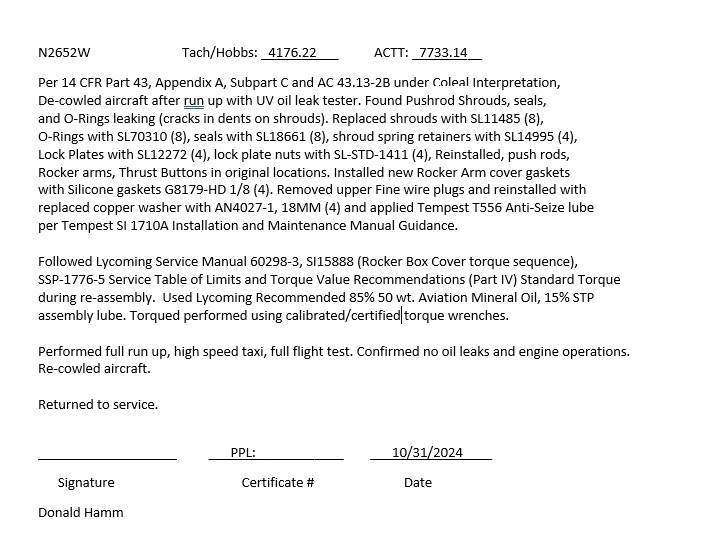

To be complete, this is my engine log entry (unsigned here). Cylinder Drain Tubes on separate entry:

-

Did the run up today, then did a high speed taxi. Checked things out and did a full flight in the pattern -- flew and ran great! No more leaking oil on the top after 1.5 hours of run time! She looks pretty good -- did see some residual oil from the leak but at least its not all over the place anymore (before and after the run). I'll do another cleaning to get as much of the old oil out but this looks to have taken care of about 90% of the leaks (oil cooler fittings and the quick drain need updates). Overall, really turned out great and boy this engine runs well... -Don

-

Decided to do cylinders #1 and #3 -- pretty straight forward but, on #3 the exhaust valve spring has an ash-like coating on it - I didn't remove it but I'm wondering if this is what Sal's was eluding to about cam guard (#1 has the silicone gasket). Also replace the #1 cylinder drain tube…

-

Initial run up today went well, did an extended run with the cowling off so I could look for leaks. Warmed her up, did about 1500 RPMs, ran smooth! I’ll button her up and do a full run up and maintenance flight next. The left side had the leaks so I’ll stop where I’m at to make sure all is good. I fly her in the pattern for a couple of days, then probably change the oil as it’s right at that time again… -Don

-

Yes, marked them so I knew where they went… sharpe dot on the exhaust. Same with the rockers… -Don

-

#2 cylinder updated -- same steps -- note the spring clamp is oriented differently (just to be complete). Replaced the dented tube on the exhaust side since it was clearly leaking at the dent:

-

I had to buy a 3 ft piece of aluminum at Lowe’s - $30. Did the job!

-

I document it completely for sure. I did check on this and from what I saw, replacing was ok. If an IA balks, I’ll let them re-do it. It really is not a complex process. Removing a mag, cylinder, yeah, not gonna do that without AP/IA. Pushing Coleal? If this was a complex job (which to me this wasn’t and well within my skill set), I’d agree. I guess time will tell… The reason I documented it was to show I’m working with what I can tell is in the spirit of Coleal. Simple maintenance task that are not complex. -Don

-

Before I started, I got everything ready AND put rubber mats down -- just in case I dropped anything (don't want a broken spark plug -- those fine wires are expensive):

-

DId number 2 cylinder the same way (it had a big dent in the tube). I also inspected #4 and the shroud for the intake side had a bad spot right where it entered the cylinder. While I was at it, I replace the #4 cylinder drain tube since it had chafing on the aluminum tube. I did put chafing tape on that area also. Pics of #2 and #4 cylinder completed and ready for a run up. I plan on doing #1 and #3 too. Just taking my time and not rushing things ;o) I know these are good tubes, new seals with new spring clamps. I also know the spark plug has new washer too. Not a bad job and after reviewing Coleal, this is not a complex disassembly and simple to do with the right set of tool. I didn't do this because it was cheaper (it certainly was not since did buy all those tools -- including the calibrated torque wrenches) but since I felt I had the necessary skill set, I did it. I did use the assembly lube on all contact areas, push rods, and rocker arms.

.jpg.002315ccb839741c773bec076759ea33.jpg)

.jpg.f1b09a491b267c10b535a926cdacccd2.jpg)

.jpg.5279605fc8b04053a9d31030e7373dbf.jpg)

.jpg.470af937ff391a8d59b934bbbf24c3e6.jpg)