1980Mooney

Basic Member-

Posts

3,337 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by 1980Mooney

-

I have a 530W/430W stack like you are considering and am perfectly happy with them. I see no reason to change them. They are perfectly integrated and cross-fill. I could spend $30,000 to get new models with larger touch screens but get no better functionality.

-

Are you contemplating purchasing one versus the other? If so I would definitely get the GNS530W for a couple reasons. First the screen is much better and easier to read - both size and resolution. Also Garmin is near the end of being able to support a GNS 430. I had mine overhauled recently and was told that they’re no longer able to get new screens. If you do buy a GNS 430 W don’t pay much for it.

-

You may be right that I have conflated 2 Jonathan Scott Pollack's living in the Northeast into one. But what I do know is that Mooney's Jonathan Scott Pollack is educated as an attorney and owns N705SE. He is Instrument Rated. His pilot license, aircraft registration and law license all show 129 E 82ND ST # 3A, New York, New York as the address. FlightAware shows that N705SE is based at Great Barrington Airport (KGBR) in Massachusetts near the New York state border. It also shows that the plane has made one trip to Kerrville in the last 3 months. It arrived in Kerrville on Jan. 10, 2022. It appears to have then made trips to Corpus Christi and San Antonio and returned to Kerrville. It departed Kerrville for KGBR on January 22. It is still "Crickets"

-

Exactly The original shock mounts are made by Lord and about $18 each - brass/nonmagnetic studs I assume specified for the days of magnetic instruments. Lord J-6984-64 Instrument Panel Shock-Mount at SkyGeek.com The shaft going through the instrument panel is shorter. The ones referenced in Aircraft Spruce in are J-6984-1. They are 1/8 inch too long. (the same length stud on each side) Overview Lord round instrument panel shock mount, as used in Cessna aircraft. Overall length 1-1/4". Rubber molded on 8-32 threaded projections. New manufacture. There is a remedy - you can cut 1/8 inch off one side on each mount. Aircraft Spruce also has some cheap ones with ferrous studs. Looks like you may be a new "J" owner. You might want to look at this: Page 614 (56-10-06, page 0) mooney.free.fr/Manuels M20J/M20J/Mooney M20J Illustrated Parts Catalog.pdf Also mooney.free.fr/Manuels M20J/M20J/Mooney Service Manuel M20J Vol. 1 of 2.pdf http://mooney.free.fr/Manuels M20J/M20J/Mooney Service Manuel M20J Vol. 2 of 2.pdf

-

Pre buy inspection near Austin TX

1980Mooney replied to TSC1020's topic in Vintage Mooneys (pre-J models)

-

Pre buy inspection near Austin TX

1980Mooney replied to TSC1020's topic in Vintage Mooneys (pre-J models)

Here are 2 topics from Mioneyspace on Experience with Blue Skies. Not very flattering -

GAMA 2021 Full Year Single Engine Piston (and Single Engine Electric below) Aircraft Shipments and Billings Report is out. Cirrus dominates. Mooney is MIA. Textron lost ground to Cirrus - built no (zero) Bonanza's in 2021. But they announced that they are bringing the Cessna 182T back into production to better meet market demand basically unchanged from 2005 when last built. Diamond and Tecnam remain solid performers with a decent share of market. Piper's numbers are stronger than they appear. They lost some share in basic SEP trainers but built more of their lucrative pressurized singles - piston and turboprop (which are not reflected here) and lucrative twins (also not reflected here). Extra, American Champion, and Sonaca are steady. CubCrafters growing. Pipistrel growing (in addition to 26 pistons, delivered 48 Electric trainers and certified Panthera "modern Ovation"). ICON in decline - novelty wearing off, parent company issues. Although not shown in the GAMA data, a registration search shows that Maule is building again, and Game Composites builds about 12 planes per year. It seems like especially bad timing for Mooney to give up on aircraft manufacturing. Quarterly Shipments and Billings - GAMA SE-Piston 2018 2019 2020 2021 Mooney 14 9 0 0 Cirrus 380 384 347 442 Textron 208 203 306 254 Diamond 98 203 213 207 Tecnam 180 197 138 186 Piper 134 203 178 146 CubCrafters 19 16 64 50 Flight Design 43 63 38 41 Pipistrel 22 8 17 26 Extra 24 25 22 22 American Champion 13 10 14 20 Sonaca 4 24 19 19 Icon 44 41 22 18 AVIC 4 2 7 3 Pacific Aerospace 0 0 1 1 From Registration Search Maule 4 1 0 5 Game Composites 1 11 12 12 SE-Electric Pipistrel 0 0 13 48

-

It’s just as well that Aeroshell #6 is not available. They made a change in its formulation a while back and it is suffering premature separation of the mineral oil. Van’s is reporting the problem too https://vansairforce.net/community/showthread.php?t=178968 My Hartzell is streaking the blades and throwing on my windscreen. It is currently in a Hartzell shop for a reseal with Nyco GN3058 a lithium synthetic grease. Hartzell no longer uses Aeroshell on new props https://hartzellprop.com/SERVICE-DOCUMENTS/SL/HC-SL-61-366.pdf

-

Mooney market? maybe im missing something!

1980Mooney replied to pkofman's topic in Modern Mooney Discussion

Based upon serial number it looks like Mooney only built about 140 M20TN’s. Some were exported. Some crashed. AviationDB shows 121 airworthy in the US. There are four for sale right now on controller. That’s over 3%. That’s more than the fleet in general. -

Yes but all the Mooney purists would lose their minds. They would say it looks too much like a Cirrus. After all we enjoy enduring gear up landings, paying higher insurance rates, paying higher annuals to swing gear, replace no-back springs, replace Lord Disks, lubricate, repair nose gear truss bearings, repair bent nose gear truss from excessive tow bar turning and to have a wide turning radius.

-

Perhaps it is all perspective but I don't call the Mooney Corp. of 2013-2019 "small". Yes today they are small. But between 2013-2019 the Chinese owners admitted to infusing $150 million capital into Mooney (per AvWeb ref. Company statements). A newly opened engineering and test facility in Chino CA had 80 employees by 2017 with plans to go to 150. $50 million was invested in the M10T trainer. They had developed " test procedure / plan, test articles, full sets of new drawings, test flights etc." for the M10T - they were in the business of developing planes. https://www.aerospace-technology.com/projects/mooney-m10t-aircraft/ But that all came crashing down. They laid off everyone (80) in CA and closed the facility. In 2019 they laid off 229 in Kerrville. Between 2013 and 2019 Mooney could have made further investment in their flagship M20 line but besides the door, they didn't. It wasn't due to lack of funds or knowhow - it was done by choice. Widening the cabin or increasing the UL would have been truly incremental for their technical, engineering, development, testing and certification skills during that period. Today, with each passing day of silence from Mooney Corp or their management, it looks hopeless. https://www.avweb.com/air-shows-events/mooney-consolidates-in-kerrville/ https://www.aviationconsumer.com/industry-news/mooney-again-will-it-ever-thrive/ https://www.avweb.com/insider/mooneys-last-act/

-

I suspect you are right and that is true. When Rocket Engineering was a tiny start-up with meager funds back in the 90's they had to do a full set of flight tests when they crammed the TSIO-520 in the K to produce the Rocket and when they crammed the big IO-550 in the front of the J to produce the Missile. But Short Term Thinking dictates doing as little as possible. If Mooney wasn't willing to make the incremental effort and incremental investment at that time of adding a door then they never will. The cost to do it now will be much much higher - starting from scratch, no material engineering staff, And the available funds were pissed away on the failed trainer M10T. Current management seems to be focused on flipping the company with the online broker of last resort. Not a surprise that Mooney is no longer in the plane making business.

-

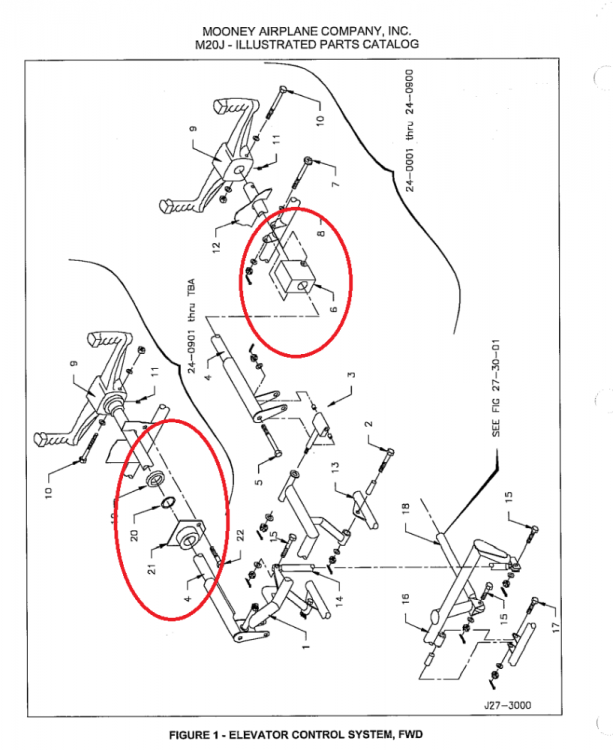

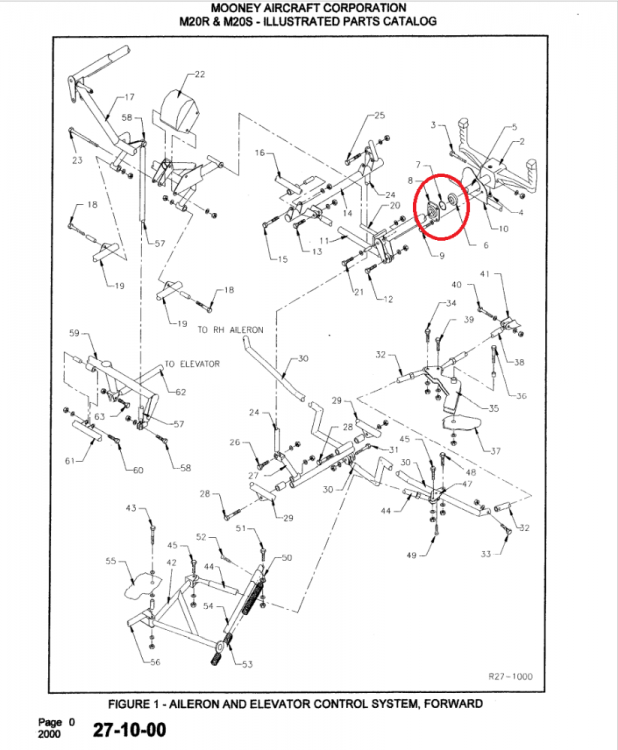

Correct - that is a pic of one salvaged currently for sale.- just to help illustrate because the parts drawings are hard to visualize sometimes. I thought mine was chrome plated too - however some of it looked a little rough so I polished it as much as I reasonably could.

-

You are correct. Since 1979 they have used the same bearing on all Mooneys. I use LP2 which doesn't seem to attract as much dust but I have it in a hangar - might be worse tied down.

-

I replaced my eyeball sleeve bearing while everything was assembled a few years ago for the same reason as mentioned by the OP. The wires have to be cut, the yoke handle pulled, the wires pulled out of the shaft with a string in place to pull them back in, the linkage disconnected at the firewall and the shaft then pulled towards the firewall to clear it from the instrument panel frame (either out of the bearing or unscrew the bearing cap and pull it all out together). The yoke shaft (control shaft) has a welded bracket on the firewall side which necessitates pulling it out towards the firewall. (see pic) Reassembly is the reverse. It is easiest if your remove the pilot seat. It is tedious but not difficult. While under there lubricate all the linkage points and check for play.

-

You just made the point that they should have widened the fuselage while they were at it. They had to go through all the structural substantiation of the "cage" regardless. They probably did 60%-70% of the work. They drained their finances on the failed trainer M10T - what they did with the Ultra was "penny wise and dollar foolish". A small incremental investment of time and money in the Ultra would have yielded a bigger return. Instead, we have the remnants of a company that will likely never build another plane.

-

262 was from Mod Works 261 was from Mod Squad https://books.google.com/books?id=eK-0kCuwKz8C&pg=PA90&dq=mooney+m20k+Flying+Magazine+252+modworks+conversion&hl=en&sa=X&ved=2ahUKEwj6hZi7nJH2AhXzm2oFHQiRDqkQ6AF6BAgCEAI#v=onepage&q=mooney m20k Flying Magazine 252 modworks conversion&f=false

-

@Danb Mooney has been using the same "eyeball" or "donut" bearing on the same yoke shaft since 1977 on J through Ultra. Parts diagram is from an Ovation. (see pic below of Ultra assembly) I think it is a sintered bronze Oilite sleeve bearing. Make sure that your yoke shaft is smooth - no imperfections or corrosion. To replace the sleeve bearing you have to remove control handle, disconnect the shaft and carefully remove the wiring on one end.(radio tap to talk switch, pitch controls, etc) in order to get the old bearing off and the new one on.

-

All that engineering and they didn't bother to widen the cabin a couple inches. What a waste. So what if they sacrificed one or two knots. They truly did not understand marketing or what the paying market wants (in addition to Useful Load)

-

Anyone have a used out of spec no back spring I can buy?

1980Mooney replied to philip_g's topic in Modern Mooney Discussion

Exactly - it is in fact used and advertised in such condition (either salvaged or a replaced spring). At the beginning of this topic the OP said he just wants an old used one to get the dimensions and reverse engineer it by a supplier in Japan. As said above, an owner might be able to make a replacement spring that looks like it fits and actually works.....for a while! Without testing no-one will know the actual life of the "new" OPP spring. For all anyone knows, the new OPP spring might have a shorter life than the original. The irony is that the owner might go to all this work only to have the spring fail sooner than if he had never touched the original at all. -

Anyone have a used out of spec no back spring I can buy?

1980Mooney replied to philip_g's topic in Modern Mooney Discussion

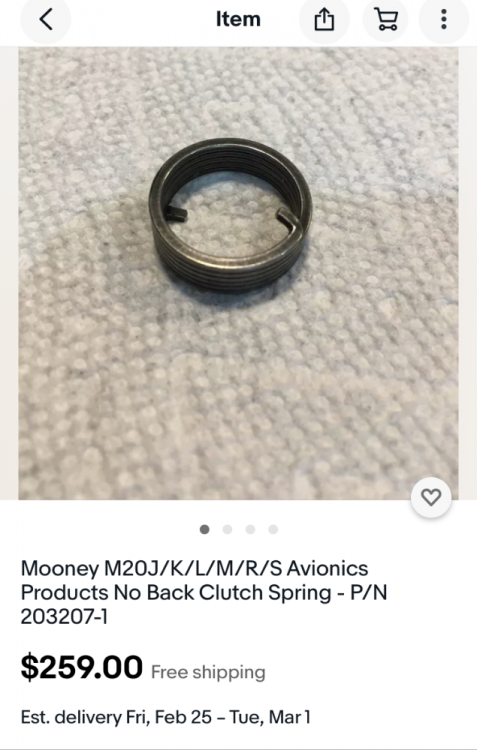

There has been a used one for sale on eBay for a while. Mooney M20J/K/L/M/R/S Avionics Products No Back Clutch Spring - P/N 203207-1 $259. It’s Avionics Products - isn’t that what you want? If so surprised you haven’t started there -

We need to add a few more wide bodies Pipistrel Panthera 47 inches Diamond DA50RG 53 inches And narrow Narrow Piper Comanche 45 inches Diamond DA40 44 inches I doubt anyone is going to bring a clean sheet new design to market that is less than 47 inches cabin width - preferably wider.

-

Anyone have a used out of spec no back spring I can buy?

1980Mooney replied to philip_g's topic in Modern Mooney Discussion

"still technically in business".... It is a company carrying the overhead cost and liability of an "airplane manufacturing company" that is only a "parts company". All the fancy titles and cost for the executives, the liability for everything manufactured in the last 18 years (regardless of past bankruptcies), the Engineering Dept that is working on what??- it is not sustainable with the few $millions from part sales. -

Anyone have a used out of spec no back spring I can buy?

1980Mooney replied to philip_g's topic in Modern Mooney Discussion

Oh so you have some deep seated hatred of Canadians?