-

Posts

467 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by PJClark

-

Optimum No Rinse (ONR), 1 oz in 2 gallons of water. 5 gal bucket. Microfiber towels. Optimum big red sponge. Wet wipe gently with sopping sponge. Dry with microfiber towel. Polish with another dry microfiber towel. Do a section at a time (1/3 the wing is my section) No hose, no rinsing. The 2 gallons will do the whole plane with about half leftover. When done: GTecniq Liquid Crystal C2V3. Lightly spray a section. Wipe off. Polish with dry microfiber towel. Magical.

-

Pilot Panel DWG or Step File for G3X and G5

PJClark replied to Speed Merchant's topic in Modern Mooney Discussion

Advanced Aero Technologies Group AATG Greeley, CO -

Pilot Panel DWG or Step File for G3X and G5

PJClark replied to Speed Merchant's topic in Modern Mooney Discussion

I don't have the drawing but this is what it looks like in an '86 252. The GFC500 controller is in line with the switches just above the throttle. That is an EDM900 not a 930 -

Thanks. Yeah within a couple days of the OP my mechanic had the cowl off and the filter box had "slid inboard" creating the gap. Apparently it adjusts to give a tight fit. It now has a tight fit. Now that's interesting. When I flew mine for the prebuy, I'd studied the Rocket power chart and intentionally wanted to test how close it would get to book speed at 65% power. So I set 30" and 2200 rpm, and to be conservative since it was not yet my airplane, I leaned only to 1500 TIT instead of the 1600 in the chart. The result was 17.3 gph. Which is lower than the chart says it should be, and cooler TIT than it should be. now I should say I went back and looked closely at my photos of the cockpit for those flights, and I discovered that I misread the RPM guage when setting power: I set 2300 at 30". But still 17.3 gph and 1500 TIT, not 1600 or even 1650. And the CHTs were all cool. AND I was flying 185 KTAS at 7500 MSL. I've about decided that the engine and the airplane are still doing what they were doing when I flew those prebuy flights, I just have all new instrumentation telling me things are different! voodoo...

-

I think it's actually even better than that. In any series circuit, the current is the same through the whole circuit. In the old circuit, for the resistor to have dropped half the voltage, the bulb's resistance and the resistor's had to be the same since the current has to be the same, and the resistor was selected to halve the voltage. the LED is different from the old bulb. It will pass a specified current at a given voltage...for example, 1 amp at 14V or 1/2 amp at 28V. That means the current in the ENTIRE circuit, including through that old resistor, is reduced to the current through the LED. Thus, the old resistor is now not getting as hot as it used to, because the LED is limiting the current: it's acting like a massively larger "resistance", kicking the total circuit's apparent resistance way up, reducing the total current. So your old resistor is cooler, probably about 10X cooler. I think. But that EE degree is now 38 years old so I may need correcting. War Eagle!

-

Keeping the cockpit cool when parked outside

PJClark replied to Yourpilotincommand's topic in General Mooney Talk

-

Keeping the cockpit cool when parked outside

PJClark replied to Yourpilotincommand's topic in General Mooney Talk

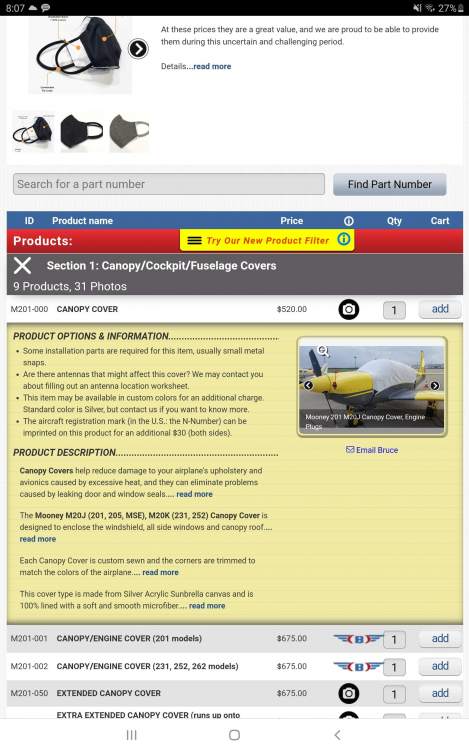

@Yourpilotincommand it came with my airplane, it's a Bruce custom cover. Not cheap and mine still has the old Mexican reg number embroidered on it.. thinking about fixing that,, but meanwhile it works, weighs 8#, and is very easy on and off -

Keeping the cockpit cool when parked outside

PJClark replied to Yourpilotincommand's topic in General Mooney Talk

This worked really well for me yesterday: about 90F outside, airplane was there from about 1130 to 1600. Cooler than ambient inside when the cover came off.. pilots vent was left open baggage and entry door closed and locked. -

@Fry made some really, really nice ones using 3D printing, a massive improvement on my hangar elves' effort. He may be willing to share his files for those who can use that to be the "owner specified" piece of "owner produced parts".

-

@shawnd they are owner produced parts. PM me if you'd like instructions. Straight in replacement the LEDs are good from 9-30V

-

-

Aithre Illyrian and P2 audio advisory system

PJClark replied to AUWDE's topic in General Mooney Talk

War Eagle! -

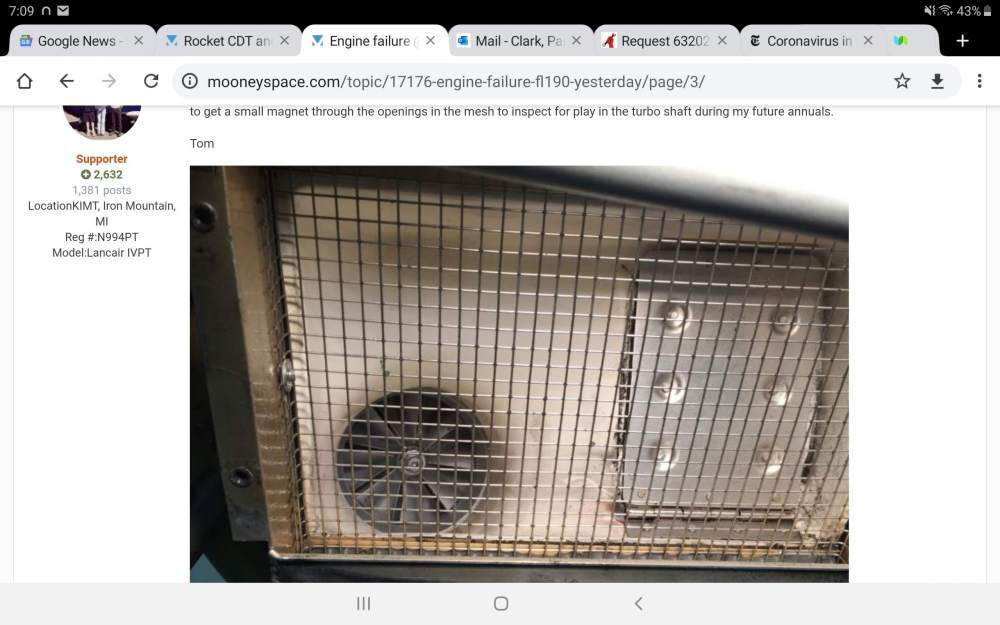

I tried with my phone, but it's too tight in there to get anything but a face full of filter. If any Rocket men are flying this weekend though, put your hand into the induction inlet and tell me if you find a gap or some kind of seal and no gap. I did do a quick ONR wash on all leading edges and cowling and took this pic...

-

Thanks. Just got back from the airport. I confirmed that there is no "closure" inside my inlet duct between the duct and the air filter housing. There's a gap between the front edge of the filter housing and the inside of the cowling/inlet duct. I can easily fit my fingers into the gap and feel the inside of the cowling Should there be a gap there? Seems to me the intent is some ram air pressure at the filter and I doubt there's any without that sealed up. I figure also some warmer cowling air is being sucked into the induction system Anyone know if there should be a seal or something between duct and air filter? I've looked thru both the rocket service manual and install instructions and I can't see anything that would answer this question. Thx

-

yes I did. I used the Aerolites 508 LEDs. My right side had a socket like the Sylvania above, the left one had something completely different. I took the lamps and the new socket to my Annual at AGL and they replaced both for me...I don't exactly know how they got them in there, didn't look like they had to remove the lenses to me. PJ

-

-

I'm late to this party, but I also left my engine driven vacuum pump in solely to power my vacuum speedbrakes. Removed standby vac. Lost almost 50 lbs when I did my panel: the entire KFC200 system is 37 lbs alone!

-

I have a Rocket. The manual Alternate Air control is disabled in the Rocket. It works automatically only. No way to test it on the ground or anywhere else. On the Rocket the induction inlet is a NACA duct on the bottom left side of the cowling, not where it is on a 252 or 231. The interior of that duct is painted to match the rest of the cowling, so the filter almost certainly got some overspray no matter how well masked it was. My concern was that with the cowling also masked, or the engine masked while fuselage was being painted, if some overspray also got to the Alt Air mechanism, and it's now stuck open. But I've not seen the mechanism. Some mechanic is about to see it for sure. Don't even get me started on JPI. There appears (to me) to be a fair amount of randomness in their process. My 252 came with a mandatory FF instrument. The ROCKET has a max power limit/requirement to get 31-33 gph at takeoff power. They set up the 900 without the FF as primary--and we sent them the same POH insert I sent to @kortopates yesterday morning. I had to twist their arm to get a new software load and pay a shop $100 to install it. Great instrument. Programming guys a little iffy/idiosynchratic.

-

Looks like my renewal is less than $100 more than last year. Same company.

-

I have a 900. My Rocket is a 252--always intercooled--never had a CDT guage before the 900. No op limit on that temp, obviously. JPI just programs some weird stuff.

-

Savvy confirmed my suspicion that the CDT doesn't matter. My IAT on the flight was about 107. Good to go. The CDT is clearly an optional alert programmed by JPI for whatever reason...probably they set that as the same IAT limit in the Rocket POH but that's a guess. The alert didn't turn on the RAL, I just looked down in my scan and saw it steady reading CDT. To be forever disregarded. Now...anyone have thoughts about the idea of alt air stuck partly open and allowing warmer cowling air into the compressor? Thus increasing CDT and IAT by about 30-50 degrees and resulting in hotter everything?

-

Need some perspective from the Rocket drivers. Yesterday climbing out on my way to 16,000 my JPI alerted with CDT at about 250 (when I noticed it). It slowly climbed up about 275 when I'd had enough and reduced power. As near as I can tell there is no CDT limit in the Rocket. Anyone disagree? I see an IAT limit (called a Cylinder Intake Temperature in the Rocket POH insert) and the limit is 235...which I suspec is where JPI set the alert on the CDT. Just a guess. The questions are: 1. What does your Rocket run for CDT while climbing at full power in the mid teens? 2. What does your IAT run in cruise? Now a theory. When I flew mine for prebuy last April, on the way back to SAT and AAA I ran it at 30", 2200, 17.3 gph, 1500 TIT, 10,500 MSL. Temp was 8C. It ran there at 195 KTAS and the cylinders were all comfortably below 380. That flight sold the airplane to me. Closed and the airplane went straight to the paint shop and I picked it up in late August. On the flights from SAT to KGXY for Avionics with a stop in KABQ to drop of Bob Cabe, I ran the same 30", 2200 rpm at 14,000 feet, and I could not lean below about 20 gph and had to leave the cowl flap full open to maintain CHT below 380. If I recall I was also only running about 185 KTAS. It was hotter in August for sure...but TAS should increase and the mighty Rocket should still have been making sea level power at that altitude. And it wasn't running cool as I've heard so many do... @aviatoreb and @Cody Stallings Fast forward to November. I picked it up from avionics and flew 3 hops home to ohio at 15,000. OATs below 0F most of the way. Still had to have cowl flap open and at least 19 gph to keep #5 in particular below 380 CHT. Dec I had the fuel system checked for rough idle...and this is the point...the mechanic said the air filter was clogged with paint. So he replaced it. Also did some baffle work and installed GAMIs at that time. Now this morning I described my experience yesterday for one of our Rocket friends, and he wondered if the alternate air door might be open and feeding hot cowling air into the compressor. Higher CDT. Hotter IAT. I looked at some of my Savvy uploads this afternoon, and my IAT usually runs around 70 degrees...less than 100 anyway. Yesterday it was at least 107 as I recall. That hotter induction air would likely heat up the CHT a little? and the hotter induction air would produce less power (less dense?--K model POH seems to indicate less power produced with alt air open due to temp). Anyway the big question: Can maybe the alternate air door be stuck at least partially open because it got fouled with some paint overspray, and I've been running hot and slow since the paint shop because of it? thanks in advance for the patience reading this lengthy tome and any experience or knowledge that can point me and my mechanic toward a cooler, faster Rocket!

-

LED Replacement for Whelen Model #70303 Light

PJClark replied to StevenL757's topic in Avionics / Parts Classifieds

@Fry if you'd like to PM me I can tell you a story of some hangar elves' antics that resulted in a solution you can see 2 posts up -

C2V3 on plexiglas... I don't know...been thinking about it. I can't decide if it's my imagination, but it SEEMS like C2V3 sorta accidentally applied to wingtip lenses makes them look smoother, clearer, newer. I have not been able to take the plunge on the windscreen...