-

Posts

163 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by adverseyaw

-

Thanks @gsxrpilot for the share and collaboration over the last few months! Everyone, please visit the site, register an account, and see what we have to offer. Our hope is that formation clinics and Oshkosh registration will be possible soon -- when that happens, we'll share more through the member list, our Google mailing list, and here on MS. Please PM me if you encounter bugs or have feedback. Thanks and here's looking forward to a great 2021 flying season!

-

Is there any difference between the J and K panel? From the same year, at least. I can imagine differences in rocker switches but it seems to me that most of the layout and the outer dimensions would be the same.

-

It's taken me longer in the past -- about two years ago it was 2-3 weeks to get the CDs. Fast enough if you already own the plane. If you're in a rush, Insured Aircraft Title Service (and likely others) will get you the contents of the CDs quickly for a small fee ($20) and will have them emailed within 24 hours. They used to keep the PDFs on-hand and just email them within an hour, but I think they were bit on a transaction and now they pull the physical CDs from the FAA and email them within a day. On the STC, I was digging into this when I was looking at Rockets a few months ago. Link below is someone who got the STC from Rocket about three years ago. Rocket 2900 vs 3200 GW - General Mooney Talk - Mooneyspace.com - A community for Mooney aircraft owners and enthusiasts Here's the breakdown and sheets for the two STCs: Posted October 18 (mooneyspace.com)

-

GTN-650XI Autopilot Compatibility?

adverseyaw replied to bencpeters's topic in Avionics/Panel Discussion

The Garmin page for the old 650 has the same STEC "supported" info as the 650Xi. From that it seems like the 650/650Xi are designed about the same way. GTN™ 650 | ADS-B | Garmin That said, ask your avionics installer. I've learned that the gotchas around avionics compatibility are endless. Even different part numbers (revisions) of the same model sometimes have different capabilities and incompatibilities. -

I think Mark Rouch at Top Gun Aviation in Stockton has done them, as well. They don't seem like rocket science to install (the instructions are pretty straightforward) but they do need to be programmed/configured for the airplane, and you need to run a line to the battery. Having a mechanic familiar with both Mooneys and Sureflys seems like a smart move.

-

PAR36/46 LEDs for M20K 252 landing/taxi lights?

adverseyaw replied to shawnd's topic in Modern Mooney Discussion

And if you order the wrong size, you can just buy a plane to match. Hate to let a good light go to waste. ... on a more serious note, the M20J Missiles (IO-550) have two-light cowls like the K. Is this a stock M20K cowl? I assumed it was custom from Rocket but maybe the bigger engine fits under the factory K cowl. -

Even on my mid-body J, the yaw damper was a great addition. The whole GFC500 setup is a fantastic autopilot (very crisp, solid) and is miles ahead of the Century IIB I had prior. The CIIB would wallow laterally in turbulence but the 500 with the damper is rock-solid. Plus, it provides rudder trim through the entire flight envelope (which the J doesn't have from the factory). If I replace the autopilot in my long-body, I'm getting the GFC500 with the yaw damper. It'll be interesting to hear your experience post-damper upgrade!

-

PAR36/46 LEDs for M20K 252 landing/taxi lights?

adverseyaw replied to shawnd's topic in Modern Mooney Discussion

I've been looking at the Aero-Lites G2s as well but the PAR36s have been out of stock for a while. I just got off the phone with them and they expect more to arrive in a few weeks, middle of December. -

Autopilot! KAP-150 v/s KFC-150

adverseyaw replied to CharlesHuddleston's topic in Avionics/Panel Discussion

There are also multiple part numbers of KC 192, for example the 065-0042-03 vs. the -16 depending on what it was originally mated to (mechanical AI vs. EFIS). Make sure you get one that's compatible with your other avionics. The -16 is not compatible with the newer Garmin PFDs and there may be a similar issue for your Aspen. Like Jake mentions, your avionics shop will know more. -

damaged elevator , where to buy replacement

adverseyaw replied to dominikos's topic in Modern Mooney Discussion

Going rate for elevators is $2.5k-$3.5k. Aircraft Components quoted on the upper end to reskin and paint a Mooney elevator. There are a few shops with parted-out J/K/M/R elevators online, and those tend to run around $2k. By the time you factor in freight and painting, it seems like a wash between reskinning the existing elevator and replacing it with a serviceable used unit. -

Solutions for a rocket with low useful load?

adverseyaw replied to Schllc's topic in Modern Mooney Discussion

...back to the original question, looks like SA00243SE is an option. Found this thread that indicates that as of February 2018, Rocket would sell you the STC for $3k. -

Solutions for a rocket with low useful load?

adverseyaw replied to Schllc's topic in Modern Mooney Discussion

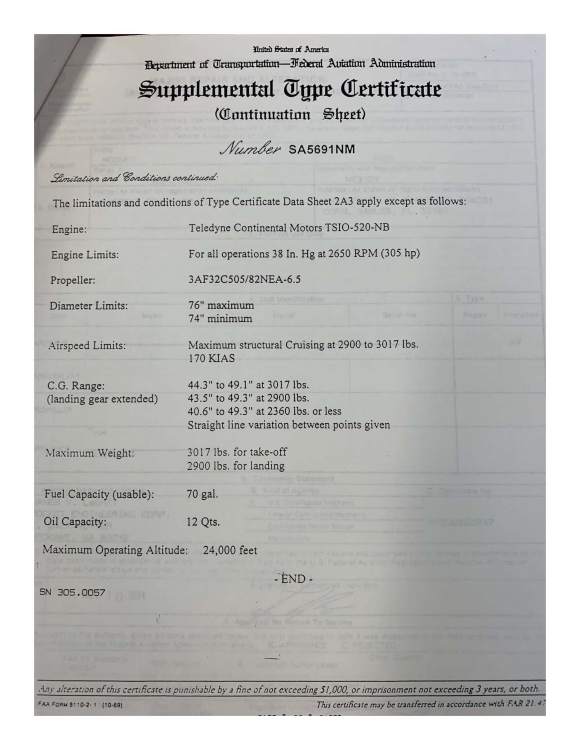

Here we go, figured it out -- it's two different STCs. Found these copies online. SA5691NM is the original Rocket STC that installs the TSIO-520. It increases takeoff weight to 3017 pounds. SA00243SE is an additional STC by Rocket that appears to increase the gross weight. I've omitted the first page but it requires SE5691NM to already be on the airplane. It's not clear to me if SA00243SE involves changes to the airplane (besides limited nosewheel tires). Does anyone know? -

Solutions for a rocket with low useful load?

adverseyaw replied to Schllc's topic in Modern Mooney Discussion

Does your STC paperwork say 3200 or 3017? I have to assume that the STC is what determines the truth, since that's the only that updates the type data. If more weight can be had, it would come in the form of an updated STC. -

Solutions for a rocket with low useful load?

adverseyaw replied to Schllc's topic in Modern Mooney Discussion

I've heard the same. That said, I looked at a different Rocket recently, and the original STC papers showed the gross weight was changed from 2900 pounds to 3017 pounds (takeoff only -- landing stayed at 2900). The subsequent W&B performed by mechanics used the 3017 pound weight. Nothing in the paperwork for the plane mentioned 3200. Maybe 3200 applied to Rockets based on later M20Ks? The one I looked at was pretty early in the production run. -

That LASAR list is great. They say 6 hours of mechanical inspection, plus 6 hours to open and close the plane. The latter number is probably a worst-case-scenario, as the list doesn't involve pulling the interior nevermind that, it does have the 208B inspection on there. That explains the 6 hours. (For what it's worth, I'm not arguing to do a short pre-buy. It's just that in my experience, the numbers are closer to 6+6 hours described by LASAR, not 20-30. I guess the log review adds time. I've also never had a mechanic do a flight test -- I've bought four planes, all with pre-buys, and none of the four mechanics wanted to fly the planes.)

-

I'm being inclusive :-) Maybe some early C's can be done in 5-10 hours? I keep dumping new parts into my plane so 20+ is the norm for me. I'm curious to hear what would take 25-30 hours on a pre-buy. The only time-consuming thing I can think of is the 208B inspection on older roll cages, as I think that requires pulling a lot of the interior apart.

-

Nor is there for an annual. An IA must only use "a checklist" to complete an annual***. A good annual is based on manufacturer's checklist, and if you're planning for good annuals in the future, you should include a lot of that in your pre-buy. A pre-buy is to inform you about the value of the airplane by inspecting its condition. The pre-buy should take into account anything expensive (which includes anything on your next annual), and shouldn't waste time on cheap things like brake pads or rigging. The manufacturer's annual checklist is the natural starting point for both: for an annual, it should be expanded to include known squaws. For a pre-buy, it should be reduced to skip anything cheap to fix, and expanded to include concern areas you have about this plane. Most thorough Mooney pre-buys can be done in 4-8 hours*. A pre-buy should never include repairs. Most Mooney annuals can be done in 5-20 hours (or more)**, because it will include inspection of cheap, time-consuming items, and it will almost always include some repairs. (To emphasize gsxrpilot's earlier point: simply starting an annual takes the plane out of service and requires a signature to return it, plus rectification of any airworthiness items found in the annual. Don't do it.) * LASAR says 19 hours: 6 inspecting, 6 opening and closing the plane, and 7 on flight test and logbook review. None of my mechanics have ever wanted to fly, so you could imagine between 12 and 18 hours. ** Looks like I was optimistic on hours spent on my J annuals. Last two years have been 35+ hours each. Simpler Mooneys may not get down too far below that after all. *** 43.15 says "you can use your own" but must at least include everything in 43 Appendix D

-

Mooney drivers who have the Garmin GFC 500

adverseyaw replied to Little Dipper's topic in Modern Mooney Discussion

I think we're speaking the same language, although I could have used more precision in my last post. :-) Unlike a paper airplane, which can be built in a way that truly introduces no asymmetric loads, a single-engine piston airframe is always subject to left-turning effects. The designer building in offset in the motor mount and vertical stabilizer is evidence of this, and that evidence is the beginning of the story, not the end. In the quest for more speed and less load on my yaw damper, I will heed the prevailing advice and will have my rudder rigging checked at annual. :-) But for the physics of it, I agree most with the statement that this rigging will be for a particular configuration (a point within cruise) and will not necessarily apply to the rest of the envelope. If we differ on whether the cruise envelope can be adequately covered by a single rigging, this is a question that can be resolved with measurements! Then we can just argue about what "cruise" is ;-) -

This is great info -- thank you in particular @exM20K and @StevenL757 for sharing your experience. My J model is not going to be part of the equation. I'm looking for either a Bravo or an Acclaim (runners-up would be a 252 or Ovation) and will either be buying into a plane with it already installed, or will be adding it after the fact.

-

Hi all, I'm curious about TKS installations. I've started the ball rolling on stepping up from my J model and would like to know more from folks who have deice installed. A few questions: Is there a meaningful difference between factory-installed TKS and aftermarket TKS? I've looked through the logs of two planes with "Mooney" TKS and found that in both cases, it was installed after the plane was built. This makes me think there's not a big difference. Anyone who has painted a plane with TKS deice -- did you remove the panels for painting? I know about CAV, are there other TKS installers? Did you add TKS or buy a plane with it, and later find that it was not worth the investment? Has anyone measured pre-/post-install airspeed numbers? I've seen the quoted numbers but am curious if anyone has measurements. Thanks for your experience :-)

-

Mooney drivers who have the Garmin GFC 500

adverseyaw replied to Little Dipper's topic in Modern Mooney Discussion

It's not a lot of left rudder, but "not much" adds up over hours of flight time. Static rudder trim is a compromise across your entire IAS vs. torque envelope, which includes climb (low IAS, high torque), cruise (mid IAS, mid torque), and descent (high IAS with varying torque). Most light planes I've been in require left rudder in descent, which is required because some right rudder is dialed in for climb and cruise. So, left rudder does not surprise me. It's possible the rudder is mistrimmed for cruise. I would also not be surprised if there are multiple "cruise" configurations, especially at different altitudes. I don't recall needing much rudder between 5-9k (haven't flown there lately) so maybe it's just that at 11-15k, where I'm flying these days, the IAS vs. torque ratio is different. And, I agree with the aileron part, which has its own set of IAS considerations. I had Mark at Top Gun balance my aileron trim last year, which may have incurred some rudder effects. All of these trim settings balance against each other. Sadly no plane with a propeller flies squarely -- they all fly a little sideways and we just have to tweak the controls to get them as close to straight as we can. -

Mooney drivers who have the Garmin GFC 500

adverseyaw replied to Little Dipper's topic in Modern Mooney Discussion

Mid-body. 1978 J model. My plane needs left rudder at WOT cruise. -

Mooney drivers who have the Garmin GFC 500

adverseyaw replied to Little Dipper's topic in Modern Mooney Discussion

P.S. I'm really happy I sprung for the yaw damper. No more cramped feet on long X-Cs! -

Mooney drivers who have the Garmin GFC 500

adverseyaw replied to Little Dipper's topic in Modern Mooney Discussion

Love mine so far, it's a great autopilot. It does exactly what I want it to do at all times. The knobs on the head unit perform the same function as the heading/altitude bug knobs on the G5s, and it's way easier to use the much bigger knobs in the center stack. Only two issues really: My 1978 J has the CIIB trim switch, without any room on the yoke for A/P disconnect. My installer insisted that disconnect had to be on the yoke. So, now I have a slightly awkward bracket holding the disconnect switch beside the PTT switch. GPS loss will supposedly discontinue an approach, even a radio ILS/LOC approach, and put the plane in attitude-hold mode. Haven't experienced it in person, just what the AFMS says. More details on this thread: -

The fuel servo finger screen has a spring-loaded override that will allow fuel and particulate matter past if it's sufficiently clogged. That's what was happening to mine. (And yes -- great photo!)