-

Posts

163 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by adverseyaw

-

IO-360 misfires at idle and low MP

adverseyaw replied to adverseyaw's topic in Modern Mooney Discussion

I don't know. The guy I bought the plane from had trouble with the overhauled servo and sent it out for repair, but I'm missing that document. It may need to go out again. (I would like to pinpoint the issue before sending the mag out, but it's certainly a possibility.) The 1000-1700 was me running the engine up. Any idle time in the trace is time when it was skipping. (In the entire trace I probably had 5 solid minutes of idling.) Good point. I haven't run across the 6/1 second setting in my EDM 830 but will look again and see what I can capture. Will do. We've leak-checked most if it. Good points -- will check into the 1-second setting and will continue to plug away at the EGT4. Interesting. Will look into this. Thanks all! -

IO-360 misfires at idle and low MP

adverseyaw replied to adverseyaw's topic in Modern Mooney Discussion

The problem occurred within a few seconds of engine start, and continued through the entire data log. The log is about 30 minutes long and the sputter probably happened a few hundred times, most noticeable at idle and at RPMs below 1700 or so. This is off of the Savvy website so could ask them. Getting details on the plugs like you suggested is probably a good first step though. -

IO-360 misfires at idle and low MP

adverseyaw replied to adverseyaw's topic in Modern Mooney Discussion

I'm running 10:1 compression pistons and do a lot of work to keep the CHTs in check. Unless timing 20 BTDC will adversely affect idle, it's probably a good discussion for another day :-) (Unfortunately the pistons aren't a variable I can change, and I haven't heard of more issues at idle, so for now I'm exploring what I can do with the other facilities on the engine.) -

IO-360 misfires at idle and low MP

adverseyaw replied to adverseyaw's topic in Modern Mooney Discussion

Went to 20 BTDC per Lycoming SB for reducing CHTs. Those are good suggestions. I actually don't know what plugs are on the plane. I'll check soon. Thanks! -

IO-360 misfires at idle and low MP

adverseyaw replied to adverseyaw's topic in Modern Mooney Discussion

Yeah, I did a bunch of searching before I posted. Found some threads but nothing that stuck. Most of the ideas were things I've tried. EDM data attached. My EGT4 connection is toast, so unfortunately that data is not useful. Blue line is fuel flow and green line is RPM. -

IO-360 misfires at idle and low MP

adverseyaw replied to adverseyaw's topic in Modern Mooney Discussion

This one, I take it? Am digging through now, thanks much. -

IO-360 misfires at idle and low MP

adverseyaw replied to adverseyaw's topic in Modern Mooney Discussion

Back when I was clogging injectors with debris, I was getting EGTs to peak 100-200 degrees on affected cylinders. I've only run it up twice since then, but no notable EGT changes since then. -

IO-360 misfires at idle and low MP

adverseyaw replied to adverseyaw's topic in Modern Mooney Discussion

I could be talked into that. That said, I've never experienced it on carbureted aircraft I've flown, nor the M20J I got my complex endorsement in. Do others encounter this as well? -

Hi everyone, I'm trying to track down an occasional stumble I'm seeing at idle and through the bottom half of the power band. The engine, an IO-360-A3B6D in an M20J, runs well at full power. Symptoms: every few seconds, a cylinder will fail to fire (or fires softly). The engine doesn't afterfire/backfire. In trying to track this down, I had some fuel injectors get clogged due to debris in the fuel bladders. That work is done but the misfire remains. So far I've: Cleaned or replaced pretty much all of the fuel system (bladders, boost pump, mechanical pump, fuel servo, flow divider, all fuel injectors, all screens). It's clean now, no debris. Pressurized the induction system, no leaks Timed the engine to 20 BTDC Pulled the plugs a few times, they're clear (not sure if my A&P gapped them) Done about 20 runups with pretty much every combination of MP, mixture, and mags. So far, no clear culprit. It misfires at pretty much all mixture and mag settings, and all MP below about 20". In maybe 10% of the runups I do, it will run like a top (no stumbles!) for a few minutes. So I know it's possible for it to idle cleanly. This engine has less than 100 hours on it since overhaul so infant mortality of some part or another may be a factor. Any ideas where to go from here? Thanks much

-

That's tremendous, so great so meet you @MooneyMurph. 1XG is getting a lot of attention from my A&P at the moment and will hopefully back in the sky soon :-)

-

I'm curious as well to know which one that is :-) I pulled the Dukes pump out last week and installed a Weldon. No filter in the pump head but I think my mechanic pulled the screen nearby.

-

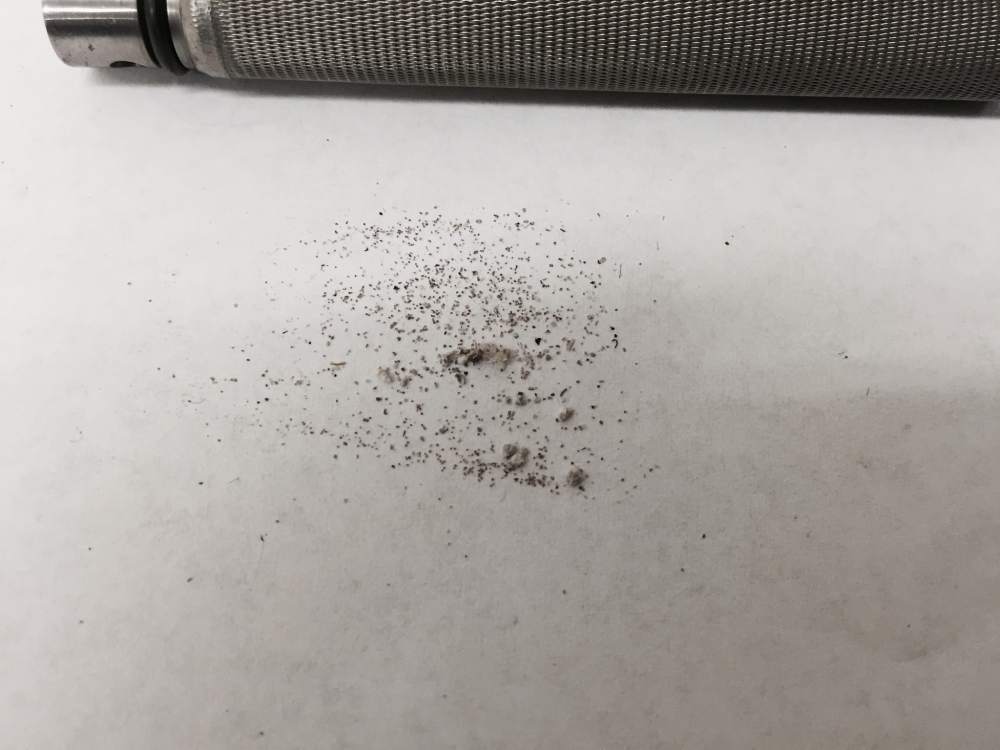

It was overhauled this time last year and has 50 hours on it since then, not sure its age before that. Talking with my mechanic and engine builder, we're thinking the fuel pump is the most likely culprit. These are great ideas -- it seems like the screens upstream of the servo all have larger openings. The servo screen is the finest one and seems to catch the sandy particles from further up. (My mechanic also mentioned they look a lot like blasting media.) No doubt. I've only seen one or two flakes come out of the fuel drains in the last month or two but my A&P will be clearing the finger strainers in the tanks and will see if there's anything in there. Yep, it's got the Dukes filter. We haven't seen anything in there so far, although the holes in the screen are a lot bigger than the fine screen in the servo (which is where everything is getting stuck.) Thanks all above, this is helping us nail this down. An update based on what we've found and things we've tried: The servo inlet filter crud may be sand or blasting media. It may be coming from the mechanical fuel pump. The junk in the injectors is coming from the servo or flow divider, OR it's coming up further upstream (the fuel pump) and the servo inlet screen is getting clogged enough that the bypass spring is letting it through. Unfortunately the extent of clogging so far means that once we identify and clear the source, we're going to have to disassemble and clean the mechanical pump, servo, and flow divider.

-

These are all great ideas... a few things we've checked in response: Fuel hoses are the new brown silicone ones Fuel cap flanges seem to be OK, and so far the particles don't look like rust Current theory we're evaluating is that we have some residual particles being caught in the servo screen, but the particles in the injector are coming from either the servo or the flow divider. (Of those, servo is much more likely candidate. Not much in the flow divider to go wrong.) Thanks all so far

-

Some of it stuck to a magnet, but not all of it. That's on my list but given that we've dumped 20 gallons through it already (and the boost pump runs a gallon or two clean after every cleaning), I don't have my hopes up. :-(

-

I'm stumped and could use a hand with my IO-360 in my 1978 M20J. I'm collecting small particles in my fuel servo strainer. Occasionally some sneaks through and clogs up a fuel injector -- in the process of diagnosing this, it's clogged injectors over a half-dozen times. The particles are small and mostly ferrous, and only collect in the servo. The gascolator screen is completely clean. A few things we've eliminated. Whenever my mechanic cleans the injectors and screen, he runs gallons of fuel through the boost pump and it all comes out clean. Happens with a brand new Weldon boost pump. (The 17-year-old Dukes gave up halfway through troubleshooting.) Definitely not the injectors; those are too far downstream and we replaced them anyway since the screens were shot. The engine has ~50 hours on it and the mechanical fuel pump, servo, and flow divider are all overhauled. They could be a problem as we haven't changed them out yet. Has anyone seen anything like this? First photo is the initial pile of junk we removed from the fuel servo screen. Mostly ferrous. Second photo is the next pile we removed after 0.5-1.0 hours on the engine. Same material.

-

I recently met Don over email when he offered to help me build instrument time as I work toward my rating. We were just scheduling over the weekend. He was so enthusiastic about helping out. Such a tragedy to hear. I'm familiar with the hillside. It's prominent on the approach to BLI. Rest well, Don.

-

Putting vinyl ("decals") on your plane

adverseyaw replied to ragedracer1977's topic in General Mooney Talk

This thread has been quiet for a while, but thought I'd bring up: today I spotted a Diamond that had previously had a vinyl wrap, but was ramp checked by an ASI and was grounded saying that the wrap affected flight control surfaces. I didn't see the quality of the work up-close prior to it being removed from the aircraft so can't comment on the specifics. Having an A&P sign off on a wrap seems like a smart idea. -

Relocating SVS light and control knob bracket

adverseyaw replied to adverseyaw's topic in Modern Mooney Discussion

Great to hear :-) -

I've never used these, but I heard Mike Busch weigh in on his experience with EI systems installed in a few aircraft his company manages. From what I recall: They were run in EI+magneto configuration (he didn't say which engines, but I assume they had factory split mags) Runup ignition drop is lower when EI is the only source of spark, indicating they're more effective There was a problem with ElectroAir EIs causing less than ideal engine characteristics (maybe higher CHTs? Don't remember) due to malfunctioning MP sensors, which caused the EI spark to advance too far. This seems like a solvable problem but speaks to the issues that can arise in new designs. The thing I don't get about these is how the backup mag, with fixed timing, works with the EI, which can be advanced. I'm sure there's a straightforward explanation for how this works but I don't know what it is.

-

Relocating SVS light and control knob bracket

adverseyaw replied to adverseyaw's topic in Modern Mooney Discussion

Well, blarg. I know the pushrod has a z-bend with some room left (found the shuttle valve last time the cowl was off) so maybe there's enough space for my A&P to move it around a bit. Still scratching my head about where it could go, though. Under the yoke is the best I've come up with so far. -

Relocating SVS light and control knob bracket

adverseyaw replied to adverseyaw's topic in Modern Mooney Discussion

Yep, just looking to move the knob and light. Will definitely get an A&P to do the work, just wondering if anyone had inspiration on other locations before I get it off to him. And yeah, the whole thing will eventually get tossed out for an Aspen or G5s or whatever else is the best choice when I upgrade. (I'm sure things will change by the time that happens, so I'm not really thinking about it until then.) -

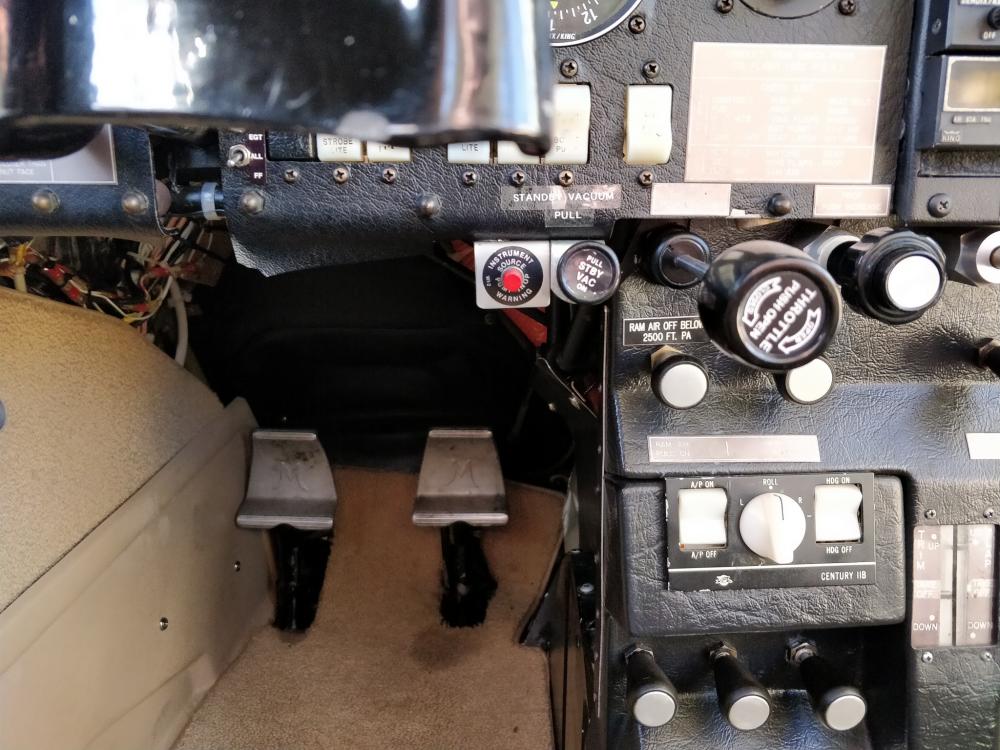

I have a Precise Flight standby vacuum (SVS III) in my J model and the bracket is right where my right knee goes. Does anyone have recommendations on alternate mounting locations? Moving them to the passenger footwell doesn't seem worth the hassle, since I'll just be making it a problem for whoever is flying with me. Is there another place to mount these that would get them further out of the way? Maybe even moving them to the center of the footwell, immediately below the yoke, would be an improvement. (Eventually I'm planning to lose the vacuum instruments but will be hanging on to them for at least a while.)

-

-

Not too much time at cruise at the moment. Ask me in a few more months.

-

I did some digging prior to purchase. On one hand, I've heard about warranty disputes and one secondhand case where a customer was pretty unhappy about the way accessories were installed on an engine in a twin Beech. On the other, these complaints were all at least a few years old and they've had documented changes in ownership since then. I called the BBB in Denver and they confirmed zero complaints in the last three years. There are enough FF powerplants out there that it's pretty self-evident they're familiar with overhauling engines. On balance, I like that they're an experienced engine shop. I dislike the prospect of following up if I have to make a warranty claim, but the evidence says to me that they won't leave me hanging. Plus, we're all just one prop strike away from an overhaul anyway.