Aerodon

Supporter-

Posts

1,315 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Aerodon

-

Congrats Pieter, looking forward to your spreadsheet of information. Don

-

I have a new EDM930 display unit, ideal for the start of an upgrade from an EDM700, 830, etc. I have new and 'as removed' parts on hand to make up the rest of a system. Aerodon

-

I don't use this very often so maybe someone else needs it for ground operation of your avionics. These cost $785 new from ACS. Aerodon

-

I have a couple of those side panels with round holes for other clocks. Send me a pm. Aerodon

-

Nicely done with the color coding. The annunciator is calibrated to trigger an alarm when the fuel reaches a low level. A JPI EDM900 can be programmed to provide a low level alarm (to the red/yellow annunciator or a separate low fuel alarm). I'm not sure if this is on the calculated low level or measured low level. It look like the GI-275 can have a discrete out on reaching a measured low fuel level. But the annunciator is not looking for a discrete in, its looking for a voltage or resistance below a certain level. I'm going a different direction, replacing the annunciator panel with a series of Eaton annunciators. Personally I think the Mooney low fuel at 2.5G is useless, I prefer an overall low level of 8-12G. Aerodon

-

Major versus minor alteration; voltage regulator

Aerodon replied to Jetrn's topic in Modern Mooney Discussion

Here is a picture of one of the two ACU's installed in my 252. It was probably made by Zefronics for Mooney, but maybe they have a secret stash somewhere? Alan Fox is parting out a 252 and probably has two for you, along with the mounting bracket? And there are a couple of service bulletins around the ACU's. One is to splice an additional ground near the ACU, another is to relocate the 'field V' sense wire away from the field breaker. This one makes sense, if the field breaker trips there is no way for the ACU to provide the warring light, when you really need it. But Mooney went about it in a really convoluted way with wire splices to the annunciator panel and the hi/lo vacuum switch. It's much easier to relocate this ring terminal from the field breaker to the annunciator and hi/lo breaker. Don -

Complete system, really nice 2019 unit. Current production model that can be used with all different fuel quantity transducers. Reprogrammed by factory for your N# and engine limits. IMO, you can reuse your JPI EGT/CHT harness and probes. And maybe one or two other transducers like FF and OAT. Don

-

I have two transponders for sale: 1) GTX345DR - like new with paperwork and new install kit $7500 2) GTX345R with GPS with 8130 and new install kit $5500 3) Vertical mount instead of horizontal mount for above $500. The DR is the unit that Canadian customers need. The 'with GPS' is the unit you need for a G1000 upgrade or any other installation where you do not have a WAAS position source. Can be controlled with a G3x or GI-275. Aerodon

-

TSIO-360M Variable Absolute Pressure Controller

Aerodon replied to CBarberJD's topic in General Mooney Talk

I have a TSIO360MB that I am thinking of parting out. We can have a discussion about the whole M induction system if you want? Aerodon -

A PlanePower alternator control unit (ACU) has a 'fault lamp' that operates when there is a fault by provide a ground for a lamp and 1A CB. I think my 252 has something similar for 'low volts'. There is not much that can go wrong with this circuit other than a short in the wiring. And if you are having problems with this annunciator while the voltages appear fine, more than likely to be a wiring short. Not difficult to trouble shoot either, apart from the intermittent nature. Aerodon

-

A mere 10:04 hours on Friday: https://www.flightaware.com/live/flight/N5810T/history/20240815/2314Z/RPLC/WSSL

-

J Model Comm Antenna: The "7" Vs. the straight

Aerodon replied to 201Steve's topic in General Mooney Talk

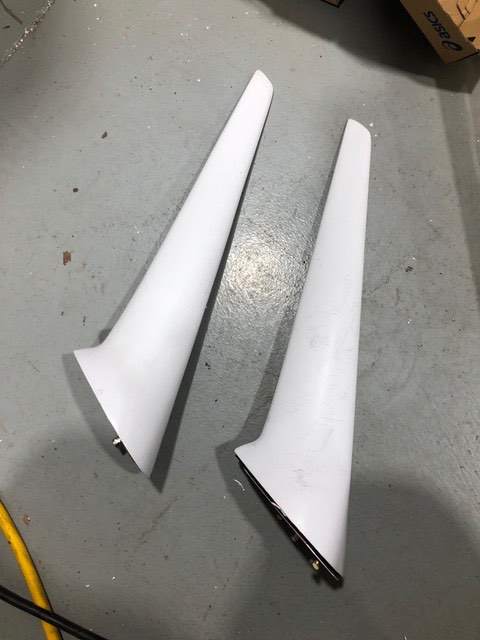

I removed the front one so I can install a traffic antenna. Had to take headline off. I can't remember if there were nut plates underneath the screws, but there are spacers and washers between the mounting plate and the out skin. So even iff there are nut plates, you don't want those rattling around. I removed the rear one to install a GPS/Com antenna for my lynx traffic system, had to move the antenna sideways and drill some new holes. But there is already a nice triangular doubler riveted to the skin, so no structural issues. So now I have these two antennas for sale. Make me a decent offer. Aerodon -

I've got two more EDM700's with fuel flow coming back from JPI with new displays. Available for sale, trade upgrade etc. I can add all the components for a complete system. If you have any display problems - missing digits, fading etc. get it changed now before the factory runs out of displays. Aerodon

-

I have been around this circle so many times. The single GPS / GPXComm / GPSTxpdr are all interesting devices and have their place in the market. But if you want to interface your new GPS to the autopilot (and you do), it always starts getting complicated with relays and annunciators etc. (More install $$). And when you are finished you will have maybe a small improvement in value. If you get a combined GPS/Nav/Com, it is a much nicer interface to use and install, and if you have a nice KX155 to sell, the increase in cost for the combined unit is nit that much, and the installed value is higher. And you are 'more ready' for future electronic displays and autopilots. Aerodon

-

Its in the KFC150 manual? Don

-

What is this panel-mounted checklist device?

Aerodon replied to Vance Harral's topic in Avionics/Panel Discussion

Maybe just a timer to check things like fuel enroute? -

What is this panel-mounted checklist device?

Aerodon replied to Vance Harral's topic in Avionics/Panel Discussion

That's kinda neat for its time. So if you have landed, then flip the switch on and all the lights light up. Press them one by one as you go through the checklist and they go off. Then flip the switch when you are ready to land and they all come on again? Never used one, but that's my guess. Aerodon -

Canada (Calgary area) flying — need advice

Aerodon replied to AndreiC's topic in General Mooney Talk

Springbank CYBW is a good option. Not sure if customs is available. My recommendation is to clear customs at the easiest place to the border. Both directions. CBP are less than understanding about headwinds, ATC delays, diversions etc. Looking at your route, Regina CYQR looks like a good customs airport. Not as busy as Winnipeg, more or less on your route. If they are open all day, less of an issue if you miss your arrival time. Aerodon -

Apollo GX50 / GX60 / GX65 for sale

Aerodon replied to Aerodon's topic in Avionics / Parts Classifieds

Not offended by the comments at all. Someone will need one when the screen fails. The GX60's are still nice comms, and even with an out of date database the G50/60/65 GPS can interface with a JPI, MX20, Sandel etc. Aerodon -

Apollo GX50 / GX60 / GX65 for sale

Aerodon replied to Aerodon's topic in Avionics / Parts Classifieds

I'm in Vancouver BC, no big deal in shipping from here or WA state. Don -

I had a C172N amphibious floatplane that was impossible to fill up and takeoff with pilot without exceeding the forward limit. We carried 2x25 lb water bottles in the baggage area - big advantage is that once we had burned off fuel we could dump the water and return from the lake a whole lot lighter. Wheel takeoffs at 2550 lbs were OK, on water you want to be as light as possible. My Seneca is much nicer to fly (land) with an aft CoG, it tends to run out of control authority at forward CoG limits. There is a chart in the maintenance or parts manual that shows the recommended Charlie weights with your particular empty weight and CoG. I took out the standby vacuum in my 252 and my thinking was to put 'remote avionics' in the aft avionics bay (vs. Panel avionics). I also got two used Charlie weights so I put those in. And I did the Encore upgrade. Aerodon

-

That was an interesting read. So the sailing distance for records is 21,600 which is the distance around the world at the equator. The aviation distance is 19,850, the distance around the Tropic of Cancer. If you are going to chase records, seems to me understanding the rules is the very first step? Aerodon

-

The C172 type certificate includes the following note. A late model 172R probably weighs 1700 lbs and has a gross of 2550. 50G fuel is 300, pilot 200, ferry tanks 100. So still another 250 lbs fuel. The 30% over gross is another 750 lbs, so it is possible to carry 1300 lbs fuel total, or 215G. At 9 GPH this is 24 hours. This flight is at 18 hours, 2.5 to go. So 20.5 and maybe 2 or 3 hour reserve. Never mind fuel, I would worry about an oil filler system? Aerodon >>Special Ferry Flight Authorization. Flight Standards District Offices are authorized to issue Special overweight ferry flight authorizations. This airplane is structurally satisfactory for ferry flight if maintained within the following limits: (1) Takeoff weight must not exceed 130% of the maximum weight for Normal Category; and (2) The Never Exceed Airspeed (VNE) and Maximum Structural Cruising Speed (VC) must be reduced by 30%; and (3) Forward and aft center of gravity limits may not be exceeded; and (4) Structural load factors of +2.5 g. to -1.0 g. may not be exceeded. Requirements for any additional oil should be established in accordance with Advisory Circular AC23.1011-1. Increased stall speeds and reduced climb performance should be expected for the increased weights. Flight characteristics and performance at the increased weights have not been evaluated. Flight Permit for operations of overweight aircraft may be found in Advisory Circular AC21-4B.

-

I have a manual for you - M18LA - with prop RPM minimum and maximum Aerodon