-

Posts

5,444 -

Joined

-

Last visited

-

Days Won

25

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Ragsf15e

-

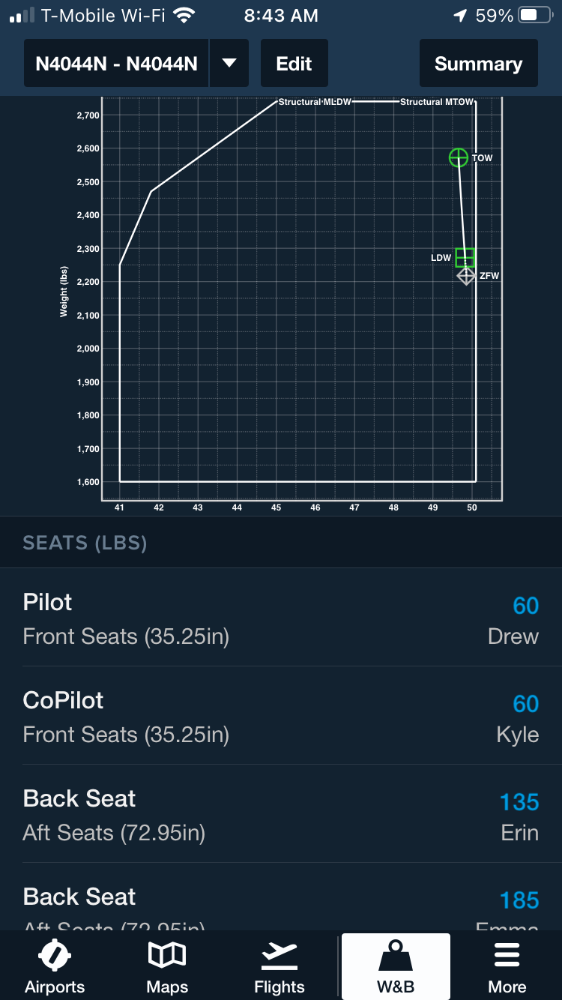

They are relatively easy to keep in the cg envelope at all loads. You may find it easy to be on the forward side of the envelope with 2 big front seaters, nothing behind, and the bigger engine/prop combos. However, just put a box of oil in the luggage and you’re good. Going out the back is tough. Especially since it’s hard to put really big people in the backseat. I have an F with ~1050 UL, 64 gallons of gas. I have two 60 lb kids and my wife is ~135. Anyone can sit anywhere, even with full 120lbs in the luggage and we’re not even close. It even works with me and my wife in the back and the kids up front (although they can’t see over the dash and their airmanship is troubling so far). I did have to reduce the luggage to 50lbs for that one - it’s probably not too safe to let 7 year old twins “co captain” anyway.

-

I’ve got an F, so different. However, if not perfectly coordinated in a power on stall (I usually use a good bit of power to simulate departure), it will definitely want to roll. Mine will go either direction depending on which side your ball is off (even slightly). One nice thing to note is how aggressive the pull must be to stall it and the significant warning (buffet, horns, etc). Another thing to try is to stall in a decent turn by pulling into an accelerated stall. It’s good to see what the bank does to you and how it feels/reacts.

-

I have seen that happen after loading new data but not completely restarting after it’s been loaded on both the pfd and mfd. it even shows that the data is the same on aux/sys pages but i had that error until turning everything off and starting up from scratch.

-

You’re not gonna see much (any) difference in a turbo as the sf is set to fixed timing just like the mags. Possible it might improve starting, but it’s subtle.

-

You can zoom in on his gi275 ADI and see the airplane pitch oscillate a degree or two. Doesn’t look like altitude is really changing but id bet it’s annoying and uncomfortable.

-

Mooney 201 lands on high power lines in MD

Ragsf15e replied to ArtVandelay's topic in Mooney Safety & Accident Discussion

If anyone on MS had this happen to them and wasn’t injured, they better be courageous enough to make some posts on the thread while awaiting rescue! ps, I really hope they are ok. -

Mooney 201 lands on high power lines in MD

Ragsf15e replied to ArtVandelay's topic in Mooney Safety & Accident Discussion

Yikes. -

Is M20C brake bleeding possible?

Ragsf15e replied to Kelpro999's topic in Vintage Mooneys (pre-J models)

Obviously it can be done, but you’re prudent to be cautious and think it through. The only time I’ve broken down on the road was a master cylinder leak. I found a mechanic on the field who had the proper O rings on hand and rebuilt the brakes the next morning. I had soft/squishy/50% effective left brakes until my home mechanic spent an hour with the plane tilted back working on it. It was fine after that. So clearly it can be done ok, but, yes, it can be a pain if you’re in a rush. -

Yeah, fair enough. I just like to make sure they are all at least slightly past peak, but at the higher altitude I usually fly, it wouldn’t hurt either way.

-

Yeah, I think there’s about 4 different published legit ways to put this together. That SB is from 1968 though and my parts catalog is newer. It shows 2 different ways depending on year/type. I talked to the parts people at Lasar since the steering horn came from there in 2003. They are sending me all new hardware, bushing, etc. They are sending a bolt, castle nut, cotter pin to go there, so I think it will be what you guys were talking about.

-

So reading m20-169, it shows this bolt and nylon insert nut (circled below).The parts manual seems to show a different bolt and nut with cotter pin. Mine looks just like tge sb, but was installed in 2003. Which one is right?

-

I like my lean find as well. Mostly for the reasons @0TreeLemur said, but also because my gami spread is close enough that my last to peak (richest) can be different based on conditions. If I cruise down low at high mp and without ram air, maybe it’s #2, up real high with ram air on, likely it’s 3. One other nice thing about LF is it allows the jpi data analysis program to quickly analyze that point and you can see if things are changing. Maybe a plug Or timing issue slowly developing? In general, you’re right that it’s unnecessary if you just watch the temps closely and have an idea how it will end, but extra toys/options are always nice, no?

-

@EricJknows this but I quoted him to expound on what he said, Oil coolers get gunked up and bent fins after a while too, so maybe cool less effectively when it’s hot out, but when it’s really cold, you can still see low oil temps and higher pressure. Heres the thing, as a pilot, you’ll notice the pressure is directly related to your rpm and oil temp. High rpm, cold temp = high pressure (like initial takeoff). Low rpm, high oil temp =low pressure (like idle taxi after landing). It is easy to see yellow range high and low in these conditions but the engine be working fine.

-

I agree, I was talking about the 22 bolt, not circled. Isn’t the ipc showing it go the other way?

-

while waiting for someone to post one put together correctly, I found this picture on MS from another airplane. Isnt the bolt (not the circled ones) in backwards?!

-

Dumb question, but will one of you guys with a “vintage” airplane post a picture of the back of your nose truss/steering horn assembly please? Thanks.

-

Looks like I’ve got some work to do. Glad it stayed on 19 years!

-

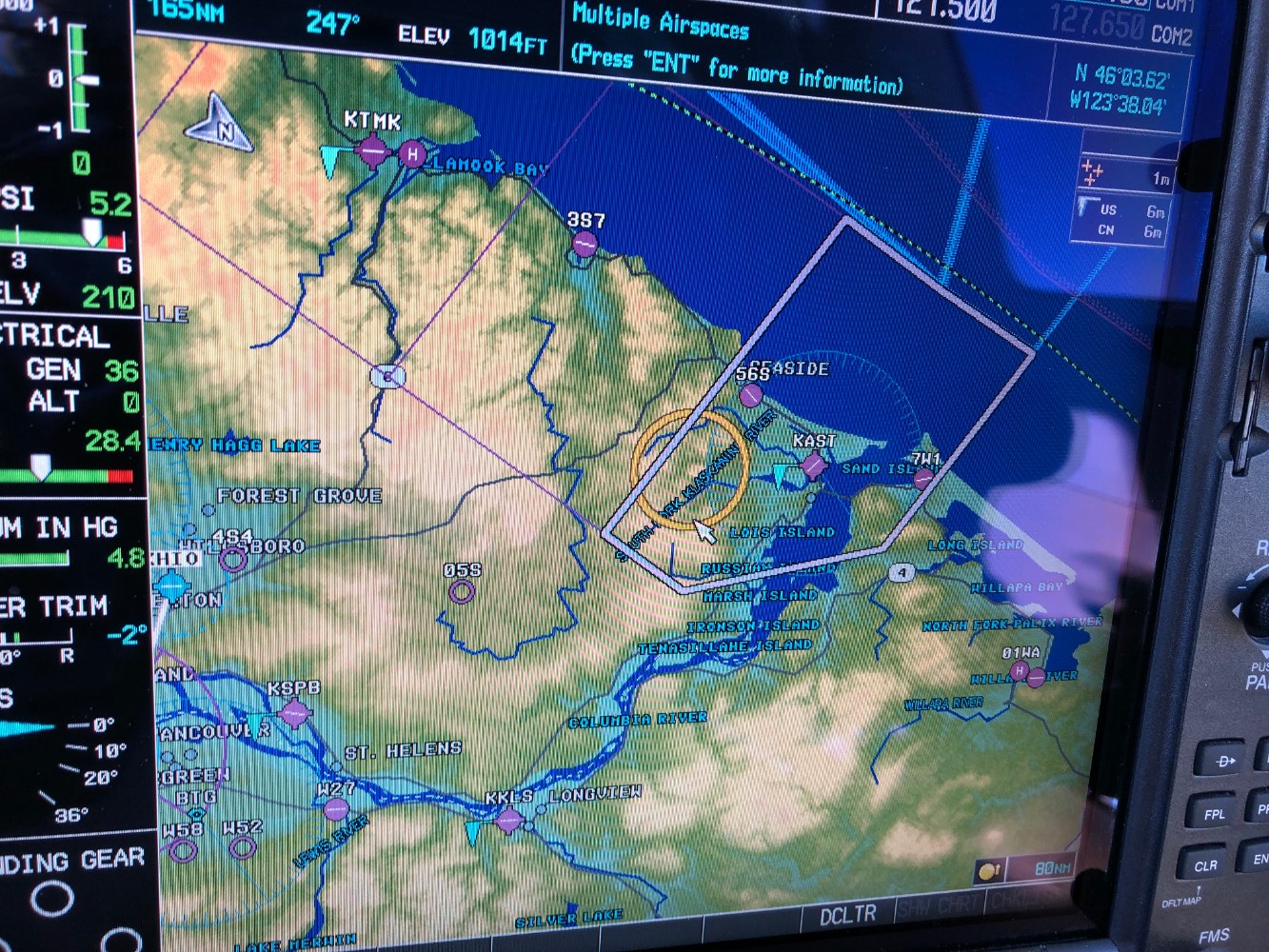

Missing ADS-B TFR data in Seattle Area

Ragsf15e replied to PT20J's topic in Miscellaneous Aviation Talk

-

I believe you guys, and parts manual has a cotter pin. Check out my picture below. This has been on there since 2003 when “new lasar steering horn (old style) installed” No pin.

-

Do you happen to remember a couple specifics.. I have the Mooney part number of the bushing that the AN4-21 bolt goes through (left side of my picture), but I can't find a standard part number for it. Any idea where you got it? (914020-031). The parts manual calls out a cotter pin as part of that bolt, bushing, washer assembly, Mine doesn't currently seem to have one, just a nylon locking nut? Do you remember if you did? If so, was it a castle nut and drilled AN4-21 instead of undrilled? As Doc mentioned, there are several SBs and upgrades, so I'm trying to figure out which version I have and what parts I have before taking it all apart. It could be a problem to figure that out and/or to find the parts.

-

For such a “simple” job, I’ve seen a lot of comments that include blood, cursing and contortion.

-

Yep, it looked like it moved in each of the areas you said. I’m going to have to prep my mechanic for this… not sure how long (if ever) it’s been since he’s taken apart one of these. Thanks.

-

I played with my nose truss this morning before flying. With the nose solidly on the ground, I’ve circled where there appears to be some play. The video link shows me moving around that part while the nose wheel isn’t moving. Anyone know if this is probably just bushings and shims? I plan to look closer up on jacks at the upcoming annual. Thanks, Drew https://photos.app.goo.gl/m4UzQPg7vC3k9Zb46

-

It’s really easy except when it’s not. I definitely recommend going back first after pulling the aft pin. Then forward and off. Ive had mine on and off four times. Three times they came off with minimal blood/cursing. Three times they went back on ok too. Once they were pretty much stuck like yours after putting them back on. Took forever to get them back off, checked, carefully put back and they magically worked. No idea what had stuck them. Go slow, be patient, expect a challenge more difficult than it should be (which isn’t much but can be frustrating). Try not to bleed on your carpet too much.

-

So #4 was about Carson speed for you? If so, it seems like it’s in a reasonable place?