All Activity

- Past hour

-

If you overprime an IO-360, it runs a little rough for a few seconds after starting. But if it is REALLY rough then it’s more likely a sticking valve. If you have an engine monitor, it’s easy to see which cylinder is dead because the EGT won’t come up. If you don’t have an engine monitor, start it with the cowling off an then shut down and feel which cylinder is cold.

-

Most likely, it’s a later model K since it has the relays and the three position flap switch with the 15 deg. position. Since the relays have been replaced, it must be a switch causing the problem. Within the box that contains the relays are two microswitches that control the 15 deg position. The schematics can be found in service and maintenance manual. Someone posted this simplified version a while back. Flap switch logic.pdf

-

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

Tom F replied to cliffy's topic in General Mooney Talk

As has been stated here before, what are our options. Mooney has been for sale for some time and no one has stepped up. I was in the factory early July '25 and based on what I heard I was thinking the last days were very soon. The Lasar guys are taking a risk and I am hoping they are successful. We need a dependable parts supplier as well as new energy injected into this once great company. And we need some damn swag too. lol I've only owned my O3 for 4 years. I was led to believe Mooney was owned by a group of Mooney owners. It was all BS. Its owned 80% by an investor and 20% by the Chinese company. The communications in the last 4 years has been non existent. I've seen more communication from the Lasar team than I ever have from past owners. In my opinion, I know like belly buttons, we all have one, Mooney never financially succeeded in large part to not having any what its costs were, hence the multiple bankruptcies. I would love to see new birds rolling off the production line, but that's probably not in the cards. Personally I want to invest and help these guys succeed, be a part of the story. I have spoke to Brett and I like what I am hearing. Owning a Mooney is special fraternity of brothers and sisters who share a passion for flying faster. -

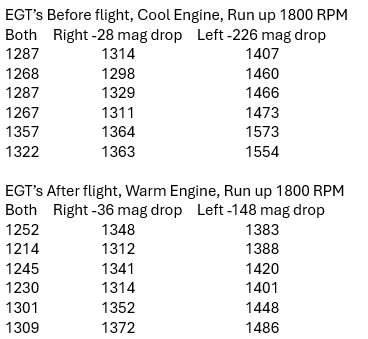

I know the mags have been on and off and thus timed. I think your engine timing is 22+/-1. Your timing can be in limits, but have a 2degree split and get different mag drops. If the timing is a little out of tolerance it becomes more significant. Using the timing cone is not the most precise thing. I know it’s sometimes hard to ask the mechanic these questions, but perhaps ask him what the mags are timed at…..or suggest retiming them both to 22 or 21? It might be that the left mag is clocked in such a way that it prefers more advanced and is causing these issues. Just seems consistent with timing….

-

What 2.25" instrument would you add to this panel design?

toto replied to birdofjoy's topic in Avionics/Panel Discussion

Nice! -

Could be the switch; could be the relay. Hard to tell which if intermittent. You could replace both to be certain. Or you could start by replacing whichever is cheaper.

- Today

-

The OP said he has a McCauley prop. Those get greased only when taken apart. There are no external grease points like a Hartzell prop.

-

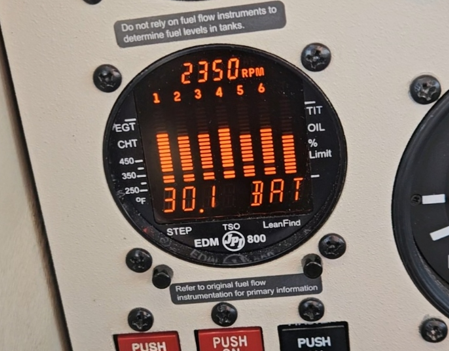

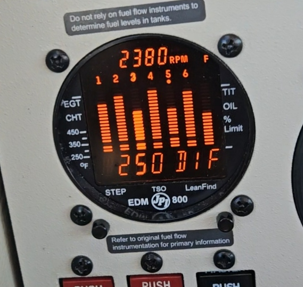

Here's some info I got today. The Left mag side is definitely hotter. I did the inflight mag check as well. At first I ran it out to LOP and it was in the high 1400's. When I did the Left check, everything immediately went off the scale. The ships single EGT gauge went way past redline so I quickly backed out of that. I went richer with the mixture and got a lower base EGT and ran the same check. The right side was smooth and normal. All EGTS rose some but nothing drastic and the engine was still smooth. The Left EGTs took off in different directions and the engine got rough. I had video and at the bottom is a screen shot just before the mag check, the second screen shot is 4 seconds after turning the key.

-

Yep. I knew hot starts were very different; this thread points out that ALL starts are very different between the O- and the IO engines!

-

What 2.25" instrument would you add to this panel design?

cbarry replied to birdofjoy's topic in Avionics/Panel Discussion

That’s a very nice and well thought out new panel! Congratulations! -

You know the O-360 and IO-360 are very different to start.

-

I’ve started them in zero degree F weather like that.

-

If you prime an IO-360, you will fill one cylinder with fuel, maybe. The rest just goes into the sump. If the sump is cold, it will just sit there or drain out the sniffle valve. Once you have fuel pressure, the injectors will provide a perfect mixture for starting. Why mess with it.

-

Well, THAT is a new one. Start cranking with full rich on a cold engine.

-

I always start IO-360s the same no matter what the temperature. It never fails. Mixture rich, throttle at ~1000 RPM setting. Crank the starter, if it isn’t making fuel pressure, I’ll turn on the boost pump until I have fuel pressure, then turn it off. The only time I prime is if I think it is flooded, I will prime to make sure it is flooded, then do a flooded start. Hot start is mixture ICO, throttle 1000 RPM, crank till it starts, then advance the mixture. Flooded start is the same as hot start, but with more throttle. When it finally catches, reduce the throttle and when it starts to die, advance the mixture.

- Yesterday

-

One thing for sure… if you have learned to use a certain amount of prime in warm weather… and the temps have cooled a bit… less prime won’t make any sense (to a chemical engineer). 100LL is known for its inability to evaporate as temps cool… the IO550 uses 40°F as the cut-off from normal start to cold start… where additional seconds of prime are used… and running the fuel pump on Lo to keep it running for a few more seconds… read up on various starts to understand them better… as a flooded start may be in your future… Best regards, -a-

-

CO2 detectors the "Good The Bad and The Ugly

Hank replied to Jpravi8tor's topic in Vintage Mooneys (pre-J models)

All I've ever seen in my Mooney is 0; even my old Ford Ranger showed 0 running the heater in winter. I even checked my gas stove, oven and gas logs in the fireplace--all read 0 in steady use, with an occasional startup reading as high as 6. Any reading of 440, much less 800, requires investigation. Check sealing around all hoses and wires through the firewall, sealing around where rudder pedals and aileron rods leave the cabin, along with the seam tape under the cabin. -

Rght out of the gate? Seriously???

Hank replied to Freddb34's topic in Vintage Mooneys (pre-J models)

Many people swear by a tool made.from PVC pipe and notched to fit over the fuel selector, with the handle end either an L or T to suit pilot preference and storage location. Make the length and handle style to suit yourself. Or learn to lean down and turn it by hand. By the time you finish your insurance dual, you should be pretty proficient; i switch mine on the ground after engine start to ensure that it's trouble-free, then check it's on the fullest tank for takeoff, and again every hour in cruise. -

No worries Hank (on derailing). I am going to try and prove I am not crazy (doing same thing over and over and expecting different result) and try less boost pump. (opposite of more cow bell if you are a Blue Oyster Cult/SNL fan).

-

I though of putting the O2D2 controller somewhere in line of sight, but could not come up with a solution that would be somewhat elegant. my O2 ports are in the ceiling (1990 Bravo) above/behind the front seats and running hose to front panel would not look very good. Thus, I chose to attach the controller with 3M Dual Lock Strips bewteen the rear seats where I can easily reach it and manipulate the control knob. There is arguably no need for visual confirmation of function with this unit as you can clearly hear the pulses being delivered (I now that some pilots do not like this, but I got used to it quite quickly). I can still glance at the box periodically to see the green lights and confirm that battery is OK. All the hoses are out of the way behind the seats and the setup works really well. No overheating issues as the box never gets direct sun.

-

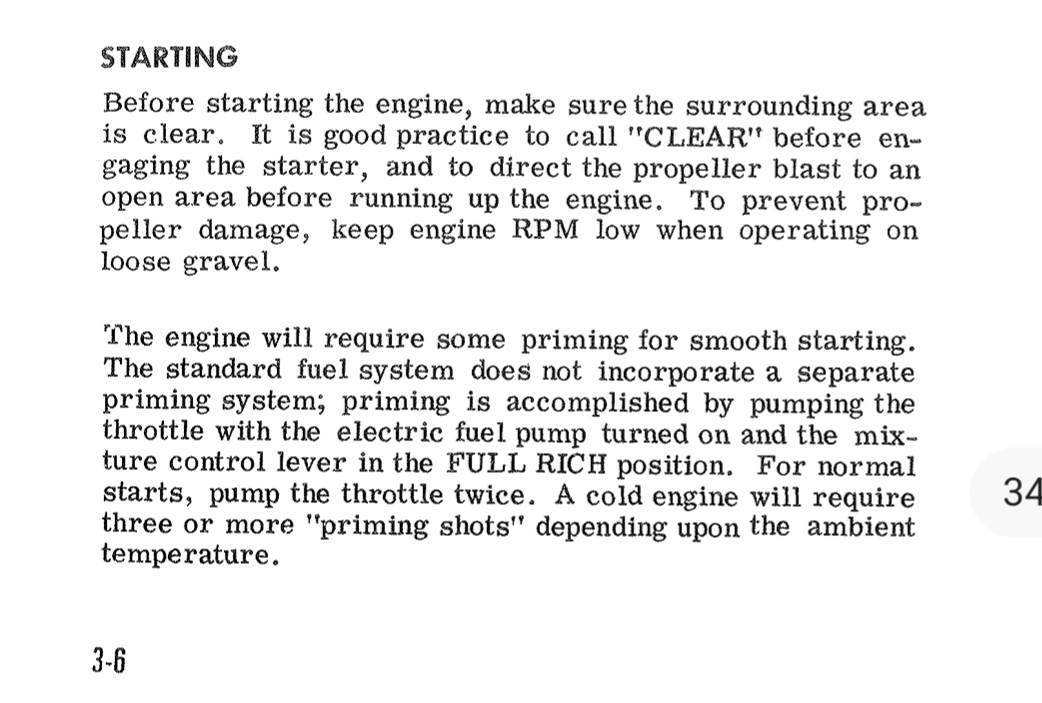

@Vance Harral, I'm not aware of ANY carbureted Mooneys with separate primer functions like found on the 172s I trained in. When cranking in very cold weather, I sometimes also pump the throttle a few times as the engine turns over, especially if it fires unsuccessfully a couple of times. Unless the engine is flooded, there is little risk of an engine fire. At the risk of derailing discussion here, this is from my Owners Manual:

-

Fresh out of annual? Fresh grease gets pushed into the hub causing some to escape out the seals… deep cycling the prop? another reason some grease may get past a seal that has been sitting awhile… when grease comes out three inches of prop blade… it will leave small bits of grease on the windscreen… a clean windscreen is required to see it… let’s invite… @Cody Stallings for some insight on prop grease leaking… Best regards, -a-

-

Mine was overhauled around the time of the Aeroshell issue. But it leaked before and after, so who knows? I think Nyco is the new recommendation, but can’t be mixed with the Aeroshell. However, you can mix Aeroshell 5 with 6, FWIW.

-

@Hank probably knows this, but just for others reading the thread... some carbureted aircraft don't have a primer systems that inject fuel directly into the cylinders. Including some Mooneys, and I'm guessing Hank's is one of them. Pumping the throttle to force the accelerator pump to spray atomized fuel up into the carburetor throat is the only way to prime the engine in these airplanes. But please be careful about dispensing "pump the throttle to prime" advice, even in carbureted aircraft. Most carbureted airplanes have updraft carbs (fuel/air path into the engine intake is opposite gravity), and some of them don't atomize the fuel all that well, especially when it's cold. In these aircraft, some of the fuel you shoot into the carburetor throat by pumping the throttle runs back down over the carburetor, into the engine cowl, onto the ground, etc. This is a fire hazard, and not just a theoretical one - a 182 at our flight school suffered significant damage in a carburetor fire caused by someone who wasn't very skilled getting the engine started, and managed to light off an engine compartment fire after excessive throttle pumping. It's definitely safer to use a primer vs. pumping the throttle, though the risk reduction is hard to quantify. If you must pump the throttle to get the engine started, one way to mitigate risk is to only pump the throttle while actually cranking the starter. With this method, the vacuum generated in the intake by the moving cylinders will draw more of the fuel droplets up into the engine, less of them will rain down on the ground. I'm aware this isn't the POH procedure, but it has been effective for me in a number of carbureted airplanes, and I think it's safer. The "hot start problem" in fuel injected engines is almost entirely caused by the the fuel injector lines being routed right over the cylinder heads, such that the fuel in them is baked and vaporized by the hot cylinders as soon as cooling air stops flowing over them, i.e. immediately after shutdown. Lycoming/Continental carbureted engines don't have this problem because the entire fuel/air intake system is below the hot cylinder heads, so there's really no comparison between carbuerted/fuel-injected with regard to hot starts. Indeed, carbureted engines are almost always blissfully easy to start when warm. For what it's worth, your engine would likely start with zero throttle pumps when warm, albeit after a few more blades than with pumping. Reduces the admittedly small risk of a carburetor fire, at the expense of more wear on your starter.

-

Given those two data points, it sounds like a real issue. Are you sure that the oil cooler lines are connected properly? What does the overhauler say?