Nokomis449

Verified Member-

Posts

180 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Nokomis449

-

M20G- POH and a few simple questions.

Nokomis449 replied to Mromano's topic in Vintage Mooneys (pre-J models)

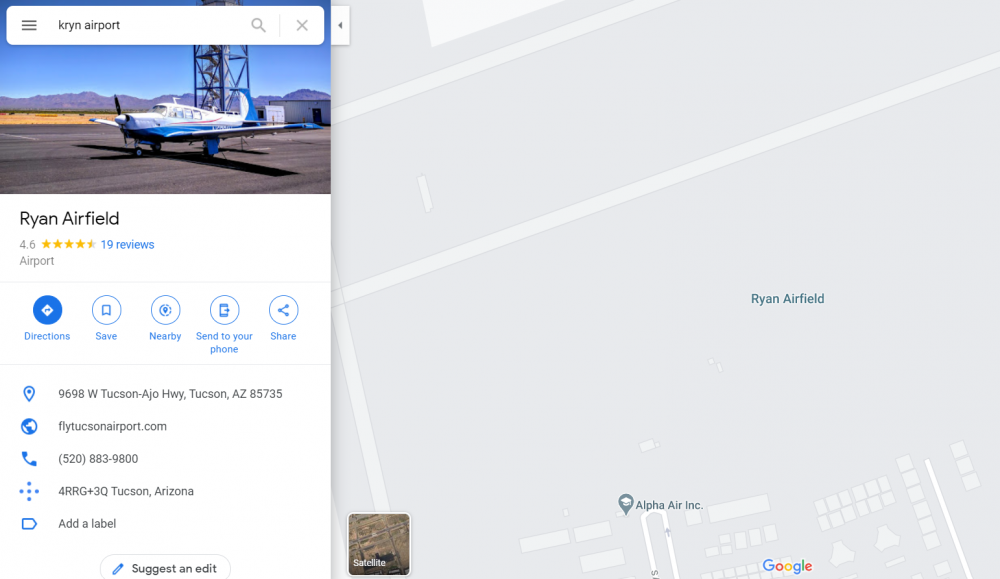

Ha, I searched for KRYN on Google Maps (because @KLRDMD says that's where it lives) and sure enough, this is what shows up: -

M20G- POH and a few simple questions.

Nokomis449 replied to Mromano's topic in Vintage Mooneys (pre-J models)

G owner here. That's a nice looking plane, and came off the production line within a month or so of mine. My O-360-A1D has been bulletproof, and I recently had it rebuilt at about 2,500 hrs not because it was showing signs of being tired but because I just felt it was time (frequent IFR/IMC, some at night, played a major role in the decision). With a few speed mods mine gets around 150kts down low, about 145 at 11k. The one for sale also appears to have some speed mods. The panel layout is "modern", although the avionics/radios appear dated. You've indicated that you're fine with that. My only "high country" experience in mine was a trip to Albuquerque's Double Eagle airport and with three 6' adults and weekend baggage it seemed to handle the 6,000msl takeoff roll just fine. ATC did vector us well west in a climb before turning us east to cross the Sandia Mountains, but that's probably SOP and I don't remember the climb rate being anemic. I've also flown a Mooney Missile (300hp) into Angel Fire, NM and I wouldn't hesitate to take the G there, respecting density altitude and related considerations. I've clowned around and climbed solo to 17,500 before and it was still willing to climb. I'm seeing good paint, good panel layout, and good interior. Once you master the Johnson bar you'll love the ease, speed, and simplicity of the gear system and hydraulic flaps. The J-bar is so reliable, it's the only certified gear system that doesn't have a backup extension system. Maintenance (of mine) is as cheap as you'll find for any retract. If this plane suits your mission, I'd say inspect the logs and schedule a PPI. Check into Savvy Aviation (savvyaviation.com); I'm thinking they offer to inspect the logbooks for you for free. -

My instructions from Penn Yan on breaking in my rebuilt 0-360 was to cycle the prop on run up once just enough to get a response and to avoid dropping the RPM to the extent practical.

-

Calling All Experts! First Time Mooney Buyer Needs Help!

Nokomis449 replied to BobCW's topic in General Mooney Talk

The first time I contacted AOPA Finance, they turned me down because I wasn't borrowing enough money. The second time, their interest rate was higher than what I could get on an unsecured loan. So like AOPA's insurance arm, their loan arm is useless to me. Thankfully, several of us local pilots now have a very friendly local bank that between us all has financed probably 10 airplanes over the last several years. -

If you're going to do aerobatics correctly you might as well get one of these - made in Bentonville, Arkansas and one of the company founders has a last name of Walton (hmmm...): https://gamecomposites.com/

-

Hopefully this'll help as it sounds like we have the same cluster. As-removed from my 1968 G at last annual, replaced with an EDM900. EDM 900 pic included to show that it's a near-perfect fit where the original cluster goes. All gauges were working when removed and I plan on listing the whole set for sale along with the working as-removed fuel pressure/manifold pressure gauge. Engine is a Lycoming O-360-A1D, 26 gal tanks. The individual fuel gauges have different part numbers and different electrical connections as one is male, one is female (see pics). If you want to verify part numbers, the individual gauges can be easily removed from the front by unscrewing the single screw holding it until the screw is loose, then pull on the screw itself to slide out the instrument. The left fuel gauge shows a stamped date of Mar 6 1968, with an additional stamped date of Oct 11 2002 which I assume is a rebuilt/refurbished? date. The right fuel gauge has a handwritten sticker on it covering the original stamps and I know not what it means.

-

Calling All Experts! First Time Mooney Buyer Needs Help!

Nokomis449 replied to BobCW's topic in General Mooney Talk

Speaking of Blackhawks... A local company, Ace Aeronautics (aceaero.com) modifies Blackhawks and other rotary/fixed wing aircraft and have an STC to install G5000H panels in UH-60/S-70's. Mostly ex-military guys, they have two of the prettiest Blackhawk paint jobs I've seen on their two in-house UH-60's. They are also a Part 145 operation and recently did a pitot/static/transponder check for me on my Mooney. They have a paint shop and all, and could well be my new go-to shop for maintenance. -

Calling All Experts! First Time Mooney Buyer Needs Help!

Nokomis449 replied to BobCW's topic in General Mooney Talk

What no one has mentioned yet is the lowly G model, AKA "The slowest Mooney". It's the longer F body with a 180hp engine (vs the F's 200hp). I'm still getting the rebuilt engine broken in, but I have a few speed mods and appear to be getting about 150kts true at lower altitudes. Flew to Spruce Creek, FL a few weeks ago for the first long stretch of her legs since the rebuild and got 144kts TAS at 11,000, 66% power, 19.4MP and 2,400RPM, 36deg OAT. Mine's a 1968 with the manual gear and it'd be a hard sell to move me into another model, because this one is plenty fast and also one of the easiest/cheapest to maintain. I'm between Huntsville and Birmingham if that's close enough for a meet-up/look-see. Full disclosure: I'm pretty biased toward the G. If you know a helo instructor named Tomlinson, tell him the Mooney driver at 8A0 sez "hi". Edited to add a pic and correct a misspilled wurd. -

I used to do it all the time when training for my IR. It's a great way to practice upset training and my instructor didn't have a problem with it. At first my success rate was dismal (overspeeding, exceeding G's, etc) and I had to start over a lot but eventually I got to where it wasn't a big deal. It helped that the FBO owner was an aerobatic (acrobatic?) pilot and gave me pointers as he watched. Toward the end of the training I was doing it in clouds and at night, and got to where I was pretty good at it. I was flying a Bravo at the time. All this was on a simulator in the FBO. YMMV.

-

-

1,000 ft will most likely require a point-to-point router at each end. Without an outside antenna, it'll be tough getting a signal through a metal hangarif that's what you have. In my case, the FBO allowed me to put a router in their attic with a directional antenna pointed toward my hangar (shingle roof), and so far the airport authority hasn't mentioned the short PVC pipe with two small Yagi antennas connected to the gutter at the hangar. It probably helps that I have it as an open network that other nearby hangars can also use. 5+ years and no complaints yet. I'm using 20 year old Linksys routers flashed with DD-WRT firmware but I'm sure there's better solutions out there. Plan is to replace the setup with modern Ubiquiti point-to-points if the current setup ever fails me.

-

A friend of mine is a Captain that pushes hazardous chemicals up the Mississippi between the refineries in Baton Rouge and Chicago. One day I mentioned MEK to him, and he said "How much do you need? I've got a whole barge full of it right now". Talk about being set FOR LIFE!!!

-

Is the KT76A TSO a slide in replacement (or acceptable to you)? If so, I've got one you can have for the cost of shipping. It was working fine when I upgraded to ADS-B Out a few years ago; been stored in a drawer in my house since. comes with tray.

-

Add mine to the list of installed AV-30-C's that will have you flying a perfect circle if you follow the DG's guidance. Mine's installed as an AI and works great in that mode. But you can also display the DG at the top of the AI complete with heading bug, but if you look away for very long the precession will move the bug out of view. Very disappointing, so I switched it to display GPS Track instead of magnetic heading. Flew my first cross country with it last Thursday, north Alabama to Spruce Creek (Daytona, FL area) and back, and the AI worked as advertised. Software/firmware updates are performed by accessing the rear of the instrument, disconnecting the D-sub, and connecting a pigtail that runs to your laptop. Another good reason to keep my avionics access panels in place and forego the 201-style windshield. In addition to the $2,000 price tag plus install, the primary AI mode REQUIRES you to tap into the pitot/static lines which then requires you to get a new pitot/static check done per the STC installation instructions (this is NOT required for primary DG mode). So add that to the price of admission, which in my case was $350. Luckily, my pitot/static/transponder test was coming due in May, so I would have paid that amount soon anyway.

-

Pilots N Paws: False River, LA to Crestview, FL

Nokomis449 replied to Prestonalton's topic in Videos

-

Engine preheat through the oil filler?

Nokomis449 replied to Will.iam's topic in General Mooney Talk

Just this week I fashioned an internet enabled CB engine preheater. I picked up a little 10" (round discharge area) electric heater, some aluminum ductwork adapters, and 4" metallic dryer vent hose from the Aviation aisle at Lowes, as well as 20' of 12ga 3 wire stranded copper cord. I also picked up a Shelly PM from Amazon Aviation and fashioned an extension cord with the 12ga and the Shelly. The ductwork adapters cover the 10" discharge area and steps it down to the 4" vent line, which goes into one of the nose inlets (a Mooney nose mod puts the inlet at the perfect size for a snug fit). The other inlet is clogged with one of those big spongy things used to wipe down/wash grout jobs. The engine cowl is then covered from prop to halfway up the windscreen with two soft Harbor Freight moving pads, which is then covered with a Harbor Freight painter's drop cloth (doubled up) that completes the "tent", running from floor to floor across the cowling. The first test was the other night, when I had a below-freezing night with a 7am departure. I'd left the heater switch on LOW (it has a Low/Off/High rocker switch) and I put the thermostat (rheostat) at the middle. At this setting, the heater would cycle on and off. The Shelly allowed me to turn on the heater via my phone when I went to bed, and displayed the amp/current draw that confirmed the heater was kicking on and off as expected. When I got to the hangar for the 0630 preflight, I turned on the Master switch and snapped this pic of the EDM900 before pulling it out of the hangar (and obviously before cranking). The EDM900's OAT probe was covered by the "tent", and therefore read about 10 degrees above ambient. Kinda neat to see the CHT's, EGT's, Oil temp, Carb heat temp, OAT, etc. display the effect of the preheater's work. After seeing these temps I think it's a little overkill, so it's currently set up with the thermostat set much lower. Most of the idea was stolen from the V-Tail hangar next to me, but theirs looks like an octopus with a 4" hose going into both sides of the prop, and a 2" metallic vent line (bathroom exhaust vent line) snaking over to the pilot side window to warm up the interior/avionics. -

Mysterious baffle cutout (1965 M20E)

Nokomis449 replied to SoccerCA's topic in Vintage Mooneys (pre-J models)

My '68 G model is very similar to yours, Hank. Aluminum screwed to aluminum all along the edges with no flexible baffles other than along the top near the prop. I've seen pics of others with baffles all around. Mine rec'd a scoop closure mod from a previous owner that may have included a doghouse mod. -

Clogged engine fuel sump?

Nokomis449 replied to Middle TN Mooney's topic in Vintage Mooneys (pre-J models)

Sometimes I can fully pull mine, walk around to see what drained, and the floor is dry. Go pull again with a little more determination, and there's a puddle on the floor. -

M20F cruise performance & service ceiling

Nokomis449 replied to Chris Briley's topic in Vintage Mooneys (pre-J models)

I find Globalair info is very... comical with their data. check out what they say is the max landing weight for my G: Operating Weights Max T/O Weight: 2525 Lb Max Landing Weight: 1585 Lb ... -

I had a non-WAAS 430 in the Mooney when I got my IFR rating. This was about the time that GPS approaches were coming on strong and ADS-B mandate was on the horizon and getting bigger. I narrowed it down to upgrading the 430 and get a Garmin ADS-B transponder, or going with a slide-in Avidyne IFD440 and get an Avidyne ADS-B transponder. The Garmin route would've been somewhat cheaper, but I would still be flying behind 1990's technology and Garmin had already shown their disdain for keeping the 430's alive by jumping up their WAAS upgrade price by a significant amount. So I went with Avidyne and have been very pleased with it. Regardless of which brand you choose, I strongly suggest getting something that will shoot WAAS LPV approaches. At some point, your personal minimums just might be lower than your non-WAAS 430 can go, and at that point you'll wish you'd spent your 2021 dollars on a WAAS upgrade. With your non-WAAS 430, the ILS is the lowest approach you can shoot and not many mom-n-pop GA airports have them. But GPS approaches are going in everywhere, and even Podunk Municipal probably has an LPV approach to 200ft.