Nokomis449

Basic Member-

Posts

180 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Nokomis449

-

Garmin 430 WAAS with GA36 Antenna w/ backing plate

Nokomis449 replied to Old Chub's topic in Avionics / Parts Classifieds

Assuming the voltage is the same, yes. If the existing GPS antenna is non-WAAS, you'll need to install the WAAS antenna and possibly replace the antenna cable also. I'm going from memory from several years ago when I removed my non-WAAS 430 and replaced it with an Avidyne IFD440. Also had to replace the non-WAAS antenna at that time. -

I stared down Lycoming and they blinked first.

Nokomis449 replied to Nokomis449's topic in Vintage Mooneys (pre-J models)

My crankshaft serial number is was V537923412. I haven't seen the ser# of the new one. If your hypothesis is correct, then there's also a good chance that someone is out there flying behind a bad crankshaft that also has an incorrect serial number (that's not on the list!). -

I stared down Lycoming and they blinked first.

Nokomis449 replied to Nokomis449's topic in Vintage Mooneys (pre-J models)

That's exactly what came off the plane that I had rebuilt- it was a Lycoming factory reman 0-time engine. They may have thrown everything out, but they installed a brand new crankshaft that was subject to the AD a few short years later. So even fresh factory/remans can have recalls. Since I plan to keep this plane forever, the extra cost of the factory reman vs having Penn Yan rebuild what I'd known for almost 20 years to be a dependable engine was not worth the perceived added value to me. Penn Yan replaces just about everything but the case and crankshaft, but whatever they put inside is either new or meets new standards. New starter, new alternator, new pistons/cylinders, etc. So I'd put my fresh Penn Yan rebuilt engine up against a new/reman from from Lycoming for dependability, and in my opinion I won hands down on value. I think you're comparing it to a field overhaul, where an A&P can put the same hardware back into an engine as long as it's not worn beyond factory spec for service. -

I stared down Lycoming and they blinked first.

Nokomis449 replied to Nokomis449's topic in Vintage Mooneys (pre-J models)

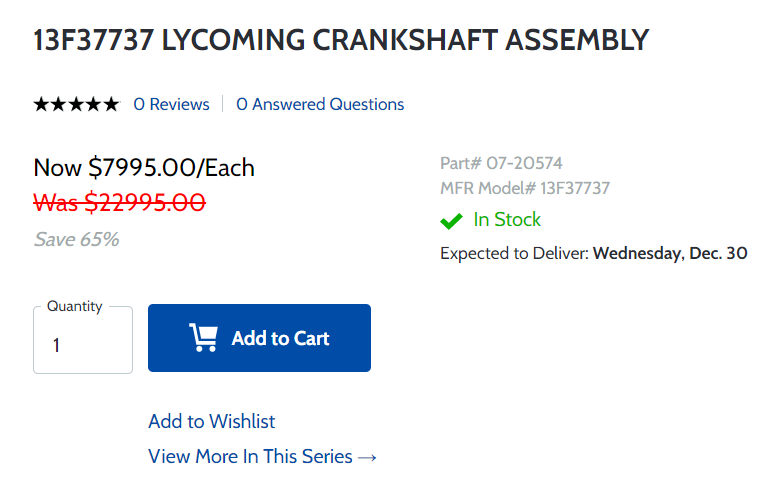

I'm not sure what number he quoted because the shock and gravity of the situation was setting in and it was the proverbial straw that broke the camel's back. But I remember it sounded a lot like $17,000. Here's the current price on Aircraft Spruce (if I picked the correct crankshaft - I searched for "O-360-A1D Crankshaft" but you know how they throw in the kitchen sink on their search result) - Spruce has them drastically marked down from list price of $22,995, so $17k was still under list: -

I stared down Lycoming and they blinked first.

Nokomis449 replied to Nokomis449's topic in Vintage Mooneys (pre-J models)

As I mentioned in a diatribe above, once Lycoming blinked I was given the option by Penn Yan of REsending my crankshaft to (Oklahoma?) to continue the overhaul, thereby adding a few more weeks to the overhaul timeline, or swapping it out for an equivalent "new tolerances" crank they had on the shelf. I opted to swap, so I now have a different crank. -

I stared down Lycoming and they blinked first.

Nokomis449 replied to Nokomis449's topic in Vintage Mooneys (pre-J models)

@MikeOH My comment to m20Doc was in reference to his comment "Someone should have looked further for your crankshaft serial number long ago". I was defending every A&P that's confirmed AD compliance on my Mooney over the years by pointing out that the way the AD is worded, there was no reason to look beyond the engines listed in the AD. For paragraph 1 in the AD the engine wasn't listed and therefore the AND part of the paragraph wasn't satisfied, and paragraph 2 specifically refers to crankshafts installed after the engine left the factory (which doesn't apply here). That's a different argument than what you're suggesting. There's no getting around the fact that my crank is specifically listed in the AD. I believe it was listed by mistake, and my email to Lycoming was to prod them to prove it was intentional. Apparently they eventually agreed with me, although they did it by telling Penn Yan instead of me. But @N201MKTurbo brings up an interesting point - what does it take to get that serial number removed from the AD? I hope whoever gets it doesn't have the same issue. -

I stared down Lycoming and they blinked first.

Nokomis449 replied to Nokomis449's topic in Vintage Mooneys (pre-J models)

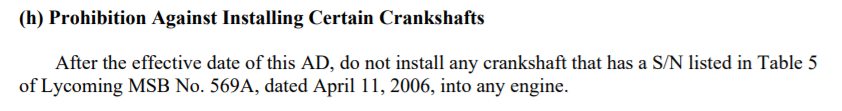

The AD is against specific crankshafts by serial number. The cranks listed in the AD are required to be removed from service in accordance with the AD. After April 11 2006 mine is not allowed to be (re)installed in any engine, including mine: Penn Yan had no choice but to red tag the crank, because it was specifically listed by serial number in the AD. I'm not arguing that my crank is good just because they didn't list my engine serial number. I'm arguing that my crank and any crank like it were never intended to be part of the AD, yet somehow my crank's serial number was included in the list by mistake. -

I stared down Lycoming and they blinked first.

Nokomis449 replied to Nokomis449's topic in Vintage Mooneys (pre-J models)

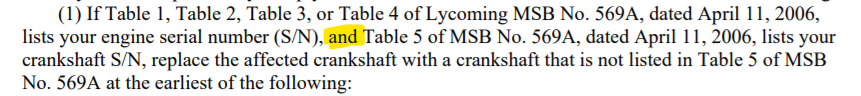

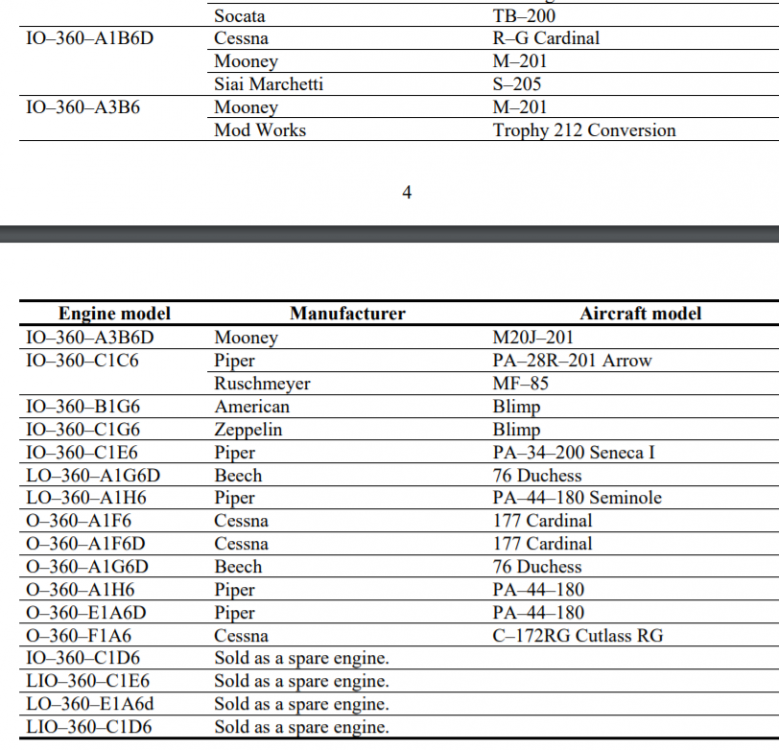

Good point @M20Doc, and you certainly know more about this than me. But I might have pulled the snippet from the wrong AD, and maybe you did too. The AD cited by the crank overhaul facility is AD 2012-19-01. Link: https://rgl.faa.gov/Regulatory_and_Guidance_Library/rgAD.nsf/0/818d35600eaac30f86257a7e00532d53/$FILE/2012-19-01.pdf When looking at this AD, I see these words: ...so BOTH the engine needs to be listed by serial number (it's not), AND the crankshaft serial # is in the list (it is). So in my thinking, since the first part wasn't true (no -A1D's were listed) there was no need to go further. The next section applies if "an affected crankshaft was installed as a replacement". My engine never had the crank replaced since factory reman, so again no reason to look further: And in reference to the -A1D not having a counter-weighted crankshaft, the entry of the AD into the Federal Registry contains this: link: https://www.govinfo.gov/content/pkg/FR-2006-09-29/html/E6-15958.htm I'm not well versed in FAA speak, but I don't see where my engine/crankshaft should be part of the AD. Lycoming had 2 weeks to prove me wrong and didn't. -

I stared down Lycoming and they blinked first.

Nokomis449 replied to Nokomis449's topic in Vintage Mooneys (pre-J models)

EDIT: In re-reading your comment, I realize now that I didn't completely answer your question below. In a nutshell: whether my engine was listed or not, my crankshaft WAS listed and is therefore required to be replaced. My argument is that the crankshaft in the O-360A1D was not like the other crankshafts in the AD, the fact that the O-360A1D was not listed supports my position, and therefore my crankshaft was erroneously included in the AD. Only Lycoming knows the reasons why, and they're not talking. You're exactly right, and that's why none of the annual inspections caught the crankshaft AD. The O-360-A1D engine was not on the AD list, so no one looked further at the crank serial #. However, once the crank was sent for overhaul in Kansas, the overhaul shop checked the crank serial # against the AD list and there it was. So if there were no O-360-A1D's listed, how in the world can a crank inside an O-360-A1D be on the list? My assumption is that my crank's serial # was listed by mistake or by typo, since no O-360-A1D's were affected by the AD. Compounding Lycoming's position is that they're documented as being the one that installed this crank in the engine. The crank overhaul shop only had the serial # to go on, and they rightfully flagged it. Lycoming knew the crank shouldn't be part of the AD, else they would have contacted one of the previous owners (all friends of mine) at the time the AD came out. I guess it was just too much for them to admit they made a paperwork mistake, and they were willing to let me pay the price. Or maybe there was a batch of incorrect cranks included, some of which were replaced at great expense to other owners and Lycoming didn't want to open that floodgate of liability. I can speculate all day, that's why I'd like an explanation from Lycoming. I'm sure it's much more boring that anything I can conjure up. Here's a partial engine list including all of the O-360 engines (assuming I pulled the correct AD). Notice that the O-360-A1D is not listed: -

I have an S-Tec 30 and it's a big help. It's coupled to the Avidyne IFD440, so it actually will fly random location holds and anything else I can plug into the amazing 440. On the other hand, I have a friend with an IFR-capable Symphony SA-160 (basically a certified version of the Glastar) and he'd like to add an S-Tec to it, since S-Tec is one of the few autopilots STC'd for his somewhat rare aircraft. I don't know the details, but the deeper he delves into installing a used S-Tec the more frustrated he becomes. Seems S-Tec has made installing a used box in a different airplane a very expensive paperwork endeavor, I suppose to drive you toward buying new. Which to me puts them in the same walled-garden mentality as Apple and Garmin.

-

I stared down Lycoming and they blinked first.

Nokomis449 replied to Nokomis449's topic in Vintage Mooneys (pre-J models)

The crank still needed to be sent back to the overhaul shop which would add another few weeks to the overhaul schedule. Penn Yan had an identical crank on the shelf and was gracious enough to swap with me. -

Subtitle: They said my crankshaft was subject to an AD and had to be replaced. I said it didn't. History: Owners prior to me hung a factory reman O-360-A1D on the Mooney M20G in the very early 2000's. It flew for around 2,500 hours without the case ever being opened. Recent: I finally decided to have the engine overhauled. It was still running fine, but a cavalcade of circumstances such as time for annual, desire for EDM900, Penn Yan offering a 10% discount, and a willing banker all made the decision a no brainer. And if nobody has a brain, it's me. So off to Penn Yan the engine went. The case was cracked open for the first time since Lycoming bolted it shut, and the crank went to some shop in the midwest for inspection/overhaul/whatever they do to cranks. A few weeks after sending the engine, I get a call from Penn Yan. The shop out west had red-tagged my crank due to it being subject to a life-limiting AD per Lycoming. Before contacting me, Penn Yan had already discussed the issue with Lycoming to possibly provide me with some relief, since supposedly Lycoming had offered discounts or something to people affected by the AD back when the AD was fresh on the books. Turns out, Lycoming had to issue the AD twice, since additional cranks were flagged after the initial AD was released. But since the AD was quite old by now, Lycoming had no interest in helping me in any way shape or form - and if I understood the Penn Yan man correctly over the thud of my jaw hitting the floor, a new Lycoming crankshaft could run around $17,000. He suggested I contact Lycoming directly. I wondered what I could accomplish that world-renowned Penn Yan couldn't, and he said it wouldn't hurt. So first I did some research on the AD. As it turns out, my crankshaft serial number definitely WAS on the AD list. But interestingly enough, my engine wasn't. In reading the AD, compliance is accomplished as follows: Look at the list of affected engines. IF your engine is not on the list, you're not affected and go fly. If your engine IS on the list, then you search the crankcase serial numbers. If you find your serial number, you get to replace your crank. A little more research revealed that to my untrained eye, EVERY engine on the AD list utilized a counter-weighted crankshaft. Not only is the O-360A1D not listed as an affected engine, the O-360A1D does not use a counter-weighted crankshaft. So with this info, it was time to contact Lycoming. Lycoming has a special department that ignores investigates these things. Penn Yan had given me the email address of the head of this department, so I emailed him for further information on my plight, and was there any way Lycoming could help me out (I'd refer to it as a "hat in hand, please please please" letter). After several days of no response, I called the number of this department and spoke with an underling that worked for the guy I had emailed. I spoke of my email and my plight, and the underling seemed as perplexed as me as to why my serial number was on the list. He promised (PROMISED!) he would look further and someone would get back to me in two days (I pressed him for a deadline, as my rebuild was already way over schedule due to this incident). Well two and three and maybe four days passed with no word. So I decided to forgo the "please please please" attitude and put on some boxing gloves. I wrote a second email to Mr. "You're bothering me" at Lycoming and landed a few punches. Thankfully I CC'd my contact at Penn Yan, just so they'd know I was still working it from my end. Here's the body of the email: My engine overhaul has been delayed a week while awaiting a response from you. I'd like an answer from Lycoming as to how I've been flying behind a crankshaft well beyond a life-limited AD, and how Lycoming did not know they had put it in my engine. Perhaps it's a question better asked of the FAA, but I'd prefer to hear from Lycoming first. I need my engine back and it needs a crankshaft, and I need this process to move forward. As I said, thankfully I CC'd my contact at Penn Yan who apparently got such a kick out of my, let's call it "brashness", that he forwarded it up the chain to the top dawgs at Penn Yan. The top dawgs at Penn Yan felt inclined to alert the top dawgs at Lycoming, and a day or so later my Penn Yan contact called me to say that Lycoming had decided that my crankshaft was not part of the AD after all. He also congratulated me on the size of my... let's call it "brashness". All in all it was nearly a two week delay in the rebuilt, but thankfully Penn Yan had my back throughout. I'm still waiting for an explanation from Lycoming, or maybe that's a question better asked of the FAA...

- 30 replies

-

- 11

-

-

-

Howdy, @Hank and Merry Christmas! It was a few years ago when we flew together - he's a retired Marine Major and has since moved on to flying twin island hoppers in the Caribbean (like in the old tv series "Wings"). At that time my G had about 2,200 hrs on it and the 3-way GPS speed test showed 143kts true when averaged between 6k, 7k, and 8k feet. While breaking in the new engine (a month ago), I got 142kts at 7k feet. Once the engine appears broken in, I'll run the full test again and see what I get. I don't think he had many speed mods on his C; I can remember seeing the big guppy opening up front. I assume that's what gave me a slight advantage. And it was slight - but you could almost hear the expression on his face when I said I'd throttle back so he could keep up. Maybe this spring after the engine finds its stride, we can meet up for a speed test and the loser (probably me) buys lunch. That'll give me time to wax the leading edges and figure out a way to cheat (Note to self: consult with the Road Runner). You've mentioned a restaurant at Eufaula (KEUF), or there's a few places up here we can hit. I've heard that Bessemer (KEKY) has a pretty good restaurant, but haven't tried it.

-

Another proud G owner here. I've actually made several trips with myself, wife and 2 of her sisters - all of us 6' tall. I explain to them that they can share a hair dryer between them, etc. and that if we're overweight when we get to the hangar, that I have sole discretion of what clothes will go and what will stay. I'm bluffing of course, but it gets the point across. I took a friend flying in it, and he caught the Mooney bug. He ended up with a C model with a nice panel, fairly fresh engine, and 3 blade prop. He was really surprised when we flew side by side for the first time - he couldn't keep up with me! He blamed his 3 blade prop, and I blamed my speed mods.

-

Good things to ponder. I haven't personally checked the prop control travel since I know he has to adjust it anyway. Don't know if he used an optical tach (I wasn't around his shop when he did the annual/engine removal and install), but he installed an EDM900 in the process. The factory tach (newly replaced about 10 years/1000 hrs ago) is still in the panel and both it and the EDM tach agree on the RPM's. I'll look into the possibility of an induction leak, but the engine runs very smooth at all RPM's, including low RPM's. It just likes to land with about 450 more RPM's at idle than it takes off with, and never produces more than 2600 RPM's at full power on the takeoff roll, and after wheels up it rarely hits more than about 2550 even though MP will hit about 28. Not sure the 2600 RPM limit and the additional idle RPM's at landing are even related. My long-time friend and IA passed away this year and this is the first time in many years that someone different turned a wrench on the Mooney, so my "go to" expert isn't around to coach me. The new IA has some pretty large shoes to fill, and he's only about 5' 8".

-

Which brings us to the ultimate crosswind solution - Circular Runways! https://www.internationalairportreview.com/article/33509/circular-runways-exclusive/

-

I'll double-check those the next time I'm out there. I mentioned the governor mainly it definitely needs adjusting to get to 2700rpm. Throttle cable does hit both stops. Gear horn sounds at about half throttle but that's just a simple adjustment under the panel, I can't imagine it's connected to any of the other issues. I'll also shut down the engine and check that the throttle cable is making it all the way to the idle stop next time I can't get it below 1,000rpm.

-

What he's saying is that IF there was a perpendicular taxiway/tarmac of any length, it could be used to land directly into the wind. Assuming all caveats are met for obstacle clearance, experience, etc., it might be the best option. ATC can even approve such actions at controlled fields at their discretion if asked, but would never "offer" it.

-

Just had Penn Yan rebuild my O-360A1D on an M20G. Also had an EDM900 installed. Still working through some engine/install squawks, but this particular one puzzles me. The engine seems to run great and fires up in a blade or two on a cold start (SoS). Engine will idle smoothly at about 750-800 RPM. Taxi out and runup are typical - idle check is still 750-800. After about 25 hours the break-in seems to be typical of what I was told to expect. The puzzler is that on approach and landing, especially in the flare, it becomes evident that pulling back to "idle" still gets me about 1200 RPM, leading to a long, LONG float before touch down. Tonight it would NOT go below about 1200 even after roll out, and the slightly uphill taxi was at about 12kts without braking. Possibly related is that the prop governor only allows about 2575 RPM both static and during takeoff roll. Scheduled to go back to the shop next week, but curious to know why the idle RPM changes. Also possibly related, I've told the IA that the prop cable seems to be harder to pull/push than before, but he checked it and said it's fine. I've checked it visually and the cable doesn't appear to be binding/have too tight turns (per the IA). Any ideas?

-

As Hank mentioned above, I bought and installed the same blue O-rings (2 big uns, 2 lil'uns) 2 years ago and and they're a winner. Don't have the link on me, but maybe someone does. I like supporting MS'ers who are helping us maintain our aging fleet.

-

My Statesman is featured in the very first post, several ad's down. N6776N. Nice to see it in its original paint scheme. It looks a little different now paint-wise, but in the same colors.

-

Yes, I understand. The underwriter might quote the same price to each agent, but as I experienced just recently the quote itself can be wildly different by the time it gets to me. After all, you don't expect Assured to pay the kickback out of their own pocket, do you?

-

Then they shouldn't send me unsolicited emails asking for my business. They should solicit my agent instead; I'm just playing by the rules they present to me. BTW, I didn't "ask the same underwriter...", I requested a quote from AOPA's agent. Whatever backstabbing they do behind the scenes is up to them, but in this case they only shot themselves in the foot once again. A few years ago I spoke with the AOPA agent on the phone and he asked me what I was currently paying. I told him, and he admitted up front that there's no way he could "even get close". I thanked him for his honesty and told my agent what he said. I've had my current agent for many years, and every year he gives me a few options and tells me which pays claims faster, which he'd avoid, who's going under, who bought who, etc. He's never steered me wrong and AOPA (or Assured Partners or whoever is AOPA's flavor-of-the-year) is the only other company I've contacted for a competing quote, and only out of stubborn loyalty to the old AOPA I knew. It's a comforting feeling to know that my agent has my back, and I let him know what other quotes I've gotten. I think it keeps us both honest.

-

While I'm still a few years from the age mentioned, I have a comment about AOPA's insurance offerings. I've been an AOPA member for about 20ish years and just about every year I give them the opportunity to give me an insurance quote (IFR, clean driving and flying record with no incidents, actions or infractions). Without fail, they're the highest. This year, my current insurer went up about 30% to renew. AOPA provided a quote that was up 50%, and ironically it was with the same insurance company. Thankfully my independent agent shopped me around and gave me an option that was only about 10% higher. My disappointment in AOPA's consistently higher offerings has made me seriously question my commitment to an organization that, per similar opinions around the FBO, has forgotten who they represent. I would hate to know that AOPA was my only hope when it comes to obtaining insurance (at any age).