-

Posts

794 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Z W

-

For instrument approaches, I set power at the top of descent to 20" MP (below this is where my gear warning comes on), 2500 RPM. This allows descent into the approach without picking up too much speed. I leave the power set there, sometimes reducing it back down to 20 if required, until the final approach fix. You should stabilize in level flight around 120 KIAS at this setting in a clean configuration, and the plane flies holds and turns very crisply. I leave the gear and flaps up until the final approach fix / glideslope intercept. Gear comes down at one dot below glideslope, which will naturally slow you to about 100 KIAS without changing your pitch much. Reduce power to 16-18" MP, depending on the amount of your headwind, which will give you about a 500 FPM descent. Once the speed drops into the white arc, I like to add takeoff flaps too. Trim to maintain 100 KIAS hands-off, adjust throttle to hold glideslope. Or, if you're flying a coupled approach, let the autopilot control the pitch for the glideslope, and you adjust the throttle for 100 KIAS. The plane is very happy at 100 KIAS down the ILS/LPV glideslope and it's easy to hold the needles. If you're ready to rapidly reduce power when you break out, it's not a problem to land, although to be honest, I don't fly actual low approaches on purpose. You can fly the glideslope slower, say 90 or even 85, but I don't like it as much due to reduced control authority, especially if it's gusty, and it leaves you banging around in the soup at a high angle of attack. For a very low approach to a short runway, though, you might want to do that to make it easier to land. You can fly the ILS faster, at 120 KIAS+ with the gear and flaps up, and once you break out, pop the speed brakes (if equipped), drop the gear, chop the throttle, and land, as Don Kaye likes to describe in his Bravo, but I don't often go to airports where that is required. The plane is very versatile and and can do a wide range of speeds with practice. With cowl flaps set for mostly closed at the top of descent, I do not have CHT problems.

-

Just started flying a k model… Is the juice worth the squeeze??

Z W replied to Alan Fox's topic in Modern Mooney Discussion

Full power, full rich, cowl flaps open in the climb to final cruising altitude will get you lowest temps, best speed, and best overall economy. If you're going high and the air is warm outside, sometimes you do have to level off in the teens for a couple minutes to cool the engine down before continuing your climb. Balancing RPM, MAP, CHT's, TIT, fuel flow, and cowl flaps is an art once you're in cruise. Some days you can do better than others. There is a wide range of settings available to optimize speed, efficiency, and temperatures, each of which is a tradeoff against the others. Most here seem to agree that keeping the CHTs under 380 and the TIT under 1625 (some say 1600) will result in longer engine life. The POH says as long as you're under redlines you're fine. -

Nice improvement with the LED, I should do that too. The 1982-vintage plastic covering our gear indicator light had gotten cloudy, scratched up, and faded, like yours is a bit. It was getting hard to read the indicator during the day, although you could tell if it was red or green under there. I spent 2 minutes polishing it with some polishing compound and a damp cloth and it cleared right up. Might help also.

-

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

Thanks for the additional ideas. Plane is still down. New A&P has ordered and received the gauges required to perform the new fuel pump set up procedure. They did not come with the proper T's or some other parts required to perform the set up, so those are now on order and supposed to arrive this week. If getting it properly set up does not solve the problem, we will look at the injectors again, and the fuel spider. -

Part of my training was to avoid major configuration changes made blind. Dropping the gear and/or flaps would seem like a good plan, especially to keep you from overspeeding the aircraft, but it's hard to imagine a faster way to disorient yourself and maybe put the plane into an unusual attitude. It might take a lot of discipline not to grab the controls while the plane settles into a descent after doing all that, even though I think it should eventually. Maybe I should go try it that way under the hood sometime and see. I also heard that when spins were a mandatory part of the curriculum, they were taught as a method to descend through a cloud layer in a stable maneuver. Initiate and establish the spin above the deck, recover below it. Probably part of why they killed so many pilots in training. Definitely not a Mooney option.

-

My instrument CFI suggested that if you ever had a dual electric and vacuum failure in the clouds, assuming you were trimmed hands-off prior to that, to take your hands off the controls, reduce power for descent, adjust airspeed with the trim wheel only (some nose up will be required once it settles into the descent), and hold your compass heading +/- 10 degrees with light pressure on the rudders. Then ignore what your senses are telling you and hope you have enough room to maneuver when you come out of the clouds. The idea is that a properly rigged, certified aircraft is stable in flight. It will settle at a speed within the green arc and descend more or less wings-level. It will not stall itself even at max nose up trim, nor roll over inverted. A disoriented pilot yanking on the controls without instruments is more dangerous than an uncontrolled aircraft. It should exit IMC in a controllable attitude and airspeed and enable you to regain visual navigation. We demonstrated this a few times in VMC. It does appear to work, at least in smooth air. The plane will wander and hunt a bit, both in pitch and roll, but descend in a stable fashion on a heading. It works less well with an iPad or other device mounted on the yoke, which is part of the reason I no longer fly with anything mounted there. This was before battery-powered backup devices like the G5 existed. They are probably a far better plan. But I've always considered the above to be a final option. I suppose it would be harder now that we no longer have a separate altimeter or VSI in the panel.

-

Should be something like: Cruise Climb: 32" MP 2500 RPM full rich (if you use this, many just do full power climbs to altitude, myself included) Best speed cruise: 28" MP 2500 RPM, lean to peak TIT about 11.5-12GPH or 13.5 GPH ROP Economy cruise: 26" MP 2400 RPM, lean to peak TIT or leaner, 10ish GPH Descent: slowly reduce power to 20" MP, 2300 RPM, cowl flaps closed to maintain CHTs. Hold until gear down. Will also give you 100KIAS for approaches in level flight. Gear down / pattern: 16" MAP should give you +/- 500 FPM descent at pattern speeds

-

I noticed a big increase in the requirement for nose-up trim moving from a C model to the K, and an equal increase in the abrupt pitch-up of the nose during a go-around. It was maybe the most difficult part of transitioning, although it's not that difficult. I do not know if it's the larger engine with 30 extra horsepower, the increase in fuselage length, or a combination of the two. Never flown an F to compare, though I'd like to someday. Cheers.

-

The K model needs a lot of nose-up trim to counter-act the flaps and maintain approach speeds of 80 knots to short final, slowing further to 75 knots "over the fence" or when the runway is made. I find it often requires moving the trim to 3/4 towards full "nose up". I've read on Mooneyspace that each K model is different in this aspect. If you don't trim it that way, you can still land smoothly, but it requires a lot of force pulling back on the yoke, especially when you reduce power to idle. It also becomes almost impossible, in my experience, to keep the nose wheel up for any appreciable amount of time after the mains touch down. Even with lots of nose-up trim, it likes to land flat. I personally try to carry 80 knots until very short final, what I was taught to call "over the fence," to maintain better control authority for wind gusts. Then I smoothly reduce power to idle while raising the nose, and sometimes adding more nose-up trim, to try to hit 75 knots. If you're light you can shoot for between 70 and 75. If you're heavy, it actually does pretty good shooting for between 75 and 80. From there, I quit looking at the airspeed indicator and fly the plane to the ground, usually. In high wind or gusty conditions I might need to add in a little bit of power but not for too long or you'll float. Full flaps helps every aspect of landing. I only use partial flaps in very strong crosswinds, and frankly, have wondered from time to time if it even really helps then. Just be aware that if you build the habit of lots of nose-up trim for smoother landings, when you do a go-around, the tendency of the plane to pitch up violently can catch you by surprise. It should be practiced. You want to be hitting the nose-down trim button as you push in the throttle, and maybe even pause at less than full power (say 32" or so) until your trim catches up, while you also raise the flaps. This all happens very fast but if you just firewall the throttle you may be fighting the yoke with both hands to keep the nose down. I do not believe it would cause a departure stall but you'll definitely scare your passengers. For this same reason, I fly instrument approaches with only half flaps until visual contact with the runway. If that requires a half-flap landing then I'll accept that rather than do a go-around with full flaps in IMC.

-

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

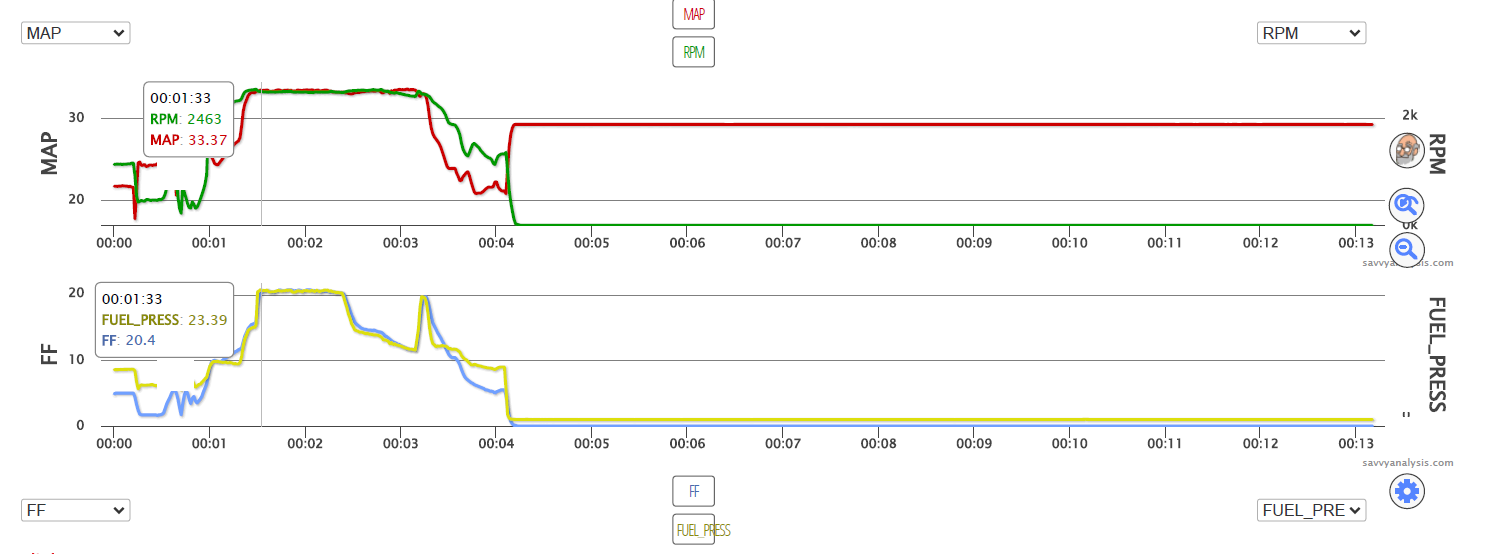

Well, I'd be happy to send a Savvy sharing link to anyone who wants one in a PM to help diagnose. As far as I can tell the link is an all-or-nothing, meaning it lets any clicker access our entire uploaded flight history of 478+ flights and never expires until I revoke it, so I don't really want that up on this public forum. Below is the graph from yesterday's runup without the popup blocking any part of the chart. I do not know where it's getting the "FUEL_PRESS" data from. At this point I've determined the new fuel pump was put on without following the engine setup process specified for it in the manual. Thanks at least in part to Mooneyspace I know the A&P now has the manual on that along with SID97-3G. That work needs to be done no matter what so I think we're going to let that happen and see how the engine runs after that. Still open to other suggestions or ideas. Thanks so much for all the help. -

Our KAP150 started doing something similar, at least, the immediate hard bank to the right when engaged. The avionics shop said shipping the computer off to a specialist shop was the only option, with fixes starting at $2500+ (probably would be more in today's dollars, this was probably 3 years ago). Put the money towards a GFC500 install instead and have been very happy with the choice. The KAP150 is a really capable and neat autopilot until it breaks. Then the costs quickly make it hard to justify. The GFC500 is just a completely different class of equipment. Hope your experience is different and it's just a setting somewhere.

-

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

I do not see any further instructions in the 262 STC that we have. Another good idea though. -

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

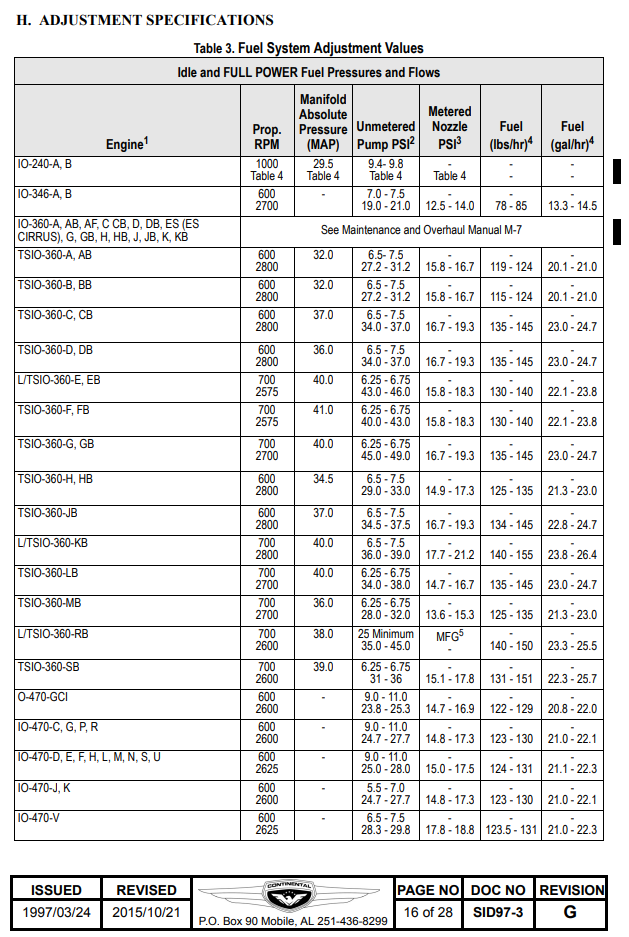

Cool. I assume you mean the parameters below? (screenshots work well). I've sent that document to the A&P. I do not understand the relationship between RPM, MAP, and FF, to be 100% honest. I'm pretty handy with cars and boats but know very little about airplane engines. Trying to learn. Thanks again. -

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

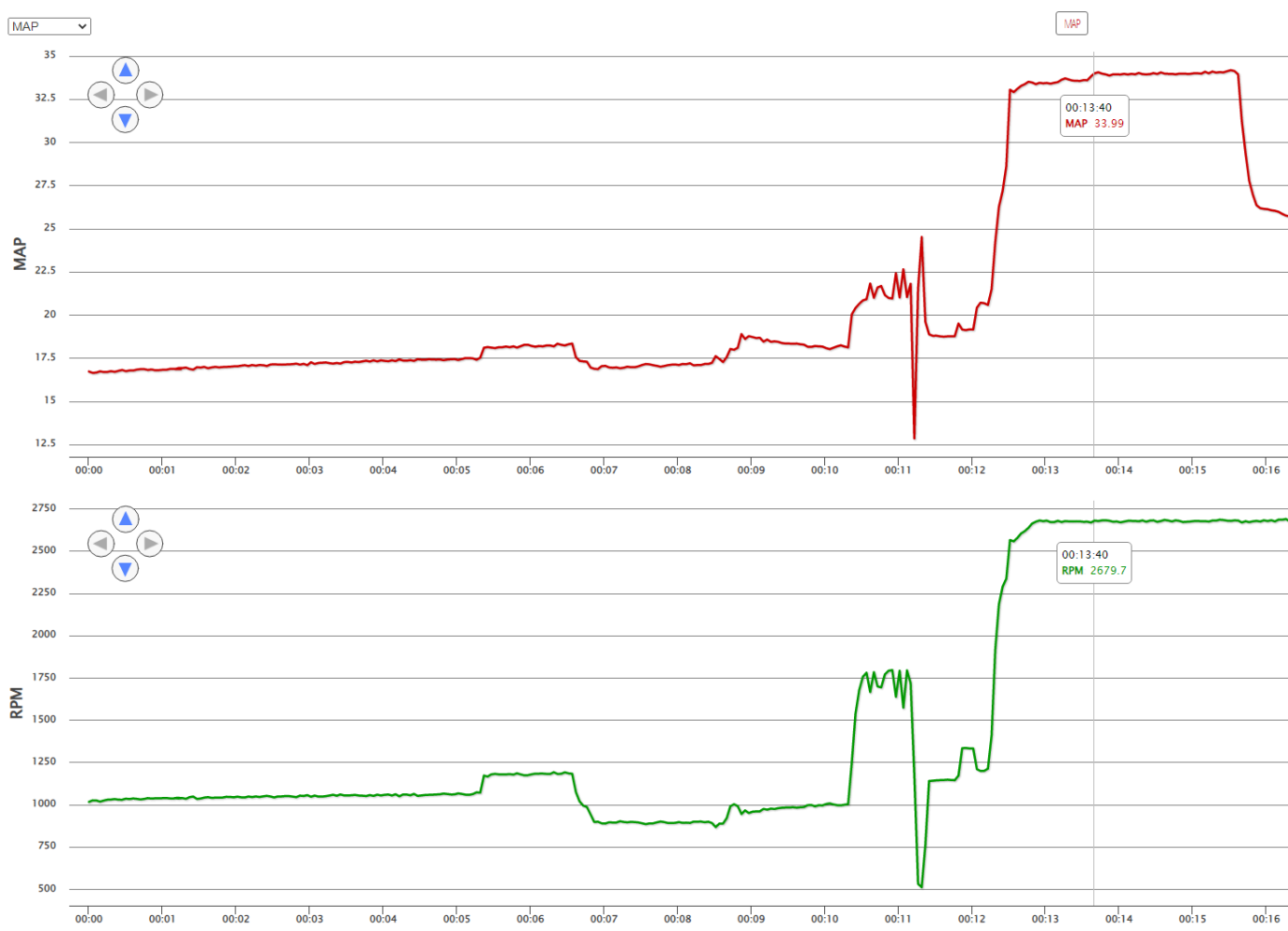

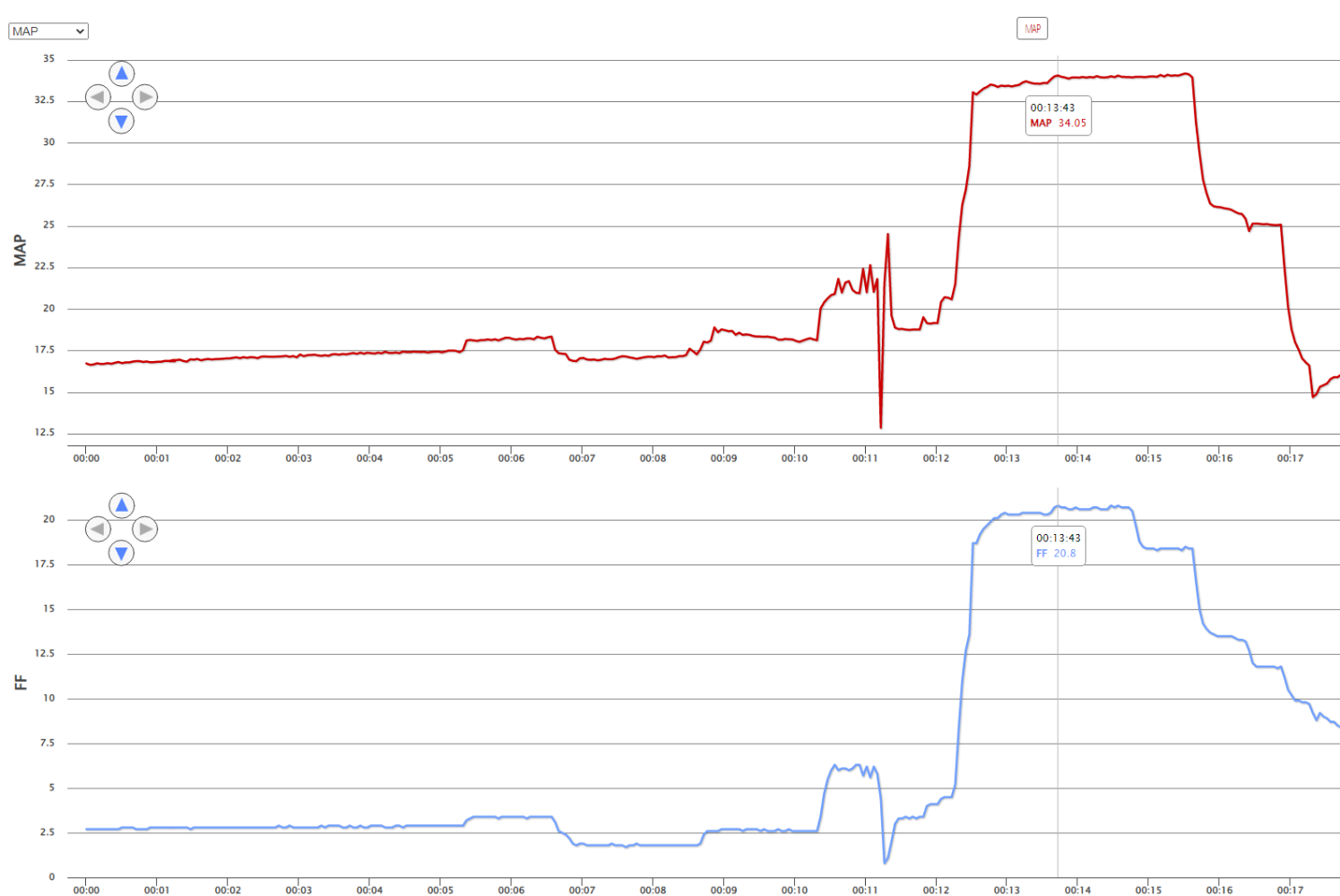

Today's test run data below. Thanks to some of the advice above, I was able to locate the Engine Setup Procedure part of the factory service manual with details on how to set up the fuel pump and send it off to the new A&P. He's going to work through that. They also put some mousemilk on the wastegate and suspect that could be the next possible culprit. Thanks for all of the help and tips, and keep them coming. -

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

2700 is redline RPM. The first report I had of RPM trouble was verbally on the phone yesterday when he said it would only do 2500 RPM and 32" MAP with the newly-installed and newly-adjusted fuel pump. I have not been by to verify myself yet. Previously it was doing 2700 RPM but only 34" MAP. Thanks for all the thoughts and input, it is very helpful. I was thinking it had to be a turbo/wastegate issue but now you've got me back on the idea that it could be fuel contamination or blockage. Supposedly all screens were checked from the tanks to the cylinders before we replaced the fuel pump (which we could not find any record of ever having been repaired or replaced in the logs). I'm going to make sure it is flowing 25+ GPH on the fuel flow gauge. We did check the #3 injector before replacing the cylinder. Lean condition was my first thought as well but when it checked out OK we just replaced it. This is a higher-time and, until now, strong running motor that has served us well. -

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

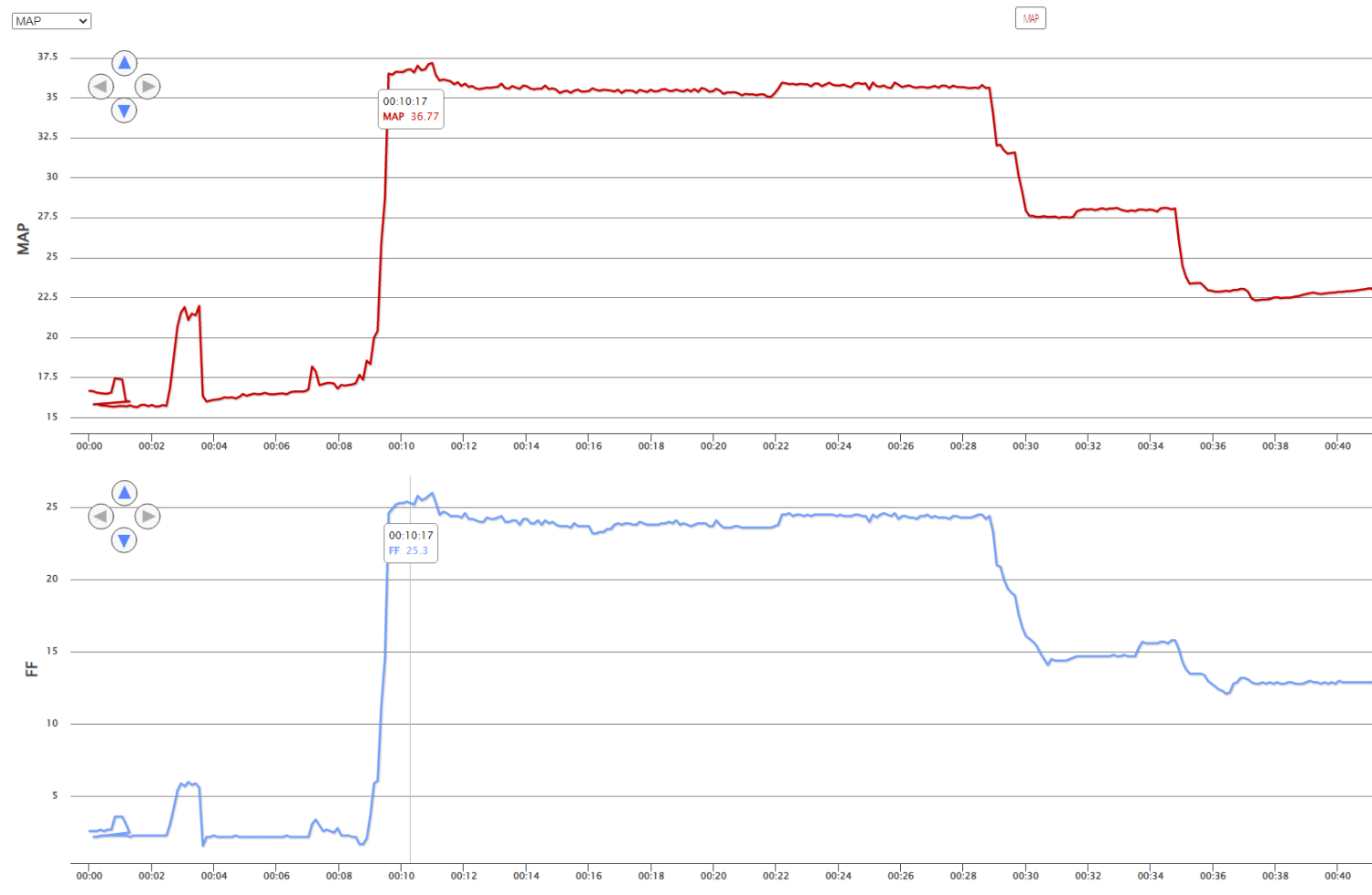

Last "normal" flight before the cylinder replacement work when all this started. Shows MAP at the proper 36" and fuel flows around 25 GPH: -

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

-

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

Thank you for the suggestions on the fuel pump setup. Will look into that. We have a G500Txi with engine logging and a Savvy account. I can post whatever might be helpful. The first A&P who did the annual had all the proper Continental books/tools and seemed to know what he was doing. His departure in the middle of the problem has made things challenging. Apparently several planes were left in various states of stuck on the ground, ours being one of them. We were confused why everything was taking so long and nobody was responding, then found out he was leaving. New A&P is walking into a bit of a mess and has his hands full. Shop owner is great and responsive, not mad about anything, just hoping to find some help here to get our bird back in the air. Most recent log of MAP/FF demonstrating the problem. This was before the fuel pump was replaced: -

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

Injectors were checked with the fuel lines. All supposed to be OK. Good thought though. -

Hello friends, I could use some help from the braintrust. Plane has been in the shop essentially since annual in June. 1982 M20K 231 with the "262" conversion, so a TSIO-360-MB1 engine with fully automatic wastegate. Facts go like this: Plane goes into annual operating fine. Two cylinders (#3 and #5) showed low compressions. A&P recommended and we tried lapping the valves in place. Also did some tank re-sealing work. Annual completed and signed off. Valve lapping worked on the #5 cylinder, but first flights post-annual had abnormally high CHT's in the #3 cylinder. Could not keep it under 400 degrees at climb power, and the engine started to run rough as soon as we leaned it off of full rich. CHTs did decrease with reduced power. Other than those issues plane ran normally. Ordered a new #3 cylinder. After installation, CHTs were nice and cool and even. However, the engine will no longer make max power. It should produce 36" of MAP. Instead, it produced only 34" MAP on the first test flight. I did not notice that until I was already flying (shame on me), but came back around and landed no problem. Otherwise the plane ran normal. Since then the shop has been chasing this problem. Hooked up a shop vac to the intake to look for intake manifold leaks. Found some, replaced all old hoses, no change in MAP. Suspected fuel line contamination from the tank reseal job. Checked all lines, supposedly clear. Checked fuel pump. I was told it was not making proper pressures or flows. Just got a new one. The IA/A&P running this small shop left recently. We now have a new IA in charge. They are struggling with this. They put the new fuel pump on and supposedly it's set for pressures and flows (have not been down to double-check). He says today it will only make 2500 RPM and 32" MAP during runup. He said we probably need to go fly it to see if the engine makes full power while moving. I told him this engine always makes full power standing on the brakes. In fact, it will sometimes overboost to 38" or so MAP, then the wastegate will open and it settles at 36". He was going to go try a high-speed taxi test this afternoon to see if it will make full power on the runway. I do not think it will. What else should we check? Plane has been down for four months at this point. Would appreciate any ideas as to how a changed cylinder can result in loss of MAP. I suspect something else was removed and reinstalled incorrectly but don't know where to look. Thanks in advance.

-

Dealership soapbox rant. Non-aviation. Motorcycle

Z W replied to Mcstealth's topic in Miscellaneous Aviation Talk

Yeah I would buy low-octane ethanol-free gas if anyone sold it around here. Premium is just the only option without ethanol near me. -

Dealership soapbox rant. Non-aviation. Motorcycle

Z W replied to Mcstealth's topic in Miscellaneous Aviation Talk

I buy ethanol-free premium gas and add fuel stabilizer to it for everything that doesn't run every day. Boat, jet ski, snow blower, chainsaws, old jeep. Necessary these days and way cheaper than replacing fuel system parts. The ethanol-flavored stuff is sold with the idea that it will be used shortly after sale and can turn to green goo in carburetors and other fuel systems if it's not. Fuel lines and other components manufactured prior to somewhere around the year 2000 may not even be compatible with ethanol and can dissolve. In a 2004 bike I doubt you'll have that problem though. 100LL works too by the way. No stabilizer required. Supposedly can lead to lead deposits on your plugs and in small engines but I've never seen it. -

Our K was very out-of-rig when we got it. Would drop a wing pretty badly to the right when you released the yoke. Handled poorly in slow flight, requiring big corrections. Yaw was a half-ball to the left in level cruise. Had it re-done by a Mooney specialist shop in Florida. They fixed the rigging on the gear doors, flaps, and ailerons. Now it flies beautifully hands-off, ball centered, no wing drop and nice and solid in slow flight. I'm told this job requires special rigging boards not found in most shops. There are other threads on it here. After that, we gained maybe 1-2 knots in cruise, if any. Worth it but not for the speed gain. I would check (and share here) your power settings. You're missing 10-15 knots somewhere, and I would find it hard to believe it's your rigging or prop. At 10k MSL, 28" MP, 2500 RPM, and 13.5 GPH, I see about 165 KTAS. If you're using similar settings, I would suspect your pitot-static system or airspeed indicator gauge. The old analog gauges are notorious for being inaccurate. Easy to check that with a 3-way GPS speed check (fly three different headings opposite more or less from each other at the same altitude and power settings, record your speed once the plane settles in, then calculate the average of the three to remove the wind factor). We gained 5kts of indicated airspeed moving from an old analogue ASI to a digital panel. Groundspeed stayed the same though, unfortunately. I've never read anything to make me want to switch from our Hartzell aluminum 2-blade prop. Good luck.

-

This thread is full of inaccurate statements about the law and some not-so-good advice. Source: I am an aviation and business lawyer, but not your lawyer. You should talk to a lawyer and likely a CPA of your own before proceeding in this fashion. Anyone considering a similar plan should do the same. The laws on sales tax, use tax, and piercing the corporate veil vary greatly from state to state. You cannot just Google this, or read about it on an internet forum. You get just enough half-truths to be dangerous, mixed in with a lot of inaccurate information. I'll give some big picture information below, but do not consider this as advice for your situation, because it is not. Purchasing someone's stock has implications for taxes. First, you inherit the company's depreciation schedule. If the plane is already 50% or 100% depreciated, you do not get the benefit of that for your purchase price, if you would otherwise be able to depreciate the aircraft. Second, it effects your tax basis, and that of the seller. They generally will pay capital gains (or losses) based on their basis in the stock compared to your purchase price, which is the lowest and best tax rate. A stock purchase favors the seller and punishes the buyer, tax-wise. If you sell the plane later, your corporation may have to re-pay some of the depreciation benefits the previous owner enjoyed and used to offset his or her income. So, you may pay $150k for the company, for example, and sell the plane (its sole asset) for the same $150k some years later, where you actually have no gain, but since the company previously fully depreciated the asset, you must repay some or all of that depreciation, and you owe taxes on the transaction to repay the depreciation the former owner enjoyed. On the plus side, purchasing stock is typically treated as the purchase of a security and is not taxable under sales or use tax, which applies to the purchase of assets. Your individual state laws may vary. Your company will however still have its liabilities. Unpaid maintenance bill for that last $10k annual? The company owes it, and now you own the company. A small risk in the context of a single airplane, but one to be considered. Piercing the corporate veil is usually much harder than people make it out to be, but again, it varies greatly from state to state. You never know what state you might crash in. It might help for claims of negligent maintenance or entrustment (letting someone unqualified fly the plane). Corporate structuring does little to help you if you are the one operating at the time of the crash. Corporate structuring does have additional benefits, the primary factor for most people who use it being privacy. It is also has useful features for shared ownership and use, including the ability to use a buy-sell agreement. No attorney I know sets up a C corporation these days unless it's intended to be publicly traded or otherwise does not qualify to be structured as an LLC or S-corporation. Seeing a closely-held C corporation is a big red flag that someone has been doing their own legal work and may have really screwed something up. If you don't know the difference between those three types of entities, you really should reconsider setting anything up yourself. This "buy the stock" technique to avoid the sales or use tax is not often used, in my experience, with people buying and selling turbine aircraft, where they could easily afford the attorney and tax consultant fees to do it right. I really only see the idea put out there by people trading piston singles and doing the legal work themselves. I believe it's because the lost depreciation quickly offsets the ability to avoid sales/use tax, and you're buying unknown liabilities. If the big players aren't using this "tax loophole" you can be sure there's a reason. Take all of the above for what it's worth, which may be less than you paid for it. Good luck with your purchase and welcome to Mooney ownership.