-

Posts

470 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Mooney_Allegro

-

I've been using both Blackstone and AvLab for years. I've had two samples that the post office completely lost, even though they were tracked. I'll never use the post office again with the samples. I've been using FedEx 2-day air and I get the Blackstone report emailed back normally just a few days after they receive it and AvLab takes a few days longer for some reason.

-

G1000 Magnetic Variation Update 2020 version

Mooney_Allegro replied to Aspen2013's topic in Modern Mooney Discussion

I updated my G1000 a few weeks ago. It was frustrating, because mine wouldn't update until after Garmin came out with the second Service Bulletin and I had to order the 2GB Sandisk card from Amazon. The 16GB I bought at Target wouldn't work, even though one of the Garmin techs thought it might work and recommended it. I did have to "right click" and choose the "reformat to FAT 32" with the new 2GB card. The formatting didn't take long. The final update to the G1000 took about 3 minutes. The frustrating part was that the different Garmin reps I spoke with recommended trying different things, but none of their recommendations worked until the final SB came out. -

I used AirFleet Capital for my financing back in 2016. They're based in Chandler, AZ I believe and have various locations. The contact name is Jim Blessing. Their number is 800-390-4324. At first I applied with AOPA financing and was rejected despite spending days on their application process. I wasn't happy with AOPA Financing one bit! My credit was perfect, with no outstanding loans. I applied with AirFleet Capital and my loan was approved within days. AirFleet was a seamless process and I'd definitely use them again for any future loans. Everyone was super nice at AirFleet. Jim is an aircraft owner and often attends all of the aviation trade shows. They would be my number one choice in the future. My interest rate back in 2016 was 4.39%. I have no idea what it would be now.

-

Oil Change frequency for turbocharged Mooney

Mooney_Allegro replied to Richard Knapp's topic in General Mooney Talk

Oil changes for the plane are between 25-30 hours and no more than 4 months time. I've been using Phillips 66 X/C 20W50 with Camguard. I cut open the filter at every oil change and if I have any questions with the filter, I send the filter element to ALS Tribology in Phoenix for analysis. I use to use Howard Fenton in Tulsa (recommended by Blackstone), but Howard died unfortunately. For the oil analysis, I send samples to both AvLab and Blackstone. Yes, it's overkill, but I like the comments by Blackstone. I don't use the US Postal Service any longer for oil samples, as the postal service has lost two of my samples, the most recent late last year. This was with a tracking number. Instead, I use FedEx 2 or 3 day air and it always gets there. The engine burns about 1 qt. in 10-12 hours roughly and the oil analysis results have been good. Everything has been in the green. Hopefully it will stay that way. My oil does get black fairly quickly, but so did my previous 1998 J model. I do unscrew my oil cap & pull it out slightly after I'm finished flying to vent as much vapor as possible. By the time I'm done cleaning all the bugs off (20 min.), I screw the cap back on. I've read that this practice may help with corrosion prevention (limit moisture), but I don't know for sure. -

Electric Mid-Continent Attitude Indicator, removed from a 2015 Mooney Acclaim Type S. It has about 700 hours and was removed to install an L3 ESI-500. Works perfectly, but has no paperwork with it. The stats are below: MFG PN: 4300-313 Serial Number: J15-10554 Rating: 10-32 VDC, 1.5A MAX Weight: 2.7 LBS Panel Tilt: 0 degrees Lighting: 28V B/W (Blue/White Lights) MOD: 5,6,7,8,9 Cost Comparison: A new one would cost $3,100 and an overhauled unit would be $2,000 Price: $500 including shipping within the Continental USA via FedEx Air. Dave 770-365-6464

-

I just paid $2.55/gallon for 100LL on Wednesday 4/22/20 at Texas Gulf Coast Regional (KLBX), and $2.60 same day at Williston Airport, Florida (X60). Amazing prices!

-

Hangar available Atlanta metro

Mooney_Allegro replied to Mooneyn201tm's topic in General Mooney Talk

Check hangar space at KLZU. I've had a hangar there on and off over the years and my experience is that they always have space available. Aero Industries 770-980-0808. There's a different company on the southside of the airport (Air Harbor), but they are a lot more expensive (newer hangars). I don't know how current this info is, but this is what I remember. -

Free Savvy Breakdown Assistance during the Pandemic

Mooney_Allegro replied to kortopates's topic in General Mooney Talk

Thanks Paul! I signed up for the service last night. Also, thanks for helping me with my Savvy engine analysis in the past. -

Dan, I don't mount the O2D2, but just lay it on the backseat if I have two people up front. If I'm by myself, I lay it next to me on the co-pilot seat. I have the same issues with the tubing. It sometimes gets tangled up especially with the headsets, iPad charging cord etc. -Dave

-

Maintenance, annual, best shops?

Mooney_Allegro replied to Mitch Morris's topic in General Mooney Talk

Highly recommend Henry Weber Aircraft, Lancaster, PA (MSC). It's worth the flight. -

blakealbers, I use the Mountain High ALPS face mask 18,000' and above and the cannulas below 18,000'. The masks are used with the Mountain High O2D2 Pulse-Demand Oxygen system that has an audible alarm and blinking red lights in the event of oxygen loss. I regularly use a pulse oximeter to check blood oxygen levels and pulse. As backup, I have a Precise Flight portable oxygen tank all set up with masks and ready to go IMMEDIATELY in the event there's an issue with the ship's oxygen. There's been at least one Acclaim crash due to inadequate maintenance on the oxygen system while flying at FL250 and a second close call in an Acclaim just out of maintenance. Luckily the second Acclaim pilot recognized hypoxia and took immediate action by descending. When I first took delivery of the O2D2 system, on a flight to Sun 'n Fun, the main oxygen supply line on the O2D2 blew off at FL250. After a few seconds, I heard the alarm, and reattached the O2 line. I had to hold it in place most of the flight. After I got on the ground, I called Mountain High to complain. They immediately sent me a different oxygen line that stayed in place. Why they sent me a line that slid out so easily I do not know. On long flights, I try to take a second pilot with me to help prevent fatique. Flying pilot, and pilot monitoring (works radios etc.) After the fuel stop, we switch duties. I recommend having contingency plans for loss of O2, frequently checking your oxygen levels, know your hypoxia symptoms, and know how your oxygen system works. It's always a great idea to check your oxygen connections in the tail if that's where your tank is to be sure maintenance hooked everything up properly after servicing. Test it on the ground before you start. Make sure everything works. I also put the face mask on while on the ground. It's too difficult to put it on in the air. (might miss radio call when taking off headset). Flying at high altitude allows you to get above most of the weather into smoother air, allows you to operate above the icing (in my experiences), and your true airspeed is much higher. It's also nice to take advantage of a nice tailwind. I had a groundspeed of 355 knots over two years ago from Las Vegas to Atlanta. The Mooney is an amazing machine! P.S. As far as comfort, the key is to not strap the mask on too tightly. I keep mine just a tad loose, otherwise I'll get a headache on a long flight. The other issue is to wear earplugs along with your noise cancelling headset. Why? Because using the mask creates a slight gap between your headset with the headstrap, along with your sunglasses, so the earplugs compensate for this and allows you to quiet things down like normal. You just have to turn your radio volume up so you can hear ATC and your co-pilot. I don't use earplugs with the cannula or below oxygen levels.

-

I guess 500 hour magneto inspections are important...

Mooney_Allegro replied to ragedracer1977's topic in General Mooney Talk

A word to the wise: Make sure your service center times the mags correctly and installs them correctly. My MSC did NOT time my mags correctly at the 500-hour mag check back in Sept. 2018. They mistimed both mags by 8 degrees and installed the mags incorrectly. I flew around for over a year with misfires at high altitude and I couldn't run lean-of-peak anymore after my 500-hour check. Plus both turbos were hotter than normal for well over a year. About three hours after my 500-hr mag inspection, after I complained, I took the plane back to the MSC and they checked everything and said all was well. After well over a year, I was so disgusted with my engine, that I flew down to Fairhope, AL in October to Continental, and they discovered the issues. Mags mis-timed by 8 degrees and the mags were installed canted to the left instead of towards each other. After Continental made the proper corrections, I can now run lean-of-peak and no more misfires at FL250. The mechanic at Continental, who was excellent (Doug Burdick) advised me that they correct A LOT of mechanic's mistakes all across the USA. I highly recommend Continental in Fairhope for engine issues. They know what they're doing. -

Can someone post the new article today (12/03/2019) from the Kerrville Daily Times? I'm not a subscriber to the newspaper. This is the "teaser"...... Mooney Aircraft employees return to work, face uncertain future Sean Batura | sean.batura@dailytimes.com Dec 3, 2019 Updated 5 hrs ago After more than two weeks of furlough, Mooney Aircraft’s workers were back on the job Monday, but their future remains hazy. A statement by Mooney’s Devan Burns, listed as a human resources generalist, said the furlough is over, and said the oft-troubled company was in negotiations with another investor. Just who that investor is remains unclear, as does much with Mooney.

-

@curusoam, First off, thanks for your comments. I have a bit more information to add to the mix. The plane has a G1000 with a datacard to record aircraft engine parameters. I'm a Savvy subscriber for over a year now, so they have the downloaded info, and I was able to find it. My fuel flow for most of the affected flight was under 18 gph. At about 45 minutes prior to landing, the FF spiked up to 35 gph for 5 minutes, then returned to normal. This must have been when the G1000 "range-ring" showed I had about 5 minutes of fuel. I checked my engine logbook after the leak was fixed last October, and the corrective action was, "Tightened fuel line on fuel transducer, leak check good". It was a five minute fix.

-

Thanks Mike. I'm really glad to hear that it didn't come out of the factory like this. I just had flashbacks from Richard's crash and now this new crash in AZ, so it's been making me think a bit more about maintenance practices. That fitting was never something I ever thought about until last October. At the various maintenance facilities I've been to in the last 4 years, it's a constant theme from management....."we are having a hard time getting qualified people, and the experienced people are retiring". It's putting me on pins and needles everytime I take my plane in for an annual. There's been too many issues I've seen on my plane where things have not been put back correctly, and by chance, nothing bad has happened. Thanks for your concern.

-

Perfect, thanks for the suggestion and photo. I've seen torque paint on I believe the major oil fittings. Is torque paint on all the fuel and oil fittings? Is that standard? If I remember correctly, sometimes I've seen cracks on some of the torque paint. I'll have to recheck the engine and look for that.

-

The mechanic who discovered the fitting was loose didn't re-torque the fitting, he just tightened it with a wrench. I apologize for saying the torque needed to be checked at every annual. I wish I had the experience to know what is right and wrong when looking at an engine. I'm not a mechanic. The only thing I'm competent to do on an engine is an oil change and check for leaks/chaffing.

-

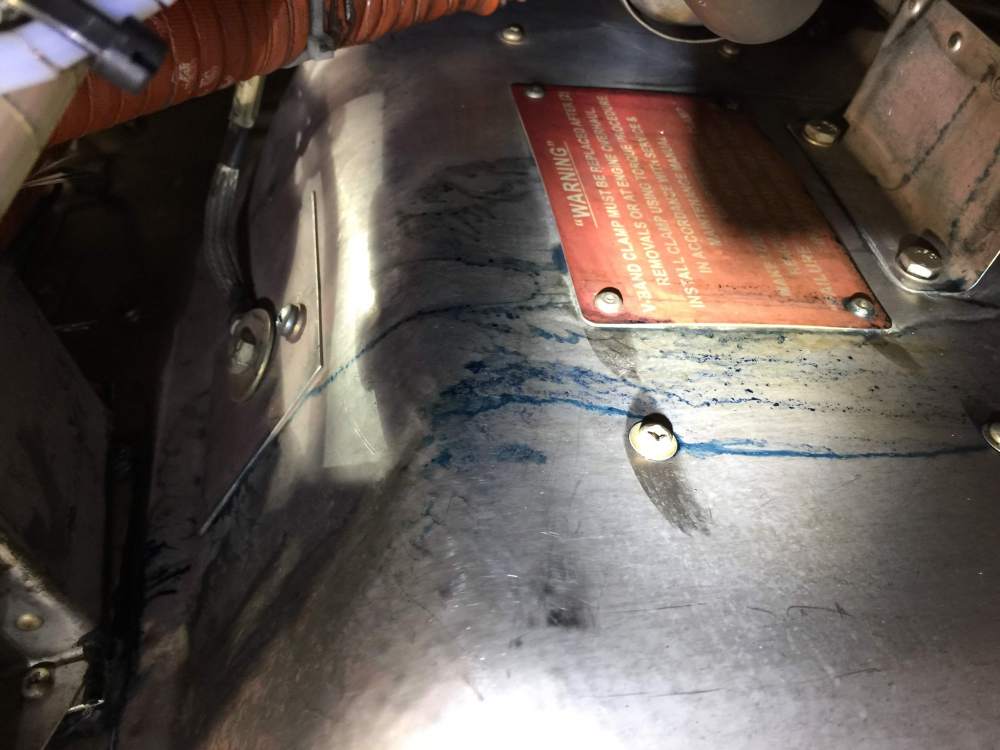

I don't know why some of the photos are not in the correct orientation as they are on my phone when uploaded to this site. Sorry, no better photos. I do have a video showing the fuel spraying out all over the firewall. As far as maintenance done in the past, a condition of purchasing the plane was that the fuel pump be replaced with an overhauled unit (due to Richard Simile's brand new Acclaim crash in Lakeland, FL back in 2015 at Sun 'n Fun). Richard's plane was only one serial number away from mine. My logbook entry has the new fuel pump listed and also "repositioned fuel line to prevent chafing", done back in 2016. The MSC that accomplished those tasks stated that they never touched the fuel line in question. The logbook has been checked. No fuel lines or oil lines have been replaced. Only a replacement fuel pump was installed at purchase as a condition of purchase and repositioning of a fuel line to prevent chafing. That's it.

-

I have a story to convey that is very alarming for me and I'm still being haunted by what could have happened. I've been told by many aviation experts that "I can count my blessings" I didn't have an engine fire or engine shutdown while cruising at 15,000 feet last year over rugged terrain and low IFR enroute conditions over New Mexico. On 17 October, 2018, I was repositioning my aircraft (2015 M20TN) from Atlanta (KPDK) to Las Vegas Henderson Executive Airport (KHND) with one fuel stop in Clinton, Oklahoma. The first leg went just fine. My fuel stop in Clinton consisted of grabbing a bite to eat at McDonalds (not many food choices in Clinton), then returning for the final leg home. I arrived back at the airport an hour later, sumped the tanks with the 75 gallons of fuel I had pumped earlier, and I was ready to file my new IFR flight plan via ForeFlight. I fueled my tanks especially full on this leg because of enroute low IFR weather 1/2 way to my destination, high terrain and lack of close alternate airports along the way. After takeoff in good DAY VFR conditions, I smelled 100LL fuel, which was a bit surprising, but I discounted it, since I assumed it was caused by filling the tanks as high as I could (100 gallons). In the 2015 Mooney Acclaim Type S, normally I don't top the tanks due to the added weight for shorter flights. In my previous 1998 Mooney, I once smelled fuel in the cabin after takeoff six months after my tanks were resealed. The culprit was a few loose screws behind the pilot's sidewall that links to the fuel senders in the wing. In that instance, fuel was leaking from those screws very slowly and making a blue mess behind the interior sidewall. I ended up fixing the leak myself under direction of the "Weep No More" repair center. That fix entailed removing the pilot's seat, removing the left sidewall, and tightening the screws carefully and cleaning the blue stains, all which I could do as a pilot/owner legally. During cruise, I made a note to contact my Mooney Service Center in North Las Vegas the following day to have the fuel smell addressed. Again, I assumed the fuel vapor was primarily caused by a small fuel seepage from a cabin screw behind the sidewall. The fuel smell continued after two hours, so I knew it wasn't due to overfueling. It must have been the fuel seepage into the cabin.....so I thought. About an hour outside of Henderson Executive, while talking to Los Angeles Center, my G1000 fuel range ring all of a sudden showed I had five minutes of fuel remaining from 60 minutes I was suppose to land with. My fuel gages still showed I would have 20 gallons remaining on landing, which is my normal reserve on such a long cross-country flight. I discounted the G1000 fuel range ring as a malfunction, but a later review of my G1000 engine parameters database showed my fuel flow spiked from under 18 gph to 35 gph over a five minute period. I relied on my fuel gages, burn rate, and time. The G1000 fuel ring is not something I rely on, but is an advisory "nice to have visual display" only. I was cleared for the visual approach into Henderson Executive, made a smooth landing and taxiied to my hangar with the fuel gages showing I had 20 gallons remaining. Since I had 32 hours on the oil and since the engine oil was still hot, I decided to do an oil change right then and there. After uncowling the engine and draining the hot oil, I noticed the firewall, nose gear doors (inside and outside), underbelly, and parts of the engine right next to the 1600'F+ dual turbo-chargers were coated with 100LL thick blue stains. I was in shock, because I'm super meticulous with my plane's maintenance, aircraft cleanliness, and I've never seen any leakage before like this with any aircraft I've owned in the past. This was a very SERIOUS leak. The only maintenance I've had done in the area was to "replace the main fuel pump" and to "reposition fuel line to prevent chafing". This was done two years ago. The MSC that accomplished this advised me they did not touch the fuel line in question. The next morning, I came back out to the airport to finish the oil change and to start the engine to find out where the fuel leak was located. Under the direction of my Mooney Service Center both in Atlanta and North Las Vegas, I started the engine, let it run at 1000 RPM's and had another pilot take video of the engine during the ground run at 1000 RPM's. We had an extensive safety briefing before the runup due to the spinning propeller. We have video of the leak, and it was a massive leak near the top of the firewall, where the fuel transducer and main fuel line are located. The fuel was literally gushing out extensively and spraying all over the firewall. It was not a pretty site to see and as I said before, I'm told that it was a miracle there was no fire or engine failure while in cruise flight. The area where the leak is located is wrapped up in orange fire-sleeve materials. About a week later, I had my MSC director of maintenance drive an hour to my hangar to diagnose the issue. His corrective action was, "TIGHTENED FUEL LINE ON FUEL TRANSDUCER". He found that this connection was not even finger tight. This area is on the upper rear firewall above the turbo chargers on the TSIO-550G engine. The fuel connection was about to let loose completely. I was flying 4 hours in that condition with considerable fuel spraying out. He said that this fitting is tightened from the factory and should never come loose on its own. He also said that it's something NEVER checked on annual or 100-hour inspections, because it's not suppose to come loose. I verified this with other leading Mooney Service Centers across the country and they advised me the same thing.....this main fuel fitting is NEVER checked on annuals. It's wrapped up in thick fire sleeving and there's never a need to check it. My MSC mechanic was super surprised that the plane didn't have a complete engine failure or especially a fire with the glowing red hot turbo chargers just below. Note: This main fuel line fitting cannot be safety wired, so it relies on proper tightness. That following week, I drove to the Las Vegas FSDO office in Las Vegas and provided all of my photos to document the issue. They were VERY interested and directed me to submit all of my documentation online, which I did. Their conclusion was that this seemed like an isolated case and it hasn't been reported in the past. The purpose of visiting the FAA was not to point any fingers, but to document the issue and perhaps prevent this from occurring to someone else. If it happenend to me, there's a good chance it will happen to someone else. So the moral of the story is: IF YOU SMELL FUEL IN THE CABIN, LAND AND HAVE IT CHECKED OUT BY A MECHANIC. PLEASE DON'T DELAY! I could have easily ended up a statistic in this case and possibly the NTSB would have never known what happened after their investigation since the plane would have most likely burned up after a forced landing in the rugged mountains or rough desert floor. At every annual, I will direct my mechanic to remove the fire sleeving from this area and check the security of the fuel line on the fuel transducer. After my incident, the MSC advised me they will start checking this on all TSIO-550G engines from now on. Another tip is to always keep the engine bay and wheel wells super clean, so that in the event there's a new leak of some sort, you'll spot it immediately. I learned this years ago while flying corporate aircraft.

- 44 replies

-

- 15

-

-

2019 Acclaim Ultra down at DVT

Mooney_Allegro replied to ragedracer1977's topic in General Mooney Talk

Sent donation via PayPal. Thanks Mike for everything you do and keeping us all informed. This is all very shocking and makes me think a lot about general aviation flying. -

2019 Acclaim Ultra down at DVT

Mooney_Allegro replied to ragedracer1977's topic in General Mooney Talk

This is just terrible news. I really hope the occupant(s) pull through. -

IO-550 starter and metal in filter and slipping

Mooney_Allegro replied to Mark89114's topic in Modern Mooney Discussion

Hi Mark, I had something similar last year with my TSIO-550G. I noticed long brass colored slivers of whisker-like material in the oil filter and the prop would spin during start, and occasionally stop during the start, and then it would start. Speaking with Continental, they said it was the starter-adaptor going bad. I had that replaced and a short time later, I also had the starter replaced with a Sky-Tec C24ST4, due to oil leakage from the seal inside the starter. All is good now with no more whisker-like bronze material in the filter and good starts. Good luck with your issue, I hope it's resolved by now. -

PIREP..... I finally received my two spare ignition keys from Mooney. It took 6+ weeks to get them after ordering them from a MSC, so plan accordingly if you need them. The good news is that they both work, so I'm very happy.

-

Propeller Balancing Issues

Mooney_Allegro replied to Mooney_Allegro's topic in Modern Mooney Discussion

Yes, I took a photo copy of the tech's notes. Here they are. He said the numbers were all over the place and he couldn't make any sense out of it. His boss finally told him to stop after 4 hours of grinding away at the starter on and off. All were very hot starts plus all the turbo cool downs. IPS .28 @ 208 .31 @ 180 24.3 @ 249'/260 .35@ 324 18.7 @ 304 .22 @ 210 37.9 @ 303 .24 @ 7 22.3 320 .48 @ 17 .48 @201