1980Mooney

Verified Member-

Posts

3,696 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by 1980Mooney

-

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

1980Mooney replied to cliffy's topic in General Mooney Talk

@Matthew P went through this a year ago......."unfortunately, no manufacturer will give me a quote because it's a part to be used in an aircraft." -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

1980Mooney replied to cliffy's topic in General Mooney Talk

Actually I stand corrected. If you bring enough money....bags and bags.....then YES - You can buy the Company and have access to everything!...... -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

1980Mooney replied to cliffy's topic in General Mooney Talk

And Mooney is not releasing the approved data (as @Sabremech said). What is the value of Mooney now? It is the engineering data, drawings, specifications, flight test data and Type Certificates, etc. - the Intellectual Property. They are not giving that away. -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

1980Mooney replied to cliffy's topic in General Mooney Talk

If it is so simple: Why didn't the US Financial LLC investors that supposedly bought 80% of Mooney put a measly $1 million of "get things moving funds" into Mooney and build inventory? Certainly they have a vested interest. And the Mooney site lists 46 Mooney Service Centers. Why don't the MSC's each purchase a measly $20-25K of Mooney parts to "get things moving" and build inventory? Certainly they have a vested interest. So now it is why don't 300 Owners send money to Mooney.... so that only three (3) Owners can pick which parts they personally want built and stocked. I think that is call the Greater Fool Theory.... -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

1980Mooney replied to cliffy's topic in General Mooney Talk

Interesting ... "be able to prove your part meets or exceeds the original part if ever challenged by the FAA to prove it is an equivalent". :"IF EVER" is a long, long time.......So if that OPP part that you "participated in" happens to fail for a future owner of the plane leading to an accident , incident or any kind of a claim, then YOU will still be liable to prove this in the future. At that time you will have no interest in the plane, probably no records and certainly no insurance to protect you. You may have to prove it to the FAA and if it is a claim for damages, perhaps you will need to prove it in court. @MikeOH is right the devil is in the details and @cliffy is right that it depends upon how complicated the part is. But the Dukes Gear Set is a good example. If I bought a Mooney with a Dukes actuator which which happened to suffer a gearup due to failure of OPP ("owner participated in") parts/gears , then I would hire a lawyer and go after the past Owner that was responsible for those OPP parts. Now when you sell your plane, you may disclose your "participation" in OPP parts you had installed and you may stipulate in the contract a written release of liability for your OPP parts from the buyer, but that only protects you with the current sale. Some planes get sold every few years. The next owner after that has no knowledge of your disclosure and certainly didn't release you from liability of your OPP part. This is the sort of thing that may come back and hit your estate. I personally would want nothing to do with a plane which had a complicated or critical OPP part. If it turned up in a Pre-buy examination of the maintenance logs I would walk or require the part to be replaced with a manufacturers or PMA part before purchase. Same reason I will have nothing to do with an Experimental. -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

1980Mooney replied to cliffy's topic in General Mooney Talk

That sounds exactly like what Arcline/Hartzell and other various Private Equity that are consolidating General Aviation businesses & FBO’s think and say…. -

You may have just found what we call a "hangar queen". The registered owner, which seems to be keeping the registration current is BUDLEY LTD. in MI. The Principal Officer of Buldley LTD is DOUGLAS CLIFTON PARKER. He is listed in the FAA Airman as a Commercial Pilot and Flight Instructor. However the internet shows he is 79 years old. And FAA Airman shows that his last 3rd Class Physical was in 2010 and nothing since then. His FAA Airman address matches the Mooney Registration address which is a PO Box. However, the mailing address of Budley Ltd is a home at 315 TERRACE POINT CIR, MUSKEGON, MI, 49445. The landline is shown as (616) 285-8062 (if it still works).... Good luck. Others may be interested in finding the plane as a project to get flying on a budget.

-

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

1980Mooney replied to cliffy's topic in General Mooney Talk

I think people get "cynicism" mixed up with "realism". This continuing notion that Mooney International can continue structured as an aircraft manufacturer while only having a future as a replacement parts supplier leads to this continuous unsustainable negative cash flow. Mooney is carrying the liability of the aircraft it manufactured 2014-2019 into the later part of the next decade. The turns into legal expense, insurance expense, filing expense. As painful as it sounds, Mooney needs to file bankruptcy, get rid of all its liabilities, shrink down to the smallest footprint needed to just manufacture Mooney parts or maybe even license someone else to build them. They don't need a CEO, COO and Chief Engineer. They just need a plant manager. Otherwise it just drains anyone that tries to do it. It drained the Chinese and they brought buckets of cash. It drained the "US Financial" investors and I don't think that they brought any cash. And it will drain LASAR too if they are unrealistic and overpromise. -

Need Help With A Part: Lasar DOUBLER - 680031-029

1980Mooney replied to PeteMc's topic in General Mooney Talk

680031–029 Propeller Doubler Spinner McCauley Hartzell | eBay It says that they have two (2) available and they are Yellow tagged. -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

1980Mooney replied to cliffy's topic in General Mooney Talk

You are correct - your last sentence captures it perfectly. The only time that Mooney was able to "spread it (fixed costs) out over volume" was when they were making aircraft. As Maxwell said previously - Mooney can't make it on selling parts alone. If it could, then it would be humming along with Meijing still owning it. And what about the owner investor group, US Financial, that supposedly bought 80% of the company? - why didn't they provide this finance that LASAR "claims" it will bring? Now they have a "middleman" with lofty titles of CEO and COO. Mooney still has people with CEO, COO and Chief Engineer titles. What exactly does the COO at Mooney do (and what is Mooney paying for) if LASAR is "Building the plan: Sequenced a Year-1 ~$3M parts build by safety-of-flight impact and lead times.... Tightening the plumbing: Clear change control, traceable paperwork, and purchasing tied to real shop schedules."?? There is another thing that makes no sense here - perhaps business owners or those involved in a company's finances spotted it in the announcement. Mooney International (the company) is not covering it's costs so Mooney is increasing the prices it charges for products that it makes. That increased revenue (and margin) goes into Mooney's pocket - not into LASAR's pocket. But LASAR claims "LASAR Aviation is the entity keeping Mooney funded". If so LASAR will want to earn a return on that - that means LASAR needs to mark-up the price that they pay Mooney for the parts. I wager that they will mark-up another at least 10-20% for the prices that they sell to MSC's. So in reality prices are probably going up 50%. They may have good intentions but this could easily overwhelm them. On Facebook Mooney Pilots someone commented "The 30% increase right off the bat is a load of $h*t. They (LASAR) can’t even keep their own over priced parts in stock, what makes them think they can take on the whole Mooney catalog?" -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

1980Mooney replied to cliffy's topic in General Mooney Talk

LASAR is not a large company...they are a small company. LinkedIn shows 18 employees. When they announced they were moving to Prineville a few years ago, they told the press that they expected about 25 jobs. D&B Hoovers shows revenue to be $1.2 million. Even if these numbers are slightly off, LASAR is a tiny company in the scheme of things. No wonder they used AI to draft the letter. -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

1980Mooney replied to cliffy's topic in General Mooney Talk

Very true, but Mooney didn't need a middleman to raise prices 30% across the board - they could have done that themselves. "below true cost... drains our ability to keep lights on, ... That math doesn’t work for a week". Don Maxwell had previously posted on Facebook that he had seen the books and said that Mooney couldn't survive on making parts. What the heck has Mooney's so called "management" and "new owners group - US Financial, Jonny, etc" been doing all this time? Surely they knew they were selling parts below cost. And a "uniform price increase" means that they still really don't know which parts were below cost and which were appropriately priced - that is called "machete management". Most of what is in the letter - "AOG triage, quick wins out the door, weekly Kerrville+LASAR stand-ups.. Prioritizing the “grounders”: Identified the SKUs that park airplanes when they’re out of stock and locked specs, dates, and minimums.... Tightening the plumbing: Clear change control, traceable paperwork, and purchasing tied to real shop schedules." - that is just Business 101. I will ask again - What the heck has Mooney's so called "management" and "new owners group - US Financial, Jonny, etc" been doing all this time? And this "Tapping Kerrville know-how: Capturing invaluable knowledge and leveraging the know-how" - that is what all the MSC's used to do. -

I have also done it alone several times. I had 2 issues - my headliner is pretty brittle and some of the screws in the headliner are a PITA (especially to find to get started). While unscrewing the last corner or trying to thread the first corner, I ran the risk of the headliner flexing and cracking. I used some long pieces of cardboard folded into V shapes as props cut just long enough to support the headliner weight both removing and installing.

-

"Window trim/beading doesn't work...paint is not quite right....parts not here when promised...". and " I'd like to get this across the finish line. It's been too long!" OK now you sound more like a normal Mooney owner working on their 40+ year old plane. Someone on a different MS topic said that they estimate how long it will take to work on their Mooney and multiply by three (3)....

-

A couple tips: You are responding to a post from 2018 The OP summarized only NTSB "accident" data - that is only serious accidents, injuries and fatalities. It ignores "Incidents" like gear up landings (unless it resulted in a fatality), off field landings, prop strikes, etc. - the vast majority of Mooney insurance claims. Regardless the data in the summary ends in 2018 You mention N79338. It was previously owned by a MooneySpace member and put up for sale here in 2024. Is this the plane? In his "for sale" post the owner said "Some damage history prior to my ownership, apparently repaired satisfactorily. Not always hangared, and lived at KOAK for many years. Was sprayed internally with ACF-50 and maintained by LASAR during this "no expenses spared" period of its life (well, none aside hangarage)." That particular owner acquired it in 2015 so the damage is more than 10 years ago. I bet much longer when you read the logs. Old damage with good repair becomes less and less relevant with time to the point that it likely does not matter on a 60 year old plane. Eventually the only ones that are truthfully "No Damage History" are the ones that don't get flown much.....and that is not good either. I an earlier post you said that you are buying it from your "buddy". He just purchased it in December of last year. He should be able to tell you. He bought it while it was out of Annual. Since he is selling so soon, it appears he bought it to fix it up, get it airworthy and to resell immediately. You need to confirm.

-

I believe I have the last Missile conversion which was done in summer of 2001. At the time, all they were working on were JetProp DLX conversions of Malibu's. They told me that it had been about 9 months since they had done a Missile conversion and they were "rusty". They plumbed up my fuel injection lines incorrectly and they had to get the local Continental rep out to straighten it out while I was standing there. 55 sounds close. Less than that now....

-

There is an Engineering Drawing that allows removal. You won't find it in the Service Bulletins. @Andy95W posted it a couple years ago but the link no longer works. Maybe he can post it again. Don't forget to revise the Weight and Balance when you remove it. It is over 2 lbs on the nose.

-

Sell my E as is or overhaul engine then sell

1980Mooney replied to Spurious Moppet's topic in Vintage Mooneys (pre-J models)

Look at it this way - You are mentally at the point that you want to sell. It is not the oil usage - it is because you are losing interest in flying/ownership. And you are questioning whether to put more money into the plane. If it was just an oil usage issue you would be mentally committed to find the best way to spend the money to get it flying reliably long term the way you want it. Anything you do will take longer than anyone suggests or thinks here. If you are wanting to sell, then committing to IRAN or OH will add months of delay - possibly many months depending on where you are, logistics and what they find - and that is months of insurance cost and hangar expense (and possibly avionics data costs). And then depending on your location, logistics and timing of license/BFR/currency etc. and how you are going to sell it, you might have to spend more time/money on yourself in order to be current when you are actually able to retrieve your plane and put it on the market. If you spend "$25-50k" (depending on what is found), plus all your other out of pocket expenses getting it to/from the shop, variable expenses above, etc., do you think that you will be able to jack up the price an equal amount? It sounds like you have a pretty nice plane with a great panel. You said mechanically everything else is in good shape. Any "new" Mooney buyer is buying a "project" regardless. These are 60 year old planes after all. Something is always going wrong no matter how well maintained. @KSMooniac made a reference being leery of buying a plane with a "fresh annual". I guess I would be more leery of a Seller saying it had a fresh "IRAN" costing "$25-50K" (and wanting a higher price). That can be more subjective - and the "Seller" may have opted to not spend as much money as the shop suggested. - i.e. cut some corners that would have been nice to do at the time. I would think "nice this was done but not increasing price at which I would buy much". I like @KSMooniac latest comment to essentially do the minimum expense/time to get your oil consumption under control. And then get it on the market. -

Sell my E as is or overhaul engine then sell

1980Mooney replied to Spurious Moppet's topic in Vintage Mooneys (pre-J models)

Looking back at your old posts - was that back in 2020 or more recent and reflective of the current situation? -

Probably the simplest thing to do is get it serviced. @Ludwig Ludwig& Associates in Addison, TX. took over the servicing of all International Avionics Inc. (IAI) products earlier this year. The old IAI website is still up but the phones don't seem to work any more. International Avionics Inc. | Manufacture, Sell, Repair Contact info for Ludwig is in the post below and phone is 972-616-0101

-

M20L down in Argentina.

1980Mooney replied to Mooney in Oz's topic in Mooney Safety & Accident Discussion

Here is how used to look before it was exported. I suspect that it was all removed in an unapproved conversion from the TSIOL-550 to just a IO-550 similar to what Mod Works did or maybe they jury rigged it to a TSIO-550 by removing the liquid cooled jugs .. either way a "South of the Border STC...". It would still have the Rocket Engineering designed engine mount....a real "FrankenMooney". N158MP - 1988 Mooney M20L - For Sale by AircraftMerchants -

Retract Gear or Flaps First in a Go Around ?

1980Mooney replied to donkaye, MCFI's topic in Modern Mooney Discussion

After six (6) pages I hope this has been put to rest. I agree completely with @donkaye, MCFI's instructional advice. And as @PT20J says it keeps it simple (stupid..."KISS"). I was also taught that way and have been doing it from day one consistently for the past 26 years. -

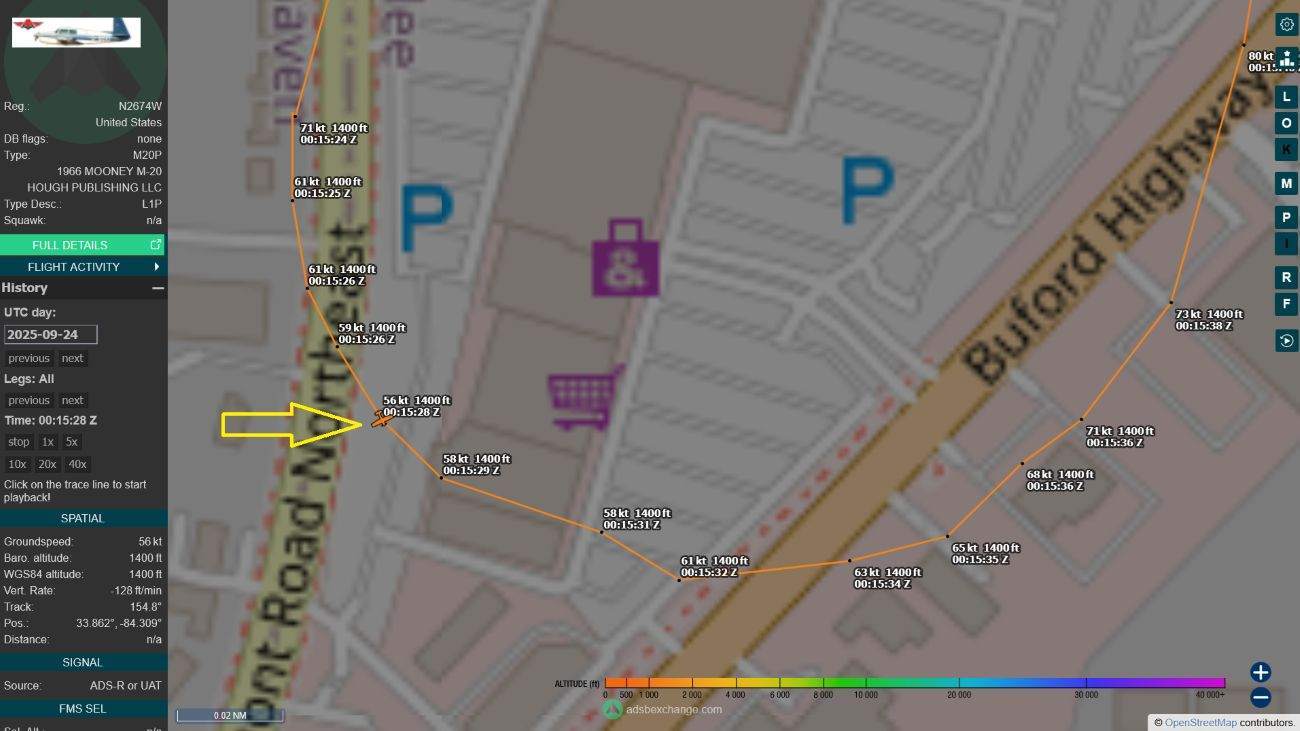

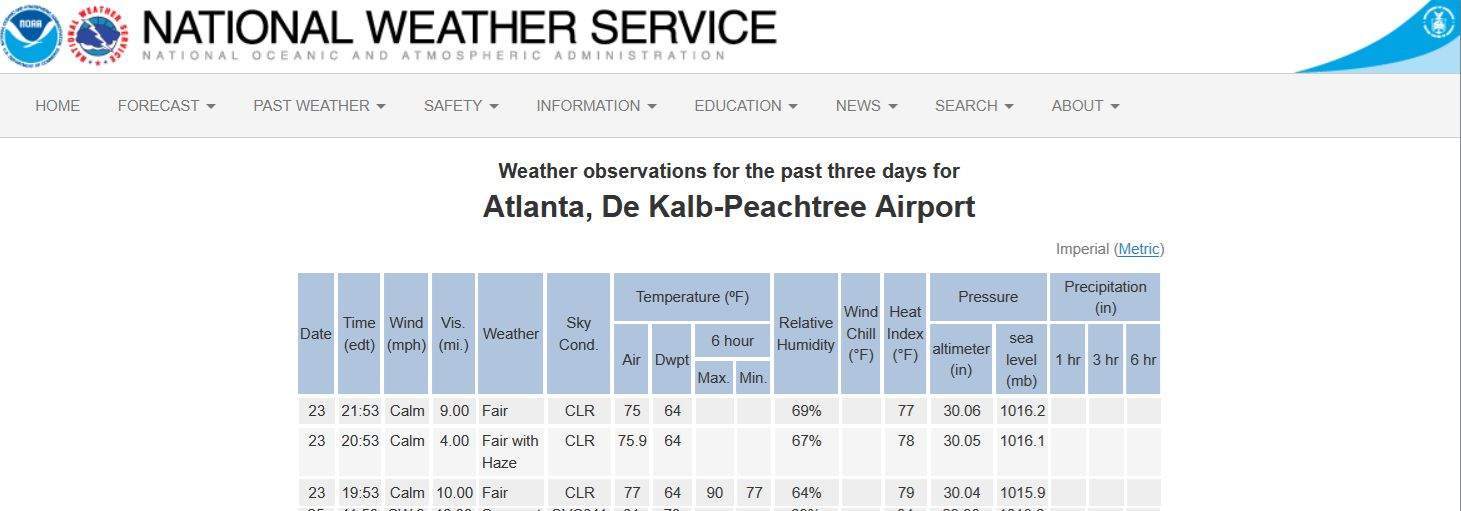

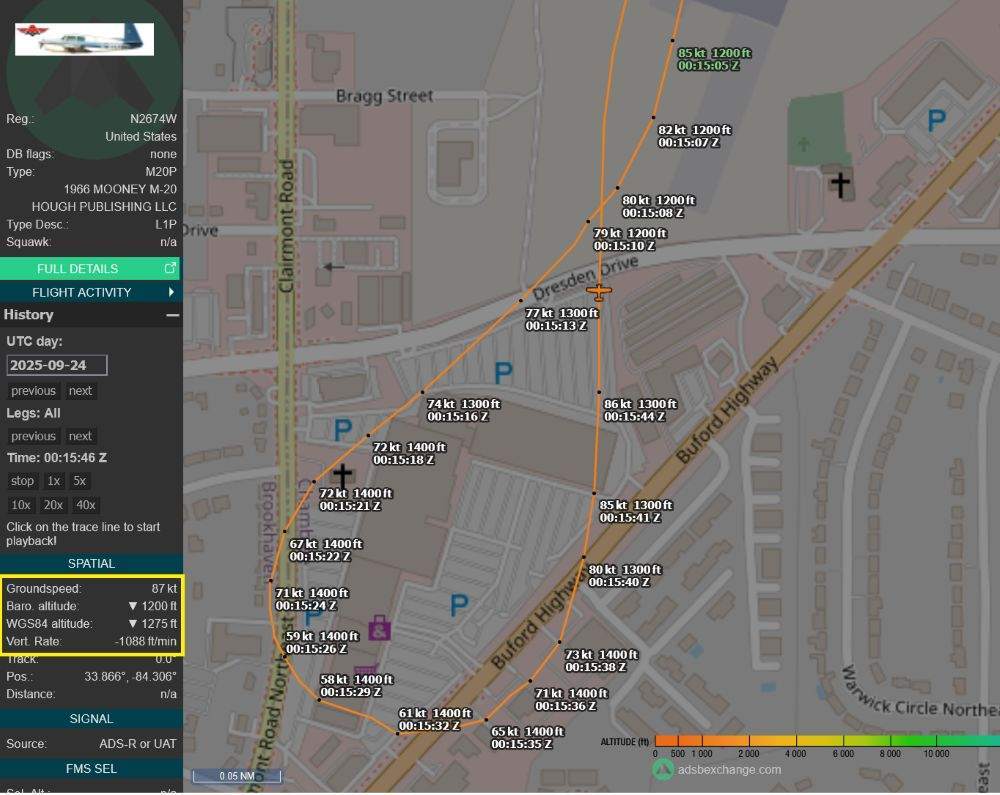

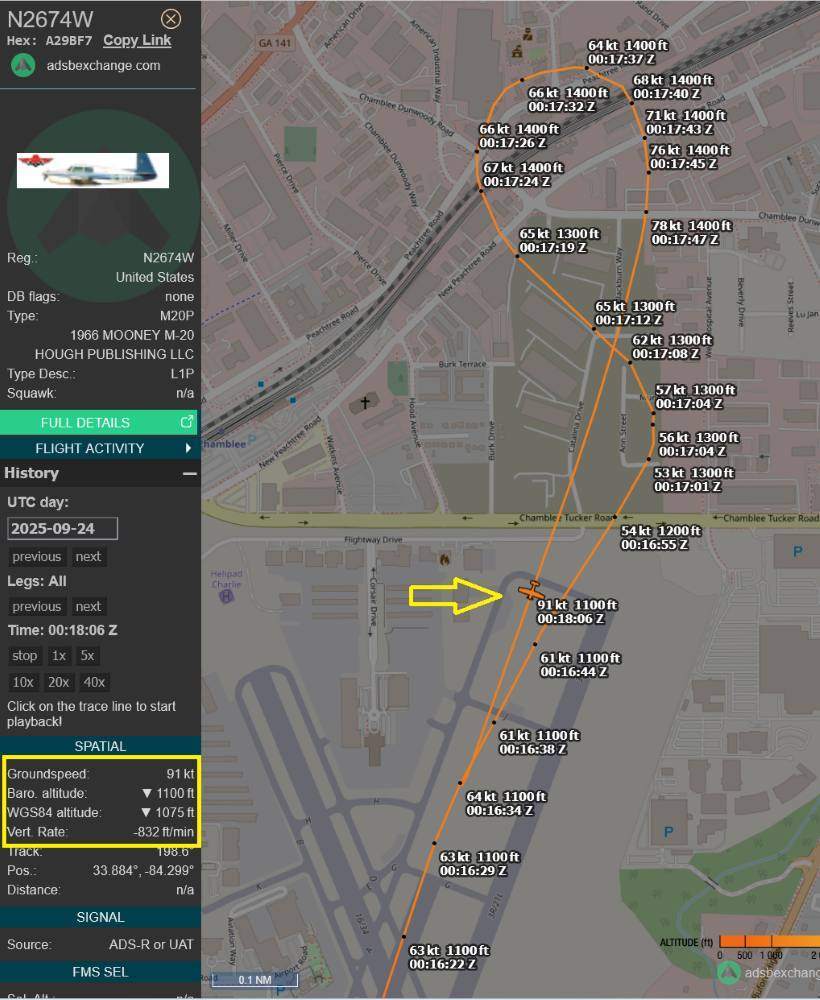

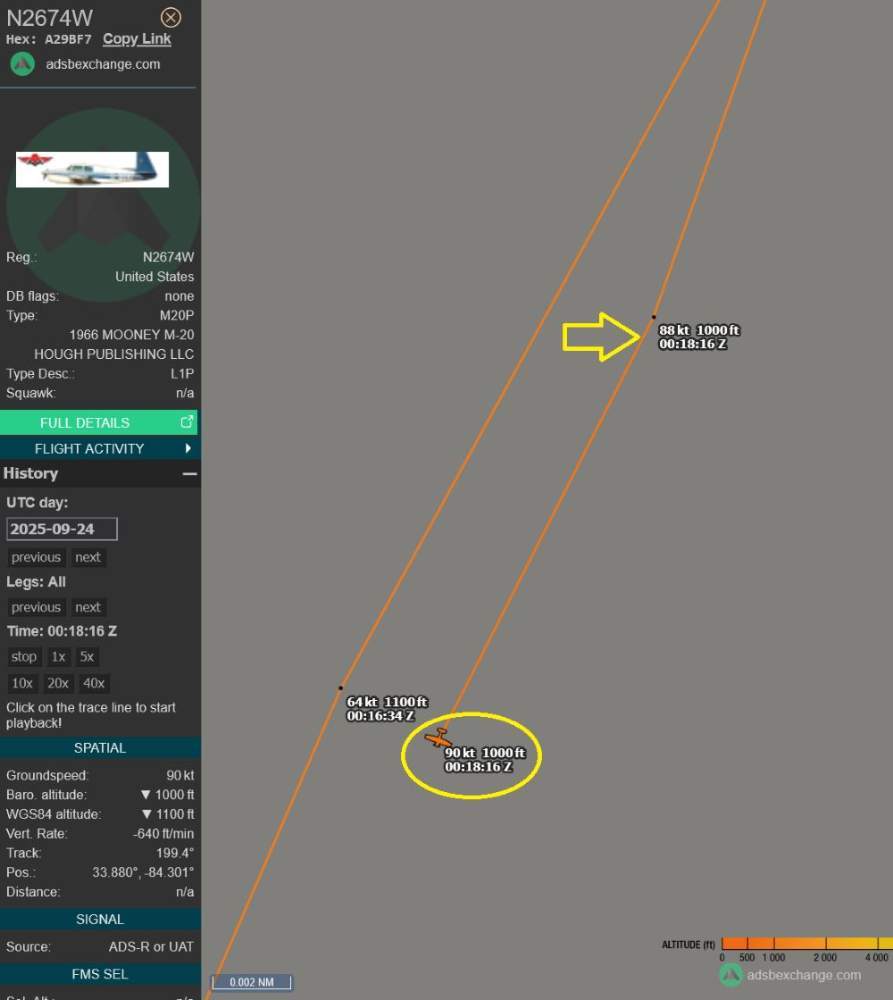

FAA ASIAS reports runway overrun on landing. Pilot sounds calm on Tower LiveATC but obviously struggled with trying to land twice. Not clear if there was any damage but plane did not fly again - not a simple "close door and take off again". Wind was not a factor - Tower said "09 at 3 knots". He told the Tower his "oil door popped open" and he asked for a "tear drop" back to the 3L 4,000 ft runway that he took off from on 21R. With baro at 30.04 it looks like the got to about 500 ft AGL in the turn. The problem was that when he turned Final and was about 1,100 ft from the threshold (over Dresden Rd) he was at about 300 ft. AGL doing 87 knots and descending at -1,088 fpm. 10 seconds later he was over the runway (about 400 ft past the threshold) and was still at about 200 ft AGL doing 79 knots and descending at -960 fpm. He was unable to land on 3L and asked for another "teardrop" back to 21R. Tower asked him if he wanted to declare an Emergency. He responded "No". Tower told him 16 was also available but he said he wanted to stay on 21R. Note that 21L was 6,000 ft long. He did not ask for it. In the 2nd teardrop he got to about 500 ft. AGL but got rather slow - mostly at 66 knots but as low as 63 knots. I calculated that he was in a 32 degree bank on about a 630 ft. radius turn But then he came screaming in on Final - at about 500 ft from the threshold, he was actually accelerating to 90 knots while at about 100 ft. AGL and increasing his descent to -640 fpm. It looks like he was forcing it into the runway. There are several topics on the "impossible turn...the impossible 180" with an engine out. This is a case of two (2) 180's with the engine running perfectly. Something as simple as an oil door open can create a helmet fire. Runway excursion Incident Mooney M20E N2674W, Tuesday 23 September 2025 N2674W Flight Tracking and History - FlightAware https://globe.adsbexchange.com/?icao=a29bf7&lat=33.879&lon=-84.292&zoom=14.5&showTrace=2025-09-24&trackLabels×tamp=1758673097 ATC Audio Archives | LiveATC.net Go to KPDK Tower #1 on the 23 at 00:00Z-03:00Z. Starts about 15 minutes in with take-off.

-

Agree with @Andy95W there are almost no facts about the installation. The AOPA article provides a few tidbits but nothing comprehensive. Since it is 378 cu inch then it is a LS2 and marine application (per the author). Weight for the engine is over 400 lbs. Add gear reduction drive, radiator, coolant, a beefed up engine mount, prop and I bet it is near or over 500 lbs on the nose of a Skyhawk. I assume he added weight to the tail. Reliability aside, this is likely a big issue.