1980Mooney

Verified Member-

Posts

3,653 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by 1980Mooney

-

True, as was pointed out previously most of us don't buy many parts that have to come from the Mooney Factory and when we do, it is usually just a single part or two. "One off parts" with no inventory that are in deteriorating condition on your plane can be troubling, alter how one flies their plane (i.e. "starting to freak out about it") and at worst ground it. But the problem is when there is an incident, a gear-up landing, corrosion in the wing, etc where your shop needs a lot of factory made Mooney parts all at one time. These events are few and far between, but if it is your plane and inventory does not exist, then you will be down for a long, long time. Cost to repair will go up and your insurance company will be more likely to just scrap your plane in order to move on and resolve the situation.

-

Vertical Compass Card Foam Replacement

1980Mooney replied to Lax291's topic in Modern Mooney Discussion

Yes it happens. Since I live in the Houston area I just go over to their shop at Hobby and buy a new foam cushion. Precision Aviation, Inc. - PAI-700 Vertical Card Magnetic Compass- 1 reply

-

- 1

-

-

Everything will seek an equilibrium. As Don Maxwell posted on Facebook, Mooney International can't financially survive on parts making/sales alone. So Mooney's costs have to go down or prices have to go up....or BOTH. I expect Mooney's prices from the factory to continue to go up. The middlemen will also extract price increases to pay for the cost of capital (i.e. the "cash" which Mooney did not have) to place orders (with up front cash costs) and for the cost of stocking/holding inventory. Low margin/limited demand parts will be discontinued or priced so high no-one will buy any (same outcome). Higher new parts prices and culling of low margin/ limited demand parts will make salvaging used parts from downed Mooney's more lucrative. (i.e. used/salvage parts prices will go up). Cost to repair Mooney's will go up. Insurance companies will be quicker to scrap accident/incident Mooney's. Mooney's will be scrapped at a higher rate. Cost of ownership will go up. Fleet will shrink. The market will achieve equilibrium.....

-

It is no different than anyone selling any owned business, a partner selling out of a partnership they founded (or maybe even has their name on it) or a group of majority shareholders agreeing to a takeover. You no longer control. You no longer have a say. It is out of your hands. You take the money, walk away and don't look back.

-

This may not be all the parts but I bought and created my own connector/splitter/hoses/cannula setup: RES010TC to connect to the large outlet on the G5/Next Salter 1225 Swiveling O2 Supply tubing connector (Male to Female) If you want to set up for two (2) then add AGISH749 - AG Industries Y adapter for O2 tubing from Amazon ComfortSoft Plus Nasal Cannula w/ 4 ft clear O2 supply tubing Even though you may hear the Rove6/G5/OxyGo Next concentrator pulse when you breathe, I wanted a visual indicator. SP Bel-Art Roto-Flo Polystyrene Flow Indicator for ¼ to ⁵/₁₆ in. I.D. Tubing (H19937-0002): Enema Flow Indicator: Amazon.com: Industrial & Scientific It is a red spinning wheel We fly in the low teens. Works fine.

-

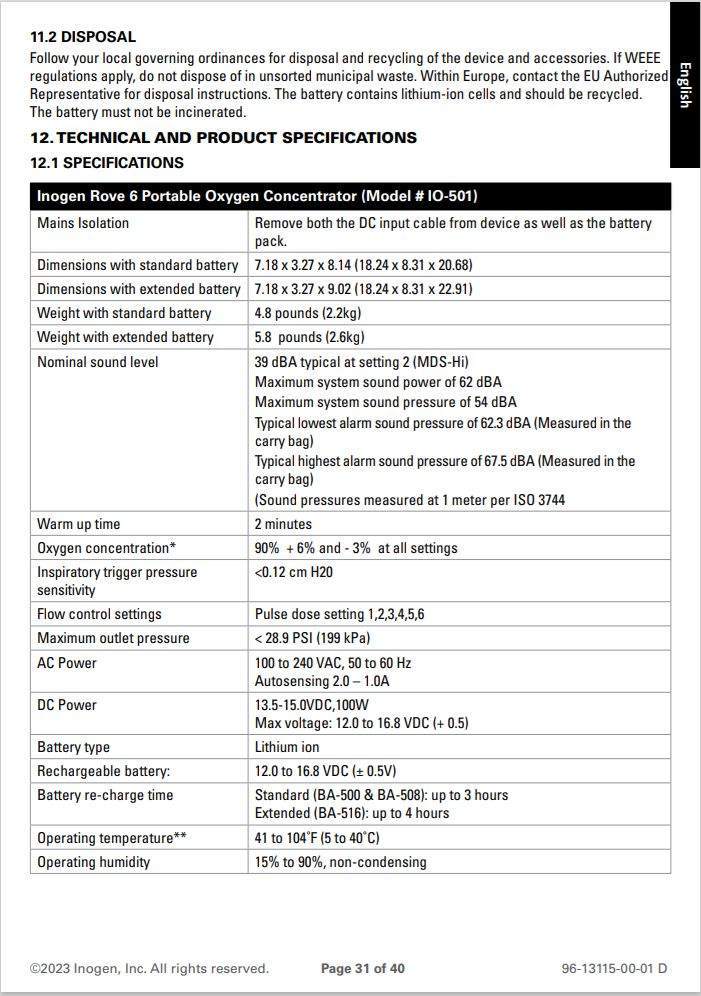

You need an Inogen G5 (or the identical OxyGo Next) or the newer Inogen Rove6. Looking at the Tech Specs in the official Inogen User Manuals, the Rove6 and G5 appear identical in size and weight. The charts of 2 PULSE VOLUME FLOW SETTINGS are identical. Inogen announced some cosmetic changes on the panel and user interface. Some sites say that the Rove6 has an improved algorithm controlling it, but it does not show up in the specs on the Pulse Volume Flow chart. I don't really see any difference between the G5 and Rove6 when comparing the official Inogen operating manual technical specs. Both have Bluetooth for use of apps. 96-08649-00-01 B _G5_English_User Manual-web.pdf 96-13115-00-01-D-Inogen-Rove-6-Manual-US-English-Web.pdf

-

Be sure to use Google search. That handy search string (site:mooneyspace.com “add anything that you want to search for here”) wont work on Bing.

-

McFarlane Throttle Cable Installation on Mooney Rocket

1980Mooney replied to Bill E's topic in General Mooney Talk

Engine quitting with full throttle on take-off roll after your mechanic made all these adjustments? I hate to ask but does he actually know anything about a Cont TSIO-520NB? This personally sound unsafe to me. Here is RAM's troubleshooting guide - they are the experts on that engine. Rocket Engineering lifted the engine/prop combination from the Cessna 340. Troubleshooting — RAM Aircraft, L.P. He should be following Cont. Manual M-0 and SID-97 Maintenance Manual SID97-3E Teledyne Continental® Aircraft Engine - DocsLib -

Yes Commander 112/114 support survives as Commander Aircraft Corp. (CAC). But they have had a very troubled and precarious existence that in many ways is similar to Mooney but with a couple big differences. Commander Aircraft Corp (CAC) produced the 114 and 114TC until 2002 when they filed bankruptcy and ceased production. Three years later in 2005, in a bankruptcy auction, a group of 50 owners named Commander Premier Aircraft Corporation (CPAC) paid $1.7 million for the FAA type certificates, as well as all jigs, tooling and other manufacturing assets. They had aspirations of restarting production in addition to support of the fleet. They moved the assets from the Oklahoma plant and to Cape Girardeau, Missouri where the City stupidly provided incentives. Things did not go well. They never got needed funding and were in debt to creditors. In 2009 they sold to a Montreal based owner named Aero-Base Inc. Creditors had to agree to discounts to get the deal done much like a voluntary bankruptcy reorganization. By 2011, the new owner of CPAC could not get needed financing and Commander Premier Aircraft Corp filed for bankruptcy and ceased operations. Three years later in 2014, the assets of CPAC were sold in a bankruptcy auction to a Chinese national, Ms. Borui Mao, for only $650,000. The new company was named Commander Aircraft Corp (CAC) again. The assets were moved from Missouri to Norman, OK into 2 leased hangars. In 2019 CAC announced that they would invest $8 million in a new manufacturing facility to build new 115/115TC. Nothing ever became of it. I don't think that the 115/115TC was ever approved. CAC continues to sell parts and provide services. The last Commander was built in 2002 by the original CAC. HOME | commanderaircraft Compare this to Mooney: Mooney Int'l is still a corporation with the balance sheet financial liabilities and the off balance sheet liabilities of past aircraft and aircraft part production (18 years going back to everything made since 2007). The so called "new owners", U.S. Financial LLC,, only bought 80% of the company. 20% is still owned by Meijing Group. It is not apparent that the new owners invested any capital into the company. It is more likely that they were looking to get rich with a quick paper flip of the company but are now stuck like a tar baby (remember the Power Point they were using to shop the company?) The main difference between Commander and with the current Mooney situation is that Commander was sold as a "sale of assets" in bankruptcy not once but twice. There were no liabilities assumed by the new buyer(s). (i.e. it was a liquidation of the company twice). Mooney was last reorganized in bankruptcy during 2001-2004. Now we have the following situation LASAR has some unclear deal to manage?/fund inventory?/ take-over? parts fulfillment for Mooney. LASAR's parts guru, Dan Riesland, is located in California and not at LASAR's Oregon home base. Mooney's tech guru, Frank Crawford, who seems to be the glue holding Kerrville support together is in Kerrville With the change, headcount (and hence knowhow), in Kerrville will continue to shrink Don Maxwell posted on Facebook that the Mooney Int'l financials in Kerrville cannot be supported by part sales alone. Three (3) years after the LASAR ownership change and move from California to Oregan, LASAR is still trying (struggling?) to get its PMA's and STC's approved and to market Brett Stokes highlights this in a July 2, 2025 Facebook post He also highlights and promotes that LASAR provides service and support for "Cessna, Beechcraft, Piper and more" - so LASAR's focus is not just Mooney. The Vintage Mooney section is full of posts of how many times LASAR has been called and emailed asking to provide 40:1 gears with no movement. LASAR may be well intentioned, but costs and logistics may overwhelm them quickly - perhaps they already are. From the comments/posts there seems to be a feeling by owners that LASAR will do more to order in quantity and keep larger inventories. That takes capital which no-one (especially the "new owners" US Financial LLC and not even the MSC's which could stock parts as they used to do) seems to be interested in or able to do. So we think (hope) that LASAR has deep pockets? Perhaps the best way forward is for Mooney to be forced into bankruptcy. IThat will be painful and destructive to owners in the short term but could clear the way for the assets to be sold for pennies on the dollar to someone that will just focus on parts manufacturing and supply (and not any dreams of new models, weight increases, landing gear mods or anything). It would get rid of the Chinese and would get rid of US Financial. It would free the IP up for the new owner/supplier with no liabilities.

- 98 replies

-

- 11

-

-

-

If you need/want the OEM 40:1 Gear Set

1980Mooney replied to Matthew P's topic in Vintage Mooneys (pre-J models)

Sounds like it is in the "able hands" of LASAR........just like all our parts now....... You should be saying: "LASAR, COME ON! This is unacceptable! Are you making/coordinating for the manufacture of parts? It does NOT appear to be the case." -

Exactly. I guess most here are too young to remember the 1968 Olympics in Mexico City at 7,434-ft. altitude. Each athlete's body oxygen requirements and acclimation were different.

-

But it only takes one missing part to ground a plane and make it unairworthy if it is a critical part and is not immediately obtainable. The real problem is the fact that no-one wants to pay for the cost to keep inventory around for the size of the market demand and the diversity of parts. @GeeBee highlighted the cost. That is why the world has moved to "just in time inventories". And think about our market and compare it to classic 1960's cars. While Mooney made 4,929 airplanes during the 1960's, Ford made nearly 2.4 million Mustangs during 1964 (midyear)-1969, a span of less than 6 years. The Mooney market cannot support multiple suppliers and large inventories without higher prices and bigger returns. We keep wondering why the Factory does not stock large inventories to immediately support AOG aircraft, but why not blame the MSC's? Why don't the MSC's, who make most of their return on repairs, keep inventories anymore? Cost is the reason. Stranded capital tied up in slow moving inventory.

-

Let's take your estimate and do a "reality check". The $5 million per year max in "factory parts" would be in the form of sales to MSC's before they mark them up for retail sale to owners and A&P's. Assuming a 40% mark-up, that would be about $7 million in Mooney parts spread over a fleet of 6,000 aircraft. That would mean that everyone, every year is purchasing on average nearly $1,200 in parts made by the factory. How many owners here are buying $1,200 per year in parts made by Mooney? That excludes the accordion intake baffles, Rochester wing fuel gauges and other third party parts which are just sourced from others with a mark-up. I think the answer is not many. It has been many years since I actually purchased a part made by the factory. I am sure Mooney makes big sales in slugs when someone attempts to repair structural corrosion or repairs a gear-up landing but how often does that actually happen vs parting out the damaged plane? I am skeptical that sales will be that high. And as @Schllc points out these sales have to be over a fleet of considerable variation. The economics must be daunting and as Don Maxwell posted on Facebook, having seen the books, Mooney cannot support its overhead selling its current level of parts. So costs have to go down and/or prices have to go up. Probably both will happen.

-

It has been previously reported that they do.

-

Did you see Don Maxwell's post on Facebook Mooney Pilots this evening? "Johnny has done his best. He has done this for no salary and has battled a major health issue. He also recently got married. I've seen the books, with the Kerrville overhead it cant make it making parts. Hard to say but its the truth. Hopefully Lasar's hat has a big rabbit in it. I wish them well as we all should." We have known for a long time that they can't make it making airplanes. Many have suspected that they can't make it making just parts either. So what is left?....

-

Rocket in landing incident at KHND.

1980Mooney replied to NickG's topic in Mooney Safety & Accident Discussion

For what it's worth, Rocket Engineering's 509-534-2025 telephone number still answers with Darwin Conrad's recorded greeting and then goes to voice mail. Just a downsizing and relocation? Or perhaps it is the end?.... -

True but Mooney International owns no buildings or land in Kerr County. They operate out of leased facilities (hangar, offices, manufacturing space) on long term lease from the City and County. Go look at the Kerr County Central Appraisal District property search. Their largest asset is inventory at $1.72 million. Next is their machinery and equipment valued at $1.53 million. They have made some leasehold improvements on the leased facilities which they have capitalized. If they downsize further and move manufacturing to a smaller facility, then those building improvement investments become worthless since they stay with the City and County facilities.

-

If Lasar is taking over those “front-end” functions previously done at Mooney Int’l then that would also mean that Mooney is further reducing staff in Kerrville.

-

Not according to this.

-

Rocket in landing incident at KHND.

1980Mooney replied to NickG's topic in Mooney Safety & Accident Discussion

What does the sign on the folding door say? Does it say Rocket Engineering or is that a realtor sign? I can’t make it out as posted. Maybe your original is higher resolution. -

Agreed that the actual pitot/static IFR cert work should not take a 2-3 day turnaround under any circumstances. That just means the plane was sitting while the shop worked on other planes. I had this also done in my hangar a little over a week ago. I have standby power, lights, fans so it was easy-peasy for the avionics tech. It took less than an hour to do 2 instruments (Aspen PFD and traditional altimeter) from arrival to leaving the certs on my glareshield.

-

Rocket in landing incident at KHND.

1980Mooney replied to NickG's topic in Mooney Safety & Accident Discussion

Let us know anything that you find out about Rocket Engineering when you are out there today - if they are still in business at KSFF. Looking online, Darwin Conrad, Founder of Rocket Engineering and JetProp DLX (both in the same facility), shows to be 75 years old now. Thanks in advance.